The Original Mountain Gun idea started with a conversation between two RevolverGuys in the late 1980’s. Tom Campbell and Ross Seyfried’s Mountain Revolver project led to some of the most practical and desirable revolvers ever made by Smith and Wesson.

It’s fitting that the Mountain Gun’s long-awaited return began the same way; the RevolverGuys this time around were Lipsey’s Jason Cloessner and Smith & Wesson’s Andrew Gore. That conversation took place at the 2024 SHOT Show as the two were catching their breath from releasing the Ultimate Carry J-frame Revolvers. The UC guns were unveiled to universal enthusiasm and were one of the biggest attractions at the show. The two discussed what their next collaboration would be, it didn’t take them long to agree that it was time to bring back the Mountain Gun. It’s nothing short of amazing that the new Mountain Guns went from that conversation to production within a year.

Getting a Hand

While at SHOT, Cloessner and Gore invited Bobby Tyler of Tyler Gun Works to the table.1 The trio discussed the project at length, sharing ideas on improving the storied design. The OEM grips on the original were one of very few areas where it came up lacking. The Pachmayr Grippers that Tommy Campbell had selected were functional but utilitarian. There’s a time and a place for rubber grips on a Mountain Gun, and that place is in the mountains, where the gun will be subjected to rough conditions and exposure to rain, snow, dust, and mud. The Mountain Guns were worthy of classier stocks for everyday use and BBQ carry.

Tyler had been building grips for many years, and he knew how to make them look and feel good. His mission statement was a nod to the masters that he looked up to: “The craftsmen of the past are what we aspire to be.” Tyler had the opportunity to purchase the rights and the patterns to Deacon Deason’s “Bear Hug” stocks from the Tedd Adamovich family, and wisely did so. Jason and Andrew had brought the right guy in on the project. When they asked if he could make Bear Hugs for at least the first hundred guns, Tyler carefully considered the endeavor and ultimately agreed to supply grips for the entire run.

Hands On

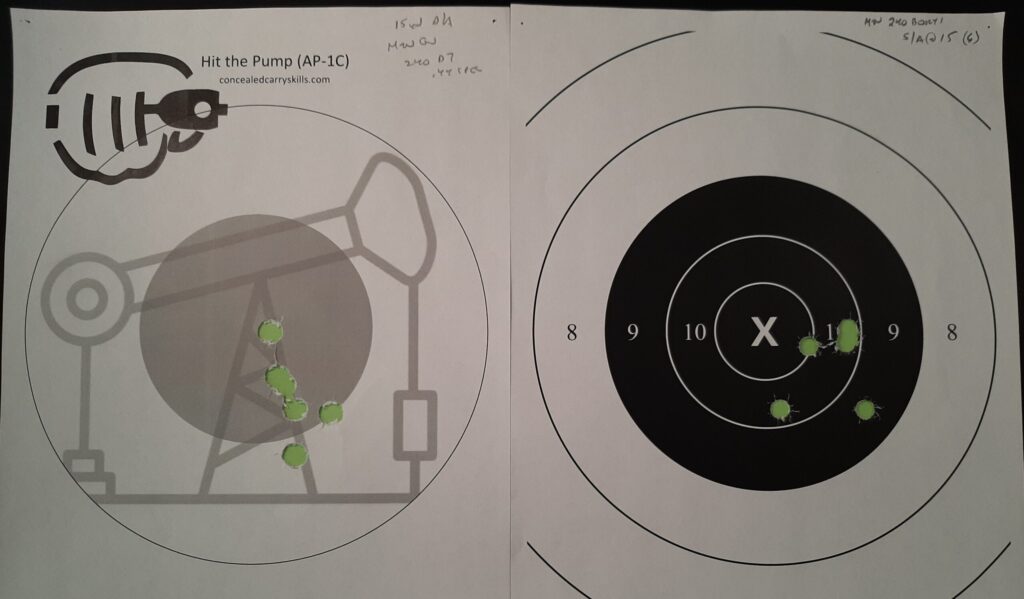

I was honored to receive one of the new .44 Mountain Guns to evaluate in February, a 629-9 NIL. The “NIL” designation refers to the revolver possessing “No Internal Lock”. This should come as incredibly good news to the long-suffering– S&W has finally made this change. The contemporary frame profile near the hammer has been maintained, for reasons we’ll explain in further detail, later.

The new frame has a smooth backstrap like all N frame round butts do these days. The 629-5 changes of 1999 included deleting the tang (backstrap) serrations and incorporating MIM triggers/hammers and floating firing pins, and the new gun follows this same pattern. The Mountain Gun frame has an angled radius on both sides of the top strap rib where it meets the barrel. This cut isn’t present on other current Model 29’s/629’s, but is used on the Model 327 TRR8 and Model M&P R8 revolvers from the Performance Center, and the taper barreled Classic Model 25 (but not the Classic Model 27).

The gun wears the satin finish and minimal badging. S&W’s logo is laser engraved and darkened, sitting just below the current generation thumbpiece. The company’s “Made in U.S.A.” declaration rides in its usual location forward of the yoke screw on the right side of the frame.

Barrel

The 4.13” tapered barrel is adorned like later model originals with the familiar “Mountain Gun” script lasered on the right side. The caliber is engraved in block print on the barrel’s left side.

The barrel is well executed and appears to be a near clone of the original from a side view. Viewed from above, the rib atop the barrel is slightly thinner than the old guns. The original rib leaves the frame at a width of .290” and narrows to .242” at the muzzle end. The new one begins at .250” and slims to .205” at the front. The original has ten serrations, where the new model has room for eight.

The barrel is forged from one piece of stainless steel and features tool cut rifling. There is nothing wrong with EDM rifling, but fellows with extensive six-gun experience (like Brian Pearce) prefer broach cut rifling because it usually produces higher velocities. My experience with a chronograph generally bears this theory out. The barrel on this 629 is properly clocked with the front sight sitting at a true 12 o’clock.

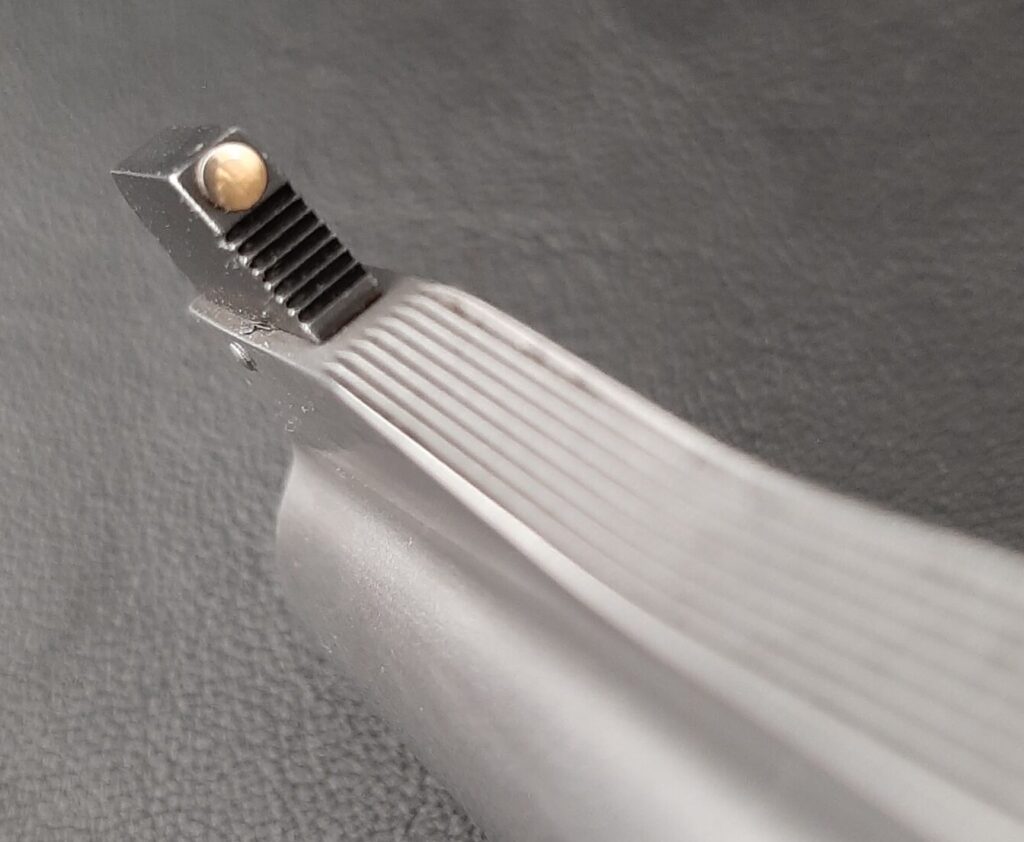

Sights, Cylinder & Trigger

The rear sight is the latest Micrometer adjustable version, the sight blade window is .140” wide to allow proper daylight around the front blade. The window is adequately deep to provide a repeatable sight picture with the front sight.

Cloessner’s experience as an end user led him to lobby to improve the original black serrated ramp. While great in bright sunlight, the black ramp wasn’t ideal in low light. Brett Curry was the lead S&W engineer on the new MG project. He started with a tall Patridge sight with a true vertical face, experimenting until he found an angle that leaned far enough forward to not drag leather when leaving a holster- but still properly take a brass bead. The top of the sight allows for sharp alignment, the bead sits just below it for poor light and quick acquisition. The sight face is serrated to cut glare below the bead. The sight blade measures .125” wide and stands .300” tall, a freckle taller than the original’s .290” ramp. It’s affixed to the rib with a solid pin and may be replaced if damaged or to suit the shooter. Props to Cloessner and Curry, they succeeded in their quest to improve the Mountain Gun’s sights.

The stainless cylinder faithfully sports the “black powder” chamfer at its front that Mountain Guns are known for. Ross Seyfried wanted this feature on the original for practical and aesthetic reasons, keeping it was a no-brainer for the team. They also added a light chamfer to the cylinder charge holes; probably the most useful modification that can be done on a working revolver.

At first glance, the hammer and trigger appeared to be forged, hard chromed steel components. A closer inspection revealed them to be the standard MIM parts for a contemporary service style (narrow) N frame. The parts were given a flash chrome coating which renders a harder surface and can be lightly polished like a forged part if desired. The resulting finish is a pleasing non-glare silver tone.

Stocks, AKA Grips

Tyler Gun Works’ slightly modified Bear Hug / BluMagnum grips were a handsome, grainy, dark walnut. They showed some hand tool marks and I later discovered that they were basically hand finished prototypes. The fit of wood to frame was excellent, the two panels met evenly with no gaps all the way around.

To complicate Tyler’s task, he had to craft them to make the round butt square. That meant the backstrap would be exposed for the top half and enclosed for the bottom where wood filled in for metal to gain square butt dimensions. The transition from metal to wood on the backstrap was well done, as was the contour of the front of the grip.

The palm swell and the amount of wood in the “sinus” behind the trigger guard agreed with my hand. The left panel was properly relieved for speedloader use (Thank you, TGW!). I confirmed that with the 4 types of N frame speedloaders I had on hand, with full length Magnum ammunition.

After the SHOT Show meeting, Tyler purchased a CNC grip machine and had to convert his Bear Hug / BluMagnum patterns to CNC drawings. He found a bunch of high-grade walnut blanks just big enough to use for grips; these were stabilized to work in varying climates, re-flattened and ran through the programmed CNC machine. Final sanding was done by hand. Bobby opted for a satin finish on the grips, based on the hard use missions they would potentially face. This made the grips easier to take care of for long service, allowing the user to repair scuffs and scratches by applying a little suitable oil. The low sheen satin finish was preferable to a high gloss lacquer coat for woods use, too.

When Tyler committed to the project, he went all in to produce the most comfortable, functional, aesthetically pleasing grip he and his employees could make.

The Mountain Gun made an outstanding first impression. Measured on a Lyman analog trigger gauge, the DA pull measured consistently just under 11 pounds. The SA pull broke cleanly at 4 pounds. My sample had one of the better MIM component trigger pulls that I could recall on a new N frame. The only small gripe was the cylinder “shut rough”. Not every time, but frequently. I suspected the fitment of the locking bolt to the front of the extractor rod was a bit undercooked- I hoped that it would wear in.

Live Fire

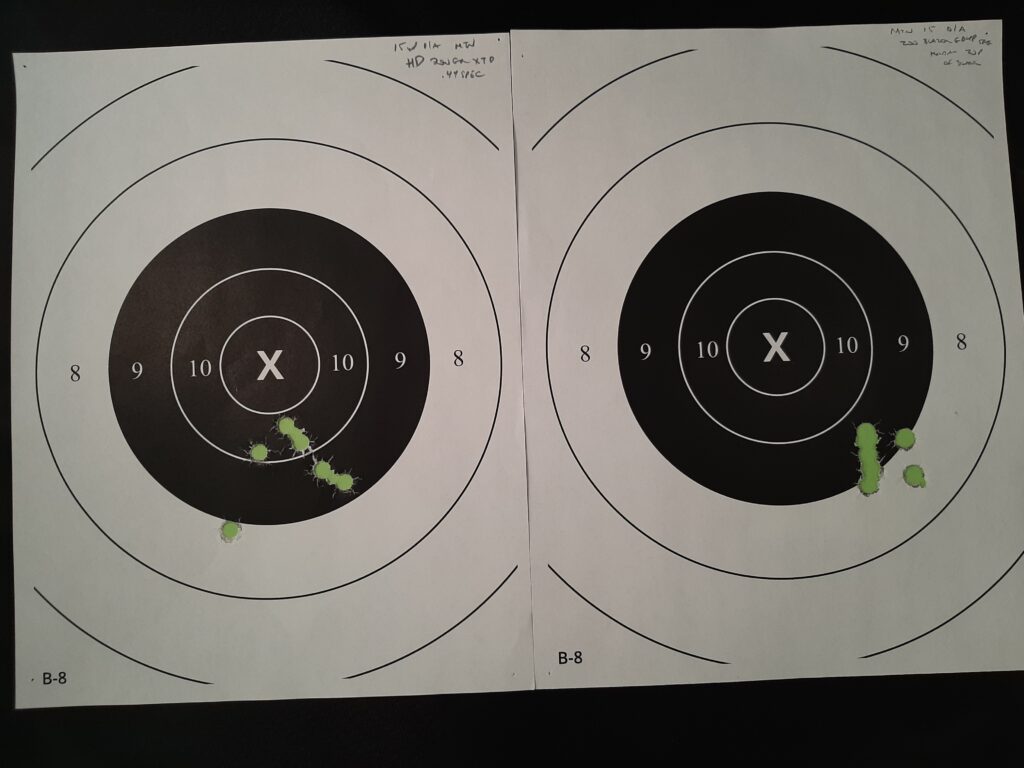

The first time out, I put 90 rounds of mostly full pressure stuff through a Colt Kodiak before picking up the Mountain Gun. My shooting hand was a bit tender by that point. I fired 6 rounds of CCI Blazer 240 grain JHPand had to replace the Bear Hugs with X frame Hogue Tamers. The Mountain Gun was rolling in my grasp and the hump of the backstrap was tapping the web of my hand smartly. This wasn’t an indictment of the TGW grips as much as it was poor decision making on my part. The Kodiak helped determine suitable rounds for the Smith, but I was in the Advil zone prior to the first trigger press with the lightweight gun.

The rear sight needed 7 clicks of upward adjustment to achieve a rough zero with moderately paced 240 grain bullets. The 200 grain bullets were striking low; a zero might’ve been attainable with them, but the rear sight would’ve been perched higher than ideal for a field gun.

The Mountain Gun was originally intended to shine with 240-280 grain bullets, and this one was shaping up to do likewise. Installing a shorter front sight would be optimal if one wanted to concentrate on light bullets; It would keep the rear sight at a more reasonable altitude above the frame.

I put 96 rounds through the Mountain Gun, mostly civil mid-range stuff, tame handloads, and .44 Specials. The Mountain Gun shot well and showed lots of promise. Paul from Ammo to Go generously sent some ammo to run for this test, but the stuff I selected turned out to be better suited to the Kodiak.

Second time around, I packed factory rounds and handloads that were more suitable for the Mountain Gun. Full house firebreathers aren’t needed for most chores and are extremely unpleasant to shoot in a 39-ounce gun. Ross Seyfried reminded us that Elmer Keith relied on a 250-grain cast SWC of his own design at around 1200 fps as his “do everything” load. The original .44 Magnum factory load overdelivered with its max loaded 240 gr. jacketed bullets travelling 1350-1450 fps; that was more speed than even Keith needed. The factories have simmered them a bit over the years, but it’s still exhilarating to shoot them, even in a 50-ounce gun. Traditionally, the options for sane shooting ammo have been to handload or rely on .44 Specials.

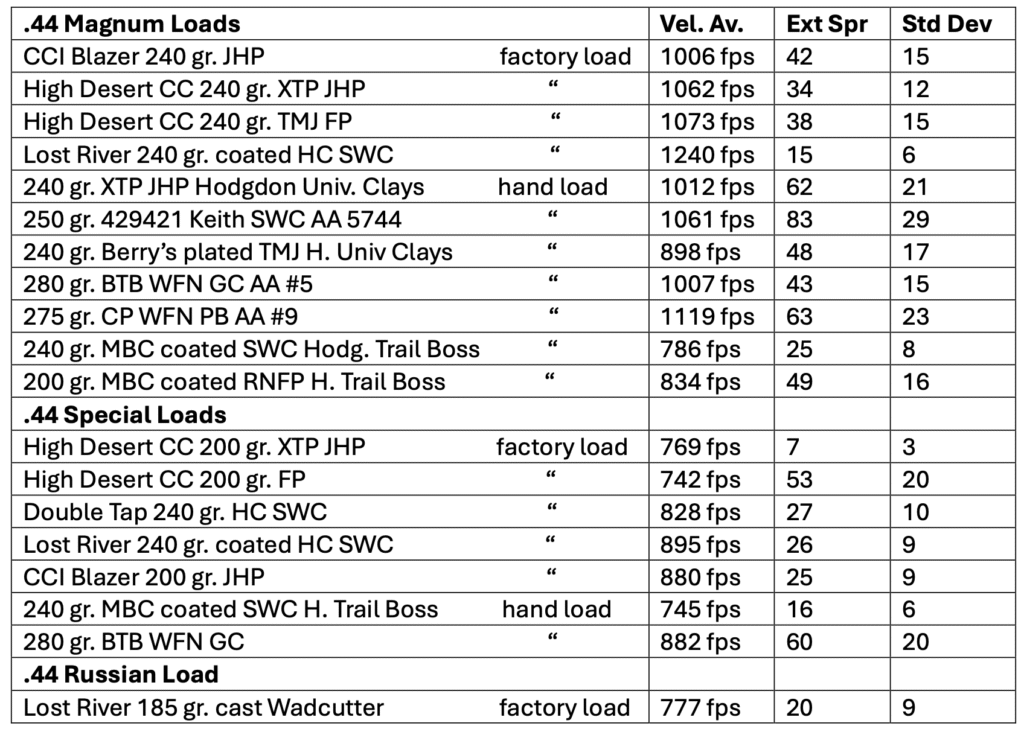

Steve Shields is the proprietor of the High Desert Cartridge Company; he strives to craft magnum ammo that’s tolerable to shoot but still performs capably. His 240 grain XTP load yielded 1062 fps from the Mountain Gun- right in the sweet spot. Shields offers a companion 240 gr. TMJ that ran 1073 fps on average. These are exceptionally useful loads in this gun; The XTP makes an excellent choice for defense or deer hunting at typical handgun ranges. The TMJ is a great training load that recoils similarly and shares a zero with the XTP.

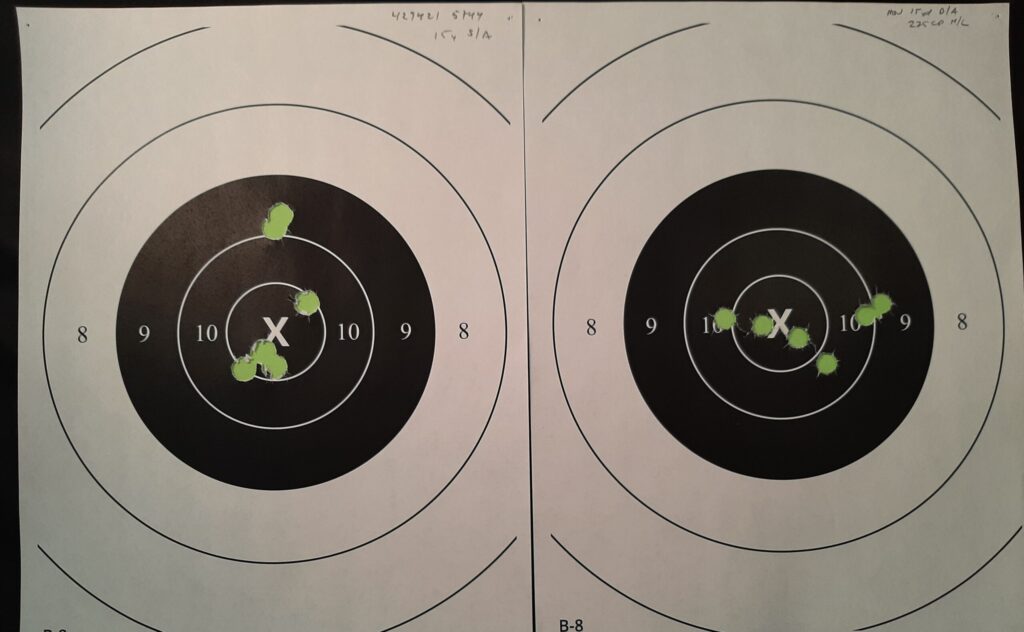

My friend Mark had cast some SWC’s from Keith’s Lyman mold # 429421 sized for the throats of my original Mountain Gun years ago. Loaded on a moderate charge of case filling AA 5744, they averaged 1061 FPS and shot accurately from the new gun, also qualifying as a marvelous choice for everyday use. A bear load (for the seldom seen black bears of NM) with a BTB 280 WFN-GC on AA #5 clocked 1007 fps (The same load ran 983 FPS in an old Mtn Gun when tested in 2007). These are the type of loads that Ross Seyfried had suggested would be imminently useful in the Mountain Revolver in 1989. His wisdom stands the test of time.

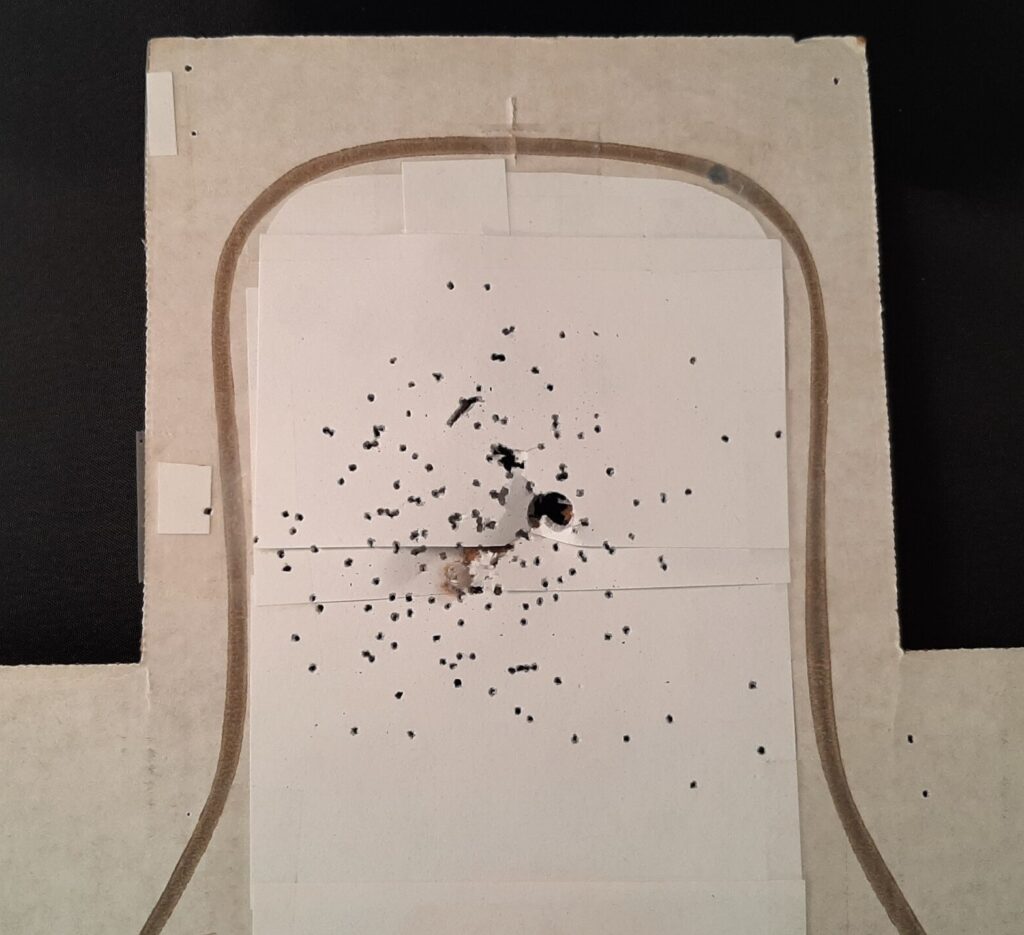

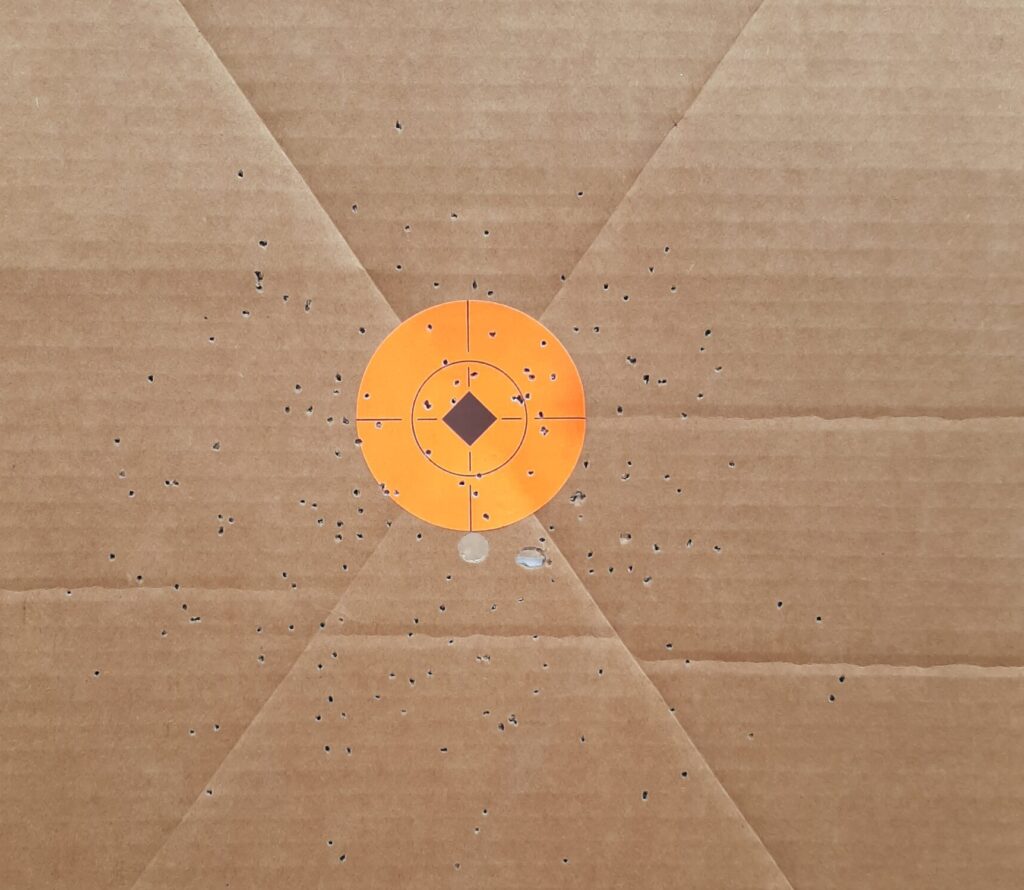

Using a mocked-up cardboard mule deer body as a target, I trudged back to 50 yards. Plopping down to a roll over prone position on a shooting mat, I sent 6 of the 250 grain Keiths at the “deer”, firing double action. The Mountain Gun was up to it, achieving six hits in the 8.5” inch circle that represented the animal’s vitals.

I had assembled some handloads with 240 XTP’s and Berry’s 240 gr. plated FP’s that were a bit more sedate than High Desert’s offerings using Hodgdon’s Universal Clays. Both shot well, as did a coated MBC SWC on a max charge of Trail Boss. The Trail Boss load was a pleasant practice load that would still do nicely for small game hunting. It hits with about the same authority as .45 Hardball from the Mountain Gun.

On my third range day the revolver wore the TGW grips. I shot 6 of the Keith handloads at a human silhouette from 70 yards first thing, cocking the gun to single action for each shot. The group printed well vertically and was a shade right of center.

I then shot Tom Givens’ Rangemaster Bullseye Course (all D/A) with the Trail Boss handload and came up with a 283/300, making time on every stage. I lost 3 into the 8-ring low at 25 yards, so I was 6 points down after the first stage. The 7-yard stage called for shooting 5 from a low ready, reloading and shooting 5 more in 15 seconds. I dropped one low into the 8-ring but finished in 13.44 seconds. Not bad for a big revolver.

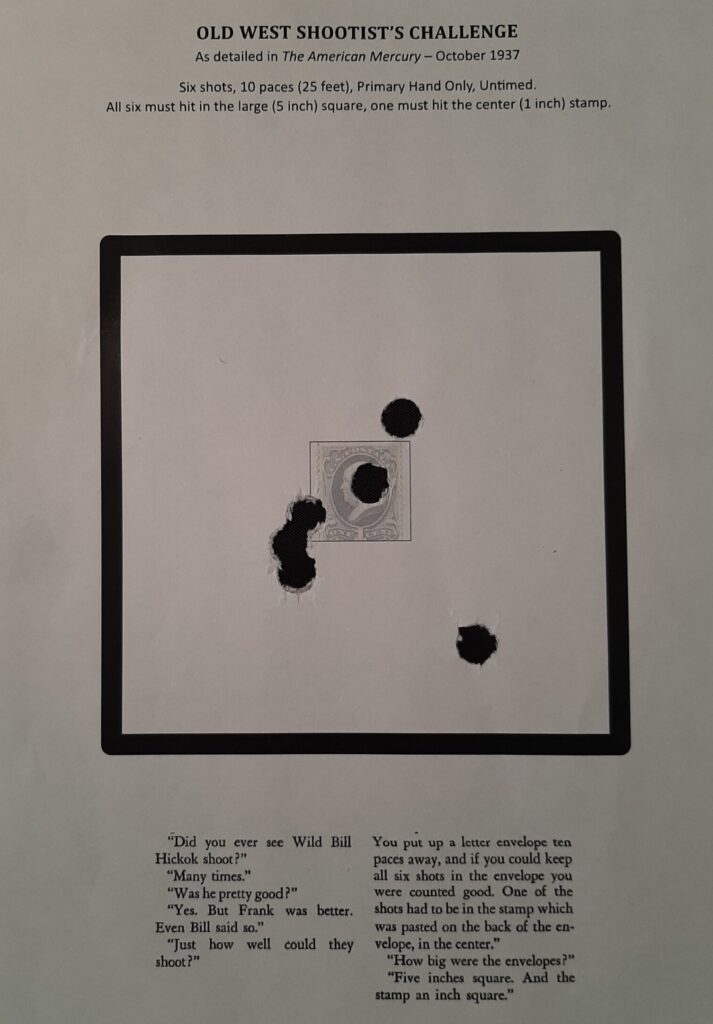

I shot the Old West Shootist’s Challenge (Hickok’s Gunfighter Challenge) at 30 feet, the Mountain Gun passed nicely. I shot some of DoubleTap Ammo’s excellent Snake Shot loads at 6 and 10 feet; the gas check and wadcutter impacted to the sights and the shot pattern was thick and uniform. The .44 Mag version was rightfully more impressive than the .38 Special load. I fired about 100 rounds that day and suffered no discomfort with the TGW grips, starting fresh. The Trail Boss loads were pleasant to shoot, I made sure I had a firm grip for the warmer Keith loads.

My last trip was used to chronograph the rounds that Ted McIntyre from Lost River Ammo had graciously sent. Like Shields, McIntyre is an end user who gets it. He believes in matching the ammo to the task. His “The Load” is a coated 240 gr. SWC advertised at 1200 fps. It ran slightly faster here at 5340 feet on a 75-degree day, averaging 1240 fps. It was one of the most consistent loads fired with an extreme spread of 15 and standard deviation of 6. The trajectory would make it a great choice for hunting medium game where the ranges might stretch a bit. Lost River’s .44 Special (coated 240 SWC at 895 fps) would make a good general-purpose load. McIntyre’s .44 Russian full wadcutter has great potential as a low recoil defensive load.

I also tested a Cast Performance 275 gr. plain based WFN hand load that clocked faster than expected. It ran 1119 fps, but the recoil was still manageable. It hit to the 240 grain zero at 15 yards and showed great promise as a sleeping bag load in dark country.

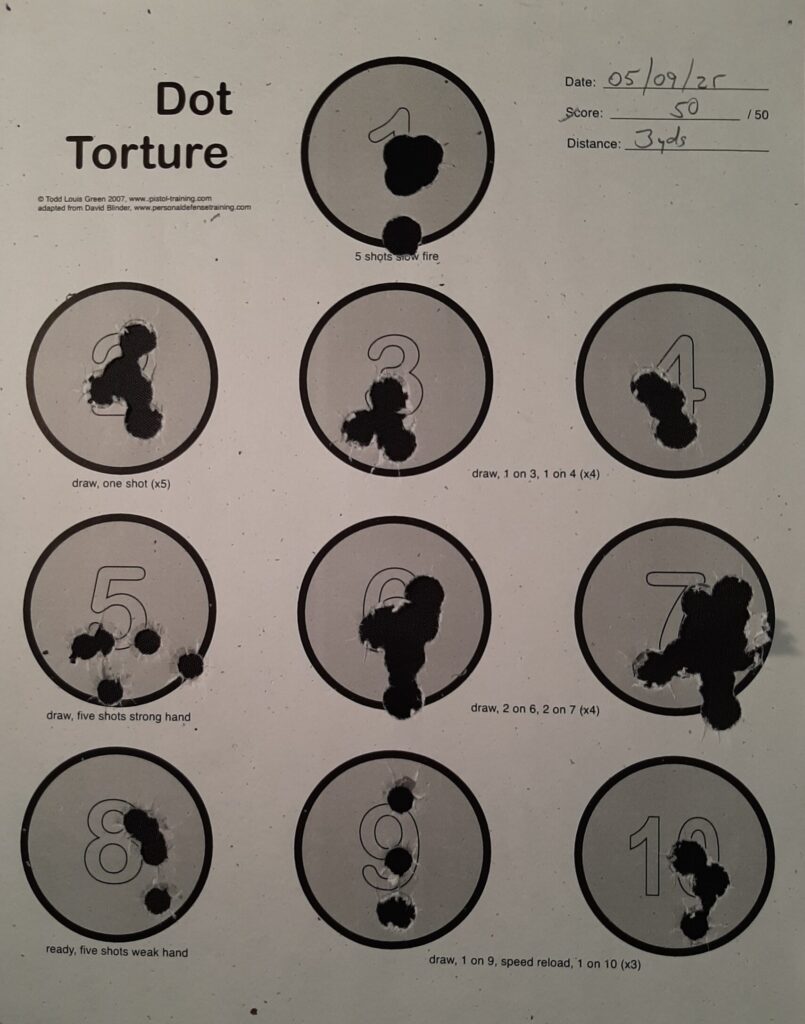

All my groups on that trip were settling a bit right, so I gave the rear sight a click of left windage. I shot a round of Dot Torture with a mixed batch of .44 Special handloads that ranged from mild to sporty. The Mountain Gun cleaned it, I probably should have backed up to 4 or 5 yards. I used a Kramer horsehide scabbard for my range work along with an old BladeTech speedloader pouch and an S/L Variant speedloader. The combination contributed to swift draws and reloads with the Mountain Gun- it was fun to run.

Like Seyfried noted with the original, the thin barrel and resulting lighter weight gave the Mountain Gun a “nimble” feel. Skeeter Skelton had the same thoughts with his Model 24 as compared to a bull barreled Model 29; a skinny barreled 4” N frame in a belt holster is just… responsive. A modern Hank Sloan style holster (from Barranti Leather or Milt Sparks) or a Simply Rugged Sourdough Pancake holster with a snapped speedloader pouch would be more secure for field use. Chest rigs are a great option for keeping the gun accessible while wearing a pack or riding in a vehicle or standing in a shallow river while fishing.

New Drop Safety

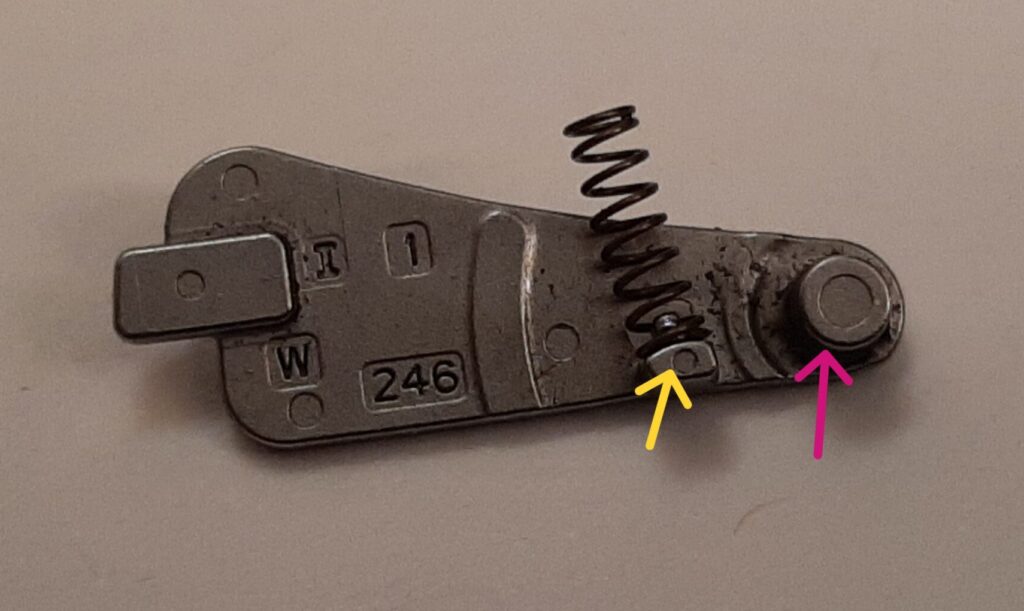

Deep into writing this article, I learned that S&W had incorporated a new drop safety into the No-Lock frame of the Mountain Gun. Smith & Wesson did away with the internal lock, but they used the space to add an additional drop safety in the same area. It explained why the “arch” of the new style frame was maintained.

There is much less going on with the new drop safety than there was with the internal lock. The drop safety parts consist of a single plate and a small coil spring (the hammer appears identical to the MIM hammer used with the internal lock). The plate has a raised post at its rear that fits into a hole in the frame to anchor it. A tab sticking off its’ front engages a slot cut into the frame wall to keep it in place. There is a “nub” on the plate that rides in the groove on the left side of the hammer, like the locking tab did on the internal lock.

The drop safety spring sits on a seat on the back of the plate and rides captive in a port cut in the side of the frame. It exerts downward pressure on the plate in normal operation, keeping the nub riding in the hammer groove, and allowing the hammer to move freely.

If the hammer is cocked and the gun is dropped and lands on the hammer, the inertia will force the plate to move against the spring pressure, and lift the nub into a notch that will block the hammer from forward travel. You can see the plate riding on the portside of the hammer (looking down from the top) when the gun is cocked.

I’m speculating the new safety has something to do with the drop tests required by the California Department of Justice to get new handguns placed on the list of models that can be sold there, but I’ve received no confirmation from S&W. That said, the new safety is part of the baseline, and will be included regardless of where the gun is shipped or sold.

This new safety, working in conjunction with the two existing internal safeties (the hammer block and rebound slide) should make the guns thoroughly and redundantly “drop proof”. I had no drama with the new system during my testing, I was blissfully ignorant of its presence. The gun ran without interruption, even with the hardest-kicking loads.

Considering the issues that some shooters experienced with unintentional lock engagements in the early lock-equipped guns, I’d wager that S&W’s durability testing with the new safety has been extensive. Hopefully they subjected the new parts to “major gunk testing,” akin to hosing the action down with WD40 and spraying it with dryer lint and worm dirt. We look forward to Smith & Wesson providing more information about the drop safety soon.

In Conclusion

I thoroughly enjoyed the time spent with this new revolver. It had been a while since I ventured out with a big bore, and it was therapeutic to handload easy shooting ammo for the .44. Mountain Guns remind you that you don’t need to drive the big bullets to the red line to get most jobs done.

Total round count was 410, with 297 Magnums, 107 Specials, and 6 .44 Russians fired. Every hammer fall produced positive ignition, there were no extraction or ejection issues. The double action pull felt slightly smoother after the polish of live fire. The cylinder closing roughly hasn’t gotten any better, but I can live with that. If S&W will let me buy this one, it will take over wilderness chores with heavy bullets and my old one will get permanently zeroed with 200 gr. bullets.

The folks involved at Lipsey’s, Smith & Wesson, and Tyler Gun Works made a fine sequel to the original–I can’t help but think that Tommy Campbell is looking down with a big grin on his face and holding two thumbs up.

Endnotes

1.) One thing that has become a signature piece with the Lipsey’s/S&W projects is grips that live up to the rest of the gun. Cloessner and the team have been good to reach out to folks that run revolvers daily for input, like Daryl Bolke and Bryan Eastridge, and our own Mike Wood. The VZ grips of the UC revolvers, the Hamre Forge AFR grips on the 432 and 632 Ti guns, and these TGW Bear Hugs are examples of that.

Kevin,

Another excellent review. The Lipsey-S&W-Wood-Bolke-Eastridge conglomerate deliver some of the most desireable S&W revolvers in recent memory.

Many thanks for the time and effort involved. I saw the 629 and 686 Mountain Guns at the NRA Mtg in April, and they were absolutely sweet !! My lust-fest went to the 686 Mountain gun – I’m a terminal .357 Magnum / .38 Special addict.

The new Mountain Guns have a visual ancestor in the short barrel M27 and M28 revolvers. The 4″ Model 28 ‘Highway Patrolman’ revolver could rightfully claim to be the inspiration for the Mountain Guns.

Excellent analysis of the newfangled excuse for a drop safety – nevermind the existing drop safety and hammer block safety have been working fine for nearly 75 years. One wonders about the inmates elected to the California Institute for the Terminally Stupid (Sacramento State Capitol Bldg). We already know these inmates know less about guns than I know about the back side of Mars, so one wonders how long they will be content that this drop safety works. Anytime you complicate a mechanism, you increase the opportunity for Murphy & Company to interfere with function. This one will bear careful monitoring.

The external attributes such as beveled cylinder flutes, the subtle frame taper, the barrel contour, all lend to a very asthetically pleasing revolver. One aspect of the MIM technology that S&W apparently uses results in very soft external contours of the trigger and hammer, and even the internal MIM components. Blending that used to be done on the old bar stock hammers and triggers now comes from the MIM mold.

Something tells me you’ll be adding this to your collection . . . I know I would.

Thanks, S. Bond. Lipsey’s came out of the gate with two really good choices. Your .35 caliber lust fest is fully justified. The feature set of this new 686+ Mountain Gun makes it arguably the coolest 686 ever. I would add the 1950 Target to the Highway Patrolman as the Mountain Gun blueprints. Those skinny barrel N frame guns from the 50’s were as cool as… Elvis. Agreed on the drop safety. Definitely a step up from the internal lock. If you happen to thumb cock one and then drop it, these new Smiths should be pretty darn bang proof. As you bring up, it is more parts for Murphy to examine and attempt to exploit. It is a very handsome and capable revolver, it’s worthy. I’m renting table space from the little girls in my neighborhood that sell lemonade; parleying home baked goods to pay the tariff on this bad boy. 🙂

Kevin:

I thoroughly enjoyed your review of the new S&W Mountain Gun. I have been a S&W Revolver guy for almost sixty years. I own or have owned many “Smith’s” in the J frame, the K frame and the N frame. Also a few S&W pistols. I don’t believe any other revolver can match the double-action trigger of a S&W. Of all the S&W revolvers I have owned I have not owned a Mountain Gun. Your article has made me decide that I need to correct that flaw in my collection. Because I’m an incurable “traditionalist” I’ll probably look for an original Mountain Gun without the “Drop” or “Internal safety.”

Speaking of those safeties, I’m sure you are correct in saying they were a nod to the California DOJ “list.”

California represents such a large market that I don’t blame S&W for modifications that allow that market to be open for their sales. And, these modifications seem to have preserved most of the original design of the gun. I just think they (the safeties) are unnecessary and are simply a nod to political correctness. The original N, K and J frame guns were perfectly safe in the hands of a knowledgable shooter. I have a suggestion to improve safety…Don’t drop it.” Or to satisfy Calif. DOJ, don’t buy or sell it, or, better yet don’t build it. This, of course is the ultimate goal of those idiots who run the state of California.

Thank you, D+B! The originals are still out there, if you’re patient. A decent example will run you at least as much as retail on a new one, though. I hear you on your thoughts on the safety. It seems to me that the 2 existing safeties are adequate, I’m not sure how the new one could be really needed. I say that not knowing if the California “powers that be” might have made the test harder for guns to pass. I’ve put 400 plus rounds through this one with no drama with the parts, but that’s under fair weather range conditions. I haven’t done the “carry it in a rainstorm, slide down the side of the mountain ” test with it just yet.

For a revolver with that price tag, the cylinder shouldn’t be closing roughly at all; in my opinion. It’s little things like that that keep me away from S&W now.

That said, I think a revolver like this would make a great platform for .44 Special. I’m not a magnum person, but I do like the .44 Special.

It is disappointing, Axel, and you’re right- it shouldn’t have left the factory like that. It is the one thing wrong with this one. It is the perfect platform for a .44 Special, most of the loads shot through this one could have been achieved in a .44 Special case. It reminds you of this fact when you torch off full house magnums in it!

Another big plus for this updated Mountain Gun is it thankfully doesn’t have the hideous, unsightly lock hole of yore. But it’s too bad the cylinder “shut rough” but with a MSRP of $1199.00 it should not. Maybe it will smooth out over time.

Agreed, Spencer. It should not. I pulled it out today and opened and shut the cylinder a lot. It is not as it should be, but it feels a little better than when it was new. Hopefully it will continue to improve.

Kevin:

Out of all the new firearms I’ve handled lately, the ones with the smoothest actions and good triggers right out of the box have been Ruger-made Marlin lever-action rifles. Those Marlins also show excellent fit and finish, which is what you’d expect out of an expensive firearm. It might be worthwhile for S&W to study the new Marlins’ production techniques.

My new 27-9 classic had a very rough closing. 200 magnums and some good cleaning now it’s all ball bearings as fletch says…

Thats good to hear, Gus. I’m going to keep shooting this one and hope for the ball bearings!