I was fortunate to spend the First and Second of October with a great bunch of RevolverGuys (and Gals!) at Range Ready Studios in Robert, Louisiana. We were all there to take part in the “Colt Python Experience,” a combination release party and training event, and I’d like to tell you more about it.

THE LOCATION

Range Ready is a unique place that combines a training facility and a multimedia studio for filming TV shows, podcasts, and training videos. You’ve heard me talk about it here before, because that’s where I shot the preproduction models of the Lipsey’s – Smith & Wesson Ultimate Carry revolvers back in February.

Range Ready boasts several outdoor shooting ranges and a 4,000 square foot indoor simulator, where students can participate in Force-on-Force role playing exercises using marking ammunition that’s fired from training weapons. The modular rooms in the simulator can be adapted and the lighting can be controlled to provide different training environments for the students. High resolution cameras, including cameras worn by the participants, capture all the action for debriefing and production.

Our friend Chris Cerino is the Director of Training at Range Ready, and keeps the training calendar full of high quality training events that range from handgun and long gun courses, to instructor development courses. Chris and his staff are true professionals, and have my strongest recommendation for those seeking quality instruction.

The unique, hybrid nature of Range Ready Studios has encouraged many manufacturers to create “Experience” training packages, where students are introduced to the company’s new products and receive instruction on them from company representatives and Range Ready’s staff. Manufacturers like Crimson Trace, EOTECH, Ruger, Savage Arms, Springfield Armory, Surefire, Taurus and others have collaborated with Range Ready to host Experience classes for students, who walk away with several days of quality instruction and some free gear for the price of admission.

We started the Colt Python Experience in Range Ready’s comfortable and well-furnished classroom, then went out to the pair of outdoor ranges for the remainder of our instruction. The ranges were in excellent shape, and were the perfect place to put Colt’s newest Python through its paces.

THE GUNS

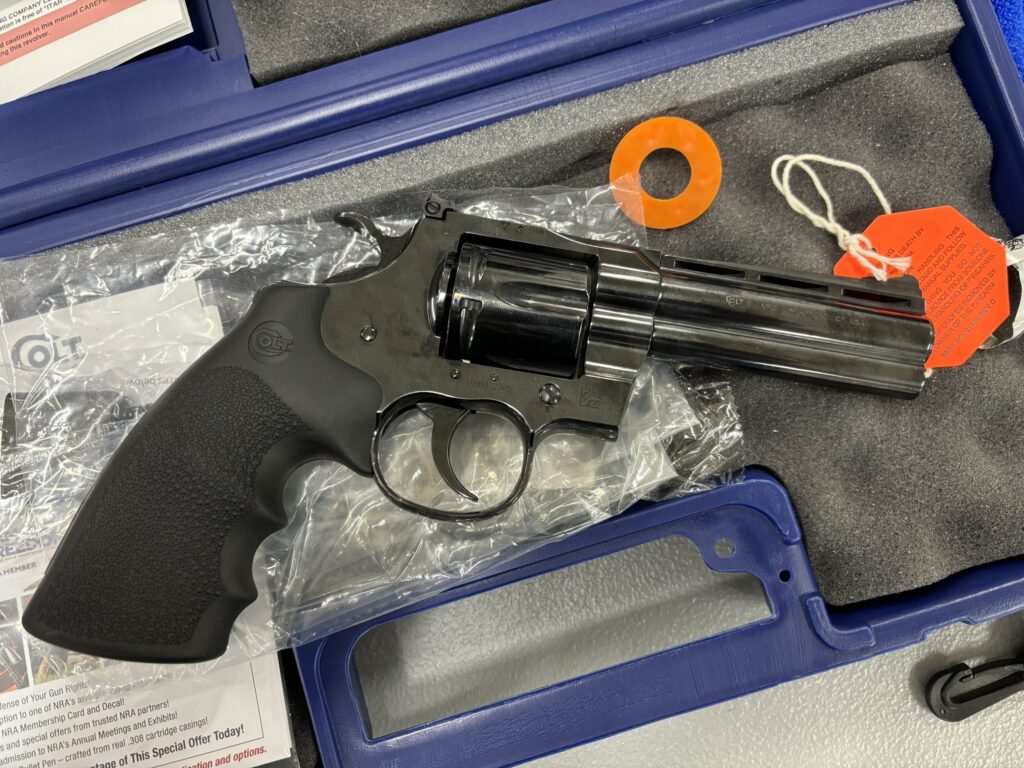

The students had initially expected to complete their training with Colt’s Matte Python, but were pleasantly surprised when Colt’s team announced they had upgraded the guns to the new Blued Python, announced earlier this year.

The Blued Pythons that Colt brought to the class were among the first batch of production guns to come out of Colt. RevolverGuy readers will recall Kevin’s outstanding review of the 4.25” blued model in these pages, which made an exceptionally positive impression on him—so much so, that even a dyed-in-the-wool Smith & Wesson guy like Kevin was reaching for his wallet, to purchase the sample.

I had seen the Blued Python on display at the 2024 SHOT Show and was disappointed that they didn’t have any of these beautiful guns available to shoot at the Media Day, so I was very excited to finally get my hands on a production sample and put it through its paces. My fellow students would go home with the Pythons they shot at the conclusion of the class, but my state’s unconstitutional laws would prohibit me from doing the same, so I was eager to maximize my time with the gun in the two days we’d have on Range Ready’s outdoor ranges.

THE INSTRUCTORS

I’d do that under the instruction and supervision of Darryl Bolke and Bryan Eastridge, our friends from American Fighting Revolver. Darryl and Bryan had successfully run the Lipsey’s – Smith & Wesson Ultimate Carry media event at Range Ready in February, and Colt wisely chose the team to lead our class of 20 students through their paces with the Blued Pythons.

Darryl and Bryan (“DB&Y”) are both experienced RevolverGuys, who truly understand the guns, their history, and how to run them efficiently. They were the right choice to help the students, and the Colt Marketing staff that joined us, squeeze the best performance out of their Pythons (see what I did there?).

THE VENDORS

Several vendors were enlisted to help in that task.

Leather giant Galco Holsters outfitted each student with their Speed Master 2.0 belt holster with a paddle attachment mounted, and an extra belt loop attachment in the box. This open top, outside the waistband scabbard is constructed of premium steerhide and features an adjustable tension screw on the trailing edge, below the trigger guard. It has a neutral cant, which I prefer on my strong side holsters.

Galco also provided a pair of their Belt E-Z Loader Carriers, for strip-style loaders like their E-Z Loader Cartridge Strips. The carriers snap easily onto the belt, and have layered tongues in the back that allow a tight fit on both narrow and wide belts (a clever design feature). A snapped strap secures the loaders in place, preventing them from falling out the open top.

Tuff Products donated some of their Quickstrip loaders, including some of their 8-cell Orange Quickstips, which allowed shooters to leave some of the cells empty to create convenient gripping and control points for the loader. An advantage of the colored strips is they allow for easy identification of a shooter’s ammunition—a shooter could choose to load a certain caliber in a certain color, for example, or they could even designate the orange-colored loader to hold dummy ammunition for dry practice, as Darryl suggested.

Federal Ammunition provided cases of their American Eagle .38 Special 130 grain FMJ (AE38K) ammunition to feed the hungry snake guns, and the Pythons gobbled them up. The Federal load was exceptionally accurate in the guns and burned cleanly. We shot hundreds of them through the guns without cleaning, and didn’t suffer any ammo-related stoppages.

GETTING STARTED

Day One kicked off with the normal administrative tasks, followed by introductions. Range Ready’s Head Honcho, Ryan Gresham, welcomed us to the facility, as did Training Director Chris Cerino, who outlined his expectations for a safe and productive training event. Colt’s Marketing team, consisting of Sara Simonow, Zoe Roth, and Kaylee Bayersdorfer, welcomed the students and delivered the happy news that the guns were upgraded to the new blued version.

Mike Barham from Galco Holsters was there to participate in the Experience and provide product support for the students, who kept him busy throughout the two days, asking questions about Galco’s extensive line of gunleather.

The American Fighting Revolver (AFR) team didn’t waste a minute, and jumped into a presentation that traced the lineage of the Colt Python, dating back to the prior release of the I-frame Colt Trooper and .357 Models and earlier E-frame Colt Officers’ Model Target revolvers that were modified by the King’s Gunsight Company to become vent-ribbed, King’s Super Target models.

From the time of their introduction in 1955 until they were discontinued in 2003 (the gun was only available as a Custom Shop product after 1999), the Pythons carried the reputation of a premium product that was favored by discriminating revolver shooters, so Colt had a steep hill to climb in 2020 when they brought an updated and improved Python back to the market.

The Colt Python Experience students would spend the next two days seeing if Colt had retained the old magic in the new gun. (Spoiler alert: They did).

CLASSROOM

Darryl next delivered an outstanding lecture that discussed the benefits of revolvers as defensive arms in the Twenty-First Century. The seasoned RevolverGuys in the audience were on familiar ground here, but surprisingly there were a few students in the group with no prior revolver experience, and a number with very limited revolver experience, so it was beneficial to review the advantages that revolvers bring to the table. Even the experienced RevolverGuys found new reasons to appreciate the revolver as a modern defensive arm in Darryl’s compelling brief.

Perhaps one of the most important concepts that Darryl covered was the notion that double action revolvers are “deliberate” guns, which require their users to be actively, mentally engaged to extract the best performance from them. Their long stroke, double action trigger systems require the shooter to pay more attention to trigger management than the shorter, lighter triggers of other gun types do. Their limited capacity and slower reloading process force the shooter to conserve his ammunition supply, and place a premium on accurate shot placement and shot accountability. These factors shape our mindset as people who carry revolvers for defense. They also influence our training, and the tactics we employ, so it was useful for Darryl to remind us of them at the outset, as a way of setting the stage for the kind of training we would do for the next two days.

After a thorough discussion on safety procedures and expectations that encouraged students to embrace a safety lifestyle, instead of just going through the motions, Bryan started working on the shooting fundamentals of Grip, Stance, Sights, Trigger Control, Follow Through, and Breath Control. We did dry-practice exercises with our new guns to get a feel for their triggers, sights and handling qualities, as well as the range commands that DB&Y would use for the next several days. The students got used to presenting their guns from their new Galco holsters and making dry-practice shots from Low Ready as well as their holsters.

One of the key elements of this dry-practice was to acclimate shooters to the concept of proper follow through. For defensive shooters, this involves much more than just properly resetting the trigger for the next shot. Instead, the defensive shooter needs to evaluate the effect of his shot and determine whether or not additional shots will be needed. This assessment is critical, since even a “good” hit may fail to do the job in a defensive encounter. While this assessment is being conducted, the shooter needs to return the gun and align the sights so the gun will be ready to make a follow-up shot, if needed.

In much of the training and competition world, shooters are encouraged to build habits that fail to take this proper follow through into account. They rapidly transition to the next target without assessment, or reflexively bring the gun to a Low Ready or holstered position after shooting, without first determining if follow-up shots are needed. Bryan crafted his dry practice regimen to help break those habits, and build the proper ones that he and DB wanted to see from us on the range later on.

LIVE FIRE

In the afternoon, we went out to the range to start putting our first shots through the guns. Bryan used a unique variation of the “ball and dummy” drill that started with a single live cartridge in the gun, and continued to add an additional cartridge after each trigger press, until the cylinder was full. The cylinder was spun each time, to position the loaded cartridges in random positions, before it was closed for shooting.

The drill allowed us to start working on our fundamentals, and helped to identify some deficiencies in our grip and trigger management on those occasions when the hammer fell on an empty chamber.

Darryl led the group through a discussion and demonstration of various reloading methods, and I was pleased to see him encourage the use of the Stressfire Reload method that I favor teaching as well. Since the students were all outfitted with strip-style loaders, he spent some time discussing and demonstrating various techniques for staging, carrying and using them. Bryan also demonstrated some alternative techniques for emergency reloads that we practiced as well.

As the afternoon progressed, we fired the guns in a variety of drills from the Low Ready position, acclimating ourselves to their operation and verifying the regulation of our sights. A few guns needed some small adjustments, but the majority were properly zeroed.

Claude Werner’s variation of the “ball and dummy” drill was used to obtain the maximum training value from the ammunition we fired, and to help identify any trigger management issues that needed fixing.

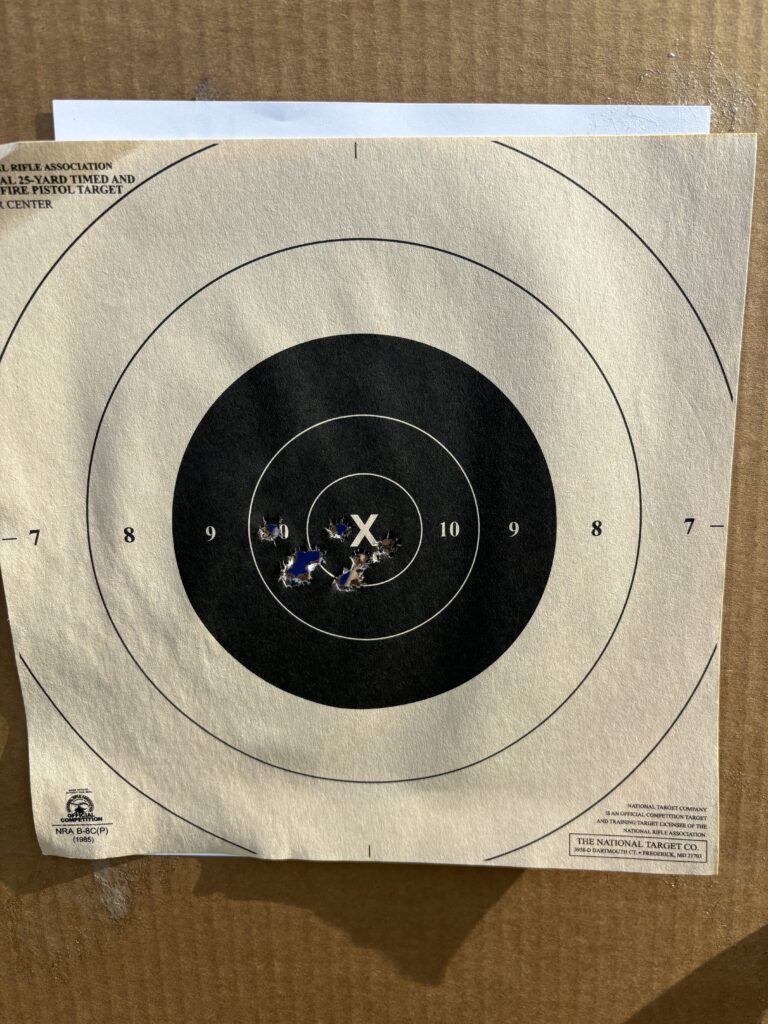

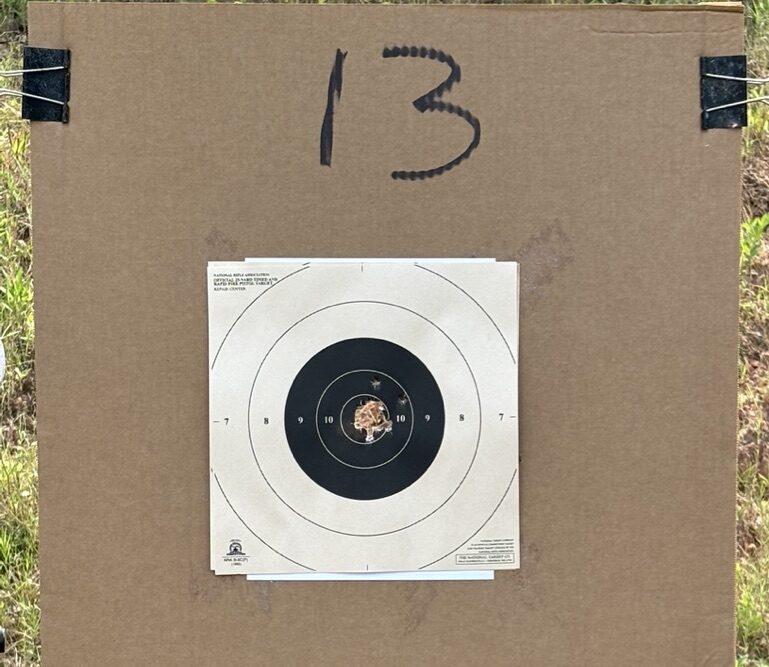

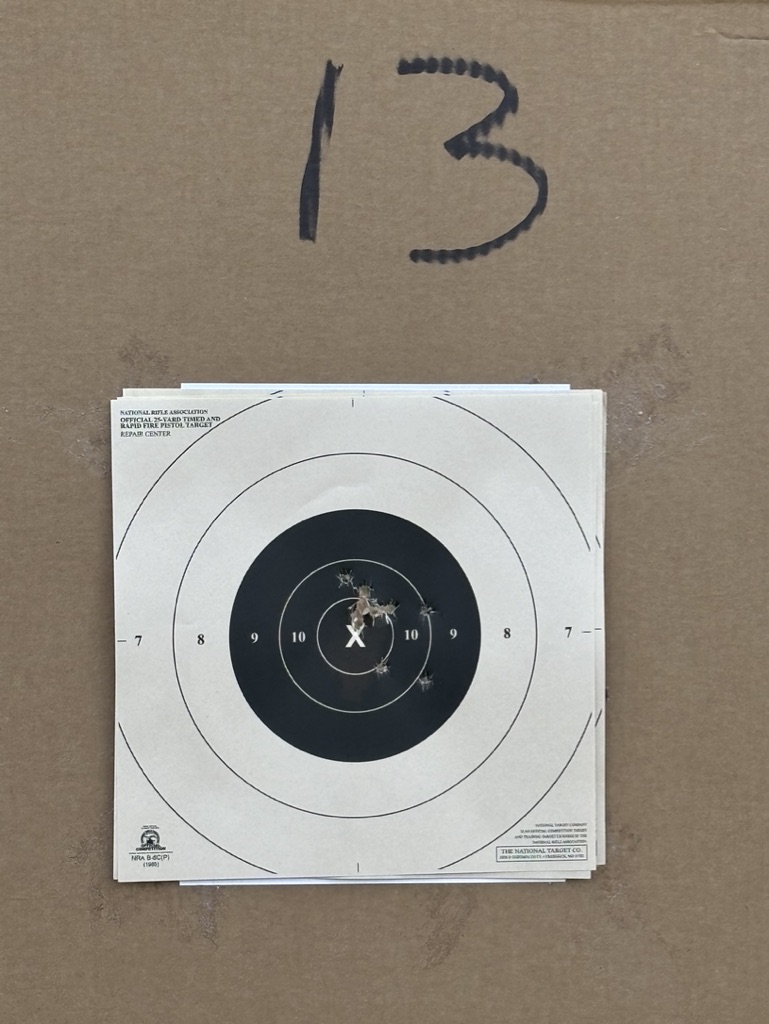

The afternoon’s shooting concluded with a marksmanship exercise on B-8 targets. I fired a tight group that was displaced slightly to the left of center, which encouraged me to adjust my trigger finger placement to avoid pushing the gun with my fingertip. A spot between the pad and the first groove proved to be the sweet spot that allowed me to shoot straight the rest of the class.

FIRST DAY IMPRESSIONS

The Blued Pythons normally ship with an attractive, presentation-style wood grip, but DB&Y wisely requested Colt to ship the class guns with rubber Hogue Monogrips installed, to make the guns more pleasant to shoot in the high-volume class. The OEM wood grips look nice, particularly against the beautiful dark finish of the Blued Pythons, but they’re too narrow in cross-section to do an effective job of distributing recoil and don’t offer as much comfort or control as the Monogrips do.

I was pleased to have the Monogrips on the guns and thought they felt great in my hand. The majority of the students agreed, and were glad to have them on theirs, too. A few shooters with smaller hands found it difficult to manage the trigger reach on the Medium-Large frame guns, and some field-expedient modifications to the rubber grips seemed to help with that.

Unfortunately, a number of students experienced sticky triggers on their guns, in which the triggers would fail to reset, or were sluggish in the reset, after the guns were fired. This happened once on mine, but didn’t reoccur after that. The offending guns were replaced with other samples from the pool for the following day’s shooting, but I retained mine, as it seemed to have worked itself out.

A debrief of the day’s training concluded the busy first day, and all of the students were eager to get into the thick of the shooting program the next day.

DAY TWO

The next day began with a short classroom session dedicated to the topic of maintaining the guns. Bryan showed us the importance of checking screws for tightness (none of the sample guns needed any tightening) and emphasized keeping the critical areas clean, to ensure proper function. He also discussed the proper way to lubricate the guns.

A safety briefing was conducted, with special emphasis on muzzle control and trigger finger discipline as they related to drawing and holstering the gun. The students would be drawing and holstering loaded guns for the first time today, so it was critical to ensure that everyone understood the associated perils, and built the proper habit patterns from the start.

DB&Y moved into a block on drawing and holstering, and the class dry-practiced those skills with unloaded guns before we were split into two different groups. One group would spend the morning working with Darryl on one range, and the other group would work with Bryan on the adjacent range. After lunch, we’d swap over.

FIRST SESSION

I started the morning session with Darryl, who began working us with singles from the holster. Galco’s Mike Barham told us the day before that our holsters had been pre-conditioned at the factory for an excellent fit, and he wasn’t fibbing. The 4.25” Pythons fit perfectly in the beautiful tan holsters, and rode securely in them, but the holster didn’t grapple with us when it was time to draw the gun. As a guy who’s nearly dislocated a shoulder trying to jerk a gun out of a brand new leather holster that didn’t want to give up its grip, I came prepared with a bottle of Galco Draw-EZ lubricant in my range bag to smooth things out, but it turned out to be completely unnecessary. The neutral cant of the holster gave a smooth release on the draw, and I was both pleased and surprised that the paddle attachment kept its grip on my belt the entire time, since my prior experience with paddle attachments had not been good. I’m still not a fan of paddles, and will eventually swap mine out for the optional belt loop attachment that also came with the holster, but I must admit the paddle on my Speed Master 2.0 holster worked admirably–it was a really solid holster to work with.

A block on reloading with strip-style loaders and round body speedloaders came next, and we worked a number of drills using the Galco and Tuff Products strip-style loaders that we’d been provided. The strips came out of the Galco carriers well, and the safety strap wasn’t as much of a hinderance as I thought it might be, once I started dialing in my technique. I eventually landed on a process where I’d join my fingers together tightly, curl my fingertips, and sweep up from the bottom to lift the strap and pop the snap with my four fingertips. After the snap was popped, I’d then transition to pinching the loader’s exposed tab between my thumb and the side of my curled index finger to lift it out of the pouch. Once the loader was out of the pouch, I’d readjust my grip on it, to place my thumb along the spine so I could push the first two rounds into their chambers after mating the strip to the gun.

Darryl worked judgment and decision making into the drills using a variety of commands that indicated what your response should be. Some commands dictated that we fire immediately, while others required us to communicate with the potential threat while holding the gun on target or at a Low Ready position, just as we may be required to do in the real world.

A block on tactical loading (replacing the spent cartridges in your partially-depleted cylinder with fresh rounds) came next, followed by a run of Justin Dyal’s Five Yard Roundup drill, which was an excellent assessment and training tool.

A rest and water break for both ranges brought us together again for a presentation on dry-practice techniques, and when we went back to the range, we collectively shot the Hardwired Tactical Super Snubby Test, and DB&Y led the group through an assessment of the targets, taking the opportunity to identify common shooter errors, then coach us on the necessary corrections to fix them.

A catered lunch break got us off our feet for a while and fueled up for the afternoon session. Incidentally, the Range Ready staff does a great job of feeding and watering the students throughout the class. We had coffee and snacks in the mornings, and some great lunches each day. There was always plenty of cold water in the fridge Thanks Hannah, for taking such great care of us!

SECOND SESSION

Bryan was my instructor for the afternoon session and started us off with a presentation on one-handed drawing and shooting. We ran a bunch of drills with just our strong hand on the gun, and a few drills with the gun in our weak hand, too.

We got another chance to shoot Justin Dyal’s Five Yard Roundup with Bryan, and although I didn’t make the 2.5 second par times, I was close on each stage and made good hits. I really like this drill and plan to incorporate it into my normal routine.

After shooting at close ranges the previous day, and during the morning session with Darryl, Bryan wanted us to stretch our legs a bit and shoot from some farther distances. With some clean steel targets beckoning downrange, we began a walk back drill that had us taking a single shot at distances that increased by five yards each time.

After a bit of practice, we regrouped for a competition in which you got one chance to hit the steel. If you missed, you were out, and you got to watch everyone else shoot. The group did exceptionally well, and I don’t think we lost our first competitor until we got to around 20 yards. As the group progressed back to about 35 yards, it had narrowed down to a handful of shooters, and we started shooting strong hand only. Chris Cerino upped the ante when he fired his next shot with the gun held upside down, and took the rest of us out, with one exception. The sole remaining student made that shot and got to choose the next one. He wound up on the ground, shooting from his back with a single hand. He made the shot and won the competition, to thunderous applause from his classmates!

By this point, it was late in the day and everyone was getting tired. The students returned to the classroom to debrief the event and return the guns for shipment to Colt, who would turn the guns around to their FFLs, so the FFLs could complete the transfers.

A DISAPPOINTING ISSUE

Unfortunately, the problem with the sticky triggers continued on the second day, despite efforts to diagnose and correct them. The guns performed much better after Bryan got a chance to clean the sludge out of the firing pin channels, which had accumulated as the result of fouling sticking to an excess of factory-applied preservative oil, but many of the guns still had an occasional failed or sluggish trigger return. My own sample only demonstrated the problem a few more times throughout the second day, but other guns suffered more.

This was particularly puzzling, because my previous experience with every 2020 Python that I’ve fired has been completely different. All of them had actions that worked flawlessly, with no signs of this issue. The same was true for the two guns that Justin and Kevin reviewed for us at RevolverGuy, and for all the other Pythons I’ve run across. I had never heard a report of sticky triggers on any 2020 Python design before this, so it was quite unusual.

When Colt got the guns back after the class, they determined that the affected guns had some out-of-spec parts, which caused the actions to drag. When replacement parts of the proper dimension were substituted, the 100%-reliable action that we’ve become accustomed to in these guns was restored.

I should also note that the cylinder latch on my sample was a little sticky at times, especially if I put any significant inward pressure on the latch, while operating it. When I focused on drawing the latch straight to the rear, without pressing inward, it worked smoothly, but since Colt is dedicated to making perfect Pythons, they’re investigating this, to see if the cause can be identified and corrected.

It was regrettable we encountered these issues in these early production samples, but also fortunate, in a way, since it allowed Colt to identify and fix them early in production. Unfortunately, small hiccups like this are a part of manufacturing these days, particularly when subcontractors are supplying parts. We’ve seen every major brand suffer some version of this problem before, and the real measure of a company seems to be how they handle it.1

I was happy with Colt’s attention to the trigger problem and the rapid correction, as well as their earnestness in evaluating the cylinder latch issue. I consider the trigger issue fixed and know the latch issue will be similarly addressed. Neither would make me hesitate to recommend or purchase one of these guns, and I know Colt would quickly correct any problems, if they did arise.2

EXCELLENT, ON BALANCE

The bright side is that the guns were excellent performers in all other respects.

The fit and finish of the guns was excellent, and honestly exceeded that of their competitors. The black oxide finish on the new Blued Python is glossy, dark, and beautiful, giving the gun a most handsome appearance. Nobody is producing guns with finishes in the same league as the Pythons, these days. They’re phenomenal.

The sideplate, crane, cylinder and barrel are perfectly fitted, and every time you close the cylinder, you’re reminded of the “bank vault” cliche—it just glides into place and locks securely with a satisfying click that confirms you just turned two pieces of steel into one. I’m not sure how Colt is doing it, but I have yet to see a single gun with a barrel that was under or over tightened—they all sit with the front sight at Top Dead Center, as it should be. Their competitors should be paying attention.

Setting aside the problems with the trigger reset, the actions on these guns were excellent. The actions were smooth and even, and didn’t stack nearly as much as the older guns did, courtesy of a redesigned mainspring on the 2020 models. The bolts were properly timed and locked the cylinders up just right, each time, to promote excellent accuracy.

Speaking of, these guns were superbly accurate. They shot very tight, consistent groups, even with the economical Federal American Eagle ammunition. Even when the ranges stretched out to 35+ yards, the guns and ammunition were making it easy to get hits in double action on 10” steel plates. Loaded with a round built for accuracy, like Federal Gold Medal wadcutters, these guns will shoot like laser beams across the course. The new Pythons are as good or better than the old ones, which always had legendary reputations for accuracy—the youngest generation of snakes is carrying on the tradition proudly.

I’ve been waiting for a blued gun from Colt ever since they returned the Python to the catalog in 2020, and I’m very pleased with the result. I think it’s the most attractive looking revolver on the market–a real show stopper—and I’m very impressed with the gun’s accuracy and the quality of its double action pull. My classmates expressed the same opinion of their guns, and were eager to receive them after they returned home.

THE EXPERIENCE

The Range Ready Studios facility was an excellent place to host the class, and provided a safe, comfortable and productive training environment. If you’re looking for a place to take some quality training, I know you’d enjoy doing it there, and would learn a lot from their highly professional staff. Keep an eye out for other manufacturer “Experiences” that will allow you to go home with some great gear after some great training.

DB&Y were excellent guides for our journey with the new Colts, and provided top notch instruction throughout the two days we were together. If you’re not already following their work on American Fighting Revolver, make sure you get over there and sign up. I know you’ll enjoy it, and I know you’ll learn from them. While you’re there, check out the information on the Pat Rogers Memorial Revolver Roundup (already filled, for 2024) and the inaugural RevolverFest in October 2025, in South Carolina (tickets not on sale yet), which will offer opportunities to train with DB&Y, and a host of other talented instructors. Also, browse through the store to see the AFR-branded pocket holsters and other goodies they’re offering.

I was thankful to be a part of the Colt Python Experience and get the opportunity to spend time with the guns, the products and the people. I think events like this, which bring manufacturers together with their customers, are invaluable, and I appreciate Colt and Range Ready inviting me along for the ride to cover it for the RevolverGuy audience.

Make sure to stay tuned to RevolverGuy for more articles on the Colt Python and some other great snake guns from Colt that we’re currently working with. We’ve got a lot of great Colt coverage coming your way in 2025 that you won’t want to miss.

*****

ENDNOTES

1.) I need to give the Colt team kudos for their engagement with the participants of the Colt Python Experience. When they weren’t shooting alongside the students, they were actively monitoring the progress of the training, and interacting with the students and staff. They were particularly interested in our observations about the issues we encountered with the guns, and I was confident they would bring the information back to Hartford, so it could be acted upon.

A few weeks after the Experience, I participated in a video conference with members of the Marketing and Research & Development teams, where we debriefed the Python Experience and the issues we encountered with the guns. Colt had already begun to examine the guns and identify the root of the trigger and latch problems we experienced, and we discussed their progress and their plan to resolve these issues. We also discussed some preferred modifications and upgrades to consider for future editions of the Python.

I know Colt was having parallel conversations about these issues with Darryl and Bryan as well.

I share this, because I think it demonstrates the Colt team is sincere about delivering a quality product. I’ve interacted with a lot of companies in this industry over the past twenty years or so, and I wish they had all been as receptive to customer feedback as Colt has been, in this case.

2.) Colt’s commitment to the customer was reaffirmed in a message we received from President J.W. Dorsey, shortly before press time, which reads (in part):

Thank you for the outreach after the Range Ready event. We have taken up your experiences with our production team and they are looking into it. As you know, the Colt brand stands for quality and we take our customer’s experiences seriously. Our production and quality teams are currently hand-testing all Blued Pythons in production, in order to ensure that we are not seeing more of this issue. We encourage anyone experiencing ANY issue with a Colt firearm to contact our Customer Service team at 1-800-962-2658 for an expedited resolution.

It’s not common for a company president to respond to our feedback, and I think it indicates Colt is serious about building good guns for RevolverGuys. It also illustrates why I’m confident in Colt, despite the issues we encountered with this batch of Pythons.

Besides enjoying living the range experience vicariously, I was most pleased about the actual participation and interaction with the folks from Colt. Unless I’m reading things wrong, they’re actually working to out-do their competition in terms of quality control (for the most part) and marketing a product that is durable and reliable.

The photo of Darryl with that Colt Trooper brought flashbacks to another world. We had those as training revolvers in our academy. They felt great, had a bank vault lockup, but had double action triggers straight out of Mordor. The best thing Colt has done for their double action revolvers is to ditch their archaic 19th Century excuse for lockwork and streamline it for simplicity and durability (not necessarily in that order).

The old Colt double action mechanisms were unlike any other revolver lockwork. The problem with ‘gunsmithing’ the old Colt action was that folks proficient with S&W or even early Ruger actions quickly ended up over their heads working on the Colt. With the old Colt, if you alter or even replace something HERE, unexpected things happen over THERE. It was a never ending game of hand fitting everything with no smooth interchangability of parts. Ages ago I worked on a pair of Pythons made in 1968. Internally, one looked to be the epitome of precision machining and hand fitting. The other looked like a team of drunken chimpanzees were running the machine tools. Fitting replacement hands was a real test of patience. I guess Colt at the time was too busy cranking out M16 rifles for the ‘Southeast Asian War Games’ at the time to pay attention to their revolvers’ trivial details. That turned me completely sour on the old model Colt wheelguns. Working on these ancient guns made you either (a) an alcoholic, or (b) a devotee of S&W revolvers. The late Dick Baker’s re-design for Colt’s Mk III, Mk V, and AA-frame King Cobra actions were great stepping stones, and the current crop seems to be even more efficient as it is simplified. That simplification appears to have borne fruit looking at Mike’s targets . . . woe be unto him who hath the foolhearty mind to stand in front of Mike’s firestick !

The issue with trigger resets on new production guns highlights the problem of balance – you increase production volume at the cost of attention to details. Out of spec parts is the product of that imbalance. A failure of a trigger reset is nothing trivial and could be fatal on the street.

I won’t even comment on all that ammo from Federal . . . I have room in ammo cans for some (okay, all) of that !

These guns are definitely simpler and stronger than the old ones, and represent a substantial improvement. Colt did it right.

The range was short, the times were generous, the conditions were great, and the targets weren’t shooting back, so everything was in my favor to make pretty targets. Take one away, and things would change quickly! ; ^ )

What an excellent way to spend a few days!!! It sounds like a first-class operation from the facilities, the instruction by DB&Y, and the participation from Colt, Galco, Tuff Products, and Federal. Thank you for the thorough debrief on your experience, Mike- I enjoyed being there vicariously through this post. Although it’s disappointing to hear of the issues many experienced with the trigger reset and the cylinder latch problem you personally had; it’s nice that Colt is taking the problems seriously and making efforts to fix them. S. Bond astutely points out in his comment the delicate balance between production volume and attention to detail, it sounds like Colt is working to find that balance. As you mentioned, my early production sample had no issues, and I remain very impressed with it. That Federal 130 FMJ is superior practice ammo in every respect. The new Pythons shine with how well they handle magnum ammo, too. It makes me cranky that your state’s foolish laws prevent you from getting to own the one you shot, I hope that changes someday. Soon! Thanks, Mike.

Thanks pal, it makes me cranky too! I was super glad to finally get some trigger time on these blued guns. The trigger and latch issues obviously need to be fixed (and I’m confident they will be), but I’m very impressed with the rest of the package.

I’m sad to hear you couldn’t keep your piece. It’s been over 20 years since I moved away, doesn’t sound like anything’s gotten better in CA. I miss the state I grew up in, but it’s not really there anymore. That said, sounds like a great experience, and I’m looking forward to the roundup.

It’s always one step forward, two steps back, but I get a feeling things will improve in the next four years, buddy.

I’ve been looking forward to this review – well done as always, Mike. I’m very impressed with the new breed of Colt revolvers and am so glad Colt is back in the game again. My experiences with the Python mirror your own (minus the sticky trigger return, which I’ve never experienced on any of the new Colts I own). From F&F to function, they really are the best production revolvers being made right now, hands-down.

Agreed, Hammer. They’re very impressive guns, and I don’t see anything close to them in the market. There are a few areas where they can be improved, which we’ve discussed with Colt, but overall, the package is strong. The failed triggers on this batch were a surprise, and I’m confident they won’t be a continued problem. The cylinder latch is more of a longstanding issue (my 4.25″ stainless suffers from it too) but they’re working on it, and I expect things will change there, too.

I have a 6” 2020 Python that I’ve shot a lot. No mechanical issues noted. As Elmer Kieth noted decades ago, the factory grips move in my hand. I put a pair of Pachmayr presentation grips on it and problem solved. I’ve noted 2 misfires in DA with handloads. Changing to Federal primers alleviated that issue but it tells me my gun is right on the edge.

I like it so much I bought an Anaconda. Love it too.

Now if they’d just make a 2 1/2” King Cobra Target 22 (I know, weird) . . .

Brett, my two 2020 Pythons have also been solid, mechanically–no issues like what we experienced in Louisiana. Like you, I put Pachy Presentations on my 4.25″, and I put Grippers on my 3″–much better options than OEM!

A 2.5″ KC .22 LR sounds pretty handy–not weird at all!

“[T]he [old] Pythons carried the reputation of being a premium product that was favored by discriminating revolver shooters . . . ” Well, maybe. It kinda depends on who the discriminating shooters were, and what they used their revolvers for. I knew several LEOs in the 70s/80s who carried Pythons, and I did, too. for a while, but when I dabbled in PPC in the 80s, I never saw a Python, or any Colt, on the line. I was told the actions went out of time too easily to be reliable in a high-round-count environment like PPC, and they were a nightmare to work on. I also found the triggers on my Pythons (a 4-inch and a 2.5-inch of 70s manufacture) to be stacky and uncomfortable, especially as the trigger blades were too narrow. I went back to my K-frames and J-frames, and when my agency issued Ruger Speed-Sixes I carried them.

That said, I’ve read that all the new Colts have improved actions that are more robust than the old ones and have eliminated the stackiness of the old triggers. I’m glad of that. I’m also happy to see that the new Pythons (and the new Colts in general) are quality pieces. I think putting the rubber grips on the ones you shot was a good choice. For some reason, Colt insists on using an angled (as opposed to a proper vertical) recoil step at the top of the Python’s backstrap, so the gun can slide down in your hand during rapid fire with Magnum loads. (At least it does in mine.) Both of my Pythons carried rubber Pachmayrs for that reason.

All that being said, I really enjoyed this article, in a “Why wasn’t I invited?” kind of way. The idea of having fun, learning new techniques, and shooting quality revolvers really resonates with this Old Revolver Cop. I hope the minor problems with these guns are fixed, and you can have another revolver experience that I can live through vicariously in your articles.

Old 1811, my dad was one of those cops who carried a Python for several decades, and it’s true that it required some extra TLC. Back then, there were still plenty of places a Colt guy could go (including the factory) to have their sixgun repaired, but the world has changed. The Pythons were reknowned for their SA triggers back in the days when shooters were still competing and training like that, but the S&Ws definitely had the better DA trigger. The Python DA was actually pretty good, but it just acted differently than S&W–reference the stacking, you mentioned. I never minded that much, but can appreciate how most folks like the S&W system better.

The DA on the new guns is very good, and doesn’t stack nearly as much as they used to. I can’t tell you about the SA, because I haven’t shot them in SA yet–why would I?

I put Pachys on both my guns–Presentations on the 4.25″ and Grippers on the 3″. They’re a far sight better than the OEM stocks. The rubber Hogues we used in Louisiana were actually pretty good feeling, too.

Why, oh why 3 barrel vents on the 4 inch Python?

RE: the old Colt Python and MKIII actions.

About 1980, Ayoob reported that Colt had an improved prototype DA revolver design but didn’t bring it out because it was too much like the S&W action.

Haha! I know that really bugs some folks, but I honestly think it looks pretty good that way, especially with a barrel that’s a quarter inch longer than it should be. I guess that makes me “weird” . . . like JD Vance. 😁

Dick Baker’s redesign of the Trooper departed from the traditional Colt arrangement for the cylinder stop (bolt, in Colt parlance) and went to more of a S&W-like setup. I wonder if he had more S&W tricks up his sleeve that never made it into production?

The new Python has a S&W-like bolt, and a Ruger-like transfer bar. It’s a mashup of good ideas. The V-spring (actually a U-spring, now) had to stay for the purists, though. I do wish they had kept the firing pin serviceable by the user, as on the original Python. On the new one, you can’t get in there for cleaning or maintenance.

“[A] barrel that’s a quarter inch longer than it should be.” Yes! I remember reading that most U.S. revolver makers added the extra quarter inch of barrel so they could sell the guns in Canada. Then a couple of years later, Canada outlawed the importation of handguns. Since the quarter inch of barrel is no longer needed, do you think they’ll go back to making true 4-inch barrels, the way Colonel Sam, and Horace and Dan, intended? Or are they now in the thrall of Big Holster, who can sell 4.25-inch holsters so the new guns won’t stick out the bottoms of my old 4-inch holsters? I would think saving a quarter inch of steel on every barrel would save them a decent chunk of change.

I hope that if you have any influence at all with the gunmakers, you can convince them that the proper barrel length is 4 inches. For some reason, they won’t return my calls.

Ha! We’ve been bending ears about it, trust me. Whether or not it changes is another question!