Part I: The Making of the Ultimate Carry J-Frame

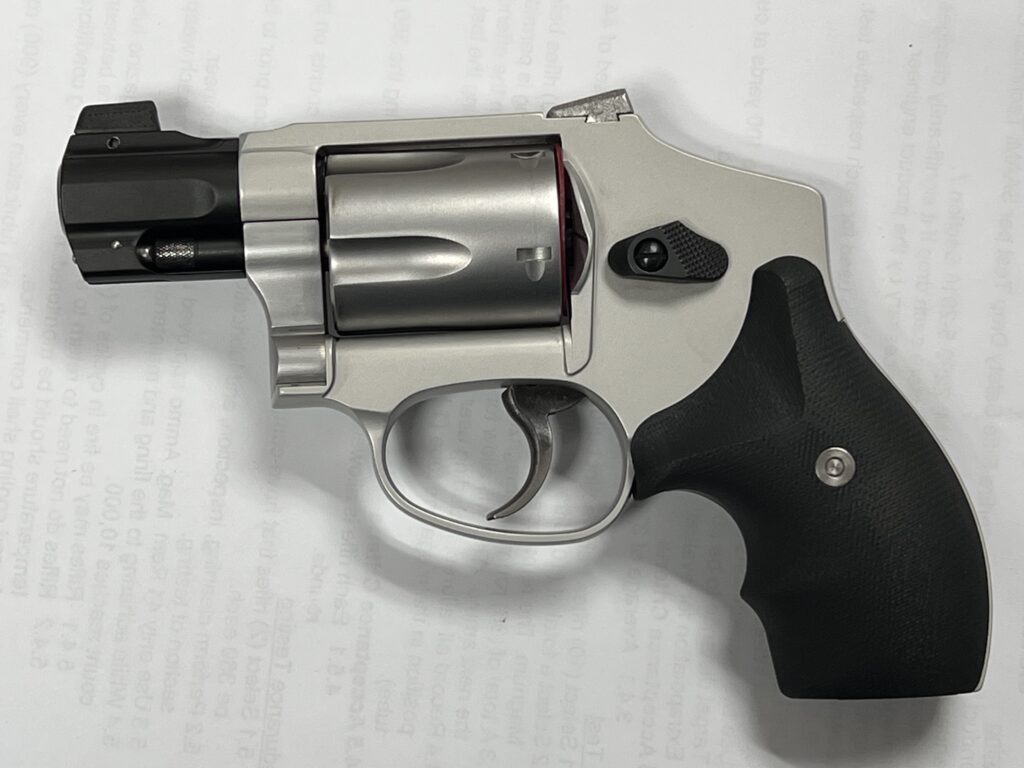

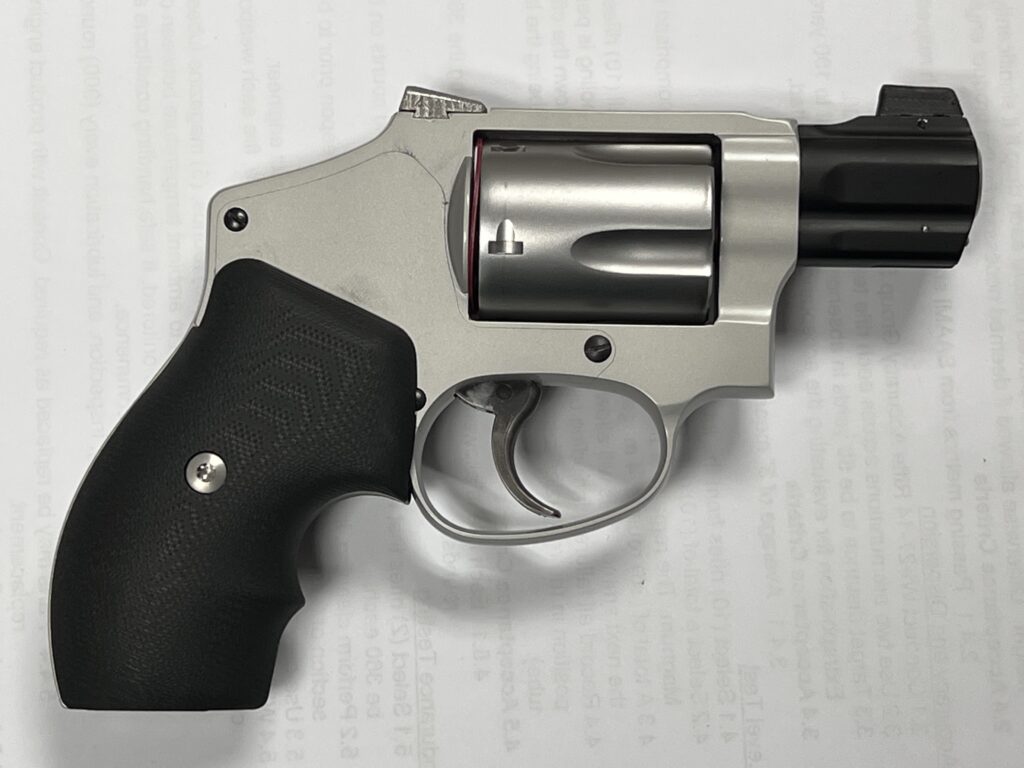

When Lipsey’s and Smith & Wesson announced their “Ultimate Carry J-Frame” collaboration at the 2024 SHOT Show, snub fans from all over the revolver universe leapt for joy, excited by the prospect of a factory J-Frame with the improvements they had wanted for so long.

Even before the first reports began to surface from show attendees, detailing the advances and features of the new guns, the buzz was spreading across the show floor and the internet. There’s a phenomenon we see every year at SHOT, in which certain guns capture the imagination and attention of the industry, and suck up most of the oxygen in the Sands Expo, and the Ultimate Carry J-Frames were some of the guns that did that in 2024. The little guns elicited a BIG response, not just from dedicated RevolverGuys, but from folks who wanted to see what all the commotion was about, and soon discovered they might actually be RevolverGuys, too.

Special J

I was fortunate enough to be read into the Ultimate Carry J-Frame program relatively early, so I knew about the guns in advance and kept tabs on their development. It was difficult to resist sharing the good news about this exciting project with the RevolverGuy audience, but I kept my mouth shut and eagerly awaited the expiration of the communications embargo on Tuesday morning of SHOT, so we could talk about these special Js.

Last month, I was grateful to have the chance, along with a selected handful of gun writers, to shoot the first production samples of the Ultimate Carry J-Frames (UCs). I burned through slightly more than half of a case of ammo in the course of a day on the range with the UCs, and walked away very impressed with what Lipsey’s and Smith & Wesson had accomplished.

For the Record

I’ll be writing about that experience, and the features and performance of the guns themselves, in greater detail soon. First, however, I wanted to start our coverage of the UCs by turning the clock back to the very beginning of the program, to tell the behind-the-scenes story of how the project got its start, and how it developed from a concept to a reality.

Why start there? Even at this early stage, I think it’s clear that the Ultimate Carry J-Frames will become an important milepost in the history of Smith & Wesson revolvers, and I think it’s important for us to capture the details of how they came about. The Roman historian Tacitus once wrote that, “ . . . victory is claimed by all, failure to one alone,” and I suspect there will be lots of folks lining up to take credit for the success of the Ultimate Carry J-Frames.1

So, pull up a seat, and let me tell you a little about the UC journey, and the people who really made it happen.

The Lipsey’s Connection

It all started in the heart of a RevolverGuy.

Actually, the seeds were planted in the hearts of hundreds of thousands of RevolverGuys over the course of seventy-plus years, who wanted more from their J-Frames than Smith & Wesson was ready to deliver, but it was one particular RevolverGuy who cultivated the idea, and sent us down the path to building the ultimate factory J.

Jason Cloessner’s formal title is Lipsey’s Senior Vice President & Product Development Manager, but for the present discussion, we’ll call him the Father of the Ultimate Carry J-Frame.

Jason started at firearms distributor Lipsey’s right out of college, as part of the sales team, and worked his way up the ladder to occupy his present position as Senior VP. In part, Jason’s responsibilities include coordinating all the special projects that are done in concert with the manufacturers whose products are stocked by Lipsey’s. To accomplish this, Jason uses his extensive knowledge of shooters, firearms, and the industry to identify market segments that are underserved, and work with manufacturers to develop special runs of “Lipsey’s Exclusive” products that will appeal to customers in those segments. No manufacturer can stock a catalog that will meet the demands of every consumer, but with Jason’s help they can build small runs of specialty guns that will satisfy the cravings of certain blocks of shooters who desire a particular feature or capability that’s not found in the regular catalog.

For instance, Jason and Lipsey’s have had a long relationship with Ruger, who’s made a number of special project guns for Lipsey’s featuring unique calibers, barrel lengths, finishes, grips, sights, and other features that appealed to Ruger fans who wanted something just a little different. Similarly, Jason worked with Glock to produce very popular reproductions of the guns that started it all for the Austrian maker, such as their P80 pistol and the first generation Glock 17, complete with special markings, sights, frames, boxes and literature.

Because Lipsey’s is the customer in these projects, and agrees up front to purchase all the guns, there is little risk involved for the manufacturer to build these unique variants—they simply make the guns, as specified by Lipsey’s, and collect the check. Lipsey’s is the one who assumes the risks, and has to do the work of marketing and selling the guns to the consumer. That never seems to be a problem, because Jason does his homework, and Lipsey’s, as the nation’s leading firearms distributor, knows how to sell guns! The Lipsey’s Exclusive guns never last long on the shelves.

A True RevolverGuy

Now, readers who don’t have close ties with the firearms industry might be surprised by the number of senior executives serving in influential positions who aren’t very knowledgeable about guns. They know business, but they don’t necessarily know much about their product, or the customers who buy it.2

Jason sits at the opposite end of that bell curve. He’s one of us, at heart; A “gun guy,” who thoroughly enjoys all manner of firearms and shooting sports. He knows the “gun culture” intimately, because he’s part of it, and it’s a part of him. Furthermore, Jason is a true RevolverGuy, who still gets excited when the talk turns to Roper grips, Registered Magnums, big bore single actions, and carved leather for them.

That passion for revolvers is tempered by his years of business experience, though. Once, when I enthusiastically suggested Lipsey’s should consider funding a limited run of the Smith & Wesson Model 58, I saw a grin on his face and a flash in his eyes that said, “heck yeah!” but it didn’t last long before I saw the wheels turning in the background, as Jason pondered if there was a sufficient market for it, and whether the limited resources could be more profitably spent on a different project that would yield a greater return.3

So, with the heart of a true believer, the acumen of an accomplished businessman, and the support of a company like Lipsey’s, it was no surprise that Jason would be the guy to advance the idea of making an improved J-Frame for the legions of RevolverGuys who have wanted something better. There’s nobody else in the industry that was better positioned to make it happen.

The Smith & Wesson Connection

To make it work though, Lipsey’s and Jason would need a partner in the effort at Smith & Wesson–someone who could take their concept, and lead a team of engineers, model makers, and workers to turn it into a functioning reality of steel and aluminum.

They found him, but as it turned out, he came from a rather unlikely place.

Smith & Wesson Handgun Product Manager Andrew Gore originally hails from Australia, a nation where handgun ownership and use are subject to strict regulation, which stops just short of outright prohibition.

Andrew is a “gun guy” though, and was an active part of the firearms culture in Australia from an early age. Prior to joining the Australian Federal Police (AFP), Andrew made a living selling firearms in a retail store, and was an active shooting sports competitor and range officer. As a Federal Agent of the AFP, Andrew conducted criminal investigations, served on intelligence teams and drug task forces, and worked assignments such as uniformed patrol, traffic, dignitary protection, and tactical team operations.

At a critical juncture in his law enforcement career, Andrew embarked on a path that would lead to him becoming one of Australia’s most capable firearms, use of force, and tactics instructors. His professional education included training at some of the world’s finest firearms training schools, including the Sig Sauer Academy, Rogers Shooting School, and the U.S. Federal Law Enforcement Training Center (where he graduated from the Firearms Instructor Training Program as a Distinguished Weapons Expert).

As a new American citizen, Andrew worked in the U.S. firearms industry as a law enforcement sales specialist at a major distributor, a sales manager at a company developing suppressor technology, the Director of Law Enforcement Sales at CMC Triggers, the manager of the U.S. Simunition Training Division, and as a senior-level manager at the parent company of Simunitions, General Dynamics.

Fortunately for us, this path led to him being hired as the Handgun Product Manager at Smith & Wesson in June of 2022. By the time he got his feet under him in the new job, Jason was knocking on Andrew’s door with a proposal for an improved J-Frame.

SHOT Magic

While Lipsey’s had a well-established and successful track record of Lipsey’s Exclusives with a variety of manufacturers, it had been a while since they collaborated with Smith & Wesson when Jason sat down with company representatives at a meeting in the Summer of 2022. Fortunately, the folks from Smith & Wesson were receptive to Jason’s pitch, which opened the door to a meeting at SHOT Show in January of 2023.

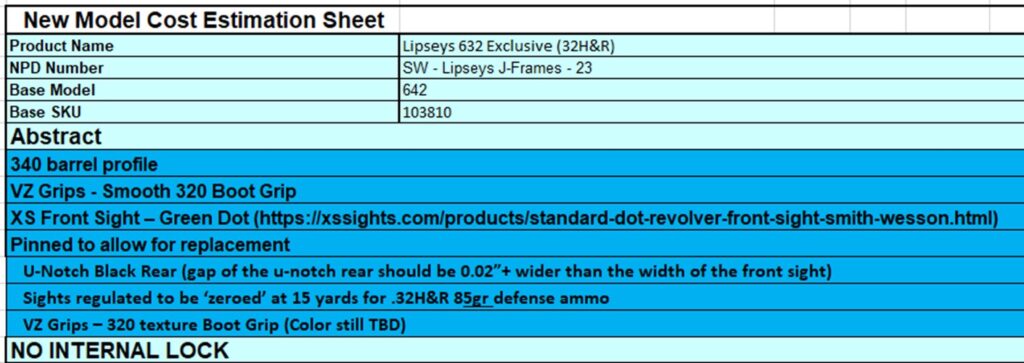

Andrew had been the Handgun Product Manager at S&W for just over half a year when he and Jason met during the busy show to discuss the potential for some Lipsey’s Exclusives. After reviewing several possibilities, the two quickly focused on a J-Frame project as the leading contender, since Smith & Wesson had available production time on their J-Frame manufacturing line.

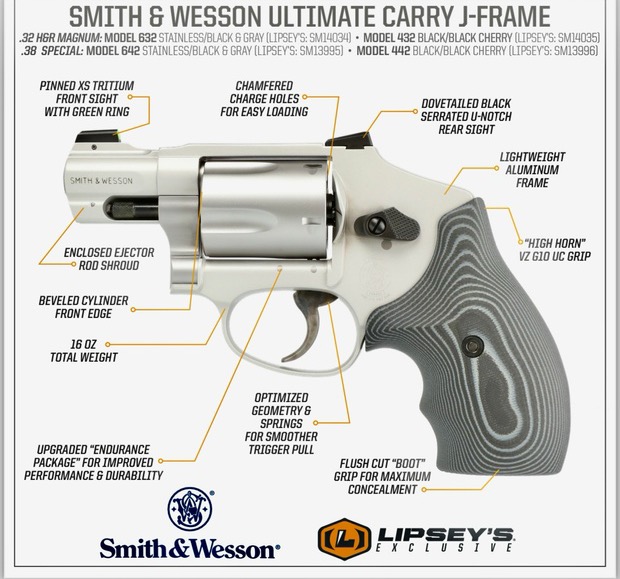

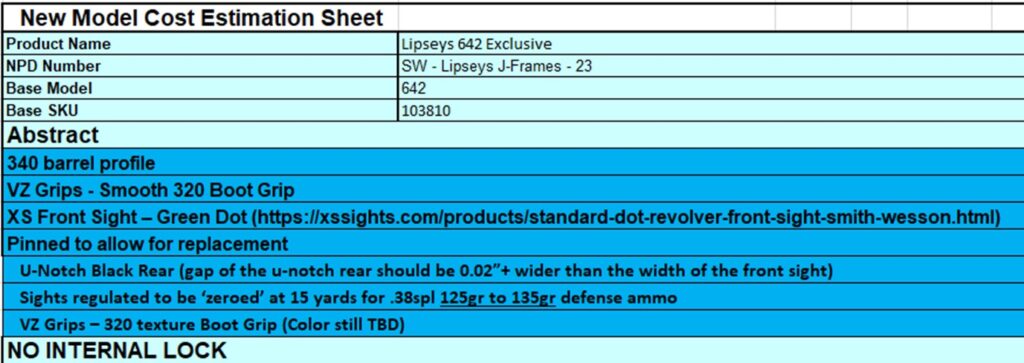

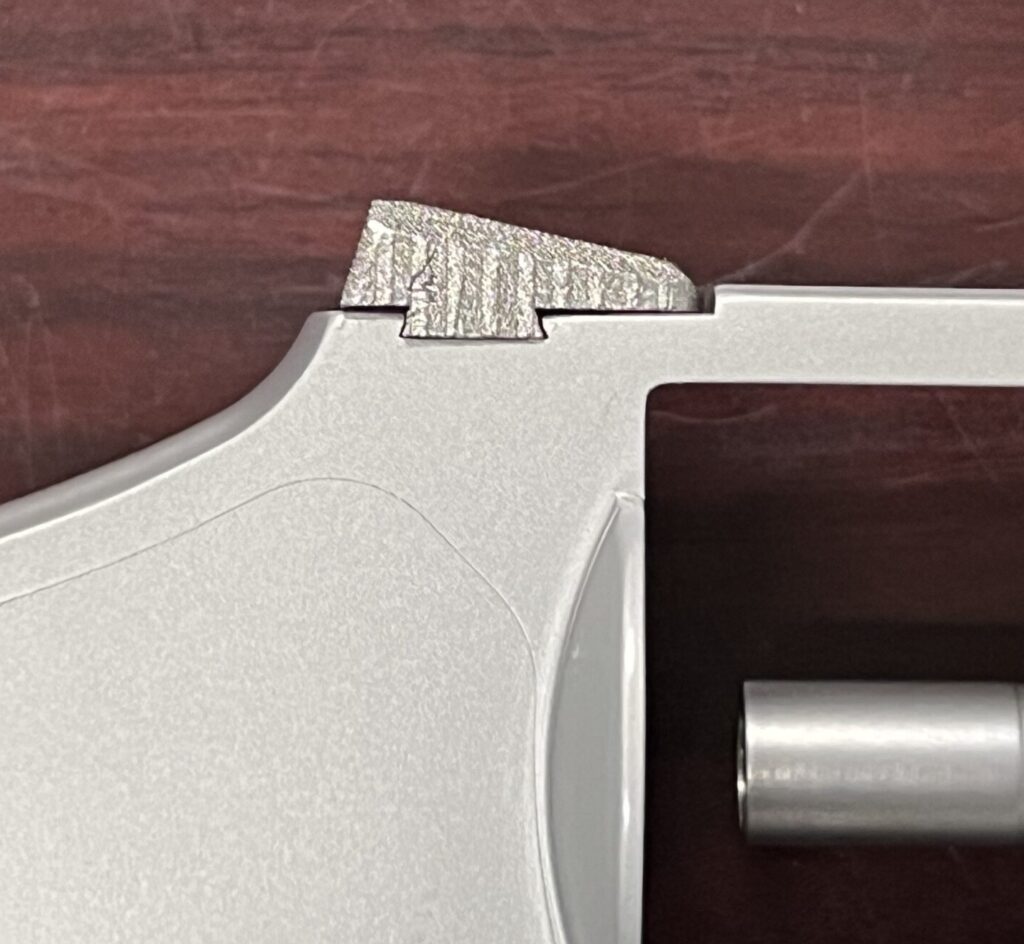

The two “gun guys” hit it off from the start, and began to sketch the basic outlines of a special edition J-Frame whose most prominent feature would be improved sights (a bright dot sight from XS Sights was suggested for the front) that were properly regulated for commonly-used ammunition (accomplished by using either an adjustable rear sight, or a dovetailed, high-visibility, fixed rear sight of the proper dimension). The pair also decided the gun should feature upgraded grips, such as a pair of G10 boot-style grips from manufacturer VZ Grips.

I happened to speak with Jason at the show, following his meeting with Andrew, and while he couldn’t discuss too many of the particulars, I was very pleased to hear about the progress Lipsey’s and Smith & Wesson were making, and to see how excited he was about the potential for some new exclusives. That was promising news for us RevolverGuys.

That Was Fast!

That first meeting between Jason and Andrew had been fast, and while they got off to a good start, Jason still didn’t know Andrew very well, and didn’t know what to expect from him and Smith & Wesson.

Andrew didn’t make him wait long, to find out.

Anyone who has spent any length of time around Andrew understands that he’s the kind of guy who gets things done. He’s not afraid to ask questions, demand good answers, set expectations, and get people busy. One gets the sense that his operational, mission-focused background makes him particularly averse to unnecessary delays, extended studies, or any sort of bureaucratic inertia that might interfere with progress.

So, within just a few weeks of the late January 2023 SHOT Show meeting, Andrew had already delivered some Photoshopped renderings of J-Frames with a variety of improved sights for Jason’s review. Some of the models wore adjustable rear sights, while others wore dovetailed, fixed sights that mimicked the one on the Performance Center Pro Series Model 640.

By late February, the two had settled on a preliminary design that incorporated a dovetailed, fixed rear sight that generally followed the 640 Pro pattern, and a two-piece barrel that would feature a pinned, easily replaceable, high-visibility front sight. Of special importance, the two-piece barrel would offer additional advantages, including the ability to properly clock the front sight to Top-Dead-Center (TDC) without cracking the frame, set the barrel-cylinder gap to the desired dimension, and shroud the extractor rod, to protect it. As we’ve previously discussed in these pages, it would also offer a potential for improved accuracy.

March Madness

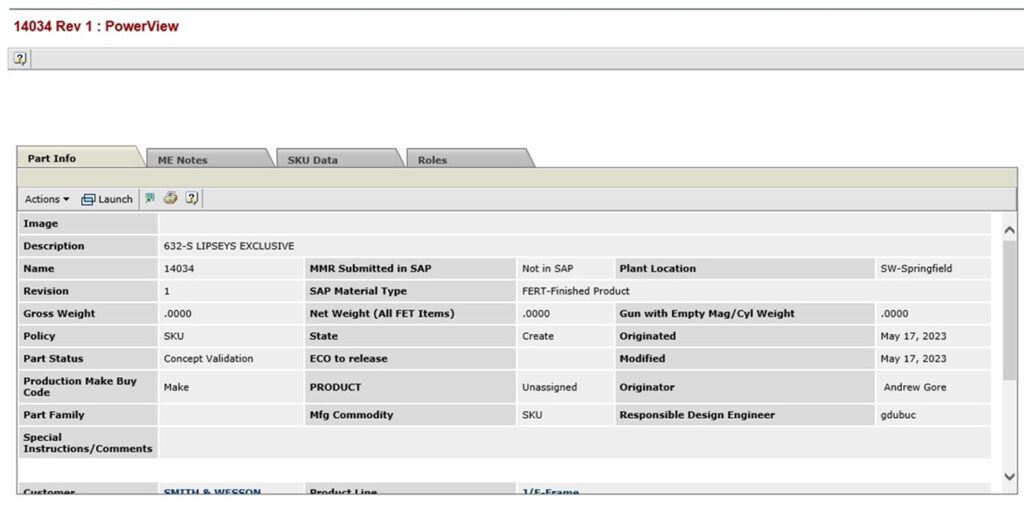

By early March 2023, Andrew had delivered the new model build sheet to Engineering, which would allow them to start working on the gun.

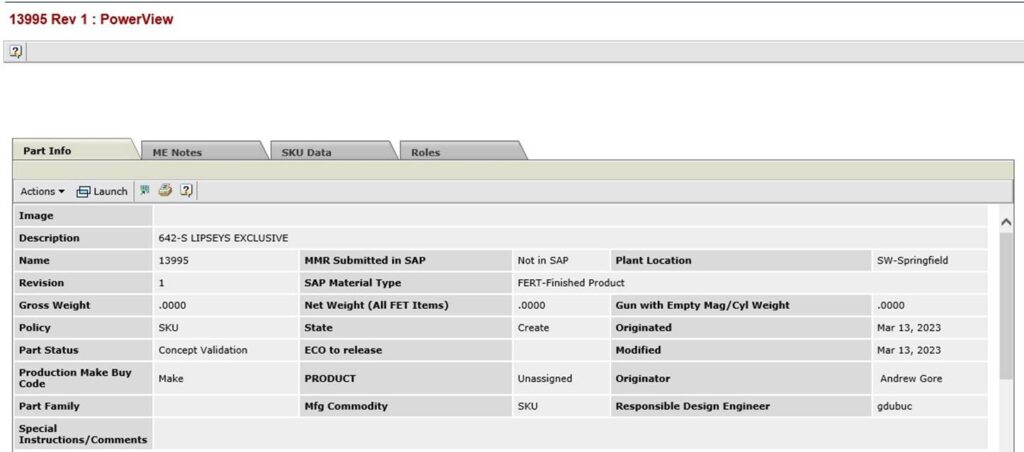

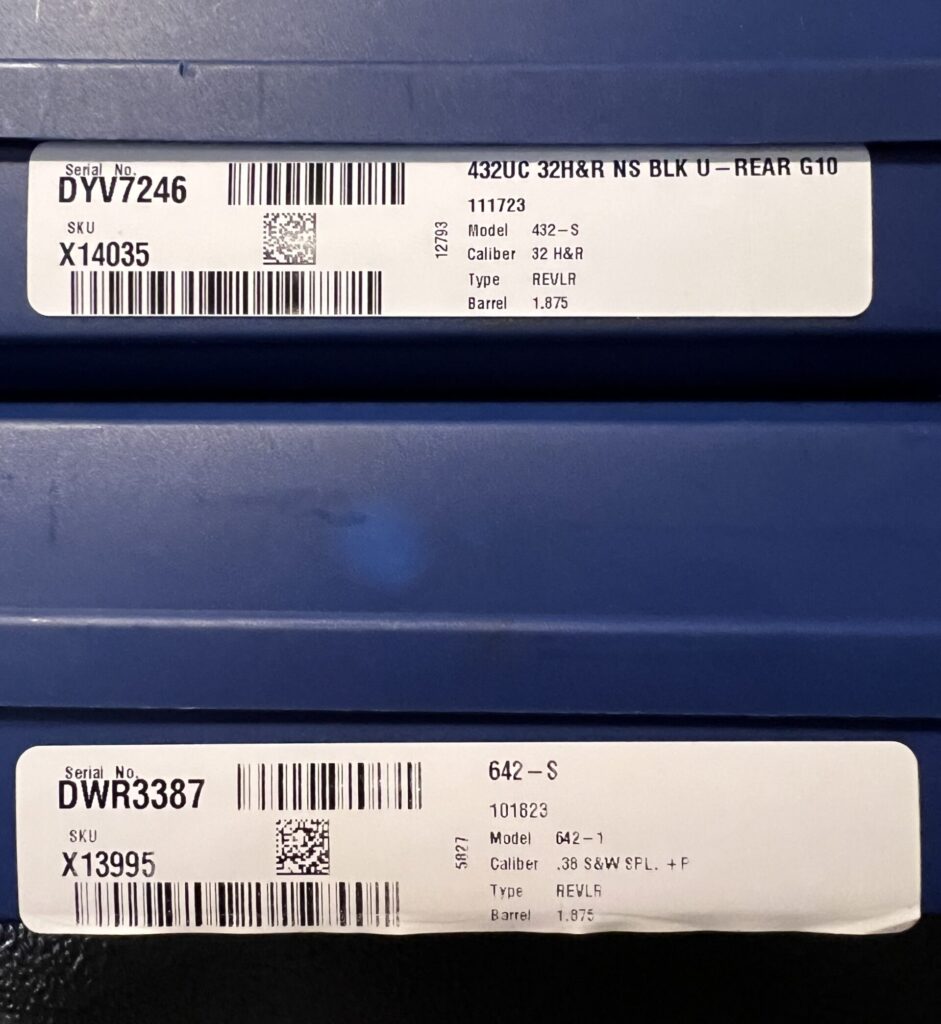

As the Engineering team got busy, experimental SKUs were created in Smith & Wesson’s inventory system for two versions of the “enhanced sight J-Frame,” as it was being informally referred to. On March 13th, 2023, a SKU for an aluminum frame, stainless steel cylinder and barrel, silver-finish Model 642-S (“S” for “Sights”) was created, as well as a SKU for an aluminum frame, carbon steel cylinder, stainless steel barrel, black-finish Model 442-S.

A few days later, on the 17th of March, I received a phone call from Jason, who wanted to hear my thoughts on what the perfect J-Frame would look like. I wasn’t sure if he was ready for a full dose of Mike Wood snub nerdery, so I started with top-level generalities, but it was soon clear that he wanted the details, so he got them in spades. We talked for well over an hour about all the things we liked and disliked about factory and custom J-Frames, and all the little details that could be improved, both inside and outside, to make them ideal.4

I was just one of several folks who received a phone call from Jason during this period. He knows the market and the guns very well, but he’s thorough, and does his research. He knew this project could open doors, and set the stage for other Lipsey’s Exclusives, if it was a success. As a result, he tapped all of his resources, and exhausted every lead, to ensure the gun would be viewed as the ultimate J-Frame by those who knew the type best.

A Turning Point

A week later, on March 24th, Andrew Gore had a meeting with Grant Dubuc, Smith & Wesson’s Product Engineering Manager, and Engineer Andrew Foley, who had been assigned as the Lead Product Engineer for the 642-S/442-S project by Dubuc. At the meeting, Gore, Dubuc, and Foley gathered to look at the first prototype of the gun’s new frame, which wore a 3D-printed model of a dovetailed, fixed rear sight design that looked good and was immediately met with approval.

A new frame design was required to accommodate the two-piece barrel, as Smith & Wesson had not used that barrel design in conjunction with an aluminum J-Frame before, and it was necessary to add a key or tab for the barrel shroud. The Scandium alloy-framed guns had been mated with two-piece barrels before, but not the straight-aluminum ones.

At the meeting, Gore made an inquiry that would dramatically alter the path of the project. Spurred by a comment from Foley about the possibility of an improved trigger pull, Gore asked the engineers if they had a wish list of aluminum J-Frame improvements that had not been incorporated into production yet? Were there any outstanding fixes, upgrades, or enhancements that had been considered, but tabled for a later date?

As a matter of fact, there were. When Smith & Wesson launched the Scandium alloy J-Frames, there were several internal upgrades that were incorporated in the new frame. Smith & Wesson engineers had intended to export those improvements to the aluminum J-Frames, but the timing never seemed right. Smith & Wesson sells more 642s than any other revolver in their catalog, and demand for them has always been pretty consistent, so it was a bit of a hard sell to halt production and reconfigure the assembly line for an upgraded variant of the gun. The company was just about to attempt it when the ChinaVirus hit, and demand for anything that went bang went into hyperdrive. That was certainly no time to make the 642 machinery go dark.

But Andrew Gore’s question to Engineering presented an opportunity, and everyone recognized it. Andrew Foley left the meeting with Gore’s marching orders to, “treat this (642-S/442-S) as the new generation of aluminum J-Frames, and do all the improvements you have always wanted to do.”

Changes

Foley got to work on his expanded mandate to upgrade the aluminum frame Js. He was ably assisted by Senior Engineers Gary Zukowski (now the Product Engineering Manager, having replaced Dubuc in that role after Dubuc was promoted to lead the Product Management Team), Brett Curry (credited with developing the M&P pistol and CSX pistol designs, as well as the new Model 66 and Model 69 Combat Magnums, among others), and Jason Dubois (who most recently designed the M&P FPC carbine), who guided the young engineer through the process and shared their collective wisdom and experience in gun design.

Aside from adding a tab for the two-piece barrel shroud, and a dovetail cut for the rear sight, the new aluminum frame was modified to accept the Titanium hammer, trigger, rebound slide, and cylinder stop studs that had been such an important upgrade in the Scandium alloy guns. As RevolverGuy readers will recall, the aluminum studs that were used in the aluminum J-Frames were robust enough to keep the guns running well for the vast majority of users, but occasionally failed in guns that were subjected to high volumes of fire from their most dedicated and enthusiastic owners. Gore’s mandate provided Smith & Wesson Engineering the opportunity to install the more robust Titanium studs in the S-Series guns, which became known as the guns’ “Endurance Package.”

The new frame also incorporated updated mainspring and rebound slide springs that were engineered to provide a lighter pull weight.

By May 9th, 2023, engineering testing of the first prototype had begun under Foley’s direction. The gun was shot to evaluate its function, performance, durability, safety, and sight regulation.

Also, in May, Jason approached Smith & Wesson about adding a .32 H&R Magnum chambering to the project.5 By this time, it was clear that Lipsey’s and Smith & Wesson had a strong working relationship, and Jason felt comfortable with making the additional request. He didn’t want to make too many demands too early, but it was now clear that he could ask Andrew and Smith & Wesson for the additional SKUs without jeopardizing the project. The idea was well received, and a 632-S and 432-S SKU were created for the new guns in the Smith & Wesson inventory system on May 17th. Lead Product Engineer Andrew Foley would now have more work to do, but everyone was excited about where the project was going.

Get a Grip

As Foley and Smith & Wesson worked on the gun, Jason and Andrew worked with valued partners XS Sights and VZ Grips to coordinate their important contributions to the project.

Zackary Kinsley from XS Sights delivered some of their “Standard Dot” sights, which feature 0.140” wide posts, and Tritium-powered dots that are encircled by a high-visibility, yellowish-colored ring.

VZ Grips delivered their first design, enclosed back, boot grip prototypes on July 12th. However, Jason’s testing indicated the grips could benefit from a more aggressive speedloader cut, to provide proper clearance for the HKS and Safariland speedloaders he tried, so that improvement was requested on September 6th and a new prototype was delivered soon after.

What’s in a Name?

By October of 2023, it was becoming more important to name the new gun, especially if it was going to be ready for a SHOT Show launch in January. By this time, Jason had recruited “industry legends” Darryl Bolke and Bryan Eastridge of American Fighting Revolver to consult on the project, and one of the most pressing jobs was picking the name.6

Those involved with the project had been referring to the guns as the “ultimate” examples of the breed for a long time, and the “ultimate” moniker kept surfacing as the group struggled to find the right name. It was Darryl who suggested that the guns were perfectly suited for the kind of work done by undercover (UC) police officers, like the 70s and 80s-era dope cops he’d worked with in the early part of his career, and the “UC” label lit a spark. The mashup of “ultimate” and “UC” gave way to the “Ultimate Carry” title, which was a nice compliment to the “PC” Performance Center label that was already in use by Smith & Wesson, so the temporary “-S” suffix was replaced by “UC” in the experimental SKU titles.

An Important Hurdle

Andrew Foley’s engineering testing (function, reliability, durability, drop safe, accuracy, etc.) of the 642 UC was complete by October 20th, which gave Andrew Gore the opportunity to travel to Lipsey’s with the sole prototype for a validation test on October 30th.

It wasn’t common for a manufacturer to make this kind of effort in Jason’s experience, but it was important to Andrew to ensure Lipsey’s was happy with the design before proceeding any further. If there were issues with the gun, the validation test would make them apparent, and if Lipsey’s wanted any changes made, this was the right time to identify them.

Darryl and Bryan were already there when Andrew arrived at Lipsey’s on the morning of the 30th with the sole prototype of the 642 UC secured in a Pelican case. The gun was passed around for everyone to see, and a heart-stopping moment followed when Bryan asked for a screwdriver, then proceeded to disassemble and inspect the gun.

It was a bold move. While Jason and Andrew wanted to see inside the gun too, and have a look at Smith & Wesson’s work, a broken or lost part could have scrapped the day’s plans before the range test even began. Fortunately, Bryan was experienced with Smith & Wesson disassembly and skilled with his tools. His inspection showed the Ultimate Carry’s bones were as good as its looks, and the guns were reassembled without drama, which made everyone happy. It was time to get on with the shooting.

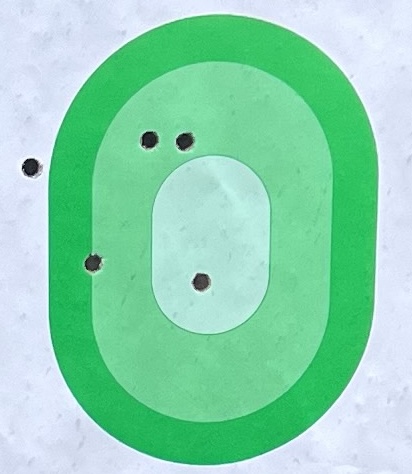

The four shooters went to the range on the cold, rainy day with a pile of ammunition loaded with bullets that weighed between 110 and 158 grains. A big question that everyone had in the back of their minds was whether or not the sights would be regulated to the desired standard, but it was soon answered when all four of the shooters fired an overlapping group at 15 yards with the specified 135 grain Speer Gold Dot.

The team shot the prototype gun for about four hours, and it was determined very early that the gun was capable of delivering high levels of practical accuracy. Everyone shot the guns very well. Darryl shot a nice group, in particular, at about 10 yards in which the rounds were touching, and Bryan shot a group at 25 yards that measured near three inches, which was a very strong performance for a J-Frame.

The gun shot with absolute reliability, but there were a few areas for improvement identified by the team. The first concerned the color of the ring around the XS Sights standard dot, which was a bright shade of yellow-green. The sight was perfectly regulated, but shooting the gun underneath the darker skies of the cloudy and rainy day, on buff-colored targets, showed the team that the color was a little too light. It was felt that a darker shade of green would offer better contrast for the sight picture.

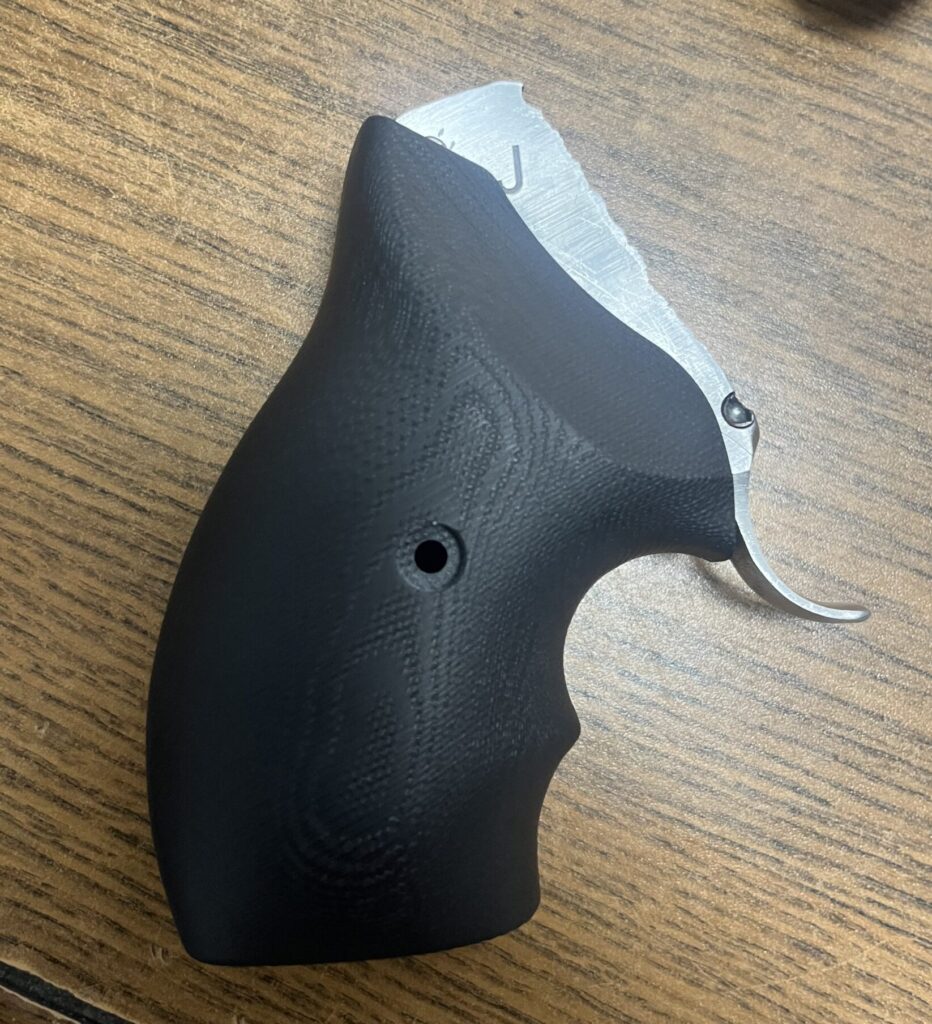

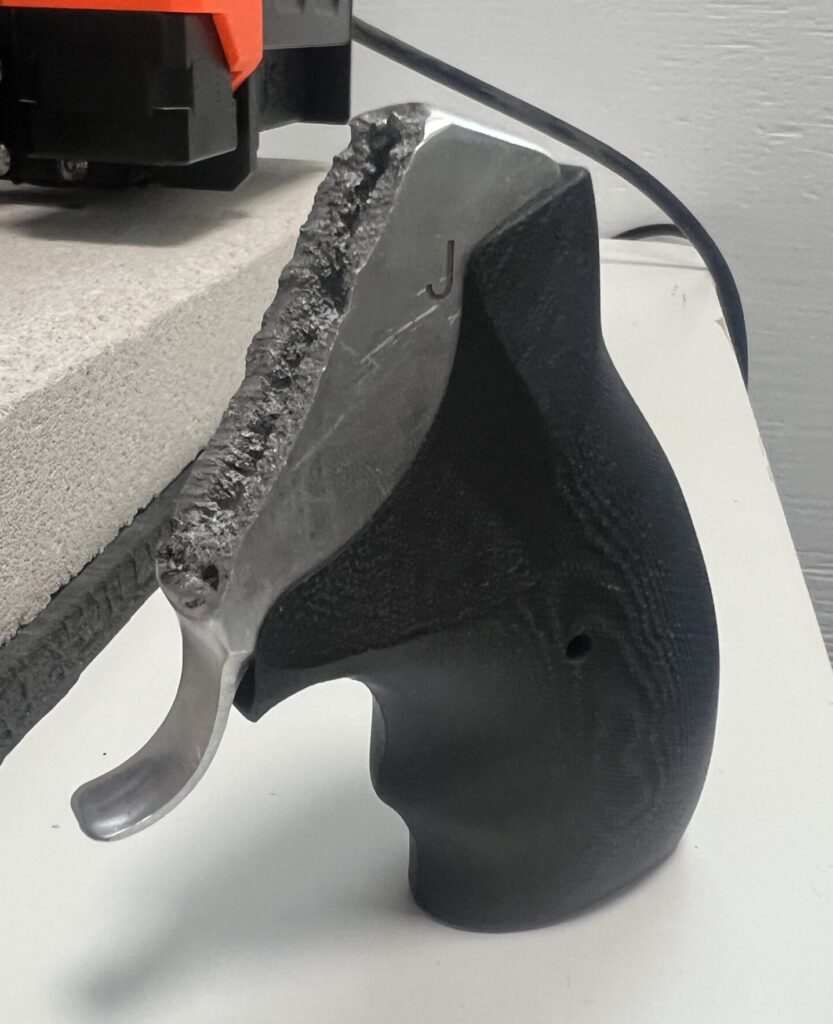

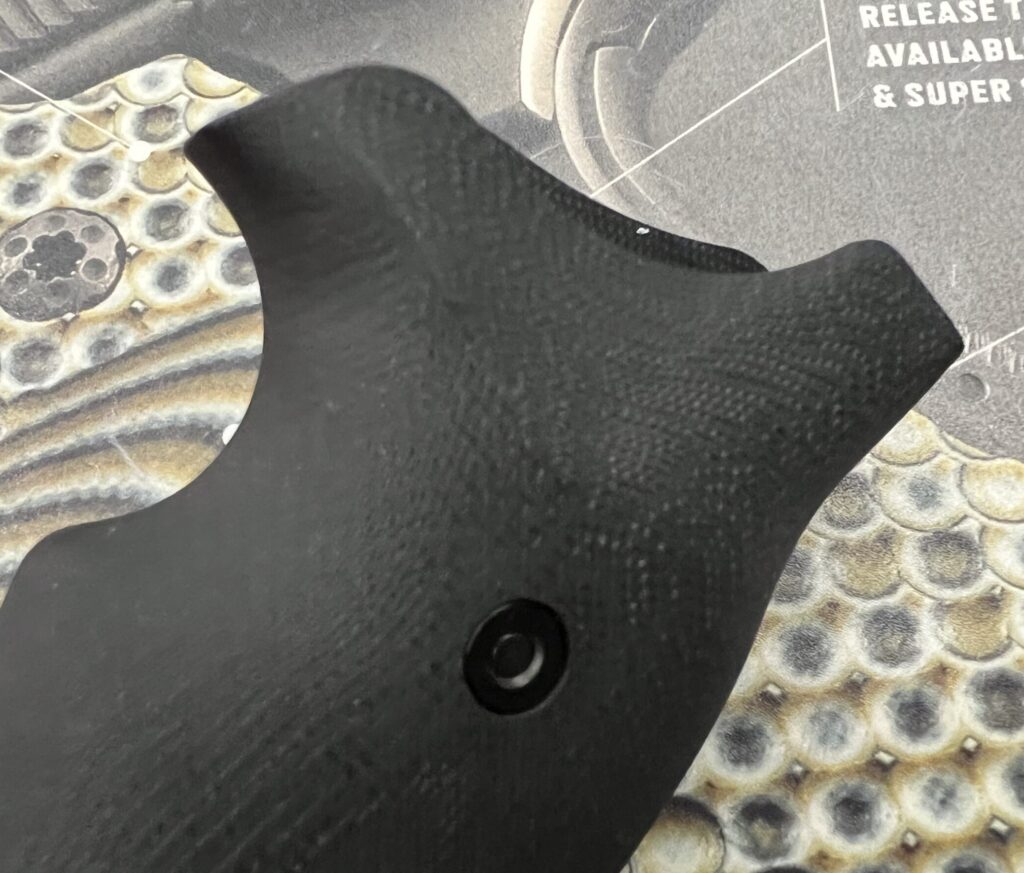

Additionally, while the second design, prototype boot grips from VZ Grips were handsome, and their new speedloader relief was sufficient, they were not comfortable to shoot. The backstrap terminated well below the recoil shoulder and its profile concentrated much of the felt recoil on a small section of the web of the hand. The team agreed that a new profile would be required, which better filled the area below the recoil shoulder, to distribute recoil and make the Ultimate Carry shootable. Drawing on his experience with a variety of J-Frame grips, Darryl suggested that a “high horn” grip, like those that originally equipped the (pre-Model 40) Centennial, would be a good solution for the problem.

The last issue concerned the rear sight, which actually performed flawlessly, but Jason and Andrew were concerned that it didn’t have a set screw, and it could possibly walk in the dovetail over time. To eliminate that possibility, they would ask Engineering to add one.

Teamwork

Although it was disappointing to identify these concerns, the team’s resolve to fix them was strong—so strong, that the team reached out to VZ Grips’ President, John VanZyck, while they were standing right there on the range. In a move that would later symbolize the deep commitment each of the parties had to the success of the project, and highlight the exemplary level of cooperation between all of the contributing vendors, the four men immediately placed a video call with John, explained the problem, and suggested the high horn fix, which John agreed to produce for them.

The turnaround from John and VZ Grips was quick, with John putting a third design version of the grip into the mail just two weeks later, on the 14th on November. 7

Similarly, XS Sights’ Zackary Kinsley and Monte Long responded VERY quickly to the team’s October 30thobservations, and just four days later, on November 3rd, they’d delivered a new front sight with a modified color to the team. The new color was a darker shade of bright green which offered a perfect contrast, even in dimmer light, and the team knew they instantly had what they were looking for.

On the 31st of October, Halloween, Andrew Gore had his own trick for Engineering when he requested the addition of the set screw to the rear sight. Andrew Foley responded with a CAD drawing of the new design the following day.

There was no moss growing on anyone’s feet. Everyone kept the ball moving down the field, knowing that SHOT Show was just around the corner.

Thumbs Up

Jason’s testing of the new design from VZ Grips in mid-to-late November revealed there was still a detail about the third design grips that needed to be fixed.

Those who have shot high horn grips know that the extended horns do a wonderful job of widening the backstrap where it contacts the web of the hand, and distributing the recoil force over a larger area, but the horn on the left panel requires special attention because of the adjacent speedloader relief cut. If the relief cut is not carefully blended with the extended horn, a sharp ridge can develop, which acts like a fulcrum for the side of the shooting thumb. This leads to a great degree of discomfort, especially when the shooter’s grip is tightened on the stocks, in anticipation of firing.8

Unfortunately, Jason encountered this with the third design, high horn prototype, and knew it had to be addressed. With the year disappearing fast, Andrew notified John about the issue on November 27th, and VZ Grips got to work, right away, on a fix.

Test Redux

Two days later, Andrew Gore was back at Lipsey’s to conduct validation testing on the 432 UC prototype, since Andrew Foley’s engineering testing was now complete on that model.

Jason, Andrew, and Smith & Wesson’s Senior National Account Manager, James Holley, shot the gun on November 29th with a variety of ammunition. The new sights were hitting just where they wanted them to with the baseline .32 caliber loads that Darryl and Jason had agreed upon (an 85 grain, .32 H&R Magnum Federal JHP, and a 100 grain, .32 Long wadcutter), and the gun was running great, but Andrew felt that Engineering should increase the amount of chamfering that each chamber received, so a request was submitted to include that in the build.

Andrew got to see the issue with the high horn grip prototype while shooting the 432 UC with Jason, and agreed it had to be addressed. With time running very short, Jason did a little alteration in the field, with the help of the gunsmith’s best friend, the Dremel tool. By taking the ridge on the left horn down a little, and smoothing the transition between the speedloader relief cut and the horn, he finally had the grip profile that he wanted. Andrew took pictures of the ad hoc alteration, and sent them to John at VZ Grips, to clarify what they needed from him.

By December 7th, the change had been incorporated into the design, and the team finally had their Ultimate Carry grip. With this final piece in place, they could now move into making the first lot of pre-production guns.

Not So Fast!

Well, almost. There was one last thing that Andrew Foley needed to pin down (pun intended) before that.

Up front, in the barrel shroud, just forward of the extractor rod relief cut, is a pin that holds the extractor rod tip locking bolt in place on the gun. It’s a tiny pin, whose head is no larger than the cross section of a paper clip, but since the team had gone to such great lengths to make everything as perfect as it could be on the UCs, including the cosmetics, Foley wanted to know what color the team wanted the tiny pin to be.

Earlier in the effort, Bryan Eastridge had suggested using a color contrasting thumb piece on the 642 and 632 models, to add a touch of flair to the special guns. The two-tone theme continued with the gun’s black and gray G10 stocks, its black sights, and its darkened MIM trigger.9 In the same vein, Foley asked if the team wanted a black locking bolt pin to match, or a silver one, instead? It was a very small detail, one that would normally not be on the radar of anyone in Engineering, but Foley was so heavily invested in the project, and so attentive to the smallest details, that he had to ask.

It was another example of the painstaking level of attention that was paid to every element of the guns, to ensure they were truly the Ultimate Carry J-Frames.

Pre-Production

With the SHOT countdown clock ticking fast, the first pre-production lot of guns was shipped to Lipsey’s on the 11th of January, just 10 days before an invitation-only media event for the guns, and 12 days before the opening of the show.

There had been a near miss with the guns, just days before, that was averted by another engineer who was paying close attention to every detail. Engineer Nathan Bruneau, who oversaw the Revolver Barrel Cell, realized a few of the barrel shrouds that were earmarked for the pre-production guns were not the right parts. Instead, these shrouds had a slightly different profile and were intended to be fit to another gun, like the Model 340. Nathan ensured that shrouds of the correct dimension and profile were obtained and provided for installation on the UC frames, saving the team from a potentially costly mistake and a last-minute delay they couldn’t afford.

Everyone was pulling on the same rope to make sure the UCs were perfect, and Smith & Wesson delivered four inert pre-production guns, and four live-fire-capable pre-production guns, in the nick of time.

As it turned out, a weather delay that grounded the FedEx aircraft fleet slowed the delivery of the live guns, and they missed the invitation-only media event on Sunday evening, before SHOT Show, but the four inert guns made it to the Lipsey’s booth and were the stars of the show.

The Ultimate Team

On Wednesday evening of the SHOT Show, I was fortunate enough to be invited to join Jason, Andrew, Darryl, Bryan, and gun writer (and fellow Shootist!) Shane Jahn for dinner, after the close of the day’s show. We had a delightful time talking guns, sharing stories, and celebrating the great success of the Ultimate Carry J-Frames, which kept people flocking to the Lipsey’s booth from open to close, every day.

I remarked to Andrew that night, that it seemed the Ultimate Carry J-Frames were the product of a special moment in the industry, where all the right players were in all the right places, with all the right ideas, at the right time. If any element had been missing, if any of the team members had been absent, or had not been 110% committed to making the project a success, the guns would never have survived the journey from concept to reality.

Call it what you want—the power of a good idea, the alignment of the stars, or the confluence of talent and commitment. Whatever it was, the Ultimate Carry J-Frame was the end result of a special effort by special people, and RevolverGuys are the lucky beneficiaries.

We’ll explore the guns and their performance in greater detail in the next part of this story, but for now, RevolverGuy would simply like to salute the folks who made it all happen for us. Well done, Ladies and Gentlemen!

*****

Endnotes

1.) In full: “This is an unfair thing about war: victory is claimed by all, failure to one alone.” -Tacitus;

2.) Sadly, we’ve seen some of these folks preside over the demise of some of the most legendary brands in the business, such as the Freedom Group takeover of Remington. Fortunately, that chapter is closed: Big Green is back and making fantastic ammunition again with gun guys at the helm, and Remington Arms is busy trying to reestablish itself in Georgia, and resume production of staples like the 870 and 700. There’s still a few industry executives who don’t know a rimfire from a centerfire though;

3.) Of course, I knew he was right, before he even said anything. While the .41 Magnum Model 58 has a cult following that would be overjoyed to see the gun come back into production, there are other classics that would dramatically outsell it, if revived. Can anyone doubt for a second that a no-lock, 3.5” Model 27 or a no-lock Combat Magnum of any length would leave it in the dust? How about a .44 Magnum Mountain Gun, a .45 ACP Model 625, a .44 Special Model 24, or any number of forgotten .38/.357 caliber K-Frames, like the 3” HB Model 13/65? I’ll hold a candle for the mightiest M&P, and will continue to ask Santa for a Model 58, but it’s probably better if we encourage Jason and Lipsey’s to tackle other, more lucrative, projects first;

4.) Jason already had the general framework for his improved J-Frame in place, but wanted to dive into the details with me. We discussed everything from materials, to barrels, to sights, to triggers, to actions, to controls, to grips, to calibers, to internal parts, to ammo, to sight regulation, to speedloaders, and everything else, from stem to stern. We compared likes and dislikes, and it’s probably not surprising that we found ourselves in agreement on most everything, since we’re both serious J-Frame afficionados who have experienced many of the same joys and disappointments with the guns over a lifetime of shooting them.

I might talk more about our conversation and my specific recommendations in a subsequent installment, but for now the most important thing is to clarify that this is the period in which Jason was fleshing out all the finer details of the gun. The basic building blocks (aluminum frame with no lock, two-piece barrel, improved and well-regulated sights, boot grip) were already in place, but this is when he got down to specifics like trigger shapes, trigger pull weights, sight dimensions, sight colors, grip features, sight regulation baselines, and so forth—all the small ingredients that make up the special sauce.

Additionally, it’s important to note that while Lipsey’s and Smith & Wesson were only working on guns chambered for .38 Special +P at this stage, Jason was already thinking about adding a .32 caliber gun to the project. All of my inputs to Jason were delivered through a .38 Special filter, because that’s “my caliber” when it comes to snubs, and I honestly didn’t think beyond it for the project. However, when Jason suggested the .32 H&R Magnum as a possible chambering during our phone call, I wasn’t surprised. I knew Jason was a fan of .32 caliber revolvers, since he’d been a driving force behind Ruger chambering their Single Six for the .327 Federal Magnum, and had done some very successful Lipsey’s Exclusives in that combination. A .32 H&R Magnum J-Frame option made a whole lot of sense to me (for reasons that we’ll discuss later) and I was immediately enthusiastic about the idea. I was also impressed with him for seeing beyond the .38 Special blinders that the rest of us had on;

5.) Jason’s interest in the .32 caliber option was strongly echoed by Darryl Bolke, who lobbied hard for the chambering when Jason first approached him about the project. His vigorous support of the .32 reinforced Jason’s commitment to ask S&W for the additional SKUs;

6.) Just days before the 2024 SHOT Show premiere of the Ultimate Carry J-Frame, Lipsey’s released a video to introduce the gun to the market. In one part of the video, Jason casually referred to Darryl and Bryan as “industry legends,” and the grandiose title immediately generated all kinds of good-natured ribbing from Darryl and Bryan’s friends, who didn’t know they had been in the presence of such “legends” for so many years! In the finest LE/MIL tradition, the more they protested the title, the more jokes it generated, and the more it stuck, illustrating the truth in gun writer Rob Garrett’s dictum, “Don’t bleed in the shark tank.” We only harass the ones we like, you know;

7.) Ironically, I’d been pestering VZ Grips since the 2022 SHOT Show for a set of high horn grips for the Centennial frames, myself. I’d previously seen a photograph of a prototype set that owner John VanZyck had experimented with, but decided not to produce, and I thought it was worth the effort to pursue them. Noted grip maker Craig Spegel had done a lot of Centennial high horns to great acclaim, but it wasn’t clear to John that there was enough of a market for them, to justify the effort. My own experimentation with a set of high horns for my 640, from maker Curtis Harlow, had showed me the benefits of the design, and I was eager to see VZ Grips produce a more affordable version that I could test and write about to promote interest in the style. I was enthusiastic and persistent, but manufacturers are constantly inundated with special requests from customers, and it made sense for VZ to focus their limited resources on other products, which they already knew they had a market for, rather than scratch a single gun writer’s itch.

It’s a different story though, when guys like Jason and Andrew, with the backing of industry giants like Lipsey’s and Smith & Wesson, make the same request! With Jason on the other end of the phone, with his Lipsey’s checkbook in hand, it made all the sense in the world for VZ to commit to making a set of Centennial high horns. I know it must have been disappointing for the group to run into this snag, especially so close to the product launch, but I’m glad that Jason, Andrew, Darryl, Bryan, and John were able to put their heads together and deliver us a superior set of grips for these Ultimate Carry revolvers. We owe all of them a debt, for that;

8.) I’ve been consulting with a grip maker and we encountered this very thing on an early prototype for a Kimber K6s grip. He made the correction very quickly after the problem was identified, and I think RevolverGuys are really going to love the final product, which we’ll share in these pages when it’s ready;

9.) The prototype Model 642 UC which was shot by Jason, Andrew, Darryl and Bryan during the Lipsey’s validation test on October 30th, 2023, was made with a black-finished thumb piece. Bryan liked the appearance of the gun and suggested the two-tone look should be preserved on the silver production models, and the team agreed. This move forced a reevaluation of the grip color, however.

The original thought, at the beginning of the project, was to use the “Predator Green” colored G10 stocks on both the black and silver-finished guns. A sample was delivered for evaluation, and the Lipsey’s team decided it wasn’t the look they wanted for the gun. In response, VZ Grips sent a selection of grips in other colors, and Jason showed them around the office, soliciting opinions. The Black Cherry color won the day, and the plan, at the time of the October 30th validation test, was to use it on both the black and silver guns.

However, the vote to adopt the two-tone look on the silver guns caused the team to rethink the grip color. The samples came back out, and it was quickly decided that the Black Gray G10s were the best choice for the silver guns with black highlights. The black guns would keep the Black Cherry stocks, and the silver ones would wear Black Gray ones.

credits

-

- Featured image courtesy of Lipsey’s

-

- RevolverGuy would like to thank the following individuals for their assistance with this article:

Jason Cloessner, Senior Vice President & Product Development Manager, Lipsey’s

Andrew Gore, Handgun Product Manager, Smith & Wesson

Rob Abruzino, Marketing Director, Lipsey’s

Chris Sasser, Videographer, Lipsey’s

Thank you for an excellent article.

This gun addresses the issues that led me away from a J-frame in 2017, when I bought my K6S. I applaud S&W for working so closely with talented enthusiasts during the design process.

I feel like we’ve entered into an exciting new era at Smith & Wesson, Wheelgunner. We’ve got a team in place that understands the demand for revolvers with the right features, and they have the attention and support of senior management. If we can keep this ball rolling, we’re going to get some great revolvers out of Springfield.

You’ve given me more hope for the fate of S&W’s revolver lineup than I’ve had in a long time! It finally seems like they’re in good hands.

Amen brother!

Great article and informative as always. In sincere humbleness and deference to your knowledge, I respectfully ask if S&W isn’t now in Maryville, TN, or do they still have offices in Springfield? I hesitated to even ask, but absolutely no disrespect intended sir.

None taken, Jim! The HQ and manufacturing of the autos (rifles, pistols) is now in TN, but the forge and revolver operations remain behind in Springfield, so I still refer to Springfield as home base for the revolvers.

Cool!! Thanks for the info!!!😁

Bonus!!!

Wow. This article was a new high mark for depth of research on RG’s page. Nice job.

Tangentially, the revolver world need’s Lipsey’s to keep kicking S&W into gear on the wheelgun side. Colt is doing special runs on their own, and doing it well (the 3” unfluted cylinder Python!). Smith needs help.

More blue K-frames would sell. The prices on full lug, blue .32 H&R Magnum and .38 Special K-frames are staggering, for example. There is no question a run would sell if Lipsey’s can get them to do it.

Likewise, ICORE has new divisions that are ready made for not just the 610, but the 25 and 625. Bring the .45s back in small numbers, Smith!

Great article, Mike. Hopefully the first of many related to Lipsey’s and S&W.

Thank you, Brent! It was fun to be a small part of this project from early on, and watch it develop. It’s even more fun to credit all the folks who worked behind the scenes to make it happen. I’m with you on the recommendations—RevolverGuy readers know my affinity for the 4” blue Combat Magnum, and I think a no-lock version would sell by the truckload, as would just about any no-lock K-Frame. The 625 well has been dry for too long, and needs to be refreshed as well.

I haven’t seen or read an explanation about why they didn’t go with 327 magnum. Does anyone know?

It’s in Part II, Joel! Take a look at it, and let me know if you still have questions.

Part II

Wow, exciting read, especially the end notes! Thank you for providing the inside story, Mike. I’ll continue to hope for three inch barrels, of course, but I might just have to order one today, as it will make a great backup and I’ve located a Lipsey’s distributor nearby. Must say, Bolke and Eastridge were cops; they should know they’re gonna get a drubbing! 😉

Ha! Absolutely! The minute Bryan heard that line come from Jason’s lips, he knew there’d be hell to pay!

Glad to hear you suggest a 3” version of the UC, Riley.

Mike,

I believe you out did yourself- again!

I enjoyed reading the history and development of the Lipsey / S&W Ultimate Carry so much that I forwarded this article to my sons.

The components of your article reflect their backgrounds: engineering , business models, and firearms.

I also like the nod to undercover officers with the “UC” moniker. I’m currently on the waitlist for a .32 six shooter at my local Lipsey’s gun dealer.

Thanks again for providing RevolverGuys with detailed information.

Yes Sir! This was an exciting project from the start, and one of the most important elements is that all the players understood they had to get it right. If this was a winner, it would open many doors, but if it was a loser, all those doors would slam shut. Everyone understood these guns had to be excellent, not just good, to preserve this lifeline and ensure we could do more like them!

Mike,

You have knocked another one out of the park! This detailed analysis of the evolution of the UC line is a fine example of your wonderful talent for assembling inside details, presenting them clearly, and entertaining the heck out of the serious gun nerd demographic. Bravo!

Having been swayed these past couple years by Darryl Bolke’s commentary on the merits of six-shot 32s as a Rule One gun, I’d been looking for a Model 30 or 31 that wasn’t so pretty I’d feel bad about having Fink’s whittle on it for me. Thanks to Lipsey’s and Smith & Wesson that notion has evaporated.

I dry fired a 642 UC at my LGS and agree that every change made to the line is an improvement. I ordered a 432 UC on the spot. Time to scratch that 32 caliber itch…

Michael

Thank you Michael. I’ve got another dose of UC nerdery coming soon, where I’ll dive into more details on the gun and my experience in shooting it.

I’ve been informed that about 70% of the inquiries received have been about the .32 caliber guns, so they obviously struck a nerve. I think you’ve got plenty of friends out there with the same interest, and I think the .32s are going to find a comfortable place back in the S&W catalog again.

Does anyone know how many 632 UC were made ? And if a second batch may be possible for all who missed the first one…..thank you.

Adrian, the UC revolvers are not going to be a limited edition. Lipsey’s placed their first order before SHOT Show, and had already placed a second before the end of the show. I think they might be on their third, already.

The plan is to continue making them until the demand disappears, which won’t be anytime soon. You don’t have to worry about missing out on the first batch—there will be a gun available for you to purchase, sooner or later.

Great background piece, Mike – thanks for doing the reporting on this. Do you know if these will be California-legal? (It seems like most Lipsey’s exclusives are not, except the single-action revolvers, of course.) These look great- it’s too bad that these don’t just become the standard versions of the J-frames.

Tyson, I didn’t mention that detail in this segment, because I planned to discuss it in the next, but I won’t leave you or others on the hook. YES, the guns have already been submitted for Kalifornia DOJ approval! Both Lipsey’s and Smith & Wesson are committed to selling these in my state. I was prepared to chain myself to Jason’s desk and host a sit-in protest, but it wasn’t necessary (it’s a nice desk, by the way).

Fantastic news! Thanks, Mike!

An outstanding thesis on what went into this great snub! Thanks for all your hard work and effort to get the story correct.

Thanks Rob. It’s a history worth preserving. I sure enjoyed getting to meet you in person and felt like we’d been friends already for a long time. Revolver people are the best in the industry.

This article shed light on a few things I didn’t know…..who knew screws and a thumb piece would cause a second and third order effect! Great Job Mike proud to call you a friend and great article.

“Legend”

Thanks Bryan, I appreciate that very much and I’m humbled.

I also appreciate all your contributions to making this thing happen. It took a team to pull this off, and you were a valuable, and legendary, member of it. ; ^ )

We got a great set of guns out of this project, but my greatest reward was the friendships I made and strengthened by participating in it. It’s been a pleasure getting to know you guys better, and I look forward to the next project!

Herr Oberst – you bring out details in the development of a product that I believe very few individuals even think about, much less comprehend, when they see the end product in the display case. Even us humble, lowly armorers tend to take for granted the amount of research and development, experimentation, trials (and even failures) that goes into the making of successful small arms.

I could envision being the proverbial fly on the wall, watching intently at the product evolution by all parties involved. I want a blued one with Zombie green grips, and a stainless one with hot pink grips for those trips into light-in-the-loafers Atlanta.

Haha! You’d turn heads with both of those!

The guys and gals who do the work on these guns behind the scenes never get the credit they deserve. We’re proud to highlight their accomplishments here!

The speed at which things happened here is pretty amazing. This is a brand new frame design, and those things usually take much more time. Everyone worked hard to make this happen fast—it’s really an impressive accomplishment.

Just when I thought S&W was beyond redemption, you’ve demonstrated that the company is open to product improvement, at least on a small scale. As far as I can tell, none of these Lipsey’s snubs has the unpopular internal lock. Kudos also for the underlug barrel design, and tough combat rear sights and super bright front sights.

Might there soon be a Lipsey’s J-frame chambered in .22 Magnum, with a three-inch barrel?

No locks, Spencer! That was a non-negotiable assumption from the start. More about that in Part II, forthcoming!

“No lock” is always music to my ears. I can only hope that S&W takes the hint and management can be convinced to get with the times!

The deletion of the lock was a HUGE part of the success of this gun. I don’t think it went unnoticed by senior management!

For anyone who eventually owns one of these outstanding UC revolvers – print out this article and store it in the S&W box. You can thank me in 20 years for the suggestion.

And you can thank Mike for the revolver (along with all the others mentioned).

Haha! That’s GREAT Steve! What a super idea!

What a great read, the collaboration and innovation from all parties is amazing to read about, I echo hopes that this is just the beginning.

I remember hearing Mark “Coch” Cochiolo, a former Navy DEVGRU, mention in a video he was working with Lipsey’s on a S&W revolver project, I wonder if it was this project or a different one.

No seals or other marine life were harmed in the making of this gun.😁

There was a military test phase I didn’t talk about in the article, involving all the services.

The Air Force representatives showed late, then didn’t come back after lunch, because they were all getting drunk in the bar and telling lies about their flying abilities. They later told S&W that the gun needed a cool paint job and a better callsign.

The Navy representatives from DEVGRU never got to shoot the gun, because their Hollywood agents called and said they were needed back on set to finish filming the latest movie about killing Osama. An argument ensued when all of them claimed to be the guy who did it.

The Army representatives worked hard all day long, but were unable to shoot the guns because the Marines switched the labels on the test ammo. The .32s kept falling out, and the .38s didn’t fit. One soldier actually did manage to get a .38 round into the .32 gun with an entrenching tool. It had to be sent to the Warranty Department for repair.

By lunchtime, the Marines had broken one gun, lost two of them, and were trying to eat another. They were sent home early.

The Coast Guard later complained about not being invited.

😆

What about Space Force?

Who? 😆

That was awesome! I just had to send that to my Army son (10th Mtn) who served 8+

years and to my Navy son (Submariner) who’s on active duty and currently teaching nuclear engineering at Annapolis. You should be at our Thanksgiving table to see and hear these two type A guys dog each other!

Hahaha! I’m sure it gets lively around the table with those two!

Folks who don’t have a background in the military or law enforcement may misunderstand our good-natured ribbing, but trust us . . . it’s a sign of respect and love to dog your brothers in the other services for their exceptionally poor choice at the recruiting station. 😁

It really is breathtaking to discover just how many people had to be in the right place at the right time to make all of this happen, and how much effort went into these new J-frames overall. Ultimate Carry is a fitting moniker, and I can only hope that these become the de-facto blueprint for subsequent installments into a whole “Ultimate Carry” series of S&Ws. The speed at which these were developed is commendable, but it just goes to show how much of a hit you can have on your hands when you have actual enthusiasts that know their products well at the helm. (Jason and Andrew have my unending thanks, among the others involved!) I can’t wait for my local shop to get a few in stock – I’ll have to snag a 632 forthwith.

I can only hope that the Lipsey’s and S&W crew have a no-lock K-frame Ultimate Carry on the drawing board next. Can you imagine a no-lock, 3″, 7-shot, 327 Magnum K-frame fashioned after the Model 65? Bonus points if they revert the shape of the frame away from the bloated Modern K-frames and recontour the backstrap to match the vintage, pre-lock frames. I’d have to break out my wallet and buy one for every day of the week if that were to come to fruition!

Thanks for the excellent article, as well as the invaluable input provided for this project. I look forward to seeing the follow up articles soon!

Zach, the Lipsey’s – Smith & Wesson team is already hard at work planning new designs. They have some wonderful ideas for follow-on projects and I think the RevolverGuy audience is going to love what’s coming!

And there won’t be a single lock on any of them!

Mike, thank you for a very interesting look at what it takes to move mountains. I think I vaguely recall a time in our countries retail history when companies actually listened to consumers. You and other Folks may have jogged S&Ws corporate memory. Time will tell.

I have been a fan since I first found J frames. One thing that always amazed me was chambering very light weight revolvers in .357 magnum. Don’t know how many shooters practice enough with those light Js with 357s to get proficient enough.

Chris Baker’s article from Feb. of 2019, “Why the Best Snub Nose Caliber is .32” is a reccomended read as these new revolvers hit the market.

My favorite snub is a model 631 that I bought when they first came out. I bought it for the extra round. Didn’t know they would become collectible so cut the hammer spur and carried it many miles until the hammer stud broke. It is in the hospital out in West Texas, hoping for its recovery soon.

The benefit these days ,my hands have turned up old overnight and the .32 family with the exception of the .327 in Js really work well for me.

Miss my .44 Specials but love my .32 magnums.

Looking forward to part 2.

Tony, you just perfectly described one of the biggest reasons for the .32 snub! It’s the right tool for the right job, for so many reasons.

It’s been wonderful to see how S&W responded to Lipsey’s input, and I hope we will keep this collaborative effort going for many years to come. There’s definitely a backlog of guns that need to be made, to meet our needs and desires.

Snub that will shoot 32 Mag with no lock, comfortable grip, nice trigger, and upgraded sights, other than the sights, sounds a lot like my Ruger LCR in 327 Federal Magnum.

Absolutely, Darrell, that’s why the .327 LCR has sold so well! The sights on the UC are night and day, compared to the LCR though.

Only thing that has prevented me.from buying one…..

Thanks for providing the low down on this project, Mike. It’s been a long minute since revolver enthusiasts had anything to get excited about coming from S&W. The UC’s are worthy of some major excitement! Thanks to Jason at Lipsey’s for his vision. Thanks to Andrew at S&W for getting on board and committing his team to the effort. It’s gratifying to see guys like them in the positions they hold. Many in their place would have “phoned it in” with a few superficial changes and some marketing hype. These guys did it right and the end result is a truly practical carry revolver. Props to them also for listening to guys like you and DB and Bryan and acting on that input. Big props for bringing back the .32 H&R Magnum chambering, too- icing on the cake! Huzzah!!!

It was truly a case of the right people, in the right places, at the right time, Kevin.

We’ve all told Andrew that he’s not allowed to leave the job, and if he ever gets dissatisfied, we’ll pass the plate around to raise enough money to bribe him to stay anyhow!

Great write-up, Mike! I loved learning about the whole process and the refinements that the UC went through prior to coming to market. Darryl mentioned last Fall that there was something “very cool” in the works, but that he couldn’t talk about it yet. Now I understand why. I can’t wait to get my hands on a UC, and I don’t think there has been a recent revolver release that I’m more excited about.

This project has energized the snub market like none that I can recall. The launch of the Kimber K6s was pretty rattling for the industry, but the relief that RevolverGuys feel, after decades of frustration with S&W, really makes the UC eclipse the Kimber effort. We’ve known they were capable of doing better, but they just didn’t. Well, now they are, and it’s invigorating and exciting. We’re all looking forward to more good things to come!

Agreed – strong sales of the UC will cause S&W to sit up and take notice about what revolver guys are really looking for (or at least I hope so). I’m also hoping this ushers in a newfound appreciation for .32 H&R and that we see an increasing number of offerings in this caliber. It’s pretty darn ideal for a snubbie, imo.

Make it a seven-shooter with a 2″ barrel option and I’ll buy one.

That seems physically impossible in a J-frame chambered for a centerfire roud, or it would have already been done. However, I have a 351C that is a 7-shot, but I think that’s as close as you’re going to get, without stepping up to a K-frame (at a minimum).

Indeed. You can’t fit 7 rounds of .32 in a J-Frame cylinder. You’d need a K for that.

ViejoLobo,

I think the closest you’ll find is the Charter Arms Professional in .32 H&R Magnum, three inch barrel and seven shot cylinder. Not my preferred brand, but hey.

At the risk of sounding like Kids at Christmas that finish opening presents and start making wishes for next year can we list few?

A K frame with a 3 inch barrel, a blue one and a stainless.

Add the special features of the UC, same sights, well maybe a gold bead front, enclosed ejector rod, cylinder mods and action mods, smooth face radiused trigger , NO internal lock and a carry melt.

Make it in .327 magnum.

With folks like you in the loop I might still be around to buy one.

“Make it a seven-shooter with a 2″ barrel option and I’ll buy one.”

Sorry, guys. This is where my comment belonged, and it somehow got reshuffled.

Owning two.32 I/Js, I can confirm that you can’t do a seven round .32 J.

Great article Mike!! I am really excited to get my hands on one of those new UCs. In my quest for the perfect J frame, I spent the extra money and bought an M&P 340. The XS sight was my main motivator. When I took it home, I discovered the little blast shield above the forcing cone was loose and would push from one side to the other far enough to catch my holster and gouge it. I took it back to my local shop, they sent it back to Smith, and about 5 months later, I got it back, repaired. I never intended to use 357 ammo in it, but the loose blast shield was not going to work for me. Currently it wears Hogue Bantam boot grips. Will VZ offer those Horn grips as a regular catalog item?

Mark, I’m sorry to hear about your QC issue with the M&P 340. Honestly, that’s the one thing that could kill these new UCs, and I’m anxious about it. My sincerest hope is these guns will be built to the level of quality they deserve. The design is excellent, and I hope the manufacture and assembly will be also. I know Andrew and his team are working overtime to ensure it, as they are heavily invested in the success of these guns.

Re: the grips, I’m addressing that in the next part, but the current plan is to send all production to the assembly line, so the guns can be made and shipped. However, once they develop some excess manufacturing capacity, VZ will be shipping extra grips to Lipsey’s, who will sell them to the public as Lipsey’s Exclusives. I’m not sure if the sales will be conducted through their dealer network, or if you’ll be able to buy direct from Lipsey’s—standby for more.

Well written article, very informative on more than one level and great detail.

I look at these as being a logical J-frame evolution of S&W’s earlier “Night Guard” series, a series of revolvers which were a few years ahead of their time and discontinued too soon.

A revival of the Night Guard series, to include these J-frames would be a great idea for S&W, due to a strong resurgence in the interest of defensive revolvers, over the past 3 years.

Indeed they would, Tom!

Yes, and it would be REALLY nice if these UC models were regular catalogue items–so you could just walk into a gun store and buy one, rather than having to special order and get on a waiting list. Do you think there is a chance of that?

No Sir, these guns were developed under contract for Lipsey’s and they will have exclusive rights to distribute them. I’m sure some of the improvements in the UC J-Frames (like the frames, themselves) will migrate to other standard J-Frames in the S&W catalog, but the UC models will remain Lipsey’s Exclusives for the foreseeable future.

Since Lipsey’s serves over 30,000 FFLs, and distributes more guns than anyone else, it shouldn’t be too hard to find a dealer that can order one for you.

Small, dedicated teams will keep a project focused better than bigger ones can — that was one of Clarence “Kelly” Johnson’s rules when he ran Lockheed’s original Skunk Works.

There’s much to like about these UC J-frames, although the lack of a .327 Fed Mag chambering makes it less appealing to me. For now, three Rugers (LCR, GP100 4″, & Single Seven 7.5″) and a Henry steel carbine will happily send my .327 downrange!

Meanwhile, I’ll watch with interest for new developments in that caliber.

Thanks Ricky. If you’re a dyed-in-the-wool .327 Fed Mag guy, this definitely isn’t your gun.

The .32 H&R chambering in these UCs hits the sweet spot, allowing sufficient performance with manageable recoil. The idea was to create an option for folks who were more sensitive to recoil, as the gun can be shot with everything from low-powered .32 Longs, to medium-powered .32 H&R (and even with some high-powered .32 H&R boutique loads that knock on the Fed Mag’s door, for those who feel the need for speed). We’ll talk about the rationale some more in the upcoming Part II of this series.

If you actually shoot a lot of .327 FM in that LCR of yours, you’re a better man than me! My maiden voyage with the .327 FM was shooting Gold Dot (100 grains, 1500 fps) in an LCR, and I decided that wasn’t something I wanted to do a bunch of. It was a lot like shooting .357 Mag in a 640. I could do it, but I didn’t think it struck a good balance between performance and control. The recoil penalty exceeds any ballistic advantage, I think. Kevin’s experience was similar, as he described in these pages.

I find the vast majority of people who own LCR327s shoot something other than .327 FM ammo in them. If yours is fed a steady diet of the Fed Mag, then you’re the hearty exception to the rule. Kudos to you for sticking it out! I think most folks will be very happy with the .32 H&R though.

Thanks, Mike! My first few shots of .327 Mag in the LCR were very memorable, as much for the dropped jaws of startled onlookers as the thumpin’ my hands took! Afterwards, I drove up to the Hogue Pro Shop for a swap to the slightly longer LCRx grip — they make a noticeable improvement to overall shootability. I find the biggest downside to the .327 Mag is its extremely loud report. Practicing at an outdoor range is much preferred, but even so other folks might want to drop a Cone of Silence over me…

A 3″ SP101 will soon join my .327 Mag family…Life Is Good!

Your articles on .32, among others, have helped persuade me as to the appeal of .32. I have a Taurus 327 snub on the way that I look forward to trying, and I hope to add a S&W 632 or 432 at some point if possible.

I would very much like to see more .32 options from S&W going forward. Whether it’s a target revolver in .32 S&W Long, or a K or L-Frame with 7 shots of .327 Federal Magnum, I just want more .32 revolvers. I love .38 Special, but I can’t deny that it can be a handful at times in a lightweight snub. And I’ve never been a big .357 Magnum shooter, so I’m open to a cartridge like .327 Federal that offers similar power with extra capacity and less recoil in the same package.

I’m planning on getting a .32 for my mother as well. I plan to load it with .32 S&W Long wadcutters or .32 H&R, depending on what she handles better. In her current state, I don’t think .38 Special is a good fit for her anymore.

Axel, your mother is a perfect example of who the 632 UC and 432 UC were designed for. More on this in Part II, coming soon.

Model 12 with 3” heavy barrel, standard width grip frame, XS sights, bobbed hammer, PGS grips & action job. Easy!

Bring back 3 inch k frames generally would be awesome. A model 12 reprise would be most welcome, especially with a 3” barrel and the UC sight set up. A variant in .32 h&r would be an excellent option too

How does the Smith and Wesson UC in 38 special compare to the Kimber 6xs?

Darrell, we’ve got some more articles coming that will cover the UCs in detail, including my impressions after shooting over 500 rounds through them. Stay tuned.

For now, I’ll say the biggest difference is whether or not six shots of .38 Special are important to you. If so, the K6xs has the advantage. Otherwise, the UC is more compact and has better sights going in its favor.

They’re both good guns and it really comes down to personal preference, in the end.

Mike

Another great article. I’ve been excited about the Lipseys UC models since word first leaked on the project. Sadly they are unobtanium around here. I’m in the market for both the .32 and .38 versions.

Maybe Lipseys will do a version cut for TK Custom moon clips? Moon clips help with unloading using that short ejector rod.

It would be great to see some K-32s from Lipseys and a reprise of the Model 12 too!

-john

Thanks John! I know the guns are shipping, but the demand has certainly exceeded the supply. The good news is these will not be a limited run—they’ll continue to be made as long as they continue to sell. Your shop will eventually be able to get some for you.

I kinda doubt you’ll see a UC cut for the clips anytime soon, but Eli at TK Custom will be happy to machine your cylinder if you want it done. Just drop him a note, and he can set it up.

I can’t wait to see what’s next, but I sincerely hope it’s a Model 12 UC.

Thank you, thank you, thank you Mike!

Another fantastical incredible informational and entertaining article for us revolver guys to consume. Thank you.

Glad it was helpful and enjoyable, Glenn!

I can’t afford one of those guns but I would love to get two sets of those grips!

Hang in there, Taylor. I think you’ll see them sold individually before too long.

How about a version in 22 Long Rifle for training and as a great little field / rabbit gun. This would make the perfect little pocket pistol for the above, and do not forget snakes.