Every once in a while, there’s a product that comes along that makes you wonder how you got along without it. I’d definitely put The Wyoming Sight Drifter into that category.

Hiding in plain sight

I’d seen the Wyoming Sight Drifter in one of the gunzines years ago, and thought it looked like a good piece of gear, but for whatever reason I didn’t rush out and buy one. I knew it was out there, but I didn’t pull the trigger on it.

I wasn’t sufficiently motivated to purchase one until I received a phone call from friend Dean Caputo, who raved about the product and urged me to get one without delay. He described how he’d used the tool that day, to move an exceptionally stubborn sight, and how he didn’t think he could have done the job with a traditional hammer and punch setup. Most of you know that Dean is a highly experienced and very knowledgable armorer, and I value his opinion greatly. If Dean thought this thing was that great, then I had to have one. It was time to get off my rear end and finally order my own sample.

Good timing

The timing for Dean’s call and recommendation was excellent, because I’d recently had one of those “Aw Crud!” moments where I opened up the safe and an avalanche of stuff came spilling out. I guess I hadn’t been careful enough when I built my “Jenga tower” inside the safe last time, and gently closed the door, hoping it would all stay in place.

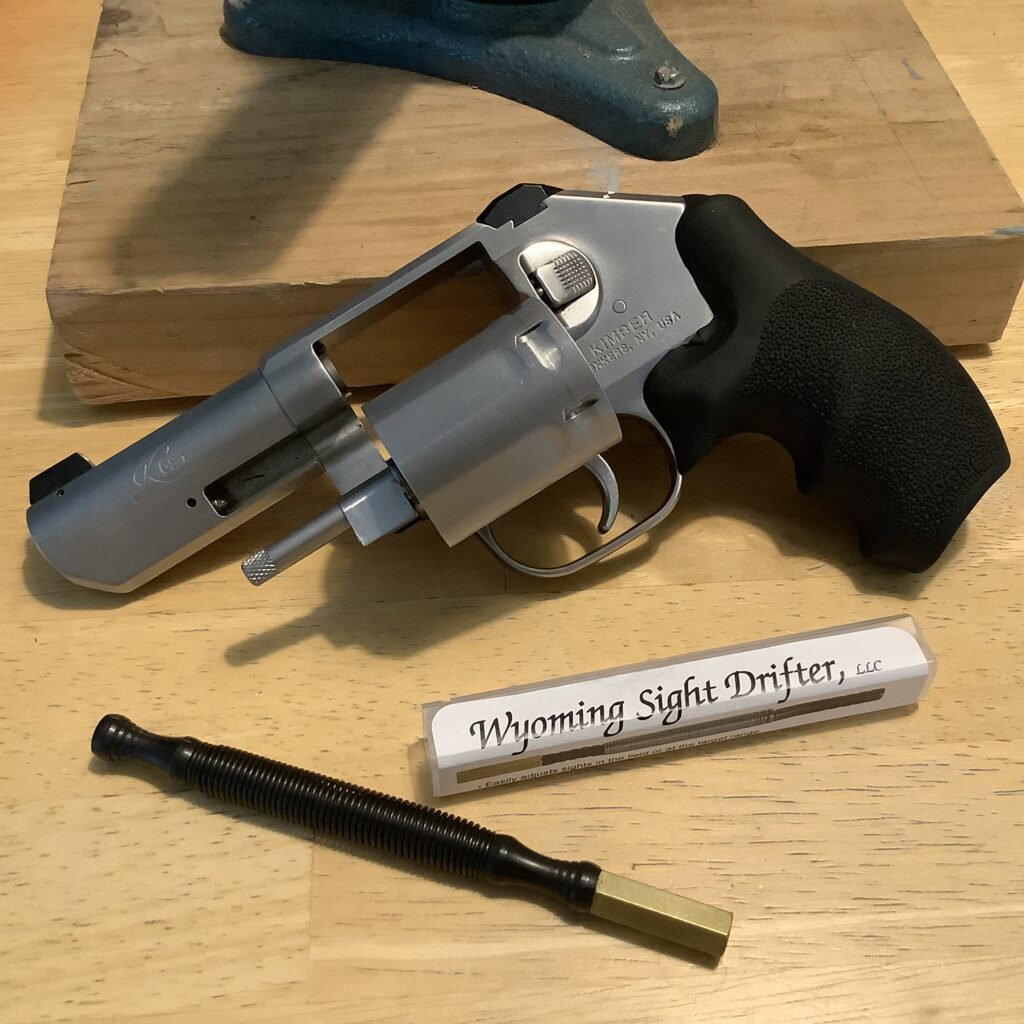

One of the things that took a tumble was my stainless Kimber K6s, in its zippered pouch. It made a good “thunk” as it hit the steel lip of the safe’s threshold, but looked to be OK when I gave it a quick inspection. I zipped it back up and tucked it away more securely, then went about my business.

A few weeks later, I brought the gun with me on a road trip, and it wasn’t until I got to my destination that I realized the gun had actually landed on its rear sight, which had been pushed nearly halfway out of the dovetail. Since I really wanted to shoot the gun on this trip, and wasn’t patient enough to wait, I borrowed some tools from my host and set to work trying to fix it.

Monkeys and footballs . . .

If there had been a camera filming me as I worked on that gun with the makeshift tools, I’d have enough video to produce three different movies: A comedy; A drama, and; A tragedy.

The short version is that I spent a good hour chasing that stupid sight back and forth in the dovetail, as I whacked it from side to side like a tennis ball over the net.

Most of the time, I’d hit the thing too soft and it wouldn’t budge, so I’d try a little more force. That wouldn’t work either, so I’d try even more. After a while I’d finally get the thing moving, but it didn’t go far enough, so I’d really give it a good whack, and send it clear over to the other side of the dovetail. Grrr.

Many bad words.

At one point, I realized that the gun had accidentally migrated off of the protective barrier I had set down before I started whacking on it, and wound up resting on the sharp edge of the metal bench, underneath. I had managed to put two gouges in the frame of the gun from smacking it when it was resting on that sharp edge.

Many really bad words.

Well, in for a penny, in for a pound. After getting close several times then screwing it up, I finally had to settle for “good enough,” put the set screw back into place, and hope it would do the trick. I knew the sight was still a little off-center, but I couldn’t get it where it needed to be with the tools I had.

When I shot the gun the next day, I confirmed my fear. The groups were OK, but they were all pushed over to the side because the sight wasn’t centered.

Crud.

help!

Disgusted with the whole thing, and not wanting to mess with it anymore, I put the gun away when I returned home, and let it sit in the safe. I was trying to build up my nerve to tackle the job with better tools, when I got the call from Dean.

Hearing about his big success with the tool, I decided to order my own, and see if I could fix the recalcitrant Kimber with it.

As I waited for it to arrive, I discovered another gun that needed to be fixed. I’d replaced the sights in a Glock pistol, and it turned out that I didn’t get the rear sight centered well enough with my pusher. I spent six hours in a gun class beating myself up for my poor trigger control, before I finally realized that the sight was the culprit, not my finger.

That made me feel better . . . and a little foolish, at the same time.

more power! argh, argh, argh . . .

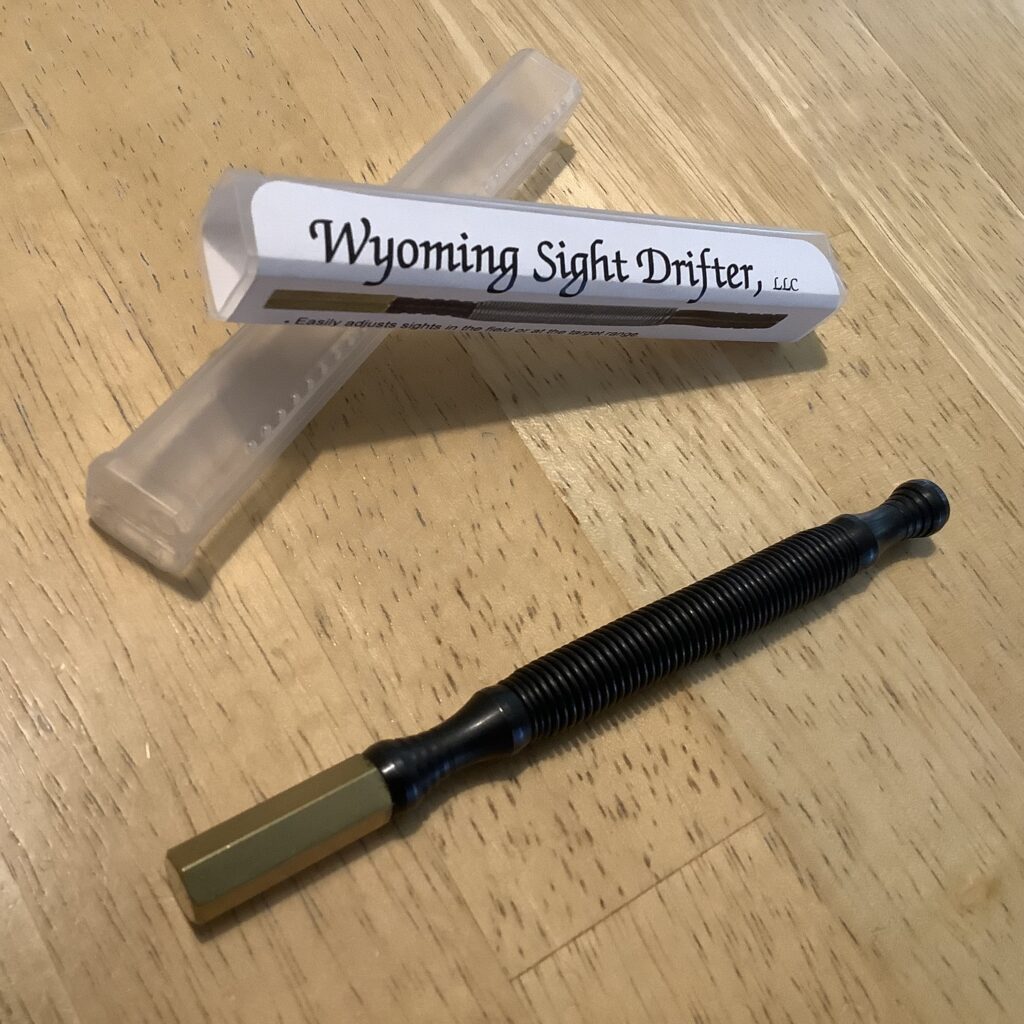

My salvation came in the mail a few weeks later, in the form of the Wyoming Sight Drifter (henceforth WSD, because I’m lazy).

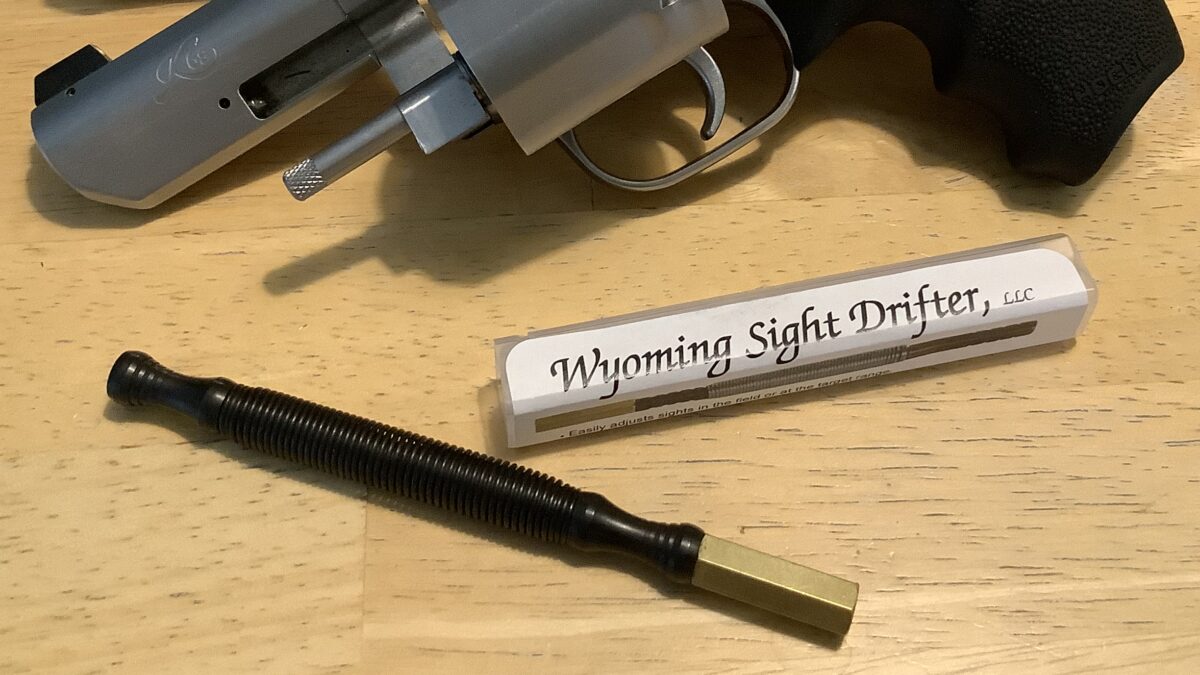

The WSD is a spring-loaded punch with a brass tool head on one end, and a pull knob on the other. The brass head has six flats on it, which allows you to rest the tool right where it needs to go. You can nudge the head right up against the base of the sight, and the flat edge will help it to stay put, and not roll, skip, or walk out of place, like the rounded punch I had unsuccessfully used before.

When the hexagonal head is in position, you hold it there with one hand, then pull the knob on the other end of the tool to stretch the spring. Releasing the pull knob will set everything in motion, and transmit the hammer force to the brass tool head. If you only need a little force, you only give the spring a little stretch, but if you need a lot of force, you give the knob a bigger pull.

Simple! Even Tim “the Toolman” Taylor could use this thing.

instant results

The thing that’s most surprising about the WSD is how efficient it is.

I had to really whack on that Kimber sight with my mallet and punch to get it moving in the dovetail, but just the tiniest little tug on the WSD’s knob was all it took to nudge the sight over. Dean reported the same, and expressed his surprise at how efficient the WSD was at transmitting the force to the exact spot where it was needed.

You can Whack! Whack! Whack! on a sight using a mallet and punch, or you can just tink tink tink on it with a WSD.

Best of all, the WSD makes it easy to make small adjustments. When I was playing tennis on the Kimber, I could never figure out the right amount of force to get the sight exactly where I wanted it, but it was easy to make fine adjustments with the WSD. That was particularly helpful when it came time to move the Glock sight, because I didn’t have to move it a bunch.

options

The WSD I purchased was the basic model, with just a single tool head, but there’s a double-ended version with a brass tool head on either end, and another version where one of the tool heads is nylon.

There’s also a version where the tool heads can be replaced with heads of a different size and shape. The latter might be real useful to a professional, particularly for pushing out various action pins, which the WSD is real good at, too.

The basic WSD is one of those things that belongs in every range bag. I’m really impressed with this little tool, which punches way above its weight.

Don’t make the mistake I did, by delaying your purchase. If I’d had one in my range bag, my nice Kimber wouldn’t be wearing two Idiot Marks in the frame, right now.

Get one for you, and another one for your buddy. It would make a perfect Christmas gift for your pal, and he’ll love you for it.

Now that is breathtakingly simple.

“The pinball wizard in a miracle cure.”

Don’t feel too badly about the idiot marks, even if no one here has ever done anything similar.

Haha! The list is “long and distinguished,” eh?

Pinball Wizard, I like that! I should have used that as a title!

This tool looks like a must have, Mike. I’m heading to their website soon. I feel your pain on ornery sights, I wonder how much foul language the WSD would have prevented over the years. It sounds like a lot just in my case. Thanks to you and Dean for the heads up.

You’ll wish you had one years ago!

A few years back I fabricated my own “sight drifter” by cutting six inches out of 1/4-inch round brass bar stock and slightly chamfering the ends. It’s nowhere as fancy looking as the Wyoming product but it does the job. But if I hadn’t made my own I’d be thinking about purchasing Wyoming’s elegant tool.

I’m a little jealous that you even need to make a Jenga tower of your hardware! Would hate to dump my weapons, although I’ve done so recently myself *cough* divorce challenges*cough* but I don’t intend them to languish in the safe looking pretty. Scars are stories. Anyway, I’m glad to hear it works on Glocks. I was qualifying with my backup (G43) which constantly prints left, and with all the buzz out there about righties shooting low left with gawks, I just figured it was me. Then one of our ordinance guys tries it, looks at it, says “your rear sight is off.” From the factory of course. He got it straightened out, but I’d like to think I could do this myself had I paid it any attention.

Yeah, I figured it was me doing the typical Glock thing, too. Felt a little dumb when I realized it was just the sights! Glad your armorer got you fixed up, Riley. They could probably make good use of this tool. BTW, sorry about the Big D buddy. Hang in there.

My only go round with a dovetailed rear sight was many years ago with my dad’s Hi Standard Sentinel revolver. It shot tight groups but to the right a little. I took the gun to the range with a nice brass punch and hammer. I got it shooting to the center of the target but I was a bit flabbergasted by the amount of hammer force required to move the sight. I recently bought a Wiley Clapp SP101 for my wife and we are waiting for it to come back from Gemini Customs. In the back of my mind I worried about having to whack on the rear sight of the gun if windage adjustment is ever needed. Your article has put my fears to rest. I will be purchasing a WSD tool as a Christmas gift to myself. My nephew recently purchased his first handgun, a Glock 19. I will be adding the WSD tool to his Christmas package of gun cleaning supplies. Thanks for the timely information.

I think he’ll like that very much, Derek! He’s lucky to have an experienced handgunner like you, to teach him the ropes.

I’m excited to hear about your Gemini SP101. I’m sure Marc will do an OUTSTANDING job for you, and I wouldn’t worry a bit about the sights on that one—Marc will certainly see to it that they are true!

My girlfriend can again blame RevolverGuy for the long list of future presents I’ll be asking for. Interestingly they have a very similar design to hammerless door hinge pin removal tools sometimes used by first responders.

Uh oh, sounds like we’d better avoid her calls. ; ^ )

That’s really interesting about the pin remover! I didn’t know about that tool, but they are remarkably similar. I wonder if that’s where the idea came from?

The funny thing is that i’m having a rear sight issue with my Kimber K6s as well: seems like the target sight’s rear sight is a bit loose in the dovetail to where it shifts around if I were to press against the rear sight (having int AIWB, say carrying a heavy object and pressing against it would move the sight) to where it was moved way off to one side. Trying to figure out how stop it from easily shifting. This sight punch def would help but haven’t found a good solution yet (that i can understand) that isn’t “put blue loctite in the dovetail as I re-center it.”

John, I can’t tell from the photos I see online, but it appears there’s no set screw in the base of the rear target sight (underneath the sight leaf), like there is on the fixed sight guns. If that’s correct, the only fix would be to replace the rear sight for one that fits better (Kimber Warranty Service), or add something in between the dovetail and the sight base, to make the fit tighter (an aluminum shim, some adhesive like LocTite, etc.).

Mike, thank you for the glowing remarks about my sight drifting tools! Glad you found it as useful as I have. Hope you’re well and Merry Christmas to you. Steve Anderson

Thank you Sir! I appreciate your work!

Great and thorough review, as always. Do you think this would work on sights that are extremely tight? Some companies seem to press their sights in with nuclear-powered hydraulics by an operator that apparently snorted coke right before his shift. My bench vice sight pusher begs for mercy as I add a cheater bar to turn the bolt, hoping the sight budges a little before I gall the frame. No set screws or anything, just a tighter fit than a ballot box behind the DNC HQ at 2am.

The XD is typically tight. The front sight on my LCP Max laughed at all attempts from both my sight pusher and a punch.

Haha! Ya got me with the ballot box, buddy! 😆

I have it on good authority from Dean that the WSD did a great job of pushing a recalcitrant S&W M&P sight that was plaguing him. Those M&Ps are some of the tightest fits in my experience, so I think that’s a good sign the WSD can tackle your XD and LCP Max, too. I think the WSD has a way of focusing the force exactly where you need it, making it more efficient than a traditional punch, and even some pushers.

Let us know how it works for you, OK?

Won’t need a sight drifter tool if your wheelgun has fixed sights. *big brain moment*

Nope, just a file, maybe!

I have similar spring-loaded tools for use as a center punch, finish nail driver, and door hinge pin removal. I never considered one with a brass tip for more delicate work! Just yesterday my daughter asked about Christmas ideas for me, and I was drawing a blank. Thanks for the heads up!

You bet, Steve. I think you’ll like it very much.

I didn’t wait until Christmas. Mine arrived today. 😉

I got the full kit with interchangeable pins and the optional Delrin pin. I’m always using pins and punches on various projects, so went for the full kit.

By the way, if anyone orders and you don’t immediately get a response, know that Steve at WSD is having trouble with his storefront provider. Seems orders were coming in and just going into limbo. Steve called and asked if it would be okay to simply send the tool out to me, and then I could send him a check when it arrived. That’s a trusting man in this day and age. A check will go out in tomorrow’s mail!

Thanks for bringing this to our attention!

Steve, thanks for the info about the storefront. That’s good to know, in case any other readers encounter a similar delay.

Steve at WSD is probably really frustrated by that, but it sounds like he’s giving great customer service and taking care of folks, which does not surprise me. Good man.

I bet you’ll enjoy that full kit! Let us hear from you when you’ve used it!

Steve at WSD called me after an online order couldn’t be processed with the same trusting offer. Hopefully my part of the bargain got there with equivalent speed.

Great tool and a really nice way to go into the holiday season.

Aric, thanks for sharing that! Steve’s obviously a good man, and is definitely giving everyone some great customer service. Makes me twice as happy that I recommended his products to the readers.

Mine just arrived.

Like a guy with a new hammer, now everything looks like a nail.

😆