This is the next installment in our survey of revolver gunsmiths, which is designed as a resource for you, the reader. It’s our hope that you’ll discover some names you weren’t familiar with before, and learn a little more about the ones you already knew.

As you saw in Part I, some of these gunsmiths are accepting service and repair work, while others are dedicated to custom builds, only. A small number of them are even doing both. One thing they all seem to hold in common, though, is a bit of a wait time. You can plan on your project taking anywhere from weeks to years, depending on the complexity of the job and the existing queue of orders. This seems to be particularly true for the more extensive custom builds from one-man shops, so make sure to plan ahead and ask the right questions, to avoid unpleasant surprises.

Also, please remember to be patient! If a gunsmith tells you he’s six months out, right now, don’t pester him about your job a month after mailing your gun. It’s understandable that you’re excited about getting your gun back as quickly as possible, but be a good customer. Remember, every phone call they receive equals time away from the bench, and more delay for all the orders in the queue. Nobody wants to get your gun back faster to you than the gunsmith!

So, without further delay, here’s another collection of outstanding gunsmiths for your consideration, listed in alphabetical order.

Bobby Tyler Gun Works

Bobby Tyler’s gunsmithing career started with a haggard collection of firearms that he purchased at the ripe age of nine years old, using the money he’d saved from working at a fruit stand. After buying the neglected collection, he spent years learning how to disassemble, clean, repair, restore, and reassemble the guns, which were later sold to help pay for college.

After graduating from the Colorado School of Trades, in Denver, Bobby hung out his shingle as a gunsmith and hoped to make a living at it, but “nearly starved to death trying to fix grandpa’s shotgun for a few bucks.” When things got desperate, he returned to his roots and created a business out of purchasing and reselling estate collections, then shifted the focus of his gunsmithing work to restoring firearms and building high-end, custom guns whose prices were still within reach for the average man.

Bobby’s excellent work gained him attention in the right places, and a series of contracts with a variety of manufacturers that helped to quickly propel his business forward. While he now does custom work for many gun manufacturers, the core of his business remains building custom guns and restoring firearms to better-than-factory-new condition.

RevolverGuy Survey Questions:

RG: Would you describe your operation as “Part-Time,” or “Full-Time?”

BT: We have been a full-time operation since 2014. From 2007 to 2014 I was busy trying to dig my way out of the debt created from trying to run a regular gunsmithing operation, and the work slowed to part-time, but ever since 2014 we have been busy building and restoring guns. It’s important for customers to understand that we’re good at what we do, because we do a lot of it. Our four engravers, for example, do hundreds of guns every year, and I keep them busy—there’s no downtime. Many engravers only do four or five guns per year, but ours are constantly working, keeping their skills sharp and actually getting better at what they do, because they’re doing it all the time.

RG: Would you describe the central focus of your operation as “Custom” work, “Service and Repair” work, or a “Full Service” combination of the two?

BT: We are definitely a custom shop now, and don’t do general service and repair work. Our focus is building custom guns, doing high-quality finishing work, and doing high-grade restorations. We’re unique in that we control everything in-house, from start to finish—nothing gets subcontracted out to another shop. When a customer sends in his gun, our staff will do all the work on it—the gunsmithing to correct problems and enhance the function and reliability, the engraving, the grip making, the sight replacements and calibration, the refinishing, the whole works. We do all of it, and we do it at a price that is reasonable for the average guy.

RG: Do you have a specialty or area of emphasis that you are known for?

BT: We’re definitely known for our color casing process and our bluing, but especially the color casing. We do color casing under contract for about 42 different manufacturers now, and our product is different than anything else you’ll see being done in the U.S.—you can tell by looking at the gun whether it came from our shop, based on the colors and patterns achieved. Color casing is different from case hardening, because we are not trying to harden the material. A frame or receiver, for example, has already been heat-treated by the manufacturer to the desired level for strength and durability, and if we were to case harden that finished frame or receiver, we would run the risk of making it brittle, so we don’t do that. Instead, we do color casing, which applies the beautiful pattern we desire to a material without changing its physical properties, and we’ve developed a process that gives us outstanding results on both carbon and stainless steels (which is pretty unique, because nobody else is doing stainless).

RG: Is there a gunsmithing service or product that you offer which you feel is unique in the marketplace?

BT: Our color casing is definitely unique, but I think what’s more important is that we created a niche in the custom gun market that didn’t exist before. In the old days, you’d have to be willing to wait three years and spend upwards of $3,000 to have a custom, engraved gun built to your specifications, but we created a shop where you can do something like that in four-to-six months, and spend much less money on it. My goal has always been to put custom-grade guns and services within the reach of the average guy, and we’ve done it. When I was younger, I wondered, “why isn’t someone doing this kind of work at a price I can afford?” so I set out to make custom-grade work accessible to people like me. We charge a reasonable price for this high-quality work, and in the process, we’ve greatly expanded the customer base in this industry. More and more people are now interested in engraving, beautiful finishes, and custom features because we put it within their reach, and that’s probably what makes us most unique.

RG: What kind of gunsmithing work do you like to do the most?

BT: What brings me the most joy is helping to fulfill the dreams of my customers. For some people, it might be a simple job, like applying a beautiful, nitre blue finish to a favorite gun, while others might want a high-end custom with fancy engraving, stag grips, custom sights, an action package and color casing. Some people may want to restore a family treasure that’s in bad shape, and we can do that too, right down to restoring the old factory rollmarks on the gun, repairing damage, and refinishing. We can actually restore an old gun to better-than-factory-new status. I get a lot of satisfaction out of making these dreams come true for our customers, and building or restoring a gun that will mean a lot to them, and deliver a lot of value for the level of work performed.

RG: Is there a particular model, brand, or platform that you prefer to work on?

BT: The way I see it, there’s two categories of guns—good quality guns, and bad quality guns. We love to work on the good quality guns and can do anything with them, but we leave the bad quality guns alone. A good quality gun doesn’t have to be fancy or refined, but it does have to have good bones, and be worth the time and effort we will invest into improving it.

RG: Is there anything that you would like customers to know/understand about your services or operation?

BT: I think the most important thing for them to know is that customer service and quality are the most important things to us. If I wouldn’t put it in my own safe, then I wouldn’t ask you to put it in yours. We won’t turn out a product that we’re not proud of, and we want to build or restore the gun that you want, exactly how you want it.

RG: How would you prefer RevolverGuy readers to contact you?

BT: We’re happy to field both phone calls and emails. Customers can call us at (806) 729-7292 or email us at [email protected]. Email is always a surefire way to get a hold of us, but we will be happy to answer the phone too—we still take our own phone calls and will talk to a customer that needs help anytime. We encourage folks to visit our website, and we’re all over social media, too, if you want to see our products there.

Chestnut Mountain Sports

Gunsmith Karl Sokol served as a police officer from 1983 to 1997, which gave him a keen insight on the necessary qualities of defensive firearms. As a police officer, firearms instructor, and shooter, Karl sought training from some of the best instructors and schools in the country, which further reinforced his understanding of defensive firearms and their use.

Karl earned multiple factory certifications as a pistol and revolver armorer, and completed a number of custom pistolsmithing schools in his quest for education. He became a full-time gunsmith in 1986.

Karl’s work has been well-received by sportsmen, competitors, law enforcement, and armed citizens all over the nation. A growing number of revolver afficionados have entrusted Karl to work on their defensive guns, recognizing his expertise in this area of gunsmithing.

RevolverGuy Survey Questions:

RG: Would you describe your operation as “Part-Time,” or “Full-Time?”

KS: I have been a full-time gunsmith since 1986.

RG: Would you describe the central focus of your operation as “Custom” work, “Service and Repair” work, or a “Full Service” combination of the two?

KS: I’m a full-service gunsmith, doing custom work, service, and repairs, but my operation leans more heavily towards custom work these days.

RG: Do you have a specialty or area of emphasis that you are known for?

KS: My principal concern is making defensive firearms as reliable as they can be. My background as a police officer and armed citizen guides my gunsmithing work, and I’m known for placing reliability ahead of all other concerns.

RG: Is there a gunsmithing service or product that you offer which you feel is unique in the marketplace?

KS: Lately, I’m doing a lot of revolver conversions where I take 4” barreled Smith & Wessons and cut them down into 3” carry guns. I shorten the barrels, install Novak-style front sights, bob the hammers, convert the actions to fire double-action-only, chamfer the charge holes, round and smooth polish the trigger, and refinish the guns (bluing, parkerizing or Mountain Tuff—all done in-house).

RG: What kind of gunsmithing work do you like to do the most?

KS: Quality work! Haha! In all seriousness, I enjoy doing reliability tune-ups on firearms to ensure they will be reliable for duty and defensive work.

RG: Is there a particular model, brand, or platform that you prefer to work on?

KS: I like to work on Smith & Wesson revolvers (all the J, K, L and N-Frames) and Ruger revolvers (especially the SP101s, GP100s, and Redhawks) the most.

RG: Is there anything that you would like customers to know/understand about your services or operation?

KS: I’m a one-man operation, so I’ll be doing all the work on your gun. My background is law enforcement, where I served on a small agency and worked as a firearms instructor for the department. My approach to firearms begins with a “tactical” mindset, and I take my work on service and carry guns very seriously. I’m dedicated to making sure they will work properly in a time of need.

RG: How would you prefer RevolverGuy readers to contact you?

KS: Email is probably the best way to start a conversation. Readers can contact me at [email protected] and they can also see my website for more information about our services.

Defensive Creations

Gunsmith Dave Laubert followed a familiar path, getting into the trade when he became dissatisfied with the quality of work done on his guns by other ‘smiths. As a tool and die maker, and a machine trades teacher at a vocational school, Dave already understood how to do precision work in metal, so when his competition guns came back in worse shape from a trip to the gunsmith in the 1990s, he decided to start doing his own work on his guns.

Over time, fellow competitors and shooters started asking Dave to do odd jobs for them, and events took their natural path, with Dave establishing his business, Defensive Creations, in 1999.

Dave is an active member of the American Pistolsmiths Guild and has become known for his work on 1911s and Smith & Wesson revolvers.

RevolverGuy Survey Questions:

RG: Would you describe your operation as “Part-Time,” or “Full-Time?”

DL: I started out as Part-Time, but have been a Full-Time operation since 2013.

RG: Would you describe the central focus of your operation as “Custom” work, “Service and Repair” work, or a “Full Service” combination of the two?

DL: I did general gunsmithing until 2008, but since then I’ve focused on doing custom work on handguns. I still do a little service and repair work for local law enforcement, but I mostly focus on full-custom handgun builds now.

RG: Do you have a specialty or area of emphasis that you are known for?

DL: I made a reputation working on 1911s, but in 2018 I was asked to do some work on a couple Smith & Wesson K-Frames and really enjoyed it, so I’ve been working a lot on those, since. I’ve been doing a lot of S&W revolver conversions, where I take a four-inch, square butt gun—often a surplus law enforcement gun–and turn it into a three-inch, round butt with custom features like a dovetailed, gold bead front sight, a crowned barrel, a full action job, and other improvements.

RG: Is there a gunsmithing service or product that you offer which you feel is unique in the marketplace?

DL: I think one thing that sets me apart from many places is that I like to give the customer lots of options to choose from. I don’t build package guns, only—I like to give the customer an à la carte list of options and let them decide what the gun will look like. I develop a close relationship with the customer, and we do a lot of talking back and forth during the course of a project, to guarantee they’ll get exactly what they want.

RG: What kind of gunsmithing work do you like to do the most?

DL: I work on Ruger and Colt revolvers, but enjoy working on Smith & Wessons built prior to the year 2000 the most. A lot of these guns are old, police service guns that are beat up. I’ll take them and blueprint the action, removing fore-and-aft play in the yoke and cylinder, and establishing the proper clearances between the cylinder, frame and barrel. I’ll turn back the barrel one turn, and recut the forcing cone to set the proper B/C gap. I’ll add a dovetail up front, clean up the internals, put a 14K gold bead or platinum line sight up front, and do whatever else the customer wants. Recently, for myself, I took a Model 64 and installed a Model 66 barrel and cylinder on it, cleaned everything up, and gave it a nice finish, making my own K-Frame “Ladysmith” version.

RG: Is there a particular model, brand, or platform that you prefer to work on?

DL: I’ve got the most time on the Smith & Wesson revolvers and it seems like they’re easier to slick up on the inside than the investment-cast Rugers. I prefer the older Smiths, but will work on the new ones too—I just won’t pull the barrels on guns made after 2000, because myself and other trusted gunsmiths have found that it’s too easy to crack the frames during barrel removal. Unfortunately, we’ve encountered this problem frequently enough that I no longer attempt it. I can clean up their actions really nicely, though.

RG: Is there anything that you would like customers to know/understand about your services or operation?

DL: I’m a one-man shop, and I handle all the office work, too. I don’t have a secretary—I take all the calls and open all the mail, and I work 40-60 hours per week, so I can’t turn major jobs around quickly. Lead times vary, depending on the job. I’m currently about 12 months out for full custom jobs, but can still do some smaller ones like sights or triggers fairly quickly. I’ve got some customers that are sending me several guns at a time for full custom work, so it’s easy to get behind quick on the big jobs.

RG: How would you prefer RevolverGuy readers to contact you?

DL: Email is probably the best. I’m really good about responding in a timely fashion to all the emails I get. I’ll answer the phone, too, but if I’m busy working on something where I can’t be interrupted, then I won’t be able to answer. Please don’t contact me on Facebook Messenger! A lot of people share my work on Facebook, and others see it and try to contact me through that, but it won’t work. The best way is by email. You can reach me at: [email protected]

QPR Precision Gunsmithing

Milt Morrison is the proprietor of QPR Precision Gunsmithing, and is a proud graduate of the reknowned Lassen Community College gunsmithing school, where he started his journey to becoming a Master Gunsmith.

Milt served as a gunsmith for the California Highway Patrol for 10 years. He also served as shop foreman for the legendary Bill Davis operation (Cake-Davis, at the time—giants in the PPC revolver business, who popularized the “Smolt” conversion first done by Ken Kagahiro), and owned and operated Qualite’ Pistol and Revolver, a highly-rated gunsmithing operation in Denver, CO, where he designed, manufactured, and distributed after-market parts for Ruger single action revolvers. He’s also served as a training and firearms consultant to a host of military and law enforcement agencies, and has worked for numerous firearms manufacturers.

With an extensive resume of factory certifications and industry experience, Milt is well-positioned to advise his customers and deliver guns that perform to the highest standards.

RevolverGuy Survey Questions:

RG: Would you describe your operation as “Part-Time,” or “Full-Time?”

MM: I run a Full-Time operation, here in Idaho, just a little west of Boise.

RG: Would you describe the central focus of your operation as “Custom” work, “Service and Repair” work, or a “Full Service” combination of the two?

MM: We’re really a custom shop, but we do service and repair work for the locals here, because there’s a demand for it and it helps to keep the lights on. I’m a Master Gunsmith by trade, and work on all kinds of firearms, but my real love is doing custom handguns.

RG: Do you have a specialty or area of emphasis that you are known for?

MM: I’m definitely known for my custom handgun work. I’ll work on any and all handguns—autos, revolvers, single and double actions. I just finished a DoD contract working on a 1,300 Meter rifle, so I do the long guns too, but my custom handguns are my specialty.

RG: Is there a gunsmithing service or product that you offer which you feel is unique in the marketplace?

MM: I think one thing that sets me apart from some gunsmiths is that I work to maintain the manufacturer’s specifications, using the manufacturer’s parts. There’s a number of gunsmiths who will alter springs and substitute aftermarket parts when they’re working on a revolver action, for example, but that’s not my style. Instead, I’ll hand-fit and adjust the base parts to create an excellent action that holds the factory specs. You don’t need to throw away the originals, and buy a bunch of new springs and parts to get a good action, you just have to understand the mechanism and know where to focus your attention to get a good result. Particularly when you’re talking about a defensive revolver, if you go outside of the manufacturer’s specs, you open yourself up to all kinds of liability issues, and there’s no reason to do that. You can get a great action—and a great action doesn’t have to be light, it just has to be smooth–within the limits set by the manufacturer, if you understand the gun.

RG: What kind of gunsmithing work do you like to do the most?

MM: I love working a gun from end to end, and optimizing the whole package. There’s not one task that I like more than the other, I just like making everything come together and work like it’s supposed to—perfecting the total package.

RG: Is there a particular model, brand, or platform that you prefer to work on?

MM: I love working on all of them. I was fortunate to work closely with the factory technicians at Smith & Wesson, Colt and Ruger, so I understand the factory specs and know what areas need a little attention to improve the guns.

RG: Is there anything that you would like customers to know/understand about your services or operation?

MM: When I attended Lassen, the senior instructor, Bob Dunlap, emphasized that we needed to have a deep understanding of how the gun functioned, before we could fix or improve it. I’ve spent almost 40 years learning how these guns work, working with the best engineers and technicians at the factories to develop a deep understanding of them. In some cases, I even helped the factories develop the specs for their products, so I truly know what’s going on under the hood, and I know how to extract the best performance from them.

RG: How would you prefer RevolverGuy readers to contact you?

MM: They can email me using the Contact Form on my website, or call me at (208) 465-0071. I may not be able to answer the phone right away if I’m working on something in the shop, but I’ll return the call if you leave a message.

The Gunsmith

Nelson Ford is a classically-trained gunsmith, having graduated from the prestigious Colorado School of Trades gunsmithing program in 1980, where he was taught all of the skills necessary to build, repair and service firearms, from stem to stern.

While at the School of Trades, Nelson demonstrated the qualities that would later make him a master at his craft, working with great precision, care and patience to produce top quality work the first time. To illustrate, when Nelson and his fellow students were assigned a project to dovetail two pieces of raw steel with hand tools, some of his classmates went through as many as 200 pieces of stock in the course of completing the assignment, but Nelson finished it with his two original pieces, after 80 hours of meticulous work, creating a perfect dovetail through which no light passed.

After graduation, Nelson sought out industry experts to help expand his education and knowledge base. He learned Heliarc welding from a friend and fellow gunsmith at the legendary Pachmayr Gun Works, and even visited Bob Chow, the renowned bullseye gun guru (and 1948 Olympic Shooting Team member), as the first stop on his honeymoon, spending all of his honeymoon money to purchase Chow’s remaining stock of parts–obviously, he married a great woman!

Nelson set up shop as The Gunsmith on 32nd Street in Phoenix, Arizona and has been gunsmithing for 41 years now, building a reputation as one of the premiere 1911 and Smith & Wesson revolver gunsmiths in the world. Nelson was acknowledged by American Handgunner as one of the top 100 pistolsmiths in the nation, and is proud to be one of the experts that Smith & Wesson turns to when they need help. He’s also grateful for the respect of his fellow gunsmith peers, who frequently hire him when they want a full-custom S&W revolver “done right.”

RevolverGuy Survey Questions:

RG: Would you describe your operation as “Part-Time,” or “Full-Time?”

NF: I run a Full-Time operation and work long hours to keep it going. On one side of my shop vise, it’s labeled “pain,” and on the other side, it’s labeled “effort.” There were times in the early days when I didn’t know if I’d make it, but I’m still here and the lights are still on!

RG: Would you describe the central focus of your operation as “Custom” work, “Service and Repair” work, or a “Full-Service” combination of the two?

NF: I’m a full-service gunsmith who specializes in 1911s and Smith & Wesson revolvers. I’ll fix them and build full-custom pieces, but I don’t work on any other platforms. If you bring me your plastic pistol or grandpa’s shotgun and want them repaired, I’ll hand you a card and a recommendation for another shop across town—I send more people to them than the Yellow Pages.

RG: Do you have a specialty or area of emphasis that you are known for?

NF: Most definitely. I am dedicated to working on the 1911 pistol and Smith & Wesson revolvers. I’ve become well-known for my work on the Smith & Wessons—in fact, (Smith & Wesson Historian) Roy Jinks once told me that I’d better not retire, because “nobody else works on Smith & Wessons like you, anymore!”

RG: Is there a gunsmithing service or product that you offer which you feel is unique in the marketplace?

NF: I think what makes me unique is that I have such a close connection with the guns. I truly love these old Smith & Wesson revolvers and understand them inside and out. These guns are in my blood, and I take great satisfaction in rescuing these old and battered classics, and returning them to service in better condition and operation than when they left the factory.

RG: What kind of gunsmithing work do you like to do the most?

NF: The most difficult part of working on a revolver is not going into the action and making it smooth, but getting the cylinder to spin freely and lock up in the right place. It’s difficult to get the yoke to line up the cylinder chambers perfectly with the barrel, to make the center pin line up properly with the hole in the frame, to set the proper fore-and-aft cylinder spacing, to get the ejector rod perfectly straight—these are the jobs that take the most work, and the most precision, and I really enjoy getting all of them right so a revolver will perform at its best.

RG: Is there a particular model, brand, or platform that you prefer to work on?

NF: I love the older Smiths, especially those made before the frame-mounted firing pin made its way into the guns in 1996. I don’t pay much attention to the guns made after 1996–I’ll work on them, but my passion is for the older guns. Incidentally, while I’m a total nut for any of the prewar guns, I have a special love for the guns modified by the D.W. King Sight Company, which I enjoy collecting.

RG: Is there anything that you would like customers to know/understand about your services or operation?

NF: I’m currently 40 days out on most small jobs, but the delivery schedule is always changing, so you need to talk to me about your job. I have a deep appreciation for, and understanding of these guns, and it takes time to get all the small details just right, so you can’t rush the work.

RG: How would you prefer RevolverGuy readers to contact you?

NF: They should definitely call me at the shop: (602) 992-0050. I don’t use the Contact Form that’s on my website (which we set up so long ago, and haven’t updated), or email, so give me a phone call. I can’t always answer it immediately, but I will get back to you as soon as I can if you leave a message.

*****

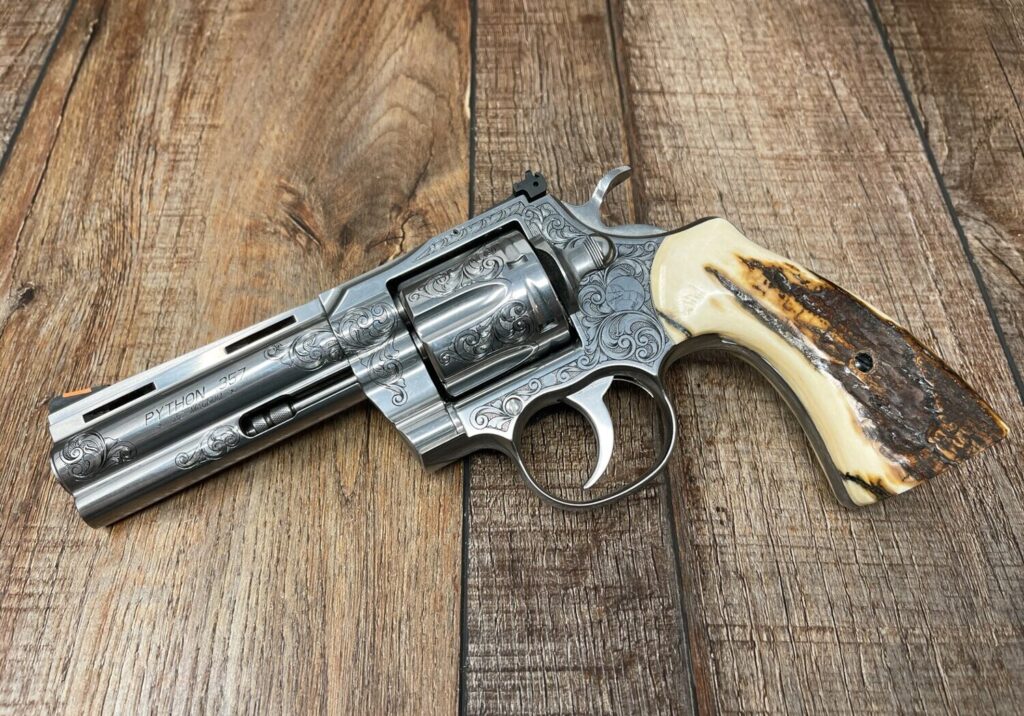

Featured Image courtesy of Defensive Creations

Mike, I’m sure I speak for all of us out here when I say these additions to revolverguy are incredible. The photos and the information are a great resource to tuck away for future projects.

I’d like to offer that perhaps if there is a third installment that it include Frank Glenn. His history in the wheelgun world is long and revered. He recently did a duty action job on my daughter’s new production S&W Model 10 that is not only smooth, but still reliable enough to ignite crappy imported primers.

His work on Colts is what makes him a bit of legend to many of us. A few years ago he tuned my grandfather’s battered 1917 back to service and it’s now a favorite at the range. Recently, he did some work on my new production Python that has made it an even better ICORE Classic division gun, which is saying something because they’re pretty darn spectacular right from the factory.

Thanks Brent, I actually reached out to Frank at the start of this project and he politely declined. He said he has so much work on the books already that it will last him to retirement.

I’m glad you got some guns done by him before he calls it quits! I’m sure they’re super.

Well nuts I guess I had a feeling you might say that. I think the first time one of this revolvers was on the cover of a magazine was the late ‘70s, so he’s more than earned retirement. I hope other smiths embrace the new Colts. Thanks again for a great article series!

Mike, this article put me in a happy place. Thank you for starting this Saturday off right! These guys give me hope for the future of classy and functional revolvers. I am starting a piggy bank to have one done down the road!

Thanks buddy, glad it put a smile on your face!

Beautiful photos, I keep getting ideas! Thanks!

Mike, thank you for part two, like Brent noted above, this series is to be printed in color and it then becomes my new Sears Christmas catalog.

For some reason I keep hearing Hannible Lecter’s words echoing in my ears, “What do we covet ? That which we see!”.

Anymore info on the ivory stocked beauty at the top?

Tony

Maybe we can get Dave, himself, to tell us. I’ll check.

Lord have mercy!–more excellent firearms “infrastructure” recommendations for anyone who desires high-end custom and repair work. Left to my own devices, it would have taken me a very long time to identify these experts and learn their specialties. Outstanding info.

Insulin For Eyeballs ! This gives a whole ‘nuther meaning to Eye Candy Overdose.

Stunningly beautiful works of art that, in my opinion, can only be truly expressed on the American classic revolver ! They are all priceless treasures for future generations to appreciate and admire.

So many thanks to these talented artists for sharing their workmanship !!

Tony, I am Dave Laubert the builder of that model 29.

It had the barrel swapped from 6 to 3, action job, trigger job, gold bead front sight, CCH by Tylers Gun Works in Texas. The ivory stocks were something the owner had aquired years ago.

Thank you for looking. I can be contacted by email: [email protected] or 330-823-6906

Thank you Dave. It is a beautiful revolver!

Mike,

Thanks for this next installament! Great stuff.

Can you tell us more about the unusual finish on the pair of bobbed hammer, 2″ S&W revolvers that appear as the first pic on the Defensive Creations write up? They look like they may have started out as nitride or PVD, but whatever Mr. Laubert did with them is very cool work.

Thank you again!

Chris, that’s a conventional, bone-charcoal case-hardening. Beautiful, isn’t it? Reach out to Dave for more details about it.

Wow! Superb information and well presented Mike! It was easy to read through your questions for each gunsmith because they were all the same and gave a each response the ability to be compared to the others.

They all have much in common (expertise, craftsmanship, quality, knowledge) yet they have their own unique focus.

Great job Mike!

Thanks Steve! This has been a lot of fun, getting to know all these superb craftsmen, and learning about the unique twist they each put on gunsmithing.

It makes me wish I had a box full of old Model 10s for them to work on!

Thanks for yet another great article, Mike. So many ideas…so little time. I’d bet that case coloring would sure look snazzy on an old 2″ Model 10. Now where did my wife hide the checkbook?

It sure would! Check the drawer in the kitchen . . . I think I saw it in there, next to the IOU for your birthday. ; ^ )

I just recently had Mr. Sokol build a 3″ m10 from one of the frames from jgsales. I’ve been very pleased. It was really well done.

Ryan, thanks for the great testimony on Karl’s work. I’m sure he did a super job on yours! I wish I could have purchased a handful of those frames from JG!

All of these gun smiths appear to not have working websites.. are any of them still in business?

Hi Raphael,

Bobby Tyler is definitely still in business, and his website is working.

Unfortunately, Karl Sokol has passed away in the interim.

Dave Laubert’s website is still working, and he’s still in business. He tells me that he’s about to open up his books for new orders, since he’s almost caught up with his backlog of old orders.

Milt Morrison had to slow down for a bit to take care of family, and shuttered the website, but is getting things back in gear. I think the website should be functional again soon.

Nelson Ford is still in business and his website is still working (it was never very robust—just a landing page with contact info—best to give him a call).