When you grab a fistful of revolver, the interface between man and machine begins with the grips (or “stocks,” if you’re a Colt guy) on the gun. The shape of the frame certainly has significant bearing on how the gun will feel in your hand, but a good set of grips can make it feel like an entirely different beast.

They can also make it look like an entirely different gun. Even the most pedestrian gun can suddenly look like a movie star with the addition of a handsome set of grips, and a fancy gun just doesn’t look right to most folks, unless it’s wearing a set of custom stocks.

Such is the magic of a good set of grips, so I was exceptionally pleased to meet one of the industry’s best masters of the grip making craft, Scott Kolar. Scott is the owner and operator of SK Custom Grips, and has been transforming chunks of wood and bone into functional works of art for over twenty years. I was particularly impressed with his work, and knew the RevolverGuy audience would love to learn more about his journey and his products, so I was grateful when he agreed to sit down with me for an interview.

Filling a void

At its core, Scott’s story is one of good old-fashioned American ingenuity.

In the late 90’s, Scott wanted a set of custom grips for his Ruger Bisley Blackhawk, but couldn’t find any that fit his hand well, so he decided to make his own.

Scott didn’t have any prior woodworking experience, but with encouragement from members on the (then) new Sixgunner Forum, where he was starting to hang out, he began to work on a pair of grips for his Ruger. “The first set was horrible,” he said, but he learned from his mistakes and kept trying until he finished a good pair, made of mesquite.

Excited by his accomplishment, Scott posted a picture of them on the Sixgunner Forum, to share with his new friends there. He was surprised when a fellow forum member immediately offered to buy them, and even more surprised when the gentleman offered to contract for ten sets, total. Scott laughed when he told me that the buyer explained, “I want to get a collection of these before you’re famous.” I guess he could spot talent, early.

Gaining airspeed

Scott’s work gained more attention on the forum, and soon he was approached by gunwriter John Taffin, who wondered if he could “do something” with a box full of Italian, SAA clone grips that Taffin had immediately replaced with better looking alternatives. The reddish-stain that the Italians had used to excess hid any trace of the wood’s grain, and Taffin hoped Scott could refinish them, and make them attractive and useful again.

Scott did the work, and Taffin liked it so much that he did an article on the refinishing job, and soon placed orders for giraffe bone 1911 grips and more revolver grips, which Scott was happy to fill. Scott’s work was soon showing up regularly in John’s books and articles, and in those of other writers, such as Max Prasac.

This publicity led to more orders, including many from custom gunsmiths who were looking to finish off custom projects the right way. Soon, he was making grips for the likes of Dave Clements, Hamilton Bowen, Andy Horvath, and the late, John Gallagher, among others.

What had started as a simple project was now quickly bypassing hobby status, and turning into a part-time business for this full-time Air Force officer. It wasn’t long after he started that Scott hung out his shingle as SK Custom Grips, and as the orders started to come in, he found himself dedicating more and more of his off-duty time in the shop.

Big moves

One of the bigger projects that helped SK Custom Grips to get noticed was the Engraved Ruger Single-Six (RSSE) model, launched by custom gunsmith Bobby Tyler in 2019. Bobby made 100 of these engraved, case-colored, rimfire masterpieces, and Scott hand-fitted each one of the frames with a set of beautiful, handmade walnut grips. “Bobby insisted on the very best walnut for the RSSE project,” Scott said, “and they really turned out great.”

Scott also hand-fitted the grips on each of the 150 extra guns that were produced as Lipsey’s Guns Exclusives. The Lipsey’s Exclusive Ruger RSSEs were not engraved, but featured Bobby’s case-colored hammer and trigger, and Scotts walnut grips. “The wood wasn’t as high of a grade as the Tyler guns, but it was still beautiful,” said Scott.

All 250 sets of grips were churned out by Scott in just a few months—it took a big push to get them all out the door, mated to their individual frames, but the results spoke for themselves and established SK Custom Grips as a shop capable of working both small and big jobs.

Materials

While Scott started his grip making journey with mesquite, he’s since worked with “just about every species of wood in the world,” as well as animal bone.

Exhibition-grade, American Black Walnut (“I won’t buy the regular stuff, only the wood with intense figure–AAA”), burl Mesquite (“Unlike Maple, Mesquite doesn’t generally grow burls, so there’s not a lot of it out there”), Ironwood (“There’s a lot of figure in Ironwood”), and exhibition-grade French Walnut are favorites at SK Custom, when it comes to wood.

His bone mainstay, however, is even more exotic. Scott sources mammoth ivory, from all over the world, for clients who want an especially unique look. It’s difficult and expensive to obtain–and getting more so, all the time, due to recently-adopted export restrictions in countries like Russia, who has just declared it a cultural artifact—but also stunningly gorgeous. Scott says that a defect-free piece of clear mammoth ivory, “looks as close to elephant ivory as you can get—like a 50-to-75-year old piece of elephant ivory.”

Careful work

Mammoth ivory is increasingly expensive, though, and there’s a lot of waste and scrap involved in working with the material. As Scott explains, most sellers require a minimum order of 100 blocks, but a full 30% or more of them may not be any good, and will go in the trash. The suppliers don’t sort the good cuts from the bad cuts, so there’s a lot of waste in purchasing the mammoth ivory–“I usually expect a 50 percent attrition rate when buying 100 to 200 blocks,” he says.

Unfortunately, he’ll encounter even more losses when he actually starts to work with the material, because there are many interior flaws waiting to be discovered in the ivory. The tusks delaminate in the ground, and once you start sawing, cutting, and drilling the ivory, you’ll find them and have to scrap the piece. The mammoth ivory will crack while you’re working on it (“usually about five minutes before you’re finished,” Scott says, sarcastically), and it will have to go right into the trash can with the other scrap. Once he can find a stable piece of the material, though, it will stand up to the rigors of shooting with normal care. He hasn’t had any of them returned yet.

The sourcing difficulties and manufacturing losses definitely drive up the cost to the consumer, but the end result is so phenomenal, that many are willing to bear the cost of mammoth ivory. Just look at the stunning colors and patterns in the photos, and you’ll understand. No two sets of ivories are alike (“they’re all snowflakes,” says Scott), and they lend a beautiful sense of individuality to a custom project.

Wood is good

Fortunately, working with wood is a less difficult task, and there’s less scrap and waste (and therefore, less expense) involved, which is probably why about 80 percent of Scott’s work is done in products like French Walnut or burl Mesquite.

It takes a fair amount of work to source these high-quality materials as well, but Scott has good relationships with his suppliers and can get what he needs for his special creations.

He also has some inventory to work from. In example, he still has a supply of French Walnut blanks from a lucky find, in Washington state, from about 30 years ago. Back then, he found a lumber mill with end cuts from shotgun stock blanks that were about 8-to-10 inches long–perfect for his needs. “If you can believe it, they were burning them like regular firewood,” Scott said, so he arranged to purchase the whole lot at a bargain price, and “filled a dump truck full of them.” He’s still making some stocks from that supply of blanks.

In the shop

One of the biggest hazards of the job is the dust created by all this work. Scott knows about the dangers of working with wood and bone, and was recently cited in an American Handgunner column, by gunsmith Greg Derr, who pointed out that some woods even release toxic oils when sanded, thus adding to the risk.

As you can imagine, it’s not healthy to breathe in all that wood and bone dust, so Scott has had to invest heavily in air filtration systems and personal protective equipment for the workers. There are rigorous dust abatement protocols that must be followed—not only for safety, but to prevent them from getting buried under mountains of sawdust!

Speaking of his workers, Scott started as a one-man operation, but before long, he added a little bit of help in the shop as the part-time operation slowly turned into a full-time operation. Scott’s team is made up from military veterans, like himself, and includes folks like Jake Danik, the young man in the photos that accompany this article. Jake served in the Air Force, doing sheet metal work on F-15s, and now he’s turning out beautiful custom grips as part of the SK team. Scott describes him as “a perfectionist in all that he does,” and expects this trait will serve him well after he completes his formal gunsmith training at the Pennsylvania Gunsmith School.

Another one of Scott’s essential team members is Gary Cannon, an Army vet with a mechanical mind and skilled hands, who’s the Go-To Guy for just about everything in the shop. When he’s not making exquisite custom grips, he’s designing and building the jigs and tooling that they rely on every day. Gary was actually the creative problem solver who put much of the shop together, which is probably why Scott refers to him as his “MacGyver.”

Scott’s proud of the team he’s assembled, and for good reason. They’re great folks, doing great work. As he says, “we’re all proud of our military service here at SK Grips, and we are even more proud to bring that level of attention to detail that is engrained in all of our Airmen, Marines, Sailors and Soldiers.”

Favorite guns

Scott says SK Custom has made thousands of grips for 1911s, and revolvers from Colt, Ruger, and Smith & Wesson, but one of the curious standouts was the high number of Freedom Arms revolver orders they’ve received. He estimates about 30 percent of his revolver grip orders are for the Freedom Arms guns, which is quite high, considering the small number of guns they produce every year.

Scott speculates that he gets a lot of orders for the Freedom Arms guns because the factory offers a relatively limited choice of grips for these near-custom guns. I think the OEM wood and micarta grips are well-made and functional, even attractive, but the guns are so uniformly excellent that they probably deserve a higher grade of grip than you can get from the manufacturer.

Scott admitted to being a HUGE fan of the Freedom Arms revolvers, and considers them the best revolvers made. He observes that they’re built to exacting tolerances, and are exceedingly rugged, yet “look like fine artwork.” In his experience, they’re built, “like Swiss watches,” but demonstrate a standard of accuracy, functional reliability, and longevity that is unmatched in the industry.

The Freedom Arms guns have always impressed me too, ever since my first exposure to them in the early 1980s, and I agree with Scott’s impression that they’re the “cream of the crop,” but they look even better when they’re wearing a set of his custom grips. I saw several like this at the 2021 Shootists Holiday, and each was more handsome than the next.

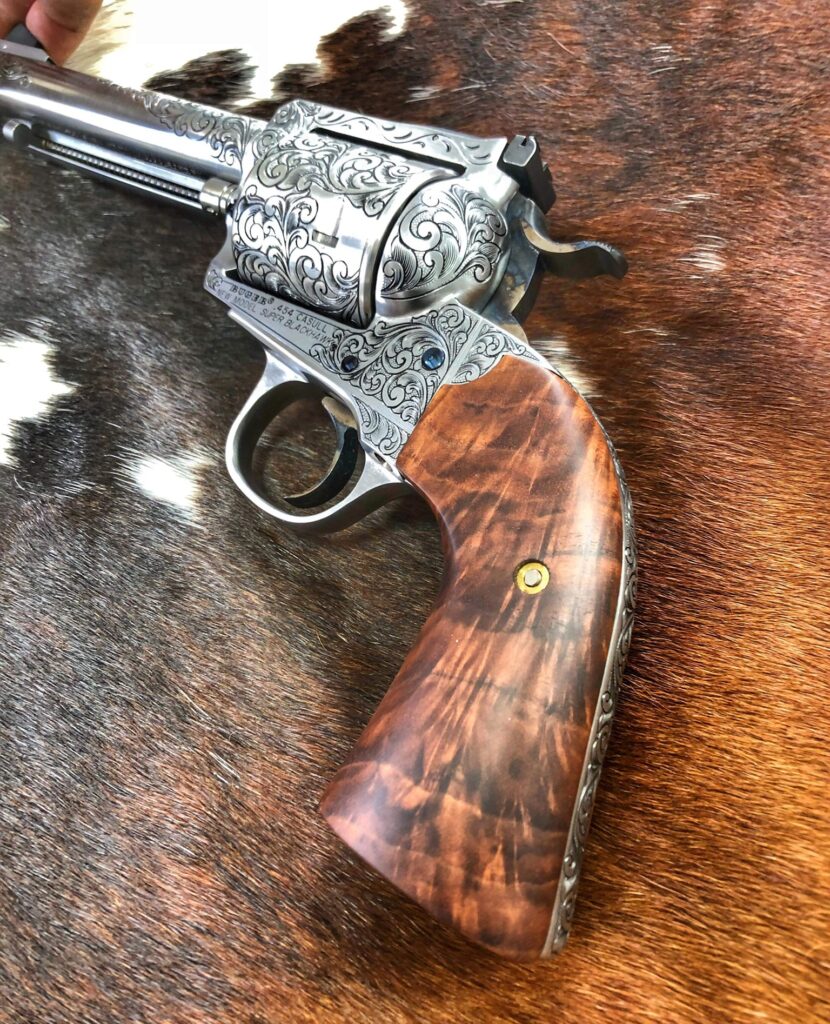

They’re tough, too. To illustrate, Scott noted that he made two sets of burl Mesquite grips for a pair of .454 Casull Model 83s owned by his fellow Shootist, John Killebrew, around 2000. John is a shooter, and doesn’t baby the guns. Over 20 years, and 10,000 rounds (Wow!) later, the grips are still in great shape.

I’m sure the grips would outlast my wrist, firing a truck full of .454 Casull! Hat’s off to both John and Scott for the accomplishment!

Busy times

There’s a lot going on at SK Custom Grips right now.

To start with, SK Custom just moved into a new and larger facility that will provide the space they need to meet growing demand. As you might expect, moving an operation from one shop to another is not an easy process, and has made a busy schedule even busier.

Scott’s excellent work has also grabbed the attention of several big outfits, and he’s signed contracts to produce custom grips for a number of special projects.

In example, the world’s largest Nighthawk Custom retailer, North East Custom Outfitters (contact information, below), has asked Scott to build grips for their full inventory of Nighthawk Custom 1911s, to include custom ivories and even some grips made from unique materials like old whiskey barrels. There’s also a possibility that Scott will be working on some grip designs for the Nighthawk-Korth revolvers in North East Custom Outfitters’ sales inventory.

SK Custom is also busy working on several new designs for popular Colt and Smith & Wesson revolvers. With respect to Colt, Scott advises the new 2020 Python’s frame is changed enough that the inlet on older custom stocks is not a good match for the new guns, so the SK Custom team will remedy the situation by making new custom grips for these beautiful guns.

A good niche

With the move to a bigger facility and the addition of several large contracts, it might look like SK Custom is focused on expansion, but Scott says he doesn’t intend to take SK Custom down the production-level rabbit hole. “We enjoy working with individual customers, and don’t want to be dragged into doing high-volume work,” he said. “We want to stick with doing unusual, high-end products—the kind that you won’t find duplicated on the other guy’s gun, when you’re at the range.”

“There’s a place for production-level products, like Altamont or Eagle Grips, but that’s not who we are.”

As things stand right now, there’s certainly enough demand to keep SK Custom busy in their chosen niche. Scott advises that current lead times are only about two to three weeks for revolver grips, which is “unheard of in the industry,” but encourages customers to contact him for a more reliable estimate, when they’re ready to start the process.

With an eye towards the future

Scott has SK Custom where he wants it, for now, but that doesn’t mean he isn’t planning for the future of the company. Their new, larger facility, for example, will definitely give them options that they didn’t have before, and create potential opportunities for growth.

In the meantime, though, he’s focused on doing what he does best—making beautiful custom grips from the best–and often the most exotic—materials. He takes great pride in being part of a small club of craftsmen doing this kind of work. “There’s not a lot of guys out there who do what I do—you can probably count them on less than two hands,” says Scott, and he has thoroughly enjoyed the journey so far.

All of us here at RevolverGuy are excited to see where the road takes him next!

*****

For more information:

SK Custom Grips

North East Custom Outfitters, LLC

86 Washington St, Suite 1

Holliston, MA. 01746

Thank you, Mike, for highlighting the work that Scott and his guys are doing. It’s inspiring to see men that are willing to go the extra mile to provide true craftsmanship in the “good enough is good enough” world that we live in!

Isn’t it? It’s also nice to see the younger generation be a part of it.

Having tinkered with furniture-making projects for many years, and struggled with many gnarly types of wood, I can appreciate the difficulty that Scott has with cutting and shaping mammoth ivory handgun grips. Without a doubt his are the most gorgeous examples I’ve ever seen.

They’re really beautiful, aren’t they? He and his team do some phenomenal work.

I don’t have any woodworking skills or experience, but can appreciate the talent that goes into a set of grips like those.

Fantastic article Mike! I have a set of bison bone on my Colt 1911 that SK Custom made. They look so similar to ivory and have that slick but warm feel just like ivory. But the cost was so inexpensive! Too bad he has such a hard time getting it now. I loved that it was American Bison bone, but Scott said that it has become crazy expensive because companies are paying high prices for it to be made into dog chews! Crazy!

Dog chews? Whoa! I wouldn’t have anticipated that. Thanks for the personal testimony about Scott’s great work!

Great article on some outstanding craftsmanship. Proud to see Mr. Kolar keeping our former military members gainfully employed. An Eagle “Tin Bender” looks right at home and a “Sourcer/Scrounger/McGuiver” is a PLUS regardless the business! Now, I just need to decide what I need restocked…

Right ON, DB!

Another home run Mike. These folks were not on my radar but they darned sure are now.

Your articles on custom revolver smiths and makers of high quality accessories have become my reference guide to spend those next few retirement dollars I can ease over into the fun gun fund. My wife has probably taken you off the Christmas card list as an bad influence on me.

Remember Dr. Hannibal Lecter’s truism, “What do we covet? That which we see!”

Keep them coming!

Thank you.

Tony

I’ve been excommunicated before I even met her! I’m going to have to find a way to redeem myself. Perhaps an article on a leather maker will do the trick? Let me know. ; ^ )

First Chig’s grips, now this… I’m going to have to buy some additional grip holders!

It’s suprising to me that this excellent article and its fine photographs haven’t received more comments. Maybe it has to do with the changing profile of gun owners, that is, the ones who are really into ugly black plastic firearms.

Thanks Spencer. Those types don’t hang out here much, though.

I learned pretty early that I was a poor judge of what would generate comments. Some of the “surefire winners” would barely solicit a peep, while some of the “filler articles” would generate heavy discussion. I gave up trying to estimate the response long ago, and just focus on putting out quality material that I would enjoy reading, myself.

I’m always grateful for the comments, and LOVE hearing from the readers, but don’t judge an article’s success by them!

I’m glad you liked the piece and Scott’s stunning work. He’s a real craftsman and a real gentleman, as well. Thanks for writing!