It’s been a few years since we ran our “Revolver Gunsmith Roundup” series here, and it’s time for us to revisit the project, and introduce RevolverGuy readers to some gunsmiths we’ve met since Part I and Part II were published.

This is especially important since we’ve lost some notable revolver ‘smiths in the past few years (men like Karl Sokol and Tiger McKee come to mind) and several more are nearing the point where they’ll probably hang up their shop apron soon. We’re not exactly drowning in quality revolver gunsmiths these days, so it’s important for us to promote the ones who are doing good work, and help them stay busy!

While some of these folks may be new to you, they’re not new to gunsmithing. Each is an experienced and accomplished gunsmith, and we’re confident in the quality of their work. Whether you’ve got an elaborate custom job in mind, or a simple repair, these are good resources for you to consider.

So, without further delay, let’s meet the gunsmiths!

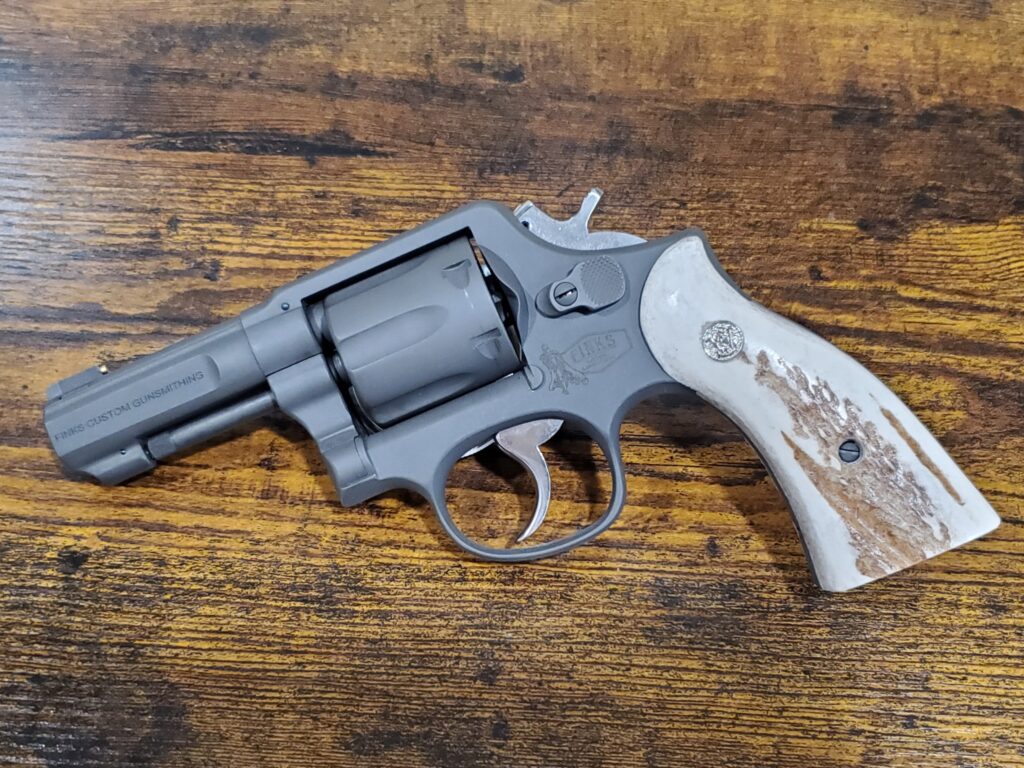

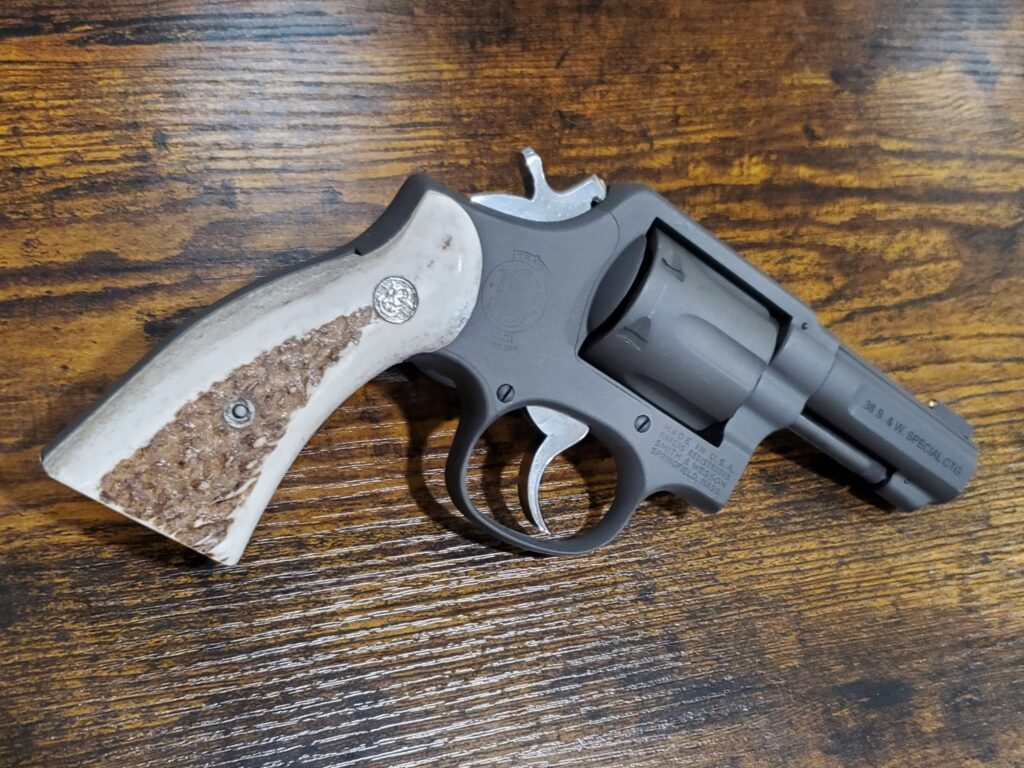

DAVE FINK — FINKS CUSTOM GUNSMITHING

[Editor’s Note]

I first met Dave a few years ago, after he had already started to make a name for himself as the new gunsmith at the Gunsite Academy. I was intrigued by the fact that most of the attention he was getting, at that early stage, was for his work on Smith & Wesson revolvers, not the 1911s and Glocks I expected to hear about. I got to examine a number of his completed guns at the Shootists Holiday in 2022, and was impressed enough that I contracted with him for my first-ever, custom build.

When I attended the 2023 Pat Rogers Memorial Revolver Round Up, Dave gave me a tour of the busy shop and I got to meet several of his ‘smiths, who were all very friendly and professional. It was obvious the team had done a lot of work cleaning up the place and getting it ready for business. It was also obvious that Dave, his wife (and office manager) Rachel, and his gunsmiths had much bigger plans for the Gunsite Gunsmithy, which included some renovations to expand the working space and reorganize it for greater efficiency, to keep up with the growing demand for their services.

I’m pleased to share Dave, Rachel, and their operation with the readers of RevolverGuy. These are all quality folks–REALLY good people–and I know you’ll get great service from them.

-Mike

*****

Dave Fink was attracted to gunsmithing after he finished his tour in the Navy, as a P-3 Aviation Electrician. He was an active competitive shooter, and interested in the modifications that his fellow shooters were having done on their guns, to enhance performance. The possibility of doing that kind of work for a living attracted him, and led him to complete the gunsmithing program at Yavapai College, in Prescott, Arizona.

Dave established a firearm finishing (blueing) business in 2017, after graduating from the program, and by 2019 the business had expanded to include custom gunsmithing work, with the addition of gunsmith/machinist Dustin Ravsten. Dustin took care of all the custom machining projects and chambering jobs, and the customers were happy to learn they could get all their gunsmithing and refinishing needs satisfied in the same shop.

By 2021, Dave Fink was teaming up with renowned custom gunsmith (and color case finishing expert) Bobby Tyler, to submit a proposal to take over the gunsmithing operation at Gunsite Academy.

The proposal was accepted, and the work began to revitalize the Gunsite ‘smithy. After the departure of famed Gunsite gunsmith Ted Yost and his five-man team, the ‘smithy had continued to operate with a single gunsmith on the premises, who was able to keep up with repairs for the student population, but didn’t have the time to do much of the custom work that Yost’s operation was known for. It was Tyler and Fink’s intent to restore that capability with Fink’s team—to service the student population, but also to restore the ‘smithy as a custom gunsmithing operation that would accept orders from students, staff, and external customers.

Finks Custom Gunsmithing at Gunsite opened in 2021 and Dave added gunsmith Dave Desjadon to the roster. The team quickly attracted lots of customers, with 40% of the students who had repairs done by the shop returning shortly thereafter to request additional custom work on their guns. Before long, custom gunsmithing orders greatly exceeded student repair orders, and Fink’s became a custom gunsmithing hot spot. Revolver gunsmith Jake Moreno was added to the growing team in 2022, to help keep up with the demand.

It was always part of the plan, however, to get back to building “production custom” guns like the Gunsite Service Pistols (GSPs) that Yost’s shop used to turn out, and Finks Custom Gunsmithing has been evolving towards that objective. The Finks team has been steadily growing, and is now eleven strong (which includes seven gunsmiths), with four of those employees hired in 2024. The shop has expanded into the adjoining building, to increase the workspace, and additional machines, tools, and personnel have been added to increase production volume.

The team is busy building production custom guns like the GSP 1911, the Revolver Round Up Special, and the Moreno Interchangeable Barrel System (MIBS), with the intent that roughly 60% of their business will be centered on these packages, with true custom builds making up another 35% (the remaining 5% of their effort will be expended on student support, doing minor repairs and upgrades on their guns, so they can continue with their training).

It sounds like Finks will be able to make a lot of shooters happy with this business model, and we’re glad they achieved their objective so quickly.

*****

RG: Would you describe your operation as “Part-Time,” or “Full-Time?”

DF: We run a full-time operation on the grounds of the Gunsite Academy, with multiple gunsmiths in the shop.

RG: Would you describe the central focus of your operation as “Custom” work, “Service and Repair” work, or a “Full-Service” combination of the two?

DF: We are currently a full-service custom shop, but we’re starting to re-gear towards becoming a production custom shop. We’ll still do some full-service custom work, but will focus more of our effort on producing custom package guns like the Gunsite Service Pistol (GSP), Modern Red-Dot Revolver (MRR), and Revolver Round Up package.

RG: Do you have a specialty or area of emphasis that you are known for?

DF: That’s a tough one to answer, so I’ll list a few things that bring us the most work. We are known for being Gunsite Academy’s gunsmith, where we not only service firearms, but also build custom fighting guns for students and instructors in the Shotgun, Rifle and Pistol platforms. Lately, a lot of our custom work has been milling guns to accommodate optics. A few years ago, we picked up the Gunsite Service Pistol (GSP) 1911 line where Ted Yost had left off, 20 years ago, as the last ‘smith at Gunsite to build custom 1911’s. Over the years we have made a pretty big splash building “Fighting/Practical Revolvers,” and we continue to try and keep the fighting revolver alive here at Gunsite.

RG: Is there a gunsmithing service or product that you offer which you feel is unique in the marketplace?

DF: Our latest innovation is our MIBS (Moreno Interchangeable Barrel System) package. One of my ‘smiths came up with an interchangeable barrel system for S&W frames that allows you to easily change barrels without the use of tools! You can have as many barrel lengths and configurations as you can dream of, and they all work on the same frame. It’s kind of like the Old Dan Wesson design, just without the extra tools and hassles!

RG: What kind of gunsmithing work do you like to do the most?

DF: What I enjoy the most is when we have a customer walk into the office and hand us their gun, then rattle off a list of shortcomings and “could-have-been’s.” After a brief discussion about what they wish was different, and what their vision of the “Perfect” gun is, we turn around and make it for them. Every shooter sees and feels things a little differently, so when they get the gun back and run it through a Gunsite class, then come back and tell us how much the modifications helped them to be a better, more proficient shooter/student, it brings great joy to my heart.

RG: Is there a particular model, brand, or platform that you prefer to work on?

DF: We see everything come through Gunsite, and we have to be ready to work on anything a student or instructor brings to us, so it’s hard for us to be picky, as gunsmiths. There are some types we see more than others, though. In revolvers, we see more Smith & Wessons than any other brand, hands down (my personal favorites to work on are the Model 10, 19 and 686). In shotguns, we see a lot of Remington 870s and Mossberg 500s/590s. For pistols, students bring about twice as many Glocks as anything else, but with that said, I enjoy the S&W M&P’s personally.

RG: Is there anything that you would like customers to know/understand about your services or operation?

DF: We focus on “practical” here in our shop. So, if we can make something perform better for our needs, we will. When it comes to your project, if you don’t have a specific idea or opinion about what you want, we end up putting our flair on it, to make it the best, most efficient tool for the job.

RG: How would you prefer RevolverGuy readers to contact you?

DF: We just expanded our offices and hired customer service reps, so we’re ready to receive your phone calls and emails!

Website: https://finksguns.com

Email: finksguns@gmail.com

Phone: (928) 756-8916

LEE HADAWAY — THE ARMS ROOM

[Editor’s Note]

I first met Lee at the 2022 Shootists Holiday and was immediately impressed by the quality of his work and his obvious commitment to customer service.

I was a little amazed when I overheard Lee offer to meet a customer that lived in Colorado Springs (about 130 miles north of Lee’s shop in Trinidad, CO) for a pickup of the customer’s gun. Lee told the customer he had to make a trip up there for other business anyhow, and would be happy to coordinate a rendezvous and save the customer the cost of shipping his gun for work.

Lee recently told me that he’s done some drop-offs for customers, too. He’s still teaching classes for gunsmithing schools in several states and will arrange to make deliveries to nearby customers during his travels.

You don’t often find that “country doctor” level of service in any business these days, and certainly not in custom gunsmithing! It’s a good indicator of the kind of man he is, that he’d go to that length to serve a customer, and protect his investment.

I was impressed with Lee’s gunsmithing journey, when I interviewed him about it, and all the twists and turns that he took along the way. Although there’s a tendency for folks to think of Lee as “the custom lever action guy,” it’s obvious that his talents and experience extend well beyond that platform. He’s a RevolverGuy, too, and your revolver project will be in good hands with him.

-Mike

*****

Lee Hadaway’s entry into gunsmithing was actually the fortunate byproduct of pursuing a different dream. He’d fallen in love with the Boy Scouts of America’s Philmont Ranch, near Cimarron, New Mexico, when he first visited as a camper in 1980, and in 1987 he was working a summer job in one of the ranch’s living history camps, and scheming to find a way to stay in the area, instead of returning to school in his native Georgia. As he looked through the pages of a Guns & Ammo Annual in camp one day, Lee saw an advertisement for a gunsmithing school in nearby Trinidad, Colorado, and thought it might be the perfect way to attach himself to the region. A visit to the school sealed the deal for him, even though the school was closed at the time, and all he could do was look through the classroom windows from the outside.

Lee graduated from Trinidad State College’s Gunsmithing School in 1990 and took a job in Tulsa, Oklahoma, where he did the warranty repairs for all the Walmart stores. “I fixed over 2,000 guns in a six-month period and learned a lot,” he said, but other opportunities brought him to South Carolina for a short period, then on to southern Alabama, where he worked for seven years before a downturn economy forced him to close shop.

As fate would have it, another door opened when a local dealer contracted with Lee to provide a hundred of the takedown lever action rifles that Lee had started to make. Lee had to repurchase the equipment he’d just sold, and move it into a friend’s pole barn, where he worked from late evening to early morning each night, “because you DON’T want to work in a pole barn in the middle of an Alabama summer day,” said Lee. He delivered 65 of the rifles before his customer canceled the remainder of the contract, because he had flooded the local market with the guns and sales had slowed.

Lee moved on to Scattergun Technologies in Nashville, building custom combat shotguns, and wound up becoming the head gunsmith of the operation. At the same time, he ran his own gunsmithing shop, where he did everything from routine repairs to custom builds for clients that ranged from Everyman to the elite of Nashville society.

When Lee got an offer to return to Trinidad as an instructor at the Gunsmithing School, he took it. The timing couldn’t have been better, as Scattergun Technologies had just been sold to Wilson Combat, and that would have meant both a pay cut and a move for Lee. He finished his last day at Scattergun Technologies on a Friday, and the following Tuesday, the trucks arrived to pack up the shop and move it Wilson’s headquarters in Arkansas.

Lee taught at the Trinidad Gunsmithing School for three years before declining enrollment forced some budget cuts that left him looking for work again, as the newest hire. He went to work for the city for the next 16 years, but also opened his own gunsmithing shop there in Trinidad.

Lee is in the 22nd year of operating The Arms Room, and has built a reputation as the premiere maker of takedown lever action rifles in the country, but he’s also an accomplished revolver gunsmith. “We were making chopped-down Smith & Wesson revolvers back in 1990, when you could get as many used ones as you wanted for $130 a piece,” said Lee. The base guns are a lot more expensive now, but if you’re looking for someone who can turn yours into a custom “chopper,” Lee’s a good man to talk to. He says those are “pretty fast, straightforward jobs” that can be turned around in less time than the more complex lever action takedowns.

*****

RG: Would you describe your operation as “Part-Time,” or “Full-Time?”

LH: The Arms Room is definitely a full-time business! I’m the boss and the sole gunsmith. It’s nice working for yourself, but the boss can also be a hard guy to work for, sometimes.

RG: Would you describe the central focus of your operation as “Custom” work, “Service and Repair” work, or a “Full Service” combination of the two?

LH: Probably 75% of my work is custom, but I get my share of repairs and adjustments too. Most of the repair and service work is from locals, but I get guns that come in from all over the place for what I think of as “basic stuff”—repairs, action work, barrel threading, that kind of thing. I had one guy send me an 1876-pattern rifle for some basic action work recently, because he’d gone to three different gunsmiths in the greater Dallas area and none of them would take on the work! So, I do that kind of work, but most of my customers come to me for custom jobs.

RG: Do you have a specialty or area of emphasis that you are known for?

LH: I ended up being known for my lever action rifle work, but I’ve been ‘smithing for 37+ years and I can work on anything. On the revolver side, I work on both single and double action revolvers. I just did several single action Rugers for a customer in Iowa, and have done some custom Smith & Wessons on Model 10s recently—in fact, I just bought a 4” Heavy Barrel that I’m gonna use to build myself one. I already talked to (Simply Rugged’s) Rob Leahy about building a holster for it, when I’m done.

RG: Is there a gunsmithing service or product that you offer which you feel is unique in the marketplace?

LH: I kinda made a name for myself, building takedown lever action rifles. I didn’t set out to do that, I just sorta backed into it. There aren’t many people out there doing those, and I’ve made a lot of them. They’ve become very popular and make up most of my work. There was a time when I would have been a little overwhelmed by having a stack of 20 orders for them, but these days, I start getting nervous when it drops that low!

RG: What kind of gunsmithing work do you like to do the most?

LH: The takedowns are cool! I like building those and enjoy making them as efficiently as possible. However, you can’t build those all of the time—you need to break up the takedown work with other projects, otherwise you’d go crazy. That’s where I enjoy working on the revolvers and other projects like that.

RG: Is there a particular model, brand, or platform that you prefer to work on?

LH: For lever guns, I prefer the Marlins. I’ve worked on Winchesters, Henrys and Rossis too, but those guns are different enough that it’s not efficient to do a lot of them. The Marlins are the best base gun for a takedown conversion. I haven’t done much work with the new Smith & Wesson Model 1854 yet, but it looks like It’s basically a Marlin action. I’ve got one that we’re doing a caliber conversion on right now.

RG: Is there anything that you would like customers to know/understand about your services or operation?

LH: We’re a small operation that does a lot of handwork. It takes time to do the takedown conversions but the quality is obvious in our finished work. We pay a lot of attention to the details.

RG: How would you prefer RevolverGuy readers to contact you?

LH: Phone or email works fine. Many of my customers are surprised that I answer the phone and talk to them, but that’s just how I was raised to do business. I wouldn’t want to send a bunch of money to a gunsmith that didn’t want to talk to me about the work that’s going to be done on my gun!

Website: www.thearmsroom.com

Email: Lee@TheArmsRoom.com

Phone: (719) 680-1255

TOM BEAUDETTE – TRAPPERS GUNS AND ARMAMENT

[Editor’s Note]

Unlike Dave and Lee, I haven’t had the opportunity to meet Tom in person and inspect his work, but he came highly recommended to me by Lee, himself, and I can’t think of a better endorsement.

When a highly-regarded industry peer is willing to vouch for you, that’s a powerful argument for the quality of your work and character. A good man’s word still means something here, and we’d be proud to feature Tom in our coverage on the basis of that alone, but after talking to him and seeing pictures of his work, I knew I’d found another talented ‘smith and RevolverGuy.

-Mike

*****

Tom Beaudette got his start in gunsmithing through his love of big bore handguns. As a young trapper in the 1970s, Tom found a handgun was his best companion, because it was light and stayed out of the way until it was needed.

And it was definitely needed! Tom was carrying a heavy pack basket full of traps and equipment and couldn’t add a heavy long gun to the mix. The smaller and more portable handgun, nestled on his hip, didn’t interfere with work, but could be drawn in an instant. The handgun allowed Tom to pot game for food, and provided protection from the unexpected. Tom notes that foot-lines produced high-priced fur back in the ’70s, and also attracted would-be fur thieves. Six or seven bobcats, added to ten or twelve coyotes, could almost generate the $5,000 necessary to buy a new pickup in that era of $0.35/gallon gas.

“I started out with a .45 Colt because I couldn’t find a .44 Magnum in the mid-70s,” said Tom. “I reloaded my own ammo and found a Speer #9 reloading manual, published in 1973, with heavy loads for Ruger .45 Colts. I was getting good results with the .45 on game, but other handguns followed, including a .44 Magnum.”

Tom’s interest in powerful handguns led him to John Linebaugh, who was doing lots of ballistic research on the big calibers, and working on the guns that shot them. “I hooked up with John in the mid-80s, and sent him one of the new Ruger Bisley’s to have him do some heavy bullet load development for the .45 Colt. Later on, I got one of the first guns chambered for his .475 cartridge. It’s either the sixth or ninth one he built—I can’t tell, because I’m not sure which direction to read the number he stamped on the gun! The .475 was the cartridge I carried for dangerous critters. I carried it in Alaska when I hunted Brown Bear and I still carry it today in a custom gun I built.”

Tom’s experience with the .45 Colt and heavy loads led him to write an article for the Shootist magazine, started by John Linebaugh. “The article was about two-legged varmints that thought they would bully me on a high lake in the San de Cristo Mountain range, in Colorado. The simple sight of my .45 in a shoulder holster, when I unveiled it, changed their attitude right away,” said Tom.

Linebaugh’s magazine didn’t last long, but the big bore spark had been lit, and by the late ‘80s Tom was customizing big bore handguns to improve their performance. Before long, he was taking summer school classes at Trinidad State College’s Gunsmithing School, and week-long seminar classes taught by noted gunsmiths like Hamilton Bowen, Jim Stroh, and others, who were invited by the school to share their knowledge and instruction with the students.

Tom enjoyed working with, and learning from, these gunsmiths, and put the skills they taught him to work. By the early ‘90s, he was working on guns for folks in the local area, and as the word about him spread, he earned more customers. By the early 2000s, he was doing a little bit of advertising on Gun List, and trying to make the business grow.

Because you can make just enough as a budding gunsmith to starve, Tom had also taken a job as a wildlife services employee for USDA, which made him a professional hunter and trapper for the federal government. He modified, upgraded, and built some guns for his fellow trappers and hunters, who used them to great effect. “I’m not trying to brag or beat my chest,” said Tom, “but I’ve shot LOTS of game with handguns over the course of my career. I’ve shot everything from coyotes, to bears, to big cats, and it taught me a LOT about what it takes to bring them down, which calibers and loads work best.”

To illustrate, Tom tells a story of a friend, whom he hunted bears and lions with, that got mauled by a large Black Bear. The friend carried a 10mm semiauto handgun, and as they rolled down the hill, he emptied the magazine into the bear. The only thing that saved his life was one shot to the bear’s head. Commenting on the friend’s choice to carry such a light caliber afield, as an experienced hunter, Tom says, “I blame advertisers. While they think their specific handgun and caliber will effectively take a certain species of game, it isn’t always true. I have shot trapped coyotes in the chest with a .40 S&W handgun and they just blinked at me. In contrast, I’ve shot them in the chest with a heavily-loaded .45 Colt with a 260 grain bullet, and it was ‘lights out.’ We talked a lot about this incident and everyone agreed–always carry enough gun to protect yourself!”

Tom’s experience in the field has improved his work in the gunsmithing shop, where he builds handguns for dangerous jobs. There are many gunsmiths who will build you a custom gun, but not many have taken as many animals with them as Tom (Gary Reeder, who we’ve featured previously in this series, comes to mind as another gunsmith who’s a highly-experienced hunter). He knows what the game will demand of his products, and ensures they are up to the task.

Tom retired from the USDA work in 2011, and does a little side work for a local gun shop, like threading barrels, and general repair and restoration work, but spends most of his time working in the small gun shop on his property, which sits in the middle of the Bear Springs Mesa. The country is filled with coyotes, mountain lions, bears, snakes, and all kinds of critters. He continues to work in the shop, to improve his work in the field. “I enjoy my life and my family,” says Tom, and I know he enjoys taking care of his customers, too.

*****

RG: Would you describe your operation as “Part-Time,” or “Full-Time?”

TB: I’m retired from my federal wildlife services job, and Trappers Guns and Armament is a full-time business for me.

RG: Would you describe the central focus of your operation as “Custom” work, “Service and Repair” work, or a “Full Service” combination of the two?

TB: We’re a full-service shop. We do both repairs and custom work. For example, I’ve got a Savage 99 in .300 Savage that just came in with a broken rotary magazine that I have to fix, and a family heirloom Winchester 94 that needs to be repaired, but I’ve also got a Denver client that just sent me a .45 Colt that I’m going to rebarrel as part of a custom build.

RG: Do you have a specialty or area of emphasis that you are known for?

TB: I do a lot of custom revolver conversions, upgrades, and action tuning. I like working with a lot of the older calibers and have done some neat conversions, like the .25-20 I built for a customer on his Ruger Single Six frame. That one turned out so well that I want to build one for myself on a medium-frame Ruger Anniversary Model. I like the .32-20 and .38-40 cartridges a lot too, and have some Ruger builds in those calibers planned. I build lots of .475 and .500 Linebaugh customs for people who need hard-hitting guns for hunting or wildlife defense.

I also do lever action conversions and upgrades. Although I don’t build as many takedowns as Lee Hadaway does, I do make some. In fact, I’m working on an octagon-barrel Marlin that’s going to be a tricky to turn into a takedown. I made a neat clone of an 1889 Marlin not long ago, chambered in .41 Magnum, which was really unique.

RG: Is there a gunsmithing service or product that you offer which you feel is unique in the marketplace?

TB: We offer handgunners and riflemen upgrades and custom work by request, which includes family gun restoration. We care about the customer and their satisfaction.

The family gun restorations are neat. Many of these old guns have broken parts that we have to source or build replacements for, and it can be like solving a puzzle. I will do the rust blueing myself if they need to be refinished, or send the gun to Doug Turnbull if we need case hardening. It’s nice to bring these old guns back for a customer.

My wife enjoys doing the wood work, and is doing lots of nice custom grips for our builds.

RG: What kind of gunsmithing work do you like to do the most?

TB: Custom single action revolver work, probably. I love working on the lever action rifles and other guns too, but I do a lot of single actions and like working on those. It’s where I got my start, and probably what people know me for.

RG: Is there a particular model, brand, or platform that you prefer to work on?

TB: I like working on all the Ruger revolvers, both single and double action, the Smith & Wesson double actions, and Marlin lever actions.

RG: Is there anything that you would like customers to know/understand about your services or operation?

TB: We are a small shop and our goal is quality work. We will work with you and keep you informed of each step. We don’t always work fast, but we will be meticulous about the job. I have lots of customers who keep coming back, having us build lots of guns for them.

RG: How would you prefer RevolverGuy readers to contact you?

TB: They can contact us by phone or email. Either one is fine.

Website: www.highcountrycontrol.com/trappers-guns-home

Email: trappersguns@gmail.com

Phone: (719) 289-0312

Thank you, Mike, for providing readers with high-end gunsmith suggestions for projects that local smiths may not be able to fulfill.

At the moment, I’m thinking about some custom work on my battered Remington Rolling Block 7mm Mauser. Maybe one of the gentlemen you’ve profiled would be interested in such a project.

I think they’d be a good match for the job!

Excellent presentation, Sir. Thank you for taking the time to give us first hand introductions to these gentlmen . . . and kudos to these folks for keeping a priceless tradition and skillset alive and kicking. It is ever so refreshing to see such works of art that can double as practical hunting and defensive firearms. Gunsmithing is such a skill that one could take a dozen otherwise identical firearms and give them such individualized treatment that the term ‘identical’ hardly even applies. My problem is that I’d never want to shoot them (ugh).

I found Lee Hadaway’s observation about the S&W M1854 lever gun mechanically resembling the Marlin rather interesting. I always found the Marlin to be a very easy rifle to work on, brute strong and reliable. I also liked that 3″ K frame shown, that would make a delightful everyday carry gun (that I’d never carry).

Now, let’s see – which one of the revolvers pictured do I like the best ?? Ummm . . . yes, those!

There’s definitely more art than science involved in making these beautiful creations!

This is a great series, and I hope we see more installments. The next time I return to Gunsight, I’ll be dropping a gun or two off @ Finks.

Hammer, I’ve got my eye on a few more ‘smiths who’d be good candidates. Stay tuned!

Great if some of those ‘smiths were in WA or MT.

Looking forward to it, Mike!

@viejolobo – while they’re not in WA or MT, you might want to check out Van Dorsten’s in WY and/or Nelson Ford in Boise. Both do great work.

Nelson Ford . . . in Phoenix, right?

Nelson Ford is in Phoenix, yes. I was referring to Nelson Gunsmithing in Boise, ID.

Mike, great job of continuing on with profiling custom smiths. You are providing an excellent resource for folks looking for someone to do modifications to their revolvers.

There are quite a few gunsmith shingles (still) hanging but it is very handy to have an in depth ( better than trip advisor) review of the Smith and his bonifides.

Have had a couple of bad experiences over the many years, usually involving their favorite tool, a hammer.

Great stuff Mike! We’re lucky to have custom gunsmiths like this out there!

I too have an old K frame I may bring to Gunsite… an actual buy back (from the ex wife!).

Ha – well done!

I have been a customer of Dave Fink’s since before he relocated to Gunsite property. I have to say, he has only improved over the years, whether it’s cleaning up 1911s or lately production customs. I currently am waiting for a Revolver Round Up custom… and can’t wait to see how it turns out.

How serendipitous that this article was posted right before my first trip to Gunsite. Dave is working on my Colt Official Police as we speak, fixing some endshake and over-timing issues to bring it back to full fighting revolver glory. He’s a class act (and so is his staff) and some of the incredible pieces of firearm art he had hanging on the walls of his shop made this wheelgunner’s eyes pop out of his head!

Thanks for adding to the list. It’s good to see more top level gunsmiths working on wheel guns and lever actions. At the upcoming Round Up, I will be dropping off a 1940’s era Police Positive at Finks to do a couple of tweaks to make it a great ( and current) fighting carry gun.

Looking forward to seeing you there, and seeing what the Finks crew does with your vintage Colt!

Good to hear you will be back as well. I will have a copy of your book. I’m hoping I can badger you into signing it for me!

Deal!

I’ll add to the happy with Fink’s hog pile. Dave says S&W revolvers are his favorite, but he and his crew work wonders on Rugers as well and my GP100 and a Speed-Six are the better for it! Look forward to having them craft a Revolver Roundup K-frame for me too.