I don’t know if there’s a dictionary entry for “Special Projects Editor,” but if there is, it needs to show a photo of Roy Huntington with one of those, ear-to-ear, “kid in a candy store” grins.

Actually, strike that. It needs to show Roy with one of those, kid trapped in a candy store overnight, with a free pass from the owner to ‘help yourself to as much as you want’ kind of grins.

Yep, that’s more like it.

EDITOR ROY

I doubt there’s a single RevolverGuy in the audience who hasn’t heard of Roy, or read at least a dozen of his entries in American Handgunner (or one of FMG’s other, excellent publications—Guns Magazine, American Cop, and Shooting Industry) over the years, but a short introduction seems appropriate, anyhow.

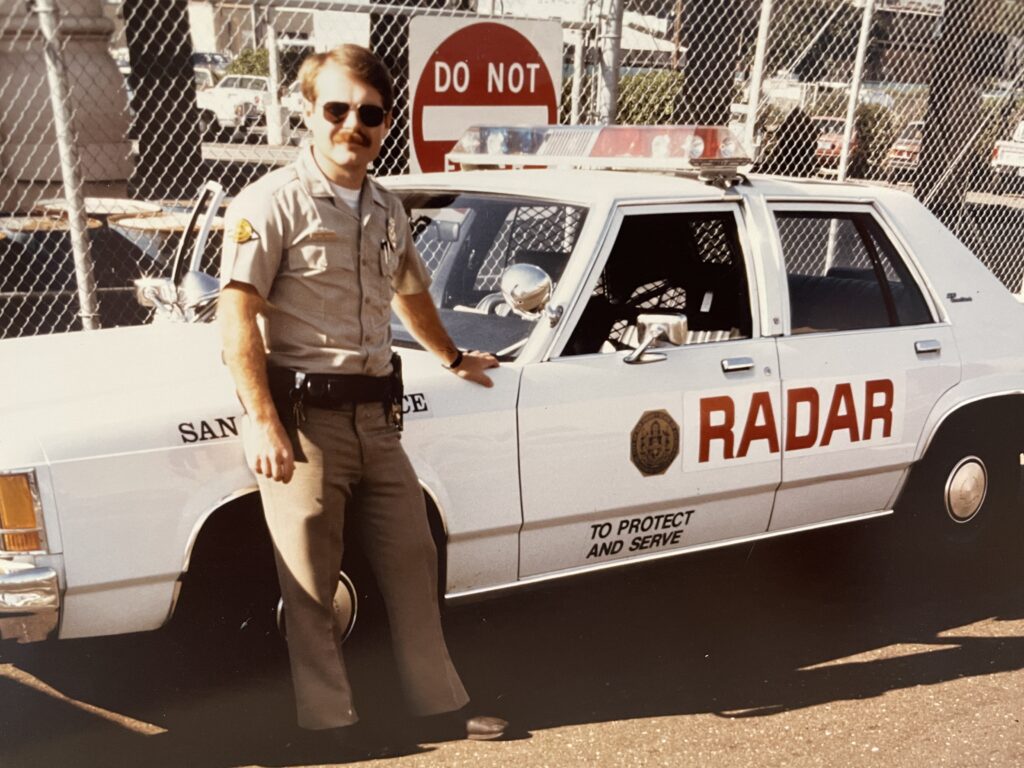

After a short stint as a Reserve Officer in nearby Chula Vista, California, Roy spent a career on the San Diego Police Department during some of the busiest decades in modern law enforcement. As a certifiable Gun Guy, it’s no surprise that he spent some of his career serving in the department’s training division, where he was responsible for conducting firearms training for his fellow officers.

Along the way, Roy began writing for my all-time favorite of the gunzines, American Handgunner, whose publisher was based in San Diego. I remember seeing Roy’s byline appear in the late-80s, or so, and it wasn’t long before he was writing all kinds of feature articles and running the monthly gun leather column (which I had a special affinity for).

Upon his retirement from the police department, Roy worked as the LE Sales Director at Bianchi for a bit, and served as Editor of POLICE Magazine for a while. In late 2000, he took on the role of Editor at American Handgunner, and wrangled gunwriters for many productive and entertaining years.

A move from California to America brought some exciting changes for Roy and his wife Suzi, and a gradual transition away from Editor to Special Projects Editor. I have no doubt that Roy thoroughly enjoyed being the Editor of American Handgunner, but I’ve got a hunch this Special Editor gig has been the best job he’s ever had. I don’t even think that kid with the free candy pass is having as much fun as Roy is in his current position, where he’s basically free to work on the things that interest him, and pass on the rest.

BEING A GUNCRANK

Over the years, Roy got to work with the “Who’s Who” of the firearms industry, and has good friends in every corner. There’s hardly a door out there that his “key to the city” doesn’t fit, and we’ve all been able to benefit from his access, as he shared what he learned with us.

One of the things I’ve enjoyed most about his writing is his attention to what goes on, “under the hood.” Like many of us, Roy’s early interest in firearms made him increasingly curious about how they worked, and that curiosity eventually led to him breaking out the screwdrivers to see what made them tick.

Figuring that out made him curious about how they could be improved, and it wasn’t long before those screwdrivers were augmented with other tools—punches, files, cutting tools, polishing compounds . . . even the professional gunsmith’s nemesis (or job security aid?), the dreaded Dremel!

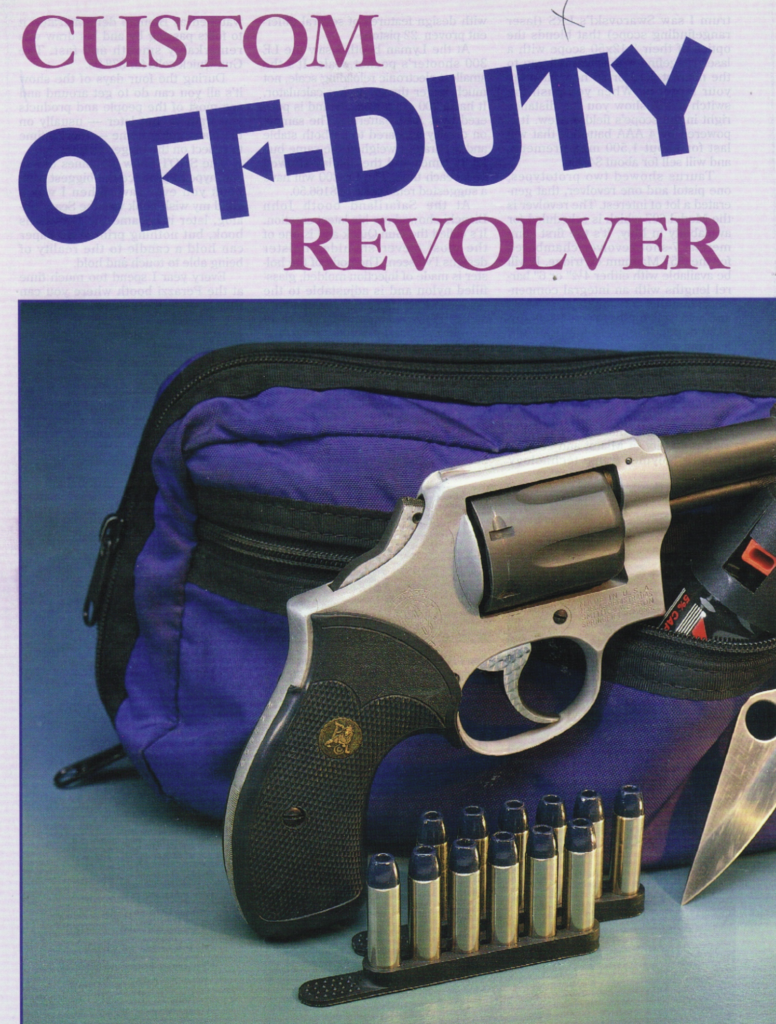

In fact, one of the earliest articles I remember from Roy was a piece about a Hong Kong surplus Model 12 that he customized for off duty carry. I remember being rather shocked when he told of how he lopped off some of the barrel on the workbench in his garage. A much younger version of me thought such activities were the exclusive domain of “real gunsmiths,” and I was intrigued how an “average guy” could get away with such alchemy.

He got to be pretty good at all of it, and always had a steady stream of his own projects, and a pile of his buddy’s guns (“Hey Roy, could you help me with this gun . . . “) to work on, when he wasn’t cleaning up San Diego or herding cats at Handgunner.

Roy is quite modest about his gunsmithy skills, and is quick to paint himself as more of a hobbyist, tinkerer, or shade tree mechanic, but all those decades of self-study and practice have taught him more than a thing or two. He’s also been fortunate to learn from some of the best in the business, along the way. There’s nothing like studying under guys like Bill Laughridge to help you learn the business.

THE INSIDER

Roy has been eager to share the things he’s learned on his journey behind the shop apron. Whether you’re interested in learning how to fix a buggered screw head, clean up some damaged checkering, put an Old West patina on your new sixgun, chamfer a muzzle, or add an insert to your front sight, he’s done the tutorials. He’s also showed us how to recover from the occasional oops, and has kept us entertained with some wonderful storytelling about the brains behind a particular gunsmithy.

For those of us who are still a little intimidated by the thought of doing our own fixin’, but are eager to learn more about how our guns work, Roy has also done some neat articles on things like 1911 rear springs, revolver timing, and such. He even cut some revolver cylinders in half, just to see how much steel was left in the areas where the cylinder stop notches were cut.

All for science, you know.

Podcast fans, haven’t been ignored, either. When Roy teams up with fellow Guncranks Brent Wheat and Tom McHale, you know there’s gonna be some laughter (especially when the Christmas spirits flow), but also some educational gems. Wanna learn how to refinish your gun stock or the gun itself? How about just picking up on some tricks of the trade? He’s got you covered.

PASSING THE TORCH

A few years back, Roy took an interest in helping to “grow” the next generation of gunsmiths, and began working with a promising young man by the name of Dustin Housel. Roy introduced “Dusty” to a bunch of the greats and created opportunities for him to learn from them. He also brought Dusty into his own shop, where he taught him many of the tricks and skills that he’d accumulated over a lifetime of “tinkering.”

Before long, Dusty was taking his first steps as a professional gunsmith, with Roy “helping out here and there” in the shop. The demands of Dusty’s military career have prevented him from gunsmithing on a full-time basis, lately, but Roy and Dusty have continued to work together and I have no doubt we’ll be hearing more about Dusty’s work in these pages, when his schedule allows.

THE ACCIDENTAL GUNSMITH

In the meantime, Roy has perfected the art of walking the tightrope between vocation and avocation.

To hear him talk, he’s just been tinkering around his shop, playing with projects that entertain him, and lending an occasional hand in Dusty’s shop, to keep things moving, but I think he’s treading dangerously close to becoming one of those “real gunsmiths” I talked about.

Shhhh….don’t tell him I said that.

There’s a lot of whimsy in Roy’s gunsmithing tinkering. He once sent me some photos of a single-shot Rossi .410 shotgun action that eventually morphed into a single-shot rifle. The process involved cutting the locking lug off the .410 barrel and TIG welding it onto a British .303 barrel that he turned down to the proper dimensions. The barrel chamber was recut for .32 H&R Magnum, an ejector was manufactured and fitted, a front sight was manufactured and dovetailed, and a Skinner peep sight was added to the receiver. Of course, the whole thing had to be refinished, too. Why go to all the work? Because he thought it would make a fun gun!

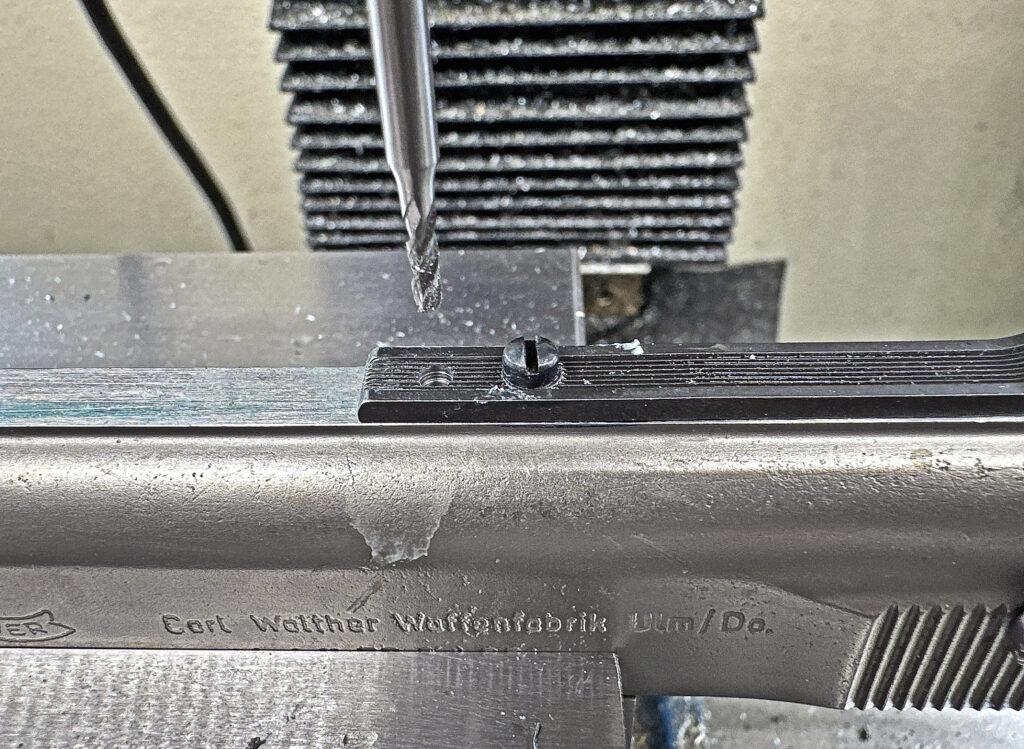

Another mail showed the installation of a Smith & Wesson J-Frame adjustable rear sight on a Walther PP in .22 LR. Roy said they were both laying around on his desk, and the idea just came to him. Of course, he had to manufacture a replacement front sight, and dovetail it into the slide, too. Now he has the adjustable sights that he always wanted on his Walther.

One “simple” project really caught my eye–Roy cut, welded, and reshaped an 1851 Navy hammer, to lower the spur for easier cocking. The end result shot as good as it looked. Roy said, “you wouldn’t believe the difference it made in handling–it felt like an entirely different gun!“

He’s worked on some more traditional projects, too. Installing a Fermin Garza front sight on a Ruger Bearcat, adding a lanyard loop stud to a Ruger Wrangler frame, doing some S&W revolver action jobs for the custom “choppers” that Dusty has been building, and replacing a S&W Model 29 ramp front sight with a pinned replacement—the kind of stuff you’d see “real gunsmiths” doing to keep the lights on.

ROY’S WRANGLERS

It’s Roy’s work on the popular Ruger Wranglers that’s turning a lot of heads, though.

Roy credits acclaimed ‘smith Hamilton Bowen for the idea. Mr. Bowen had showed him a custom, ultra-lightweight Wrangler that he managed to get down to 16 ounces by turning the barrel, adding some Titanium parts, and so forth. He hard-chromed it, and Roy said it looked “smashing,” as we’d expect from the master artisan.

That got Roy thinking . . . and tinkering.

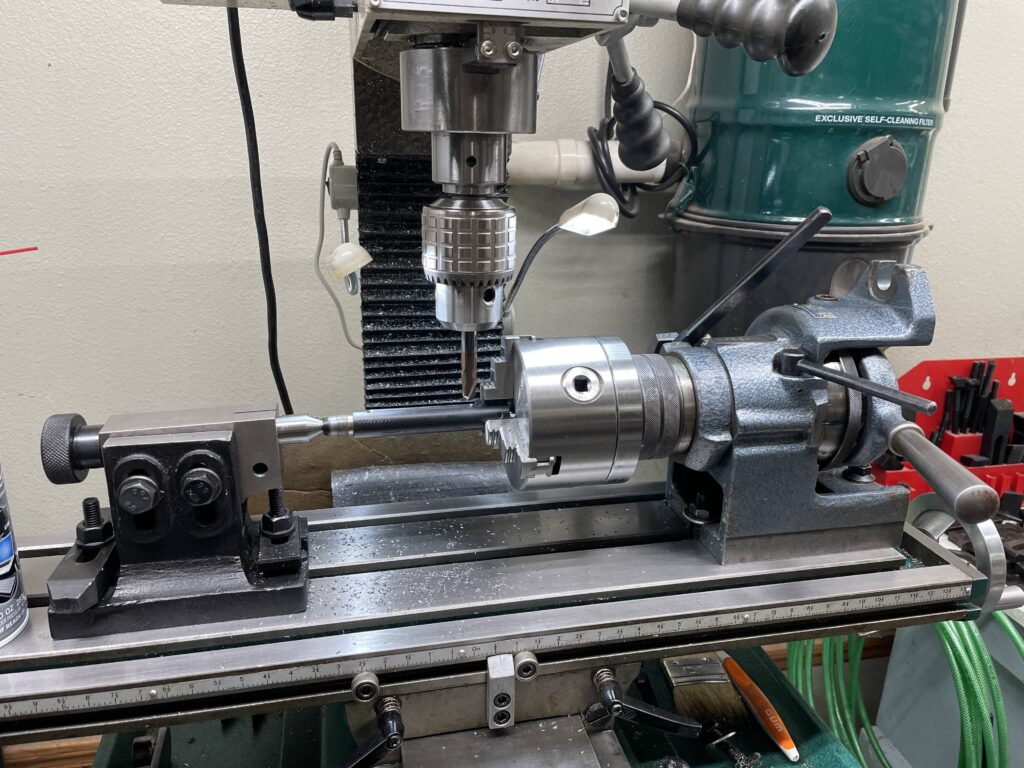

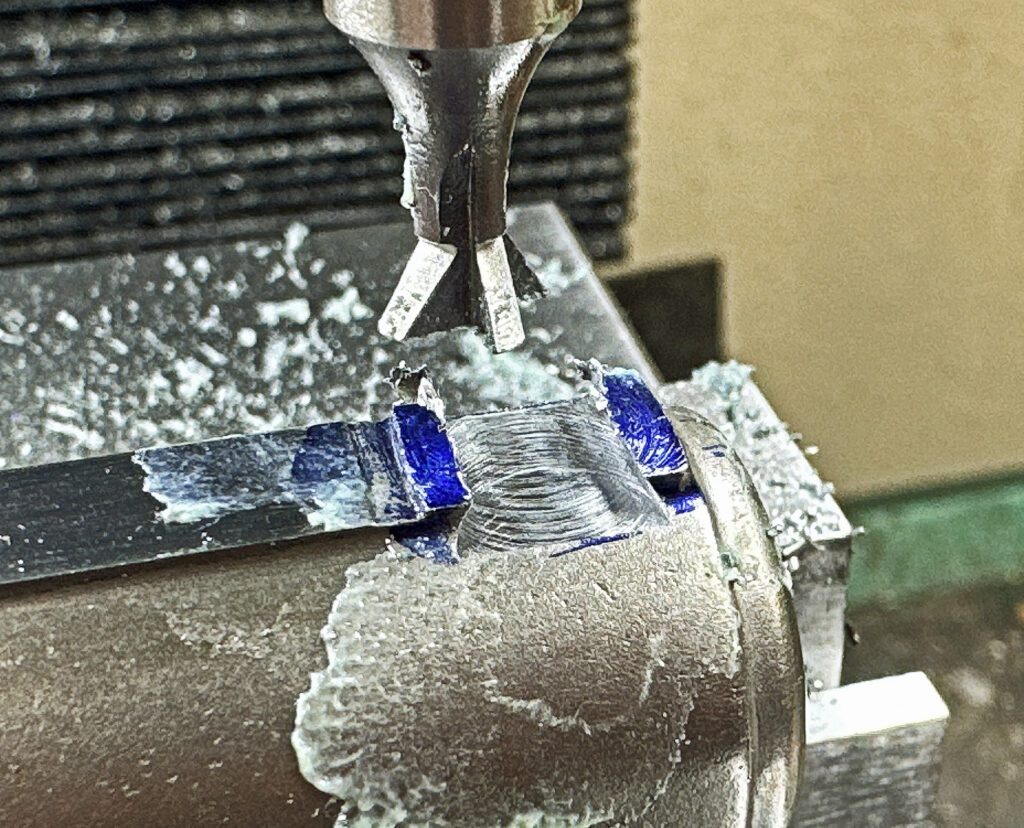

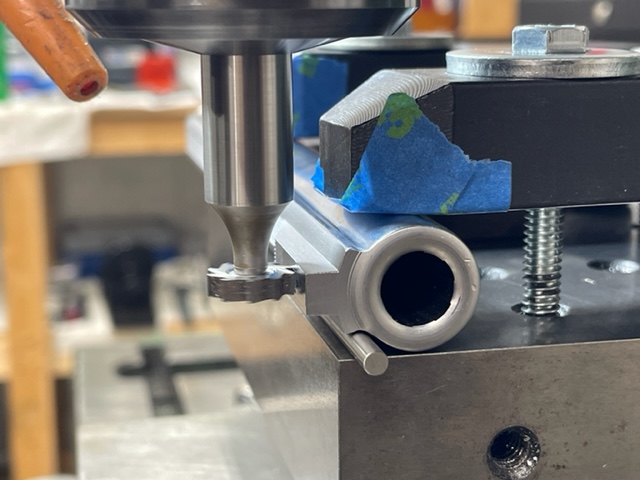

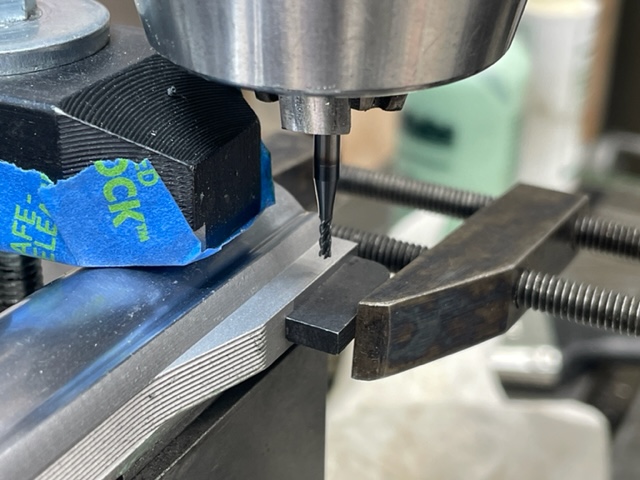

Roy said his first Wrangler efforts began as a quick job to clean up the gun’s action a bit, and maybe polish out some of the casting lines on the grip frame, but his simple project soon snowballed into a full-blown custom. He wound up grinding and polishing the sides of the hammer and trigger, fluting the barrel, cutting flats on the cylinder, scalloping the recoil shield, and recontouring the loading gate. He worked the action over, made the loading gate easier to open, and dovetailed a new front sight.

It was the muzzle chamfer and forcing cone work that really made the gun sing, though. Roy said the Wranglers consistently shoot about three inches at 25 yards from the factory, but recutting the forcing cone and muzzle shrank groups down to 1.25 inches or better.

When he wrote up the results for American Handgunner, he was surprised at the response. He wasn’t sure if many folks would appreciate putting $1,000-plus worth of work into a $200 gun, but the orders started coming in—not only for custom Wranglers, but custom Bearcats and Single Sixes, too.

So, Roy’s been doing lots of custom Wranglers lately, made to customer specifications, and he’s been having some fun with the creative side of it all. The Wranglers need to be refinished after all this work, and Roy has been experimenting with a variety of Cerakote finishes. Some are vivid, others more subdued. One customer wanted his a bright, cherry red, and Roy delivered. My personal favorite of all the ones he’s done is a dark blue Cerakote with a gloss finish over the top, which makes it look an awful lot like the classic blued finishes that I miss so much on factory-new guns these days.

AN EYE TOWARDS THE FUTURE

He’s still a little stunned that shooters would pay so much to gussy up a budget gun, but the Wranglers have been an excellent base for the custom projects, and it seems that balance between avocation and vocation might slowly be tipping towards the latter.

I think that’s pretty exciting, and I’ll be eager to see how things play out. I hope Roy never runs out of time to do those fun projects that just tickle his fancy, but it would be pretty neat to see more of these fancy Wranglers get built.

I’m also eager to see more of what he and Dusty can do, when they get back together. You can bet that we’ll keep tabs on them, and we’ll let you know what they come up with, when Dusty can hang up his fatigues for a while, and don his shop apron, again.

*****

For gunsmithing inquiries, contact Roy at: [email protected]

*****

Editor’s Note: I’d be remiss if I didn’t take the opportunity to mention this—If you aren’t getting the Wheelgun Wednesday newsletter from FMG, which features Roy’s work (and the work of some of the most knowledgeable gun scribes in the business), you should sign up for it. I enjoy reading it very much, and I’m sure you will, too. Drop Editor Ashley McGee an email at [email protected] to sign up.

Editor’s Note, Part Two! Just before press time, we learned that Mas Ayoob will be hosting a Massad Ayoob Group Revolver Class in Live Oak, Florida, on February 22-23, 2024. I first trained with Mas almost 30 years ago, and completed my first LFI class with a pair of revolvers, which Mas taught me how to shoot even better. He’s a world-class revolver instructor, and I know you’ll get a lot out of the program if you attend. I’m sure this one will fill up fast, so don’t delay!

Fun article, Mike. A gat very much like Roy’s bobbed Model 12 continues to top my entry in your annual holiday wish list as the revolver I want S&W to reintroduce. An M12 with a three-inch skinny barrel, replaceable front sight, bobbed hammer, smooth skinny trigger, rated for Plus P, and sans lock of course, would be a very fine implement. A steel frame trainer and a 22 understudy would be welcome too. Thanks again! Michael

Michael, I couldn’t agree more. A modern, Airweight K-frame makes SO much sense, but today’s S&W just doesn’t seem to understand. They’re pretty terrible stewards of their own revolver legacy, and are missing so many opportunities.

You mentioned the Wish List. I’m skipping that this year, as it started to seem redundant, always asking for the same things (K-frame Airweights, better sights, better grips, better triggers, medium-frame Rugers, ditch the lock, etc.). Maybe the industry will surprise us anyhow, even if we don’t ask? One can hope.

Mike, Whilel I’d love to think the deciders at the major manufacturers were lurking on your site, but I won’t hold my breath. In the meantime I’ll keep shopping for a round butt, four inch, M12 and have my own dream gun fabricated… Michael

Michael,

First off, my many thanks to Mike for this very kind and generous article. He never fails to show being a gentleman will never go out of style.

I agree on the Model 12 and its many virtues. In chatting with S&W over the years, I found they stopped it due to the fact people kept stretching them and/or blowing them up in their quests to “magnumize” them. Alas … for those of us who have our wits about us and would not abuse the platform, we have the ner-do-wells to thank for the demise of that most excellent revolver. I worked closely with Mike Venturino, Clint Smith and Tony Miele (then head of the Performance Center) to bring back the classic models. Finally, at a SHOT show, I cornered S&W president Roy Cuny (a good first name, eh?) who I had gotten to know pretty well. I told him if they brought back the old styles they’d sell like crazy and I’d help to promote them in Handgunner. He looked at Tony and said, “Is that right Tony?” Tony said it certainly was right. Then Roy said, “Well then, let’s do it.” And just like that the classic models were brought back. But Tony couldn’t get the brass to agree to lose the lock, which made him crazy the entire time the guns were made.

Thanks again Mike, for your kind article! Roy Huntington

Sir, it was my pleasure to run it, and I appreciate you sharing your story, and your beautiful custom guns, with us!

I also appreciate the extra history about the Classic Series guns. I sure wish we RevolverGuys had as receptive an audience at S&W today as you did back then. The interest in revolvers–and particularly the classic designs–is even stronger today than it was when you, Duke, Clint and Tony were scheming to launch the Classic Series. Alas, it’s been a little neglected. I hope S&W will breathe some new life into it someday!

Being a very minor gun tinkerer myself, my hat’s off to Roy Huntington for reaching such an advanced state of gunsmithing on his own. America definitely could use more “Roys” and far fewer “Elons”.

Amen to that!!!

Spencer, I’m glad to hear you dabble in the black arts too! I just finished helping a 16 year old boy build a black powder .32 rifle. He was taken by the experience and soon showed good tool skills. The smile on his face as he held the finished rifle suddenly made all the work it took for both of us well worth the time.

Roy:

My very minor tinkering with firearms is an extension of my many years of restoring and sharpening antique woodworking hand tools and knives. It might take me another lifetime (or two) to even have a chance of achieving just a little of your expertise.

Great writeup, Mike. I’ve enjoyed Roy on Gun Cranks and reading his articles on Guns Magazine and American Handgunner (on line) for some time. He blends a great sense of humor from life on the street with a dedication to innovation and exploration in how to make a revolver a unique, yet totally functional item.

I admit when he first started with the Ruger’s Wranglers, my thought was why would you spend all that time and effort on a $200 gun . . . but seeing the end product of his work on so many of his projects makes me wonder whether he isn’t another Hamilton Bowen, Bobby Tyler, and Armand Swensen (the S&W sight on the Walther) being morphed into one.

I do whole heartedly agree with your observation that companies ( hello, S&W, you listening ?? turn on your hearing aids ) are missing out on a silent market by NOT having airweight K frames (minus the Hillary Hole) – like the old Model 12 that is priced out of sight if you can find one. If Ruger could take the Super Redhawk and scale it down to the GP-100, and then to the SP-101, they can certainly scale it back midway to make something like a KP-100 (?)

Roy would protest and say he’s not a custom gunsmith, but his works tell a different story. I’ve seen some other images of his latest work and it’s both mechanically excellent and artistically superb. He’s really got a talent for making guns better, and I think it’s largely propelled by the fact that he really loves and understands them. This is a passion project from a real Gun Guy, not just a businesslike labor to keep the lights on.

A KP-100. Bingo!

I might be the odd one out here, but my preference would be a scaled-up LCR to keep the weight savings of the polymer and aluminum, plus the internal hammer which I prefer (if I want to shoot a gun single action, I’ll get a single action gun)

Six rounds of .38 or 9mm, 8 or 9 of .22WMR, the option of a very short grip for concealment, lightweight overall, replaceable front AND REAR sight, or follow Taurus and make it optic-ready (rather than having Wright Armory install one like I did). That’s my wish.

You guys are sneaky little buggers. I see how you’re trying to subvert my plans to not run a Wish List article, this year. I’m watching you . . . 😉

Hey, even if S&W and Ruger won’t listen, we can always send it to Caleb Giddings and see if he can get Taurus to do something with it.

The 856 Ultra-Lite guns seem pretty close to a Model 12 with a replaceable pinned front sight. 16oz for the 2in, less than 18oz for the 3in versions.

You’re a good straight-man, Kris. We’ve got an 856 UL being tested as we speak. Standby for more.

Mr. Bond, to put my name among those greats makes me squirm some. Hamilton is a dear, old friend and I’ll never be in his league. But I’ve learned a great deal from him over the years. I knew Armand from the middle 1970s when I used to compete in the Oceanside Combat League (early days of amateur “combat” match shooting). He used to park his car in the lot at the range and sort of work out of the trunk. At one match, my Colt Gold Cup lost its rear sight and I asked if he could fix it. He said, “Well laddie, I can’t fix it here but use one of mine.” So it was my first experience shooting a custom 1911 and it grew from there, for sure!

As far as the Model 12 goes, think outside the box. There are lightweight guns from Taurus and Charter which respond great to custom work. Someone who knows their way around either of them can really slick up the action, do some accuracy and sight regulation work, bob hammers, etc. You’d likely be amazed at what a nice gun you can turn out. I’ve done the Taurus .44 and lots of the .38 Specials, and only yesterday finished a Charter .45 Colt Bulldog. Bobbed hammer, muzzle chamfer, forcing cone re-cut, sights regulated, polished trigger face, milled lightning slot in trigger guard, a modest melt and since it was stainless, a nice soft bead blast. They can be very nice guns and I recommend you take a hard look at the idea. Roy

Thanks for this article, especially the links. Having closely inspected a no-return evilBay barrel, I noticed the muzzle was out of square and screaming for a chamfer. That place in Iowa should have the solution.

Edit the following out if I’ve crossed a line:

If you’re interested in seeing some of Roy’s personal guns, or owning one or two, check the green and yellow website. There’s a wheelgun or three, including a nickel 2″ 1948 M&P that I’d have bought if I hadn’t lucked into an “S” prefix snubby instead.

No problem, Lobo. We need to help Roy sell those guns! He’s got mouths to feed, you know. Do it for the children! 😁

He’s got some real beauties there, including a Model 12 (notable, since we’ve been talking about it), a Colt Officers Model, a pair of Victory models, a .38/44 Outdoorsman, a K-22 . . .

Go to Gun Broker and search by his name to find them.

It’s definitely time for me to “cull the herd” as it were here so in spite of my better judgement I am selling off part of the stash. But I’ve found it’s good to sell some guns off then re-invest in fewer and even better ones!

An 11-degree muzzle chamfer tool, pilot and handle is a great investment and one you’ll put to use often. The exact “degree” isn’t critical, you just want to protect the bore itself so the angle does that. Keeping things square at the exit is what’s critical. Shoot a gun and look at the powder marks at the muzzle. Unless it’s square, you’ll see they are darker and lighter depending on the angle of the bore as powder escape from one side before the other. Cut the chamfer, and suddenly you’ll see a perfect spacing of powder marks. It’s amazing to see and helps to explain the reasons for a square muzzle.

Mike thank you for this article on Roy Huntington. I have enjoyed his writing since it first came to my attention. His style reminds me in some way of Skeeter and Bill Jordan, kinda like you are setting there listening to him tell stories.

For me, he and Mas fill the void left by some of the gun writers of days gone by. Wait ,we are almost gone by also.

Can not speak to his smithing skills even though I think he might have helped a friend of his work on a 3 inch model 10 of mine.

His mentoring of Dustin Housel greatly impressed me. From reading Roy’s early article about Dustin to hearing Dustin talk about the many things Roy has done for him continued to remind me Roy’s actions with this young man are what we should all be doing. If those of us who love , hunting, shooting , the history of firearms in our countries history and the technology of the gun of the hand don’t pass on that passion to young folks, it could be lost. Thank you Roy Huntington you set a good example for all of us.

Another great read Mike.

Indeed, Tony! Roy has been a great mentor for Dusty and many others in this industry, and is generous with sharing his time and expertise. He’s a great role model for us to follow, in bringing up the next generation of RevolverGuys.

Tony, you have me “aw shucking” here. I was fortunate to meet Skeeter a few times before he passed, and knew Bill Jordan well enough to chat at shows. Bill had the biggest hands you can ever imagine and when he shook, his hand simply engulfed yours. When he held a Model 19, he made it look like a J-Frame!

I hope the 3” Model 10 worked out!

It’s always a delight to help young people get started in shooting, and for fellows like Dusty, working with him is a genuine pleasure. He’s a two tour of duty sand-box vet (he’s actually currently deployed again) and his passion and drive to learn is great to be around. Thanks again for your many kind words.

Roy I had the pleasure of meeting Skeeter at a Shot Show in the early 80s, wish I could have had a long visit with him.

At another Shot Show walking around with a good friend, A. G. Russell , he introduced me to Bill Jordan. As I shook hands with him I could not believe how huge his hand was.

Sadly all 3 of these fellows are gone now.

Was coming back home several years ago from running gun traps in Colorado and New Mexico when I turned off the highway onto a side road after crossing into Texas.

My wife asked where I was going, just a place I need to see.

Stopped at a bridge and got out of the vehicle. As I stood on the bridge over Tierra Blanca creek I closed my eyes and saw two young boys running down the bank and thanked them for letting a lot of us accompany them on their adventures.

Good memories.

Not to go too far down the rabbit hole, but that 856 UL eval might benefit from a comparison with the OGs:

1. M12 Smith and Wesson square butt 2″ ,loaded, with boot grips: 1 lb. 7.3 oz. (23.3 oz.)

2. Pre-’72 Colt Cobra 2″, loaded, with Herrett’s grips: 1 lb. 3.4 oz. (19.4 oz.)

[3. 856 UL CH, 2″, loaded, with Tillander grips: 1 lb. 3.6 oz. (19.6 oz.)]

–Dymo M5 postal scale, 12.30.23, weighed by me

Great info Sir, thank you!