If you’re looking for an autopistol mechanic these days, the world’s your oyster, but it’s a little more difficult to find a quality gunsmith to work on your revolver or build the custom one of your dreams.

The more complex actions found in revolvers require specialized knowledge, tools and skills to work on them, and you won’t find as many ‘smiths dedicated to working on them as the bottom-feeders, but we’re fortunate that there’s still a crop of talented folks out there who are doing great work on cylinder guns.

To help introduce you to some of them, RevolverGuy sent out questionnaires to a number of the most respected and popular revolver gunsmiths in the trade, and we’re going to share the responses we received from them in a series of installments. Many of these names will be familiar to hardcore RevolverGuys, but hopefully we’ll be able to introduce you to something or someone new in this series.

So, to kick things off, we’ll start with the first half-dozen responses, listed in alphabetical order.

Bowen Classic Arms

Gunsmith Hamilton Bowen launched Bowen Classic Arms Corporation in 1980, focusing much of his effort on the production of the quality parts that were necessary, but generally unavailable, for his custom work. Replacement cylinders, action parts, cylinder pins, and upgraded front and rear sights were all targets of his early attention.

After developing these parts, Bowen was better able to build the custom creations that he’s known for. Whether your tastes run towards single actions or double actions, hunting guns or classics, you’ll be sure to find something to make your jaw go slack in his gallery.

Bowen is a member of the American Pistolsmiths Guild (and a past President, and current Board Member) and the American Custom Gunmakers Guild. He was the American Pistolsmiths Guild Pistolsmith of the Year in 1990. RevolverGuys should definitely check out his Rough Country sights, which combine adjustability with robust construction.

RevolverGuy Survey Questions:

RG: Would you describe your operation as “Part-Time,” or “Full-Time?”

HB: We are a Full-Time operation.

RG: Would you describe the central focus of your operation as “Custom” work, “Service and Repair” work, or a “Full Service” combination of the two?

HB: We exclusively do custom work, though we do produce a fair number of parts for consumers and the trade.

RG: Do you have a specialty or area of emphasis that you are known for?

HB: We’re best known for our big bore caliber conversions, and our related cylinder, barrel and sight work.

RG: Is there a gunsmithing service or product that you offer which you feel is unique in the marketplace?

HB: Our aftermarket sights would probably be our most unique product. For service, much of our barrel and cylinder work is peculiar to us, at least on a general basis.

RG: What kind of gunsmithing work do you like to do the most?

HB: There are three of us here in the shop at Bowen Classic Arms Corp. We have a typical division of labor, and while I have trained everybody else, we all have our areas of particular expertise. Jeremy Cook runs the place and is in charge of sight production and helps with some of the more general gun work. Brian Mapes does most of the machine work now and is a far better tuner than I’ll ever be. I do virtually all of the shooting, polishing/file work, marking and detail work.

RG: Is there a particular model, brand, or platform that you prefer to work on?

HB: While we have worked on S&W double actions and Colt single actions to a considerable extent in the past, we now concentrate on Ruger products.

RG: Is there anything that you would like customers to know/understand about your services or operation?

HB: We are a little different from some shops, in that we only offer custom packages, not a menu of individual services, as shown in the catalog on our website.

RG: How would you prefer RevolverGuy readers to contact you?

HB: Our website address is http://www.bowenclassicarms.com/ ; Our E-mail is shop@bowenclassicarms.com ; The main shop phone is (865) 984-3583 with the parts line at (865) 981-8869.

D&L Sports

Dave Lauck is a custom gunsmith with a lot of real-world shooting and tactical experience under his belt. Having served as a police officer (with extensive SWAT experience), law enforcement armorer, and military/police firearms instructor, Dave understands the environment that defensive guns will be used in. Additionally, as an award-winning shooting sports competitor, and an avid hunter, Dave knows the lay of the ground in those pursuits, too.

Although Dave does a lot of work on rifles and autopistols for duty use, he’s a talented revolver gunsmith as well, with an eye for beautiful custom work on both single and double action revolvers. Whether you’re looking for a hunting gun, an heirloom quality custom, or a duty gun for defensive use, Dave can take care of you.

Lauck is a member of the American Pistolsmiths Guild, and earned their prestigious Pistolsmith of the Year Award for 2012. RevolverGuys will definitely want to check out his excellent J-Frame sights, which fix one of the most notable weaknesses of these excellent guns.

RevolverGuy Survey Questions:

RG: Would you describe your operation as “Part-Time,” or “Full-Time?”

DL: We’re a Full-Time operation.

RG: Would you describe the central focus of your operation as “Custom” work, “Service and Repair” work, or a “Full Service” combination of the two?

DL: I run a Full-Service operation, doing service, repairs and custom work.

RG: Do you have a specialty or area of emphasis that you are known for?

DL: I offer a full range of services, working on rifles, carbines, pistols, and revolvers. I also manufacture high quality parts for a variety of platforms, custom ammunition, and optics/mounts/sights.

RG: Is there a gunsmithing service or product that you offer which you feel is unique in the marketplace?

DL: The most unique aspect of our service is that it’s personal service. I’m a one-man shop, and I still like to talk directly with the client to make sure they get what they need the first time.

RG: What kind of gunsmithing work do you like to do the most?

DL: I like to do performance-oriented work. I enjoy building guns that deliver premium accuracy and are the most efficient tools for the job.

RG: Is there a particular model, brand, or platform that you prefer to work on?

DL: I have developed my own signature line/brand of D&L Sports Inc. firearms to provide clients with superior gear and performance. These guns will withstand the rigors of any service, defensive, or sporting environment.

RG: Is there anything that you would like customers to know/understand about your services or operation?

DL: Performance is a top priority, and all of my guns deliver a high-level of precision, reliability, and efficiency, in addition to looking good.

RG: How would you prefer RevolverGuy readers to contact you?

DL: My website address is www.DLSPORTS.com. Readers can contact me via email at dlsportscustom@gmail.com and can call me at (928) 636-1726. They can also contact me through the website.

Gemini Customs

Marc Morganti started his gunsmithing career with a focus on 1911 pistols, but over time his interests turned towards double action Ruger and Smith & Wesson revolvers. In business since 1997, Marc became a proud member of the American Pistolsmiths Guild in 2001, and has served as both the past Secretary and President of the Guild for nine years. As a result of his consistently superior work, Marc was awarded as the American Pistolsmiths Guild 2009 Pistolsmith of the Year.

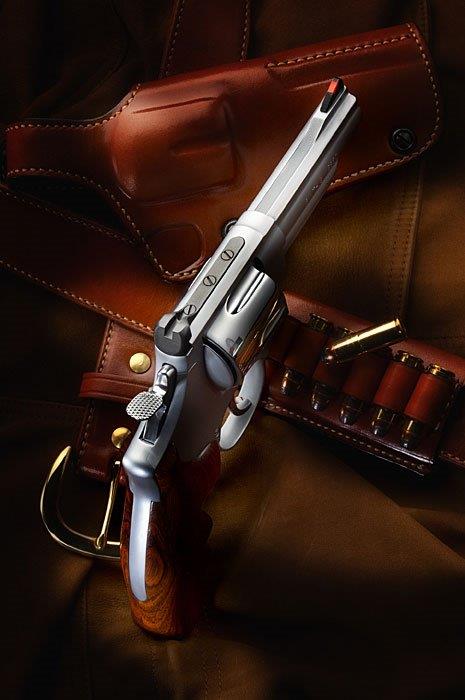

Smith & Wesson work makes up a “small, but valuable” part of Marc’s business, but the lion’s share of his efforts are focused on double action Ruger revolvers, and most of you have probably seen them grace the covers and centerfolds of American Handgunner Magazine.

Marc is a humble guy, and we had to twist his arm a bit to get him to tell us about his special work, but once you see it, you’ll know he has a right to be proud of it. As Marc told us, “We specialize in keeping revolvers a valuable and worthy option for the 21st Century, and in providing exceptional service to customers that demand the best.”

RevolverGuy Survey Questions:

RG: Would you describe your operation as “Part-Time,” or “Full-Time?”

MM: I am a full-time custom shop specializing in high-end, accurate, reliable, beautifully detailed and configured, Ruger and S&W revolvers.

RG: Would you describe the central focus of your operation as “Custom” work, “Service and Repair” work, or a “Full Service” combination of the two?

MM: Custom work is indeed the focus of Gemini Customs. We build heirloom quality revolvers and offer an almost limitless variety of custom options for our customers to choose from.

RG: Do you have a specialty or area of emphasis that you are known for?

MM: My specialty is focusing on the smallest of details. Meticulous attention to accuracy, reliability, cosmetic enhancement and ergonomics are the hallmarks of Gemini Customs. A large amount of our work is focused on high-end, heirloom grade, custom concealed carry Ruger DA revolvers. We also provide the same attention to detail in our work on medium and large-frame revolvers for duty, carry and hunting, such as the Ruger Redhawk, Ruger Super Redhawk, Ruger GP100, and S&W K-L-N-X Frames.

RG: Is there a gunsmithing service or product that you offer which you feel is unique in the marketplace?

MM: We are the only custom shop in the USA that actually precision machines, and hand fits and finishes, our own custom exotic wood grips for the guns we customize. No one else does that–no one! We also machine our own custom profile “Ultimate” barrels, machined from Krieger SS large OD blanks in .45, .44, 10MM and .357 calibers. These are for our “Ultimate” Redhawk, GP100, Wiley Clapp GP100, SP101, and Wiley Clapp SP101 offerings. We build some of the most over-the-top, high-end, custom Ruger DA revolvers available.

RG: What kind of gunsmithing work do you like to do the most?

MM: I love my work and am blessed to have customers that demand the best I have to offer. I suppose more than anything I enjoy the freedom to be creative, and enjoy that through the support of customers that want something unique.

RG: Is there a particular model, brand, or platform that you prefer to work on?

MM: I love the Ruger GP100. In my humble opinion, based on my experience, it’s possibly the best all-around, “do it all revolver ” platform ever devised. If the rules suddenly changed, and I could keep only one sidearm, it would be a Ruger GP100 . . . highly customized of course! I know, I just opened a can of worms, but it is my opinion.

RG: Is there anything that you would like customers to know/understand about your services or operation?

MM: An important thing to know about my operation, or anyone else’s custom shop, for that matter, is this: “Good ain’t cheap, and cheap ain’t good.” Also, “Good work takes time, so there is no such thing as a rush job.” The single most important thing to know and remember, though, is that, “A thing of beauty is a joy forever.”

RG: How would you prefer RevolverGuy readers to contact you?

MM: I prefer to be contacted via email initially. Most questions can be addressed there. I will make myself available for phone calls, but it can be difficult to step away from a delicate machine or hand operation to chat. Remember it’s a human doing this work, not a Robot.

RevolverGuy readers can e-mail Marc at yoda1911@geminicustoms.com, and can find the Gemini Customs website at https://www.geminicustoms.com.

Reeder Custom Guns

Gary Reeder started building guns in the early 1980s in Tennessee, then later Florida. In 1994, he moved his operation to Flagstaff, Arizona, where he set up his shop in the back of a gun store run by his wife, named The Pistol Parlor. Gary’s gunsmithing was originally focused on building full custom Remington XP-100s and full custom Thompson Center Contenders, with a specialty in rechambering Contender barrels for custom hunting cartridges.

Gary is still building custom Contenders and Contender barrels (often chambered in his own custom GNR cartridges), but his gunsmithing operation has branched into more than five dozen custom revolver series (including single action “cowboy” and large caliber hunting guns), full custom large caliber hunting rifles, full custom 1911s and Browning Hi-Powers, and many one-of-a-kind specialty guns.

Many of Gary’s custom revolver designs have been “adopted” by major manufacturers, who are now making their own factory versions. His birdshead-style grip (as seen on his “Tombstone Classic” single action) and his “Alaskan Survivalist” big bore snubs have migrated into the Ruger catalog as factory standards, for example. Once, at SHOT Show, a Ruger executive approached Gary and jokingly asked him, “So, what do you have that’s new this year, that we can copy?” If imitation is the sincerest form of flattery, then Gary should be flattered indeed!

Gary’s small, back room operation has now grown into a 3,000 square foot machine shop, where a crew of experts makes metal chips and revolver magic. RevolverGuys will want to check out Gary’s .22 Flat Nose Tool for modifying round nose rimfire bullets, and boosting their terminal performance, as well as his custom sight base for red dot optics. They’ll also enjoy reading Gary’s excellent books on hunting handguns/cartridges, and reloading. Lastly, make sure to drop by the Reeder Custom Guns Forum for an education on a variety of firearms topics.

RevolverGuy Survey Questions:

RG: Would you describe your operation as “Part-Time,” or “Full-Time?”

GR: We’re a full-time custom shop.

RG: Would you describe the central focus of your operation as “Custom” work, “Service and Repair” work, or a “Full Service” combination of the two?

GR: We definitely focus on custom work here at Reeder Custom Guns. We do a few odd service jobs for folks who really need the help, but we really don’t encourage that kind of business, because we’re so busy with our custom orders.

RG: Do you have a specialty or area of emphasis that you are known for?

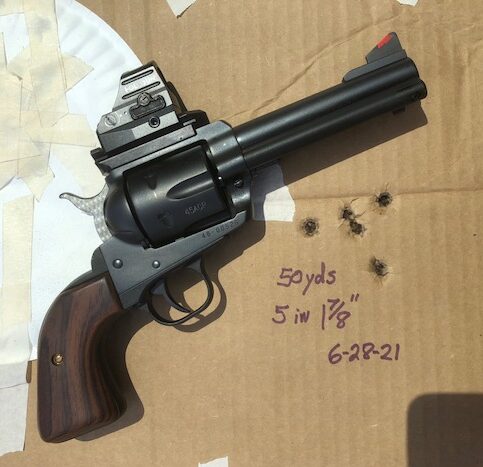

GR: We specialize in building custom hunting guns, and are known for building big bore guns for dangerous game. We understand how to build handguns that can handle the recoil of powerful cartridges—our Gunfighter Grip, for example, rounds off the sharp edges of the grip frame that will bite into the palm of the hand on recoil. Its shape reduces at least 30% of the felt recoil, and makes it easier to hang on to a hard-kicking revolver.

RG: Is there a gunsmithing service or product that you offer which you feel is unique in the marketplace?

GR: We have a full line of GNR custom wildcat calibers that we build guns for, and our red dot sight bases are a specialty that you won’t find elsewhere. Our beautiful and durable Black Chromex finish is proprietary, as well. We do our own engraving and finishing (including traditional bluing and case-hardening) in-house. We also build our own single action revolver frames and cylinders, and make our own grips, in-house.

RG: What kind of gunsmithing work do you like to do the most?

GR: I like building one-of-a-kind customs that you won’t find anywhere else. After all these decades of gunsmithing, I really enjoy working on the projects that are new and different than what we normally do.

RG: Is there a particular model, brand, or platform that you prefer to work on?

GR: We do a lot of work on Ruger double and single action revolvers. They’re a good base product for a custom gun.

RG: Is there anything that you would like customers to know/understand about your services or operation?

GR: Yes! The most important thing is to be patient, please. We have two years’ worth of orders on the books already, and your job is not going to get done quickly. Some customers have a very difficult time waiting for their gun to be finished, and it’s important for them to understand that we’re not joking when we give an extended estimate for completion. Please be patient, and understand that we haven’t forgotten you, we’re just trying to make our way through the backlog of orders that came in front of you. If you need it fast, we’re not the right shop to go to.

RG: How would you prefer RevolverGuy readers to contact you?

GR: All of our contact information is available on our website at https://www.reedercustomguns.com/information/contact.htm. Readers can feel free to call us at (928) 527-4100 or email me at gary@reedercustomguns.com.

Ten-Ring Precision

Alex Hamilton is a lifelong hunter of small and large game, and a gunsmith who has focused the majority of his work on maximizing the accuracy and dependability of custom handguns. In the past he did extensive work on rifles and muzzleloaders, but Alex now works exclusively on getting the most performance possible out of his customer’s handguns.

Alex is a 30+ year member of the American Pistolsmiths Guild, where he served as President for several years, and corresponding Secretary for 25 years. He developed and ran the finest gunsmithing student scholarship program in the firearms industry, and wrote the Guild’s newsletter for almost 30 years. He was honored with one of the firearms industry’s highest awards, as the American Pistolsmiths Guild’s Pistolsmith of the Year in 1993.

RevolverGuy readers may recognize Alex from the long-running series of gunsmithing articles that he wrote for American Handgunner Magazine. You’ll want to check out his extensive web page list of accuracy and action work services, as well as his moon clip conversions.

RevolverGuy Survey Questions:

RG: Would you describe your operation as “Part-Time,” or “Full-Time?”

AH: We’re a full-time shop.

RG: Would you describe the central focus of your operation as “Custom” work, “Service and Repair” work, or a “Full Service” combination of the two?

AH: We’re a full-service shop. We do repairs and improvements on customers’ guns, but also enjoy creating custom guns for them.

RG: Do you have a specialty or area of emphasis that you are known for?

AH: We’re best known for our action jobs and accuracy improvements, but also do excellent moon clip conversions. We offer our own proprietary TR Gun Kote finish, which is a high-tech, abrasion and heat-resistant polymer coating that provides excellent protection from both heat and the elements, as well as dry lubrication.

RG: Is there a gunsmithing service or product that you offer which you feel is unique in the marketplace?

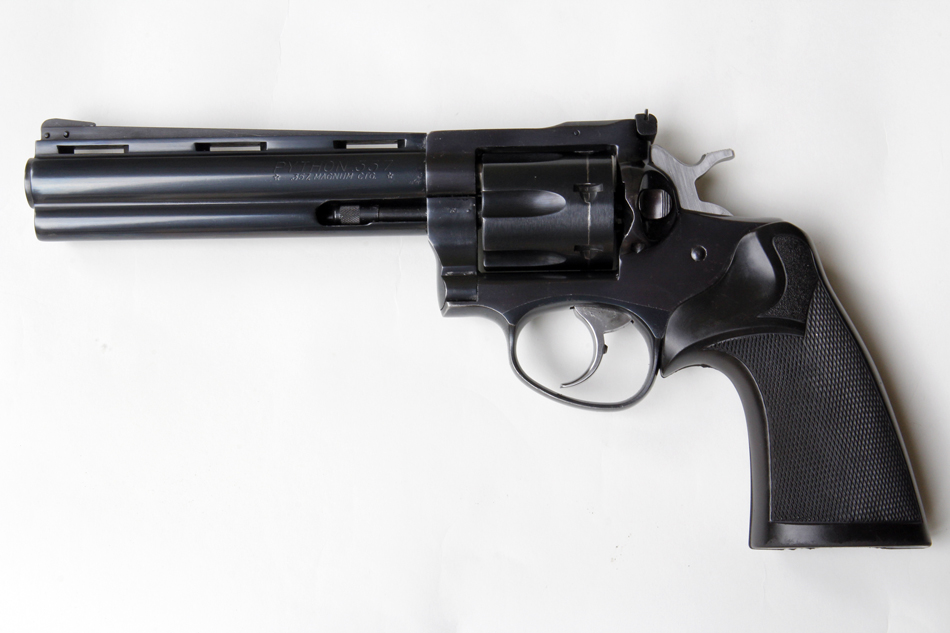

AH: We install Colt Python barrels on S&W K and L Frames, as well as Ruger frames. On the autopistol side of the house, we install manual thumb safeties in Glock pistols.

RG: What kind of gunsmithing work do you like to do the most?

AH: I really like doing action jobs, to enhance the shooting performance of a gun.

RG: Is there a particular model, brand, or platform that you prefer to work on?

AH: I prefer to work on Ruger, Smith & Wesson, and other high quality revolvers.

RG: Is there anything that you would like customers to know/understand about your services or operation?

AH: We work on a broad variety of guns for a wide range of uses. Whether your needs include self-defense, competition, or hunting, we can help you. We also do limited restoration work on firearms that are in light and moderate poor condition. Please see our website for details, photos, and testimonials.

RG: How would you prefer RevolverGuy readers to contact you?

AH: All of our contact information is available on our website at https://tenring.com. Readers can feel free to call us at (210) 494-3063 or email me at alex@tenring.com.

TK Custom Gunsmithing

American Pistolsmiths Guild Member Tom Kilhoffer and his grandson, Eli Johnson, are the gunsmiths that make TK Custom such a powerful force in the world of competition revolver shooting. In business since 1975, TK Custom is known for equipping the most talented revolver shooters in the world, including four-time USPSA National Champion Michael Poggie, and “almost everyone else in the Top-5” at the USPSA Nationals.

RevolverGuy readers know TK Custom from Justin’s previous coverage of their moon clips and tools, but may not be aware of their extensive gunsmithing services, and custom parts for Smith & Wesson revolvers. So, we were very happy to connect with Eli (who learned machining and gunsmithing from his Master Gunsmith grandfather, and has been working in the TK Custom Shop for over ten years) and discover more about the wide range of services and products offered by TK Custom—they’re much more than just, “the moon clip guys!”

RevolverGuy Survey Questions:

RG: Would you describe your operation as “Part-Time,” or “Full-Time?”

EJ: We’re a full-time shop.

RG: Would you describe the central focus of your operation as “Custom” work, “Service and Repair” work, or a “Full Service” combination of the two?

EJ: Custom work, with Smith & Wesson revolvers being our specialty. We manufacture our own line of tool steel revolver action parts, which replace the factory MIM revolver parts, resulting in our Ultimate Master Action Tuning Job being incredibly smooth, at 6.5 pounds in DA. We build custom revolvers for shooters who demand the highest performance from their revolvers, including several nationally-ranked champions.

RG: Do you have a specialty or area of emphasis that you are known for?

EJ: We’re best known for our action jobs on Smith & Wesson revolvers, and for our work in rechambering revolvers to fire autopistol cartridges. Most rechambering/conversions are from .38 Special and .357 Magnum to 9mm or .38 Super. This gives the shooter the versatility to fire both the original revolver cartridges, as designed by the manufacturer, and the autopistol cartridges in the same cylinder/revolver.

RG: Is there a gunsmithing service or product that you offer which you feel is unique in the marketplace?

EJ: That would probably be our Ultimate Master Action Tuning Job, where we gut all the MIM parts out of a newer-model Smith & Wesson, then replace them with our own custom, tool steel components, to include hammer, trigger, rebound slide, and cylinder stop. We also install an extended firing pin and replace the firing pin spring and mainspring with Wolfe parts. Additionally, we chamfer each of the cylinder charge holes, and tune the action so the single and double action pulls are the best they can be. Another unique thing we do is machine Schofield cylinders in .45 Colt to accept .45 ACP, too.

RG: What kind of gunsmithing work do you like to do the most?

EJ: I love doing action jobs! With our tool steel action parts, you can get a much better action than you can with the OEM MIM parts.

RG: Is there a particular model, brand, or platform that you prefer to work on?

EJ: We almost exclusively do Smith & Wesson action work, but we also machine Ruger and other revolver cylinders to accept moon clips.

RG: Is there anything that you would like customers to know/understand about your services or operation?

EJ: Our turnaround times are probably the best in the business! We can return action jobs in three to four weeks, and our rechambering/machining work is usually complete in three to five days. For rechambering, you only have to send the cylinder, and the ejector rod and star assembly—you don’t have to send in the whole gun.

RG: How would you prefer RevolverGuy readers to contact you?

EJ: All of our contact information is available on our website at https://tkcustom.com/contact-us. It’s easiest to use email, because sometimes we’re busy in the shop and we can answer the email later that day, but we’re happy to talk to customers on the phone, too. Readers can email us at info@tkcustom.com or call us at (217) 643-2002.

Stay Tuned!

If you didn’t see your favorite ‘smith featured, don’t worry! We’ve got more installments planned, featuring talented gunsmiths and their beautiful wares, so make sure to keep an eye on these pages and come back to visit us again.

If you decide to do business with any of these featured gunsmiths, we’d sure appreciate it if you told them that you read about them here, at RevolverGuy.com.

Be safe, and good shooting!

*****

Featured image courtesy of Gemini Customs

I just found a way to spend all that money I don’t have.

I hear ya, brother!

Thank you Mike for highlighting these extraordinary men and the fine work that they do! Looking at their websites reminds me of being a kid at Christmas time thumbing through the Sears catalog and dreaming of all the cool toys! Your article reminds me that I have some custom jobs that need doing…

Wouldn’t you just love to be a fly on the wall of one of these shops for a day? Imagine what you could learn and see, just hanging around. These folks are truly artisans that work in steel.

Thanks for the kind words. If you ever need anything, you know where I am.

Thank you Sir! It’s our pleasure to showcase your outstanding work.

I have a stainless 625 “Mountain Gun” with the skinny 4 in barrel. I would like to replace the barrel with a heavy full underlug in 2 1/2 in unit with good quality sights.

Who ch I trust to do this for me?

John, besides the gunsmiths in this article, we also recommend the gunsmiths in Part II of the series:

RevolverGuy Gunsmith Roundup Part II

Masterpieces of Artistic and engineering skill . . . oh that my wallet could keep up with it.

Indeed. The level of skill, precision and talent is really amazing, here. I’m in awe of craftsmen like these.

Mike this a great idea, very worthy of being published in all of the gun magazines.

Looking forward to the continuation.

Have had a little work done by a couple of the custom folks and the thing that sticks out is a level of customer service excellence not found in many places in today’s world.

I think the gun industry’s commitment to customer service is generally MUCH better than any other industry I can think of, and these custom craftsmen bump it up even higher.

Boy, there’s some tasty looking iron depicted here–I’d be thrilled to own just one example of any of these fellows’ products. Maybe Santa Claus will indulge me in that wish some day.

An interesting detail in the article is TK Custom’s tool steel replacement parts for Smith & Wesson OEM MIM action parts. According to what I’ve read, many gun guys distrust the MIM stuff apparently because they think it’s weaker and less durable. Have there been any serious, independent metallurgical tests for MIM?

You’re a good straight man, Spencer! I’m working on an article about MIM, in consultation with industry experts. Stay tuned.

Hello Mike,

Here is an anecdote for your consideration.

I own a S&W model 60-10 and the MIM hammer block broke in two at the narrowest point. This occurred during a ccw qualification. The hammer block stuck in the up position blocking the firing pin. Luckily, I had my 642-1 as a backup and finished the qualification.

The redesigned, replacement hammer block I received from S&W is also MIM. I understand that any and all parts can break under the right circumstances but I believe the combination of long, thin and narrow is not a good candidate for MIM. I no longer trust the gun for personal protection.

Thanks,

Derek

Thank you Derek, that’s good info. I agree about the shape/profile of the part being an important consideration, and I think some industry examples may bear that out. For instance, when Sig changed the extractors on their classic autos from forged to MIM, the new MIM extractors were much, much larger. I presume this was because they couldn’t achieve the same durability and strength from MIM in the small profile of the old part.

You sir, are a brave man..

I’m looking forward to that article.

The issue is not strength as MIM is proven to make strong dense pieces. The issue is S&W is lack of QC, visually looks of the mold voids and perception bias. As the parts come out of a mold similar to basic casting they have voids from the molds as well as excess material that forms burs. You end up with all the various edges from the voids needed for the MIM molds that need to be cleaned up.

Most all the comparisons of mim is to case hardened parts not full thru hardened precision ground tool steel alloys as you see from companies such as TK, Powers, Apex etc. While MIM may exceed wearability of a case hardened part it does not approach a full thru hardened tool steel part.

All I know is I can get a smoother more consistent trigger using machined from solid parts than any mim parts S&W has ever used..

Not that I can not get a good trigger from MIM. I can. But out of the box the old solid machined parts gave better more consistent performance than the MIM of today. Compared to higher precision fully hardened tool steel parts MIM loses in every quality, durability, and performance category.

MIM parts look and feel ugly and rough compared to parts machined from block/rod tool steel. As an example MIM trigger with its hollow rough cavity on the under side. It just looks cheap. Same with all the other MIM parts once you pop the cover plate. They do not inspire confidence in quality. It’s perception. Then there is the idea of, can you name one time in the past where a cast part was considered superior to a machined or forged part? Now of course current MIM is new high tech vs old gravity displacement casting but this still has that effect on perception.

Over the last few yrs, I have fixed,for various friends, 3 j frames and a number of full size k,l,n,x models that had terrible function for this very reason of huge burs on the MIM parts.. Just compare the old trigger and action quality prior to MIM to present. S&W has clearly lost ground in QC where as companies like Ruger and recently even Taurus have increased there’s considerably. This can be seen in the QC of the MIM parts as well.

I have never had a machined part with a 1/8″ bur from the mold on a mating surface. I have seen this issue numerous times on various parts, triggers, Hammers, cyl stop, rebound. All with huge burs dragging and gouging mating surfaces. All created terrible performance. I had a airweight J frame with a 19lb DA trigger pull caused from MIM burs. It had a terrible hitch in the middle of the travel. How did that ever past QC

There is also psychological bias. When in our past has a cast part ever been superior or even equal to solid tool steel part? In our minds cast = cheap machined tool steel = quality

This perception and psychological effect can and IMO does happen to employees as well. Those people assembling the S&W revolvers see these visually crappie cheap looking parts it effects their perception attitude and thus there actual performance and level of detail they put into their work. Something you can not get thru to a bean counter or efficiency consultant. They care about production numbers/time and costs/ profit.

Thanks for posting this. I’ve shifted my focus from quantity to quality customs when it comes to revolvers. My latest is a 3.75” stainless Ruger Blackhawk that was customized by Dave Clements of Clements Custom Guns in VA. If he is not on your list of gunsmiths you have contacted, I suggest you contact him. He’s been in the game a long time and has done some interesting work over the years.

Thank you for the excellent writing featuring Ten-Ring Precision and all my friends from the American Pistolsmiths Guild, Hamilton, Marc and TK. We have all spent 40 to 50 years apiece pleasing customers who appreciate the finest, unique custom work. I am 81 and have no idea how old those other old coots are but we have all been beating the heck out of these old guns for a very long time and love it as much today as we did in the beginning. Thank you Mike the Revolver Guy.

Thank you Sir! It’s our pleasure and honor to do it, and to help a new generation of RevolverGuys discover the beautiful work done by you craftsmen!

What a great article, Mike…and a service for all of us who are out ‘in the sticks’ wondering who’s out there that can help us. I recently picked up a new 2 3/4 69 Combat Magnum off one of the broker services, thinking I might add it to my carry rotation…but it’s a mess. I want to look closely though this list and find some help. Thanks!

Glad you enjoyed it Kevin. Part Two is just about finished and we’ll run it soon, so standby for more info on some great gunsmiths!

Mike, you are missing one of the legendary old school revolver gunsmiths: Mr. Sandy A. Garrett of Northern Virginia Gun Works in Springfield, VA, 703-644-6504. Mr. Garrett has been smithing revolvers for 50 years, and he has done excellent work on every firearm I have brought to him. He is not much for casual small talk, but if you need your gun fixed, he is your man. See his Yelp reviews for a good description from his many satisfied customers.

Thanks Arnold! I emailed him in the initial effort, but never heard back from the inquiry. Part II is nearly done and Part III is in the works. I’ll reach out to him by phone.

Mike

I’d really like to see Bowen produce a Rough Country rear sight for the new production Python.

Gemini Customs builds some beautiful guns and the angle of t.heir grips allows you to point the gun like you are pointing your finger. I also like the fact that the grips are rounded allowing for easier concealment. I definitely would not want a ported barrel like the examples of their work have in the pictures

I have a stainless Ruger Security Six which shoots well but looks bad because of blemishes. It is not scratched or dinged at all it just has dark spots. What refinishing should I consider? Polishing like a Colt Python? Bead blasting? A modern coating? Who should I talk to?

I live in Nortbern Virginia.

Thanks,

Dick Hamly

Hi Dick,

I don’t live in VA and can’t guide you to a local operation, but there’s probably some talented folks in your area who could talk to you about repairs and finishing. I’d suggest starting with your trusted gunsmith and see if he has any recommendations.

There are several folks with national reputations that would also be valuable resources. If you sent an email with photos to one of these guys, they could probably advise:

Bobby Tyler (Tyler Gun Works)

Accurate Plating and Weaponry