In Part I of this series, we discussed the birth of the breakfront holster with the Berns-Martin design, as well as the development of competing designs from popular police holster makers Hoyt and Safety Speed.

We now pick up the breakfront saga where we left off . . .

Here comes the judge

John Bianchi had barely started his fledgling holster making operation out of his garage in Monrovia, California, when he started playing with the breakfront holster concept in 1960. Bianchi experimented with a series of evolving prototypes and limited production models for the better part of a decade before he finally catalogued his first breakfront duty holster, the Model 27, in 1970.

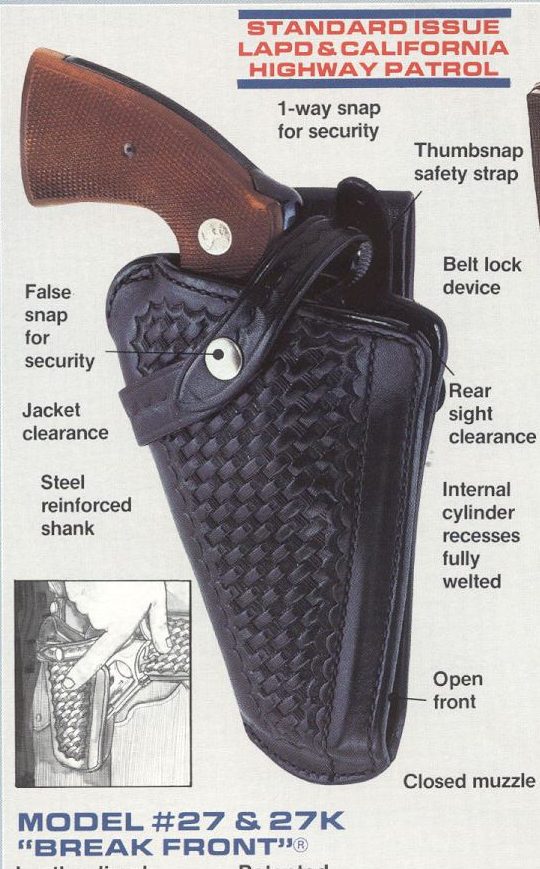

The Model 27 holster (U.S. Patent number 3,630,420, awarded 28 Dec 1971) was essentially an update of the Berns-Martin design, which used a new, L-shaped spring design that ran down the front of the holster and held it completely closed, instead of the cylinder-clamping U-spring of the older design, which left gaps in the front. The Model 27 used a sheet metal lining (later upgraded to tempered spring steel) in the belt loop to hold the holster offset from the hip for jacket clearance. It incorporated the trigger guard pocket of the Berns-Martin, and the Hoyt-like cylinder cutouts in the inner liner, to help position the cylinder and act as a lock to prevent an upwards draw from the holster. It also had a more efficient safety strap than the Berns-Martin, which was easily operated by the trigger finger as part of the draw (a similar release was later used on the Safety Speed design).

Some of the Model 27 improvements over the Berns-Martin were subtle, but there was one aspect of the design which marked a radical change—the Model 27 was designed for mass production. The Berns-Martin Company was a small outfit, and made their holsters by hand, so the output was always limited. In comparison, the Bianchi Model 27 was produced using tooling and methods that allowed for mass production. In fact, the manufacturing and production engineering aspects were the most difficult part of the design process on the Model 27. In an interview with RevolverGuy, Mr. Bianchi told us that the work performed by the in-house tool and die department (“the magicians behind the scenes,” according to Mr. Bianchi) to optimize the machinery, tools, and processes for manufacturing the Model 27 was so exhaustive, that “anyone else would have given up, because the reward wouldn’t have been worth the effort.”

Bianchi didn’t give up though, and the company was successful in meeting the demands of large agencies like the California Highway Patrol (1970) and the Los Angeles Police Department (1972), which made the Model 27 holster standard issue for their officers. The adoption of the Model 27 by these influential agencies secured even more business for Bianchi, which soon dominated the breakfront holster (indeed, the entire law enforcement leather goods) market.

In April of 1974, Bianchi acquired all rights to the Berns-Martin Holster Company (which was in the possession of acclaimed knife designer Walter “Blackie” Collins), including their designs, patents, and equipment, cementing their interest in becoming the foremost manufacturer of breakfront duty holsters. Work continued on the type, and on the heels of the phenomenal success of the Model 27, Bianchi introduced the Model 2800 Judge, which advanced the art considerably.

One of the problems with the Berns-Martin, Bianchi Model 27, and Safety Speed designs was the closed muzzle configuration of these holsters. The Berns-Martin holster was closed to incorporate a muzzle plug that was used for support and positioning of the muzzle. The Model 27 and Safety Speed designs were closed because the base of the closure spring was seated at the bottom of the leading edge.

The closed muzzle presented two complications. First, the holster body had to be longer than necessary, which could lead to interference when sitting. Second, as Jordan noted, the closed muzzle imparted more drag on the barrel in the finishing moves of the draw, which could cause overshooting and alignment errors.

The Hoyt breakfront, with its open muzzle, didn’t suffer from this issue, but the spring which held the Hoyt closed primarily exerted its force around the cylinder area, leaving little to no tension in the area around the muzzle. This less resistant spring made for an easier presentation, but sacrificed some security.

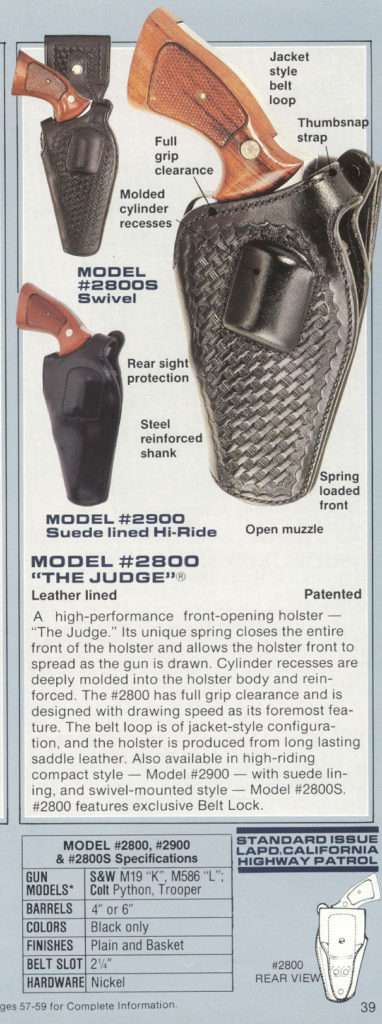

The Bianchi Model 2800 “Judge” (U.S. Patent number 3,977,583, issued 31 Aug 1976) was designed to solve this issue. The 2800 was an open muzzle design, with the leading edge of the holster split along its entire front. To hold the halves closed, the 2800 incorporated a pair of powerful springs that started behind the cylinder, running up and over it on each side, then down the length of the leading edge, to the very bottom. These springs kept the entire front seam of the holster closed in a secure manner, without imparting as much drag on the barrel as a closed bottom design. This greatly improved the quality of the draw compared to other breakfront designs, in essence providing the security of a Model 27 with the draw of the Hoyt.

The Model 2800 Judge also improved on the cylinder cutouts of the Hoyt, Model 27 and Safety Speed breakfronts by sandwiching a pair of metal cups in between the layers of leather, to hold the cylinder in place. On other designs, the upper edges of the leather cutout (where the rear edge of the cylinder would contact) could become worn with time, and lose their ability to resist an upward drawing movement. In the Judge, the metal cups that surrounded the cylinder added strength and helped the holster maintain its shape. Additionally, since the closure springs went around the cups, the cups helped to obtain a uniform clamping force on the gun in the holster. Lastly, the leading edges of the cups were covered by leather that had been skived to smooth the forward draw—something which had not been done on earlier designs.

The trigger guard pocket of the Berns-Martin (and later Model 27) was a solid safety feature, but often interfered with obtaining a proper grip on the gun. The Safety Speed offered an improvement with its cutout trigger pocket, but the Model 2800 took a different approach. Instead of wrapping the leather pocket over the top of the trigger guard, the Judge left this area open. The closure springs were routed through the leather on each side of the trigger guard to ensure that the leather sides would close firmly over the trigger guard area, and not allow access to the trigger while the gun was still in the holster. This also helped to retain the gun and resist an upwards draw, in conjunction with the metal-reinforced cylinder cups. The advantage to the design was that a full and uninterrupted grip could be achieved on the gun while it was in the holster. This novel feature disappeared on later versions of the Judge holster, however, presumably to ease production.

The Model 2800 Judge incorporated other helpful features, such as a Bucheimer-style thumb break that was more easily operated than the finger-release of the Model 27 or early Safety Speed, and also more resistant to a snatch attempt. Additionally, the Judge was designed in a manner that protected the rear sight with leather wings on each side, while still preventing the rear sight from contacting the sides of the holster during the draw. The 2800 also incorporated some advancements in the reinforced, offset, belt loop hangar, including an adjustable rubber spacer which locked the holster in place and prevented it from sliding and shifting position on the belt.

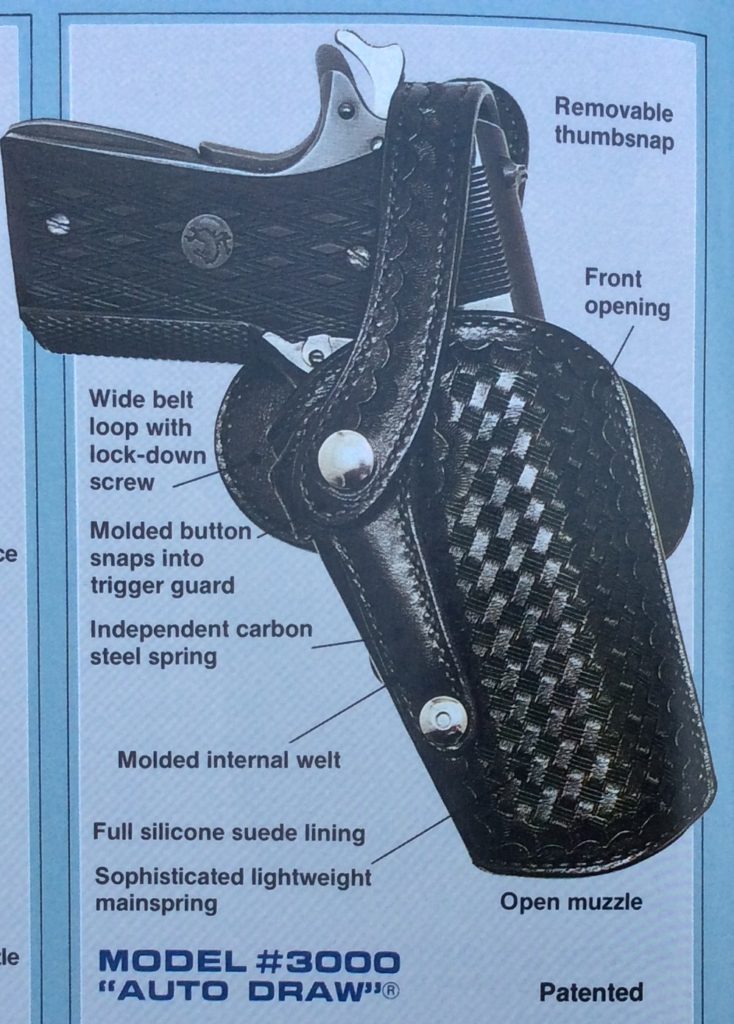

Upon introduction, the Judge holster immediately became standard issue on the California Highway Patrol, which issued it along with the newly-adopted Model 67 and Model 68 revolvers. It was similarly adopted by the Los Angeles Police Department. The Model 27 stayed in the Bianchi catalog for many years after the Judge was introduced, and remained popular in its own right, but the Judge was the new high water mark in breakfronts and found favor with many federal, state and municipal agencies. Bianchi continued to improve and refine their breakfront designs for revolvers into the 1990s (changing materials, construction and features along the way), and even launched a breakfront designed for the 1911 semiautomatic pistol (the Model 3000 “Auto Draw”), but the Model 2800 was always the standard by which other breakfronts were . . . well . . . judged.

Mr. Rogers’ other neighborhood wasn’t so friendly

By the time of the Bianchi Model 2800, most folks assumed the design features of the breakfront had reached a certain level of maturity where there wasn’t a lot of room for improvement. Everything had pretty much been tried by one manufacturer or another by the mid-to-late 1970s, and a kind of status quo had been reached.

Fortunately, Bill Rogers hadn’t got the word.

In the mid-1970s, Rogers wore many hats as a former FBI agent, a world class competition shooter, and the owner/operator of the newly-established Rogers Shooting School. He was also one of the most talented holster designers around, with an affinity for crafting police duty holsters.

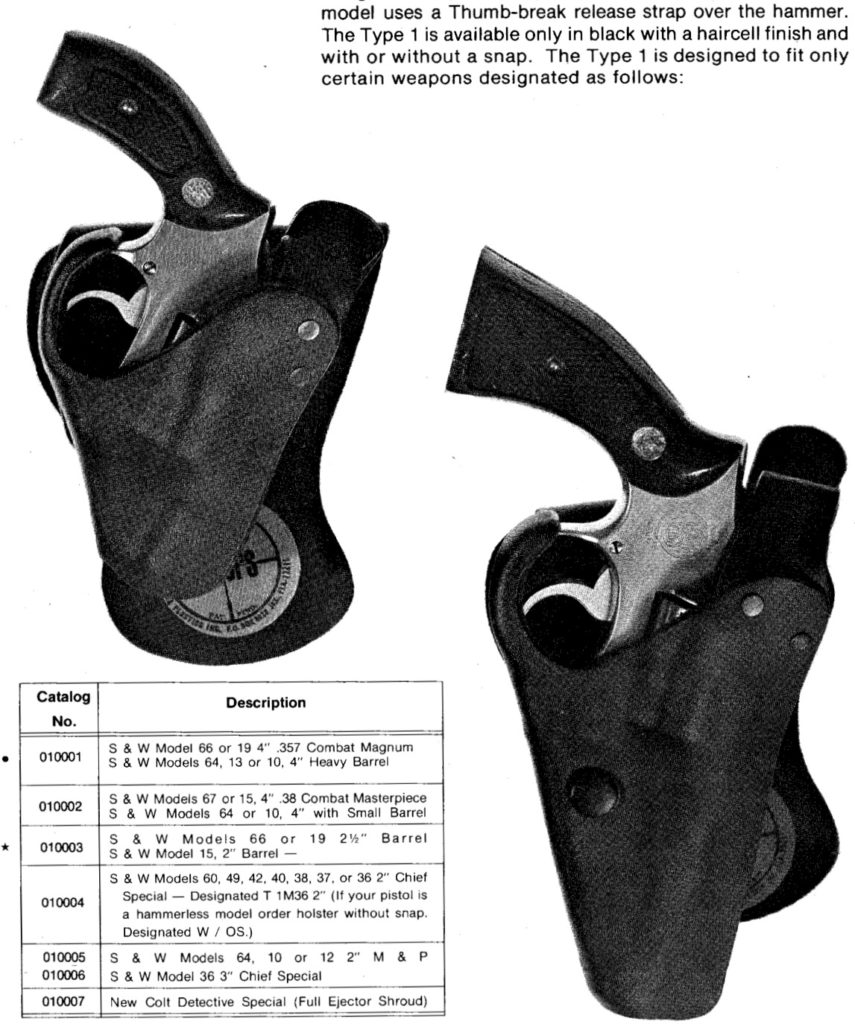

Rogers’ first holster design dated back to late 1972 (U.S. Patent Number 3,902,639, issued 2 September 1975) and gave birth to his holster business after he was awarded an FBI contract for it in 1973. The Rogers Type I Paddle Holster was a leather-lined breakfront holster with a shell made from polymer (Kydex-type material). The trigger guard area was open in the style of the times, but a curved pocket followed the contour of the guard and wrapped around the back far enough that it prevented a top draw. A simple thumb break retained the gun, which was rotated forward to release the trigger guard from the pocket, and allow the gun to come out the front seam.

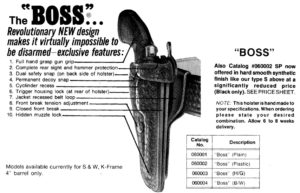

Although the innovative Type I had security features, it was a concealment rig for plainclothes investigators. It wasn’t a “security holster” for general duty use, so Rogers got to work in the late 1970s and designed the first purpose-built security holster for uniformed police officers, the Rogers BOSS.

The BOSS was a sophisticated design that used a variety of materials in its construction. The heart of the holster was a polycarbonate spine that began at the bottom edge of the holster and worked along the rear edge of the holster to the trigger guard area. Attached to this polycarbonate spine was a pocket for the gun that was made from a Kydex and leather laminate. The pocket had an open, breakfront-style seam down the front, and was held closed by a safety strap that wrapped around the front. The safety strap had a decoy snap on the outside, and a low profile thumb break release on the inside, which enhanced security. The safety strap also had a second position where it could be fastened, which enhanced security for situations that required a higher degree of retention, such as crowd control or prisoner escort.

The base of the polycarbonate spine incorporated a lock for the gun’s muzzle, which trapped it in position and prevented it from being rotated out the front of the holster by pushing downwards on the revolver grip. This rear-quarter disarm technique had become popular with savvy criminals by this time, and the BOSS’ muzzle lock protected against it.

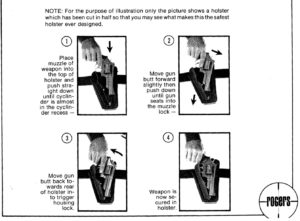

The spine also incorporated a trigger guard lock, which combined with a cylinder recess and the safety strap, prevented the gun from being drawn straight upwards out of the holster. To draw from the BOSS, a user was required to release the strap with the thumb break, then rotate the gun out the front of the holster, which would allow the gun to clear the trigger guard lock at the rear and free the barrel from the muzzle lock.

The BOSS is credited as the first police security holster (earning a “Level II” designation under the retention level standards that Rogers created), and it was an instant hit. It sold well in the United States, but it was the selection of the BOSS as the standard issue holster for the Royal Canadian Mounted Police, and all the provincial and territorial police departments in Canada, which kept Rogers in the holster business.

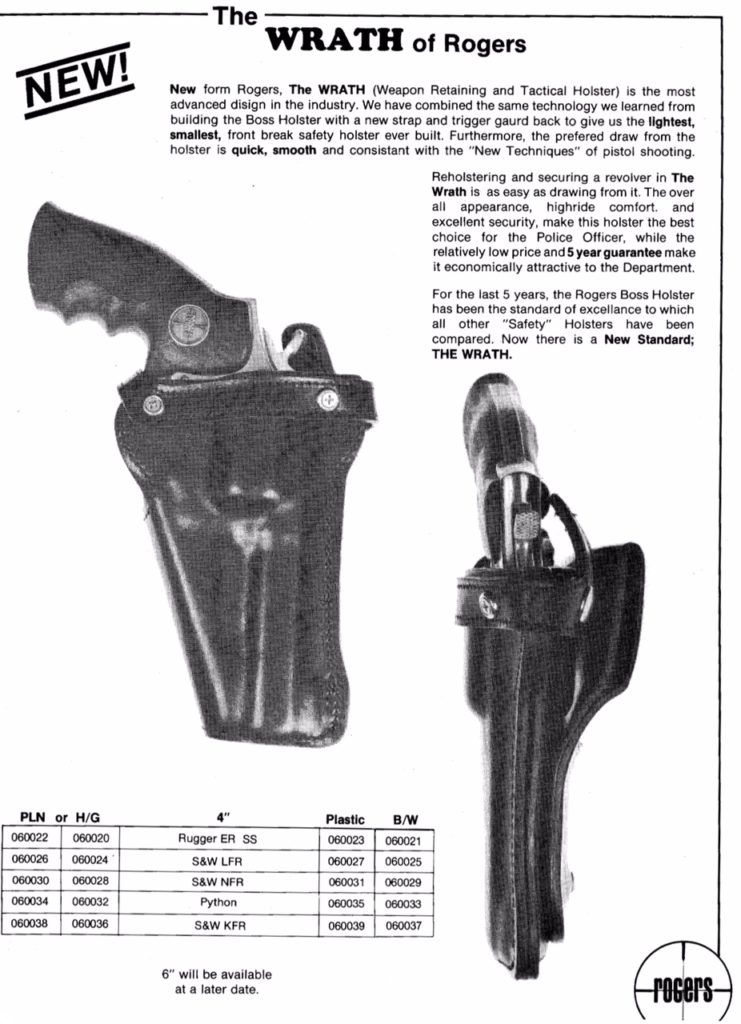

The Rogers WRATH (Weapon Retaining and Tactical Holster) advanced the breakfront art by simplifying and lightening the BOSS. In the WRATH, the polycarbonate spine was replaced by features which accomplished the same goals without the extra weight and bulk.

The leather-Kydex laminate WRATH was a breakfront design with a closed muzzle at the bottom. The closed muzzle achieved a similar effect to the muzzle lock on the BOSS, without use of the polycarbonate spine. The trigger guard lock was also omitted on the WRATH, but the routing of the safety strap behind the trigger guard, and the cylinder recess in the holster body, provided a similar protection from an upward draw / snatch attempt.

The safety strap which wrapped around the front of the WRATH helped to make it all work, as it did on the BOSS. The strap prevented the gun from being rotated out the front until the unique, hidden thumb break was released by the user.

It’s important to note that the Rogers BOSS and WRATH holsters pushed the envelope not only in their function, as the first security holsters for uniformed duty, but in their construction as well. The leather and thermoplastic laminate used in Rogers’ holster designs was a significant accomplishment and the process of creating, using, and shaping the laminate to create a custom-fitted duty holster (protected by U.S. Patent number 4,340,437, issued 20 Jul 1982) was one of Rogers’ key contributions to the industry. The laminate produced by Rogers Holster Company offered many advantages over traditional leather construction, such as resistance to moisture (including water, blood, gasoline, etc.), improved shape retention, the ability to use less expensive cuts of leather and cheaper tanning processes for the outer layer of leather, and improved rigidity for protection of the gun.

In 1983, Safariland owner Neal Perkins asked Rogers to accept a royalty payment in exchange for a Safariland-branded holster which incorporated his holster innovations. Rogers accepted the deal and updated the WRATH with a few cosmetic changes, to create the Safariland Model 275. For a few years, the Safariland Model 275 competed directly with Rogers’ WRATH, but when Rogers sold his holster company to Safariland in 1985, the Model 275 cornered the market for revolver breakfront security holsters.

The Rogers Holster Company SSII holster for semiautomatic pistols was a successful semi-breakfront design (becoming the long-lived Model 295 after the Safariland acquisition) which followed the WRATH, but by 1983 Rogers was ready to abandon his work on breakfront designs over concerns that they were too susceptible to disarms from the front, which his investigation had concluded was the most likely kind of attack that an officer would face. Instead, he turned his creative energies towards improved security designs such as the SSIII (which later became the industry-leading Safariland Model 070 after the acquisition), and changed the face of the police duty holster forever, in the process.

Talk about a revolution

When Uncle Sam adopted the Italian-made, Beretta 92SB/F pistol as the M9 in 1985, it accelerated a trend that had already begun in American law enforcement of switching from revolvers to semiautomatic pistols. The “Wondernine Wars” of the mid-to-late 1980s and early 1990s were soon in full swing, and when the dust settled, the revolver was mostly history as a primary duty gun.

Simultaneously, the breakfront holster virtually disappeared from the scene as well. The trigger guards on the new autopistols were shaped differently than the revolvers they replaced, and couldn’t be trapped in place by a pocket built into the holster like those on the round guns. As a result, with very few exceptions (such as the short-lived Bianchi Auto Draw or the more successful, semi-breakfront Rogers SSII / Safariland 295), the breakfronts didn’t make the transition to the autopistol era.

With the notable exception of the AE Nelson Leather Company, nobody is making breakfront police duty holsters anymore. Only the top draws remain, and they’re usually made of synthetics, like those that Rogers ushered in. The current crop of synthetic holsters are superior tools. They’re more secure, durable, economical, efficient, and easy to care for, but lack the appearance and charm of their leather forebearers. They certainly make the cows happy, if not the traditionalists.

In its day, the breakfront was perhaps the most popular police duty holster of all. It was faster and more secure than the Jordan holster with its awkward safety strap, and it was easier to draw from while seated in a car. It was more secure than the temperamental clamshell, and it was easier to reholster with a single hand. It easily outclassed the rabble of unimaginative top draw designs that polluted police supply catalogs throughout the 30s, 40s, 50s, 60s, and 70s.

For most officers, the breakfront offered an ideal combination of speed, security, and ease of use, which made it the King of police duty holsters in the revolver era. We won’t see the likes of it again.

The author would like to thank John Bianchi and Bill Rogers for their assistance with this article and for their outstanding contributions to holster development.

References

Adler, Dennis. John Bianchi—An American Legend 50 Years of Gunleather. Blue Book Publications. Minneapolis, MN. 2010.

Ayoob, Massad. “Safariland & Bill Rogers: The Rise of the Modern Security Holster,” American Handgunner Magazine, July-August 2016, https://americanhandgunner.com/safariland-bill-rogers/

Bianchi, John. Blue Steel & Gunleather. Beinfield Publishing. North Hollywood, CA. 1978.

Jordan, William H. No Second Place Winner. Police Bookshelf. Concord, NH. 1965.

Keith, Elmer. Sixguns By Keith. Wolfe Publishing Company. Prescott, AZ. 1955.

Aside from the holster advancements, there was a time when even though duty rigs might have all been the same – plain or basketweave, the one thing that could be personalized was the officer’s revolvers.

Back in the 1970s and 80s, many a small city department, and even many less affluent county sheriff’s departments, you bought your own sidearm and leather. Holsters were as varied as the catalogs from which they came. Even with agencies that issued everything, the revolver was where the most predominant form of personalization took place. The varieties of grips, wood and synthetic, allowed one to make a statement on what fit their hand the best. With polymer pistols, that’s all gone.

As Sam Andrews of Andrews Custom Leather (St. Augustine, FL) is fond of saying that real men wear leather: John Wayne would never be caught carrying a polymer gun in a polymer holster. The king isn’t dead. The absolute monarchy of the Service Revolver has been supplanted by the Polymer Parliament.

“Polymer Parliament” will henceforth be a permanent part of the lexicon here. Bravo, Sir!

Those rosewood stocks on the Python are an excellent example of the personalization you discussed, being handcarved to fit the user’s hand. Alas, we’ve lost a bit of the fine art in sidearms today.

All hail the King!

There really is a lot of interesting history here. We focus on the firearms (naturally) but forget there’s an entire industry around carrying them and providing them with ammunition. Keep up this series. Very fun and informative reading.

Glad you’re enjoying it! Tell your friends!

Sad to hear these are no longer available. Brink’s issued the Safariland when I joined them in’98, and I carried my model 64 in it until leaving the company in ’07… At least I bought the holster when I left.

“They certainly make the cows happy.” Classic Mike!

I really miss the term “decoy snap.” So many officers had these when I was completing my internship in 1987. I’m glad I got to see these holsters being used. They were truly an innovation for carrying a 6″ barrel revolver, which gave officers an inherently more accurate sighting radius. Great Part II!

Thank you Sir! Glad you enjoyed it. It would be interesting to know if the decoy snap accounted for any “saves,” wouldn’t it?

My leather maker (mentioned in earlier posting) refers to the materials he uses as “Premium Bovine Epidermis” (we used to bumfuzzle folks at trade shows with that name. But he didn’t stop there, check out his site and you’ll be able to get holsters, belts, ammo and magazine holders made out of alligator, crocodile, tiger shark, emu, salmon (as in the fish), tegu lizard, monitor lizard, ringed lizard, hippopotamus, rhino, elephant, elephant trunk, elephant ear, cape buffalo (last four being trophy hides only) and one of Florida’s best hated critter: Python. The tiger shark wears like iron, I’ve had a belt and IWB holster made of it for the last 18 years and it is nearly indestructible – plus it won’t melt.

He makes rigs for a lot of LEO who are usually (a) single, and (b) don’t have support payments. But, deep down, he’s a wood and steel guy.

Don’t repeat this (I’ll deny I was there), but there is a shrine in his house dedicated to the Lee Enfield rifles, and to the Webley and Smith & Wesson revolvers.

Would it be appropriate to carry a Python in a holster made of the same, or is that some kind of fashion faux paus? It hardly seems appropriate to carry one in a lizard holster.

I’m thinking a Hi-Point would be OK in jackalope hide.

Mike, thank you for the great articles. I do not have a law enforcement back ground so this has been very educational for me. Best wishes.

Curtis

You’re welcome! That’s kind of you to say, and I’m glad you enjoyed it!

Wow, what a great follow up in part 2. I truly loved this article. After carrying my issue Sig in my issue safety holster I became nostalgic for the breakfronts of my youth and started a search for a Bianchi 27. After some years of little luck I tried this new-fangled Ebay. I was in heaven; they were all there. The 27, the Judge, Hoyts and Safety Speeds and for a fraction of what they retailed for. I’m afraid I now own a vast collection of 80’s breakfronts I’ll never use as well as a new in the bag Safety Speed Clam shell. These are a source of complaint for my poor wife and I have no real argument for my continued love for them.

Jack, no explanation is needed here. You’re in good company! I do wish you’d cool it on EBay though, so I could win some of those bids myself. ; ^ )

One of my sergeants loaned me his breakfront–I think it was the Bianchi Model 27–to try out; it just wasn’t my cuppa tea, but it was secure. I about broke it trying to figure out a way to ‘sneak’ the gun out of it. Good design, but not my choice.

Then later, the desk jockeys at the Office decided they hadn’t impaired the street guys enough, so they came up with a ‘mandatory’ issue, a Tex Shoemaker (sp?) breakfront. As I recall, you had to get it unsnapped, then rock the grip forward a little bit, then pull up a skoche, then swivel the grip back to push the muzzle through the front, then push the frame/cylinder out the front. Some of us decided a five-second draw wasn’t efficient enough, and went back to ‘real’ holsters. Oddly, none of the brass complained, as far as I know.

The article got me wondering if some Kydex magician out there could come up with an efficient design for longer barrel revawvers for concealed carry? Ace

Been wondering the same thing, Ace. Some kydex bender might be able to do something neat with this idea.

When I came on board in L.A. we were issued a Shoemaker breakfront that I quickly replaced with the 2700 and then the Judge. I finally settled on a Hoyt reverse cant for my K frame. Hoyt was happy to personalize the rigs by stamping your name and employee#/badge on the back of the holster. Everyone with the Hoyts drew a certain pleasure in drawing to get that particular “pop” sound when all parts of your revolver cleared the leather at the same time. One small correction in that you can still get a breakfront made today from the AE Nelson company. They run about $180 and are very similar to the Hoyts except that the basketweave pattern runs parallel to the ground rather than on an angle (as with most other basketweave rigs). I ended up using a Nelson with my L frame for a few years before we transitioned to the 92 and Safariland rigs.

I’ll be darned, Len! Thank you for the point out to AE Nelson Leather Company! They do indeed offer breakfronts, and they look neat! I’ve corrected the article. For those interested:

http://aenelson.hostcentric.com/index.php?cPath=27_40_56_62

Yes, the Hoyt makes a neat “pop” when you pull off a great draw. My dad’s old high ride has name and badge number stamped as you describe, which is cool. Also, the inside surface is left undyed, to prevent CHP tans from turning black. A nice touch!

Great to hear from you. Thanks for visiting and sharing. I hope we’ll hear more from you here on RG. Thanks for your service on LASD. Great department, great people.

Oh, that’s why the back is tan. I always thought it was a brown holster a guy had dyed by the local shoe repair. Neat….thanks for mentioning that.

I have been searching for the front break plain black holster called the BOSS are they still available?

Not commercially, but you might find a sample on the electronic auction sites.

The only commercially available breakfronts that I know of are copies of the old Hoyt design, from AE Nelson Leather Company. See the article or comments above for a link.

Thanks for the article. I used to carry my 5″ Model 27 (yes I’m a Skeeter fan) in a Bianchi D27 as it gave the most protection from brush with the fastest access I could find. C. Rusty Sherick still makes one. I’d love to have one for my Model 12, I think that and a tweed sport coat, white button down shirt and black string tie would make me 40 years younger, at least in my mind. http://www.c-rusty.com/pages/holsters/vertbelt.html

Thank You for the article on breakfront holsters.

While I’ve never been a fan of the holsters that had an opening on the entire front section of the holster, the design did lead to some development of hybrid breakfront/top draw rigs. The development of a revolver duty holster that was both fast to draw from and secure, took some time to mature and the breakfront was a big part of that process.

The top draw rigs that had about 1/2 of the front seam open (as opposed to the entire front seam) were some of the best compromises of speed and security. Unfortunately by the time the holster designs had benefitted from that long development process, the revolver era was just about over.

The most popular was the G&G holster that used a short section of leather covered spring steel on the front seam. That holster was issued by a lot of agencies and not a bad design.

My favorite is the Don Hume model H901. The H901 is one of the few duty holsters that works with a spurless hammer and yet is still very secure. It employs a lot of the features of those early breakfront holsters but is still essentially a modified top draw rig.

Would you consider the Don Hume H901 in the same design space as say Bianchi’s #350 hurricane? Partial break front with thumb snap release.

I was a cop in San Francisco, 80-87. I had a model 28 S&W and a buddy gave me his custom made break front that he had never used. Dont know where it came from. But it was a great piece of gear. It featured a reverse cant and the thing was designed so the gun came straight out the holster. No breaking down and then out and up. I mean, grab the grip and just raise that thing like you were just holding at your side. The spring system was tuned perfectly. The release was smooth. No hangups at all. It also could not be pulled straight up or from the rear. Wish I had kept the weapon and the holster. I packed them for 7 years. Now, at 66, its just stories. But good ones. Thanks for the article. Enjoyed the history. I always chuckled at those swivel holsters. When I was in, there were still guys using them. I left before autos came in. I did have a Beretta .380 custom for off duty. Pachmayer rebuilt it for me. They took it down and totally polished and tuned everything. The mags had a dual spring system for constant feed rate so they never lost tension as the mags emptied. $1500 by the time it was done. Sorry for being long winded. But, as I said, just stories now.

Rob, the stories bring life to the hardware! I’m grateful you shared them with us. Glad to have you here. Sit down and have a look around—I think you’ll find lots more to like here at RevolverGuy.

I just bought a Smith 15-2 with a beautiful Pachmayer overmold grip, but strange holster wear. Now, having fallen down a rabbit hole through here, I have a Bianchi Model 27 on the way, a holster likely quite familiar to that gun. I’ve always been a member of the “Plastic Parliament” due to the time I’ve served, but I look forward to being able to carry good old blued steel and leather. Thank you for helping me find something I didn’t know I needed.

Welcome to the club, Christopher! I can’t imagine a better combo to start with than a Model 15 in a Model 27! Well done, Sir.