Part III—Shooting the Lipsey’s – Smith & Wesson “Ultimate Carry” J-Frames.

We’re rounding Third on our in-depth review of the Lipsey’s – Smith & Wesson Ultimate Carry J-Frames (UCs), and have enjoyed going behind the scenes and under the hood with you on these exciting new guns. In this issue, we’ll finally get to my shooting impressions of the guns, based on my time with some pre-production samples at the Lipsey’s – Smith & Wesson media event held in February.

RANGE DAY

The media event was held at Range Ready Studios, in Robert, Louisiana. Range Ready is a multi-use facility constructed by Ryan Gresham of Gun Talk TV fame.

Range Ready serves primarily as a location for filming, editing, and producing firearms-focused shows such as Guns & Gear, First Person Defender, Build Box, and other popular Gun Talk Media programs. With well-furnished studios, a 4,000 square foot indoor shoot house, and three outdoor ranges, the Gun Talk team has all the resources they need to produce quality firearms content.

Range Ready also occasionally serves as a training facility, with Director of Training Chris Cerino and staff taking students through a variety of classes focused on skill building with handguns and long guns, tactics for defensive living, and instructor development. Some of these classes are hosted in conjunction with firearms and accessory manufacturers, who donate equipment for training and send it home with the students at the end of the program. “Experience” classes like these have been conducted with the help of brands like Colt, Crimson Trace, EOTECH, Ruger, Savage Arms, Springfield Armory, Surefire, Taurus, and others, and have been extremely popular with the students. Who wouldn’t want to take home a free gun, optic, or accessory at the completion of training?

SHOTS FIRED

Range Ready was therefore well suited to hosting the Lipsey’s – Smith & Wesson media event when we gathered there on 21 Feb 24, to meet the UC revolvers in .32 H&R Magnum and .38 Special. After a presentation from Smith & Wesson Handgun Product Manager Andrew Gore, and Lipsey’s Vice President Jason Cloessner, on the development of the UCs, and a range safety briefing from Chris Cerino, American Fighting Revolver’s Darryl Bolke and Bryan Eastridge got us out on the range to start shooting the guns under their supervision.

We started with some basic drills, so Darryl and Bryan could assess the performance of the other ten writers who had gathered to shoot the new guns, and the shooters could warm up to the new revolvers. In no time flat, it was obvious this group didn’t need any remedial training or education, and we were left to experiment at will with the new guns and a wide variety of ammunition in both .32 and .38 caliber.

I started the day with one of the six available UCs in .32 H&R Magnum (a 432 UC), but about 30 minutes later I switched to a 442 UC in .38 Special that I shot for a bit, before trading it off for a 642 UC that I kept for the remainder of the day. I got about 5.5 hours’ worth of shooting in before it was time to call it a day, burning up just short of 550 rounds of ammunition in the process, not counting the couple dozen rounds I fired into Clear Ballistics gelatin.

I shot the new guns slow fire, rapid fire, near and far. I shot them with both hands and with only my strong or weak hand. I shot them with training ammo and duty ammo. Together, with my fellow writers, we shot an estimated 3,500 rounds through the six .32s and eight .38s, trying to explore the limits of their performance and discover their personality. It’s hard to do all of that in a single day, but I think I got a good enough feel for the UCs that I can give you a credible first-person report on them.1

HANDLING QUALITIES

The first place to start is with the handling qualities of the guns, and since the hand meets the gun at the grips, let’s start there.

I found the UC’s grips to be very comfortable in my grasp and really enjoyed the longer trigger reach afforded by the enclosed back strap, as my large hands often get cramped on open back strap J-Frames. I was a little concerned by the profile of the grips just under the recoil shoulder of the frame, thinking the corner there might become a source of irritation during a long day of shooting, but didn’t experience any issues with this while using my typical, “choked up” Centennial grasp.2 I shot the UCs, mostly chambered in .38 Special, all day long with this grasp and experienced no discomfort, even though the web of my hand frequently overlapped the blended corner at the top of the grip.

This wasn’t the case for everyone, however. Bryan Eastridge actually wore some skin off the web of his hand when he used the same grasp during some intensive shooting the day before. The way the gun fit Bryan’s hands, the corner was an irritant, so he told the assembled writers that he recommended taking a lower grip on the gun, with the web of the hand nestled into the curve on the back strap, below the top edge of the stocks. This grasp has the added advantage of keeping the trigger finger more in line with the trigger, so it can be pulled straight to the rear.

The general consensus among the shooters was that Bryan’s recommended grasp was comfortable, and allowed them to shoot the gun well, but my regular habits worked fine for me. The whole thing is a reminder that we all have different hands, and have to find ways to adapt to our equipment and make the best use of it. An important point though, from Lipsey’s and Smith & Wesson’s perspective, is that we all found the new UC grips to be a good addition to the gun. Some shooters may differ in their opinion of the grips, but they’re easily replaceable if you don’t like them.

The profile of the UC’s grips filled my hand well and promoted a positive hold on the gun. I didn’t experience any problems with the gun being slippery in my grasp on account of the smooth stocks, and actually appreciated the smooth surface because it allowed me to easily shift my hand around as I obtained my firing grip on the gun, during Step One of my presentation. Those smooth stocks would also be comfortable to carry up against my skin, in concealment, and would ride well inside a pocket.

Early in the day, I managed to cut my thumb knuckle on the UC’s thumbpiece when shooting the gun with a “thumb over thumbnail” grip, as I sometimes do. This is a common thing with J-Frames for me, and the reason why I polish the edges on all my J-Frame thumbpieces. After nicking my thumb that first time, I defaulted to placing my support hand thumb on top of my locked down shooting hand thumb, where it could do a better job of reinforcing my grip, and I had no further issues with the thumbpiece.

RELOADING

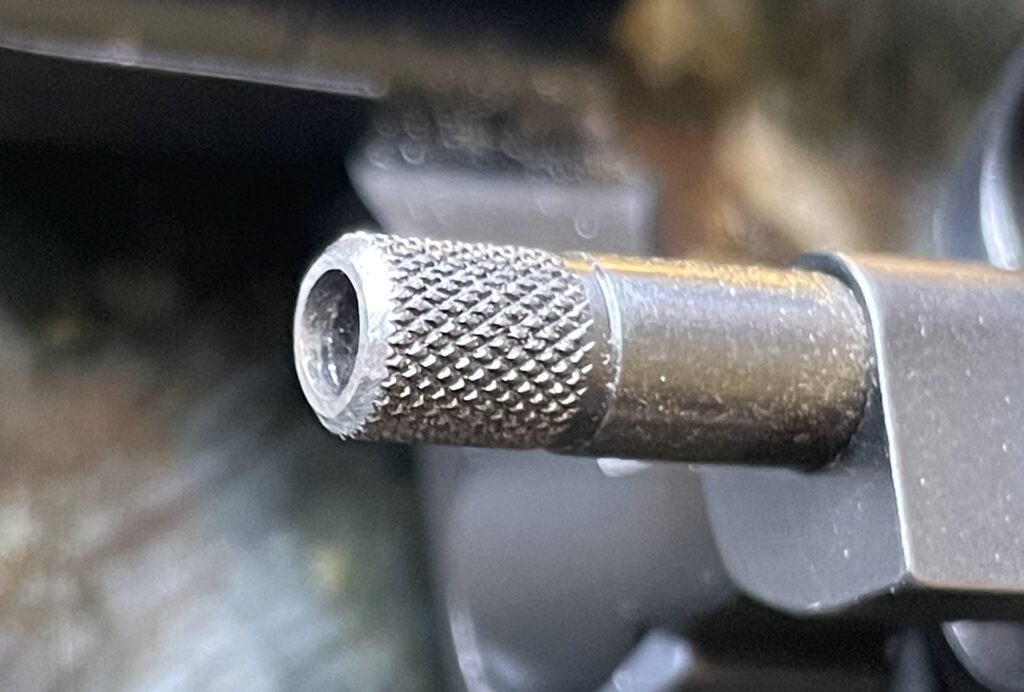

The thumbpiece operated smoothly and I had no issues getting the UC’s cylinder open to clear and reload the gun. A sharp slap with my shooting hand on the extractor rod never failed to clear spent cases from the gun, despite the rod’s short length.3

The tip of the extractor rod was not sharp, and I didn’t experience any “cookie cutter” effect with it. Nor did it stick inside the yoke, as we’ve occasionally seen on some other makes.

The chambers on the UC have a slight chamfer, and I found it to be an aid in reloading the gun, especially with the blunt-nosed wadcutters. The chamfer is not aggressive, but enough to do the job.

At the opposite end of the cylinder, the bevel on the leading edge made the gun more comfortable to hold during reloading, and slightly easier to holster in the brand new holsters provided by our friend Rob Leahy, at Simply Rugged Holsters (more on those in a future article).

I was especially pleased to confirm that HKS #36-A loaders neatly cleared the VZ grips without interference, and settled quickly into place on the gun’s cylinder. This was one of my special requests to Jason in March 2023, and it was fantastic that it happened. If the HKS #36-A loader works, then you can be assured that all of the other popular loaders will too.

TRIGGER WARNING

The action on the UCs was very good—much better than what I’ve become accustomed to on a standard 642. The pull weight is lighter, courtesy of new main and rebound slide springs, which have been optimized by Smith & Wesson’s engineers. I’d guess the pulls were a pound or two lighter than standard, and they were also pretty smooth.

Andrew Gore from Smith & Wesson advised that the guns we shot had a new rebound slide spring in them which was slightly stouter than the springs which had been on the prototypes we examined at the 2024 SHOT Show. It was determined that the prototype springs were a little too light, and gave the guns a slightly sluggish reset. I experienced nothing like that on the four samples I shot, all of which had a nice, positive reset with the new spring.4

Shooters who are a fan of staging the trigger will still find it easy to find the pause in the UC’s trigger stroke that will allow them to do it, but I prefer using a continuous stroke and found the UCs to have a nice smooth pull that facilitated good shooting. I shot somewhere north of 360 rounds through one of the guns in the afternoon, and it seemed like the already-good trigger pull was starting to feel even better as I broke it in.

One thing that bears a special comment is the shape of the UC’s trigger face. Smith & Wesson didn’t do anything different here, and the guns are equipped with the standard 0.312” smooth combat trigger that’s found on other J-Frames. That’s a good thing, because I’ve found this trigger to be comfortable for my thin trigger finger. It doesn’t have sharp corners, is sufficiently rounded, and isn’t too narrow, unlike some triggers on guns from other makes. I put over 550 rounds through four UCs in the course of the day’s shooting, and while my trigger finger was fatigued, it didn’t hurt. That’s a win.

SIGHTS

Shooting the UCs afforded me my first opportunity to get some concentrated time with the XS Sights Standard Dot sight. I’d shot a few guns equipped with XS Sights in the past, but never fired too many rounds through them, so this was a really good chance to get to know them.

The front sight was highly visible, and the bright green color of the Glow Ring really “popped” and drew my eye’s attention. The 0.160” wide notch of the serrated, black, rear sight gave me plenty of light and room to find the XS dot, which just seemed to center itself in the rear.

I’ve mentioned previously that the first time I picked up the Kimber K6s at SHOT Show and sighted down its barrel, I immediately remarked to RevolverGuy Steve Tracy that, “these are EXCELLENT sights!” After decades of suffering with the tiny and crowded sight pictures on J-Frames and other snubs, the Kimber’s high visibility, high profile sights were a very welcome relief for these tired eyes!

In the years since, I’ve seen the same drama play out so many times with shooters new to the K6s, that I jokingly began to refer to it as, “The Kimber Experience.” Shooters with prior snub experience are usually VERY pleased to see the K6s “has real sights” that look a lot like the ones on the autoloaders they’re more accustomed to.5

Yet, as good as the Kimber sights are, I like the sights on the UC even better. I have always found three-dot sight patterns, like the one on the Kimber, to be distracting, and much prefer a plain black rear sight like the one on the UC. The UC’s sight picture is uncluttered and fast to acquire.

Additionally, the UC’s sights are better regulated than the Kimber’s. The Kimber K6s front sights are taller than they should be for the ammo that people really shoot in the guns, and before I shaved them down on my two samples, I was always having to adjust my point of aim to compensate.6 In contrast, the UC’s will do a much better job of delivering bullets to the point of aim.

SIGHT REGULATION AND HOLDS

Since we’re talking about it, this would be a good time to explore the UC’s sight regulation in better detail.

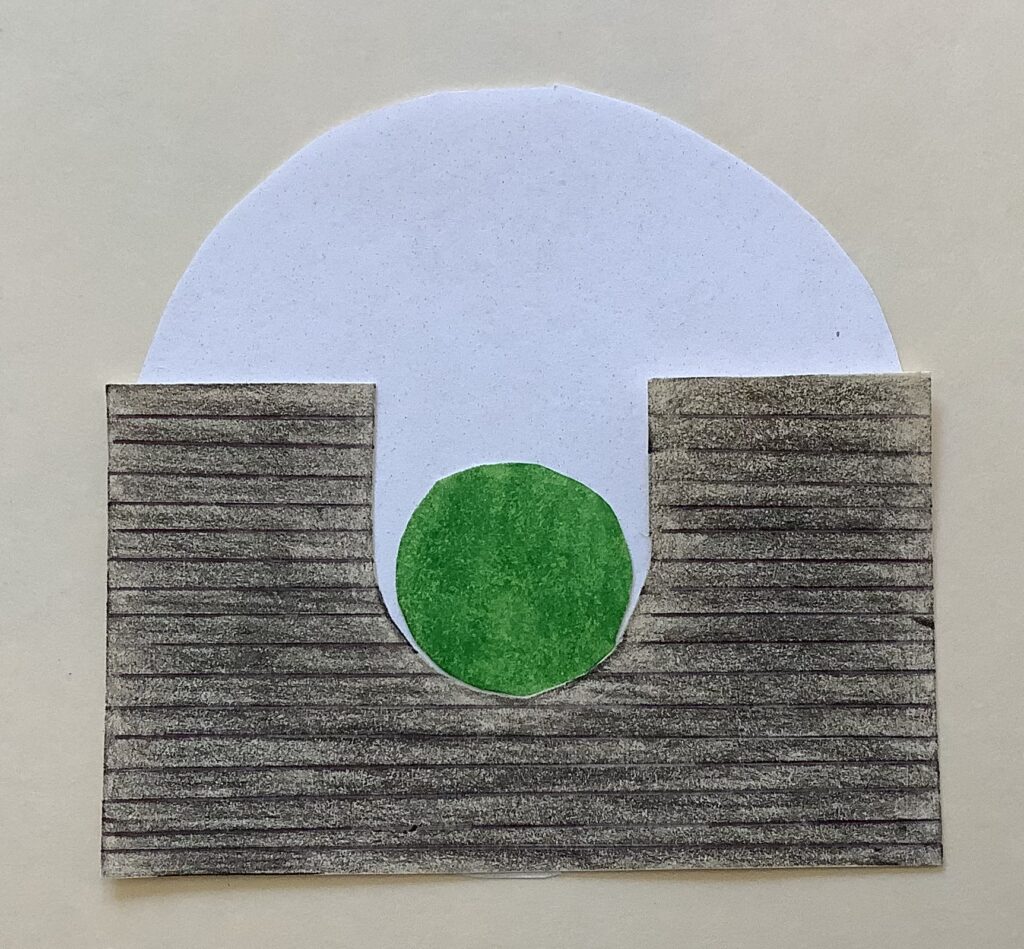

The first UC that I shot at the media event was a 432 UC, at a close distance around four-to-five yards. I wasn’t sure where the gun would hit with the 100 grain wadcutters, so I simply put the “ball in the bucket” (front dot nestled into the rear’s U-notch) and stroked the trigger.

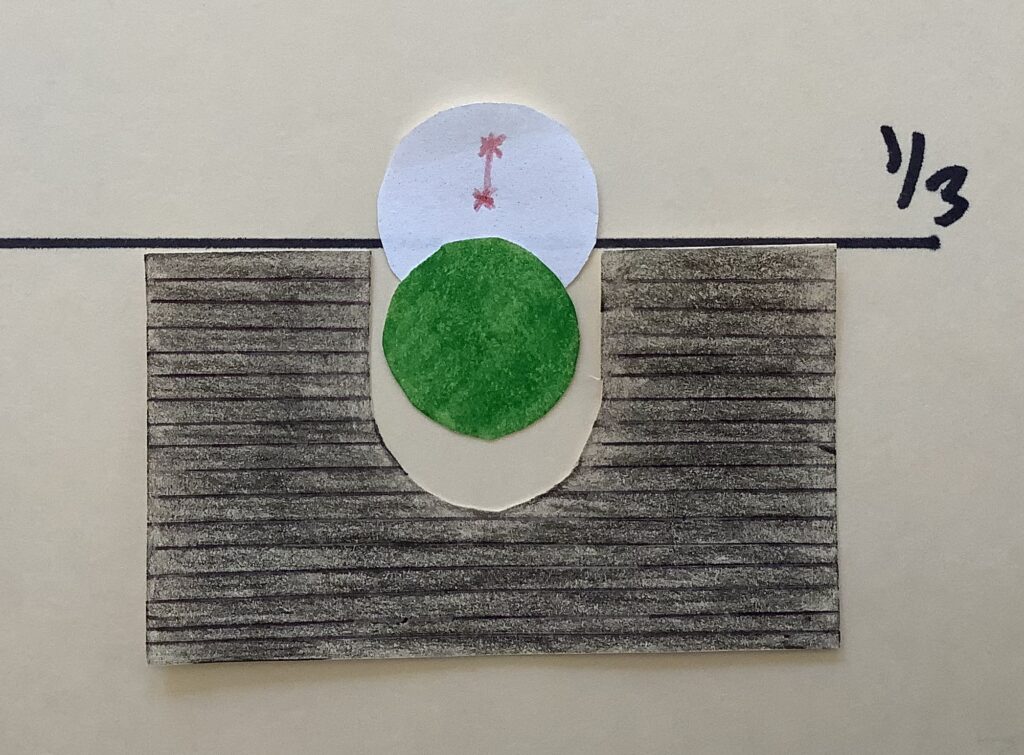

I soon discovered that I had a nice group about 1.5” below point of aim, and adjusted the sight alignment to place the top edge of the dot even with the top edge of the rear sight. This created a little gap between the bottom edge of the dot and the rear’s U-notch, like this:

This sight picture placed my rounds at the top edge of the dot, for a perfect zero, with both the 100 grain wadcutters and the 85 grain JHPs that I shot. Since I traded off the 432 UC for a 442 UC very quickly, I never got the chance to shoot the .32 beyond this close distance, but I suspect the little gap between the dot and the U-notch would have slowly disappeared as I worked my way back from the target.

The next gun I fired was a 442 UC, which was traded for a 642 UC shortly thereafter. At the close, five-yard (plus or minus) distance I had good luck, once again, with holding the top edge of the dot even with the top edge of the rear sight. This alignment planted everything I shot though this pair of .38s (from 148 grain wadcutters, to 130 grain FMJs, to Federal Hydra-Shok Deep and Speer Gold Dot) on top of the front sight, whether I fired with two hands, just my strong hand, or just my weak hand.

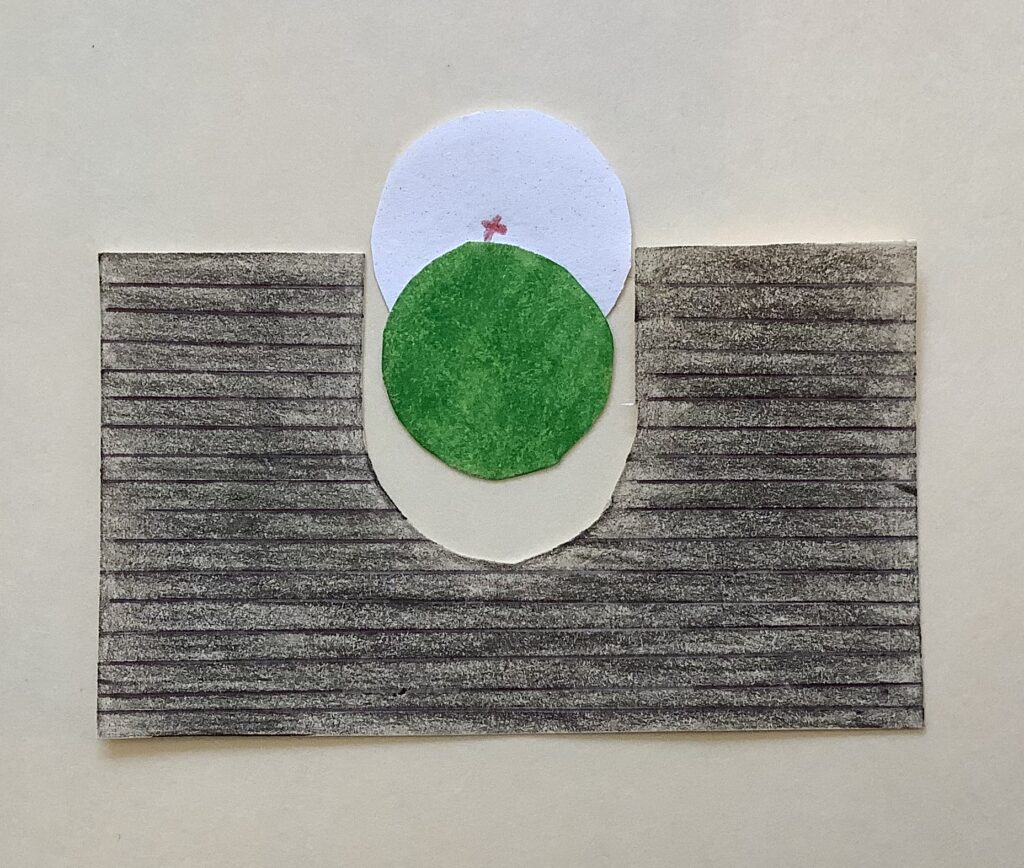

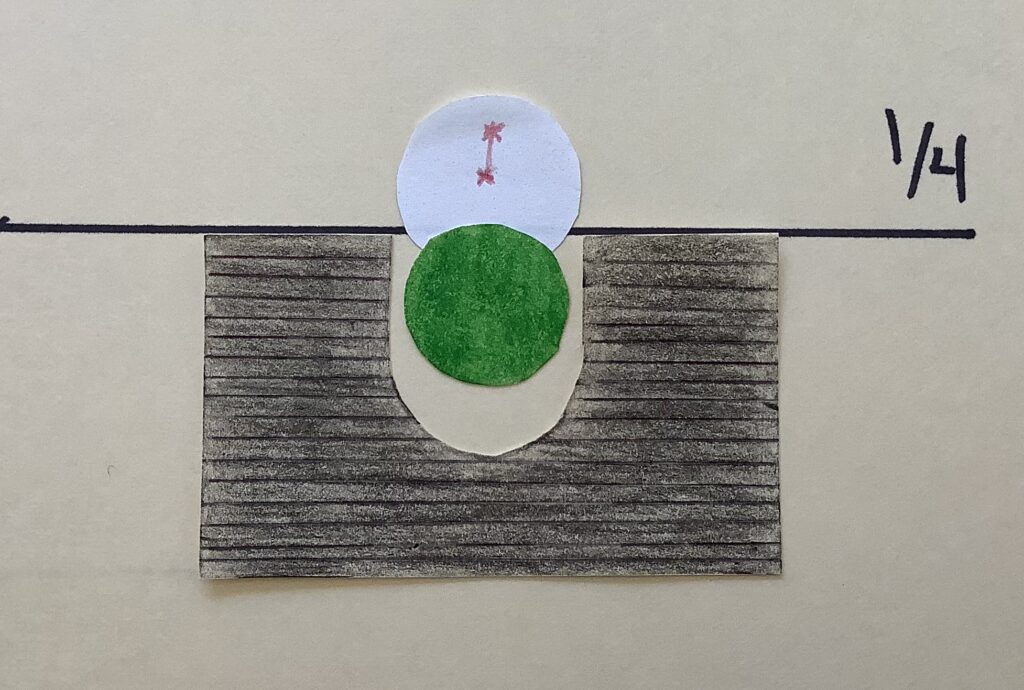

After everyone had spent some time at five yards getting to know the gun, it was time to start working back and stretching the UC’s legs. We moved the line back to 15 yards and I started working on a 10” steel plate with the same sight alignment, placing the top edge of the sight at the midline of the target, like this:

This sight picture had my shots landing in the top half of the plate with 130 grain FMJ. At this point, I could have put the ball back into the bucket and moved the point of impact down to align with the point of aim, but I was eager to push back to 25 yards, and my partners on either side were too, so we moved the line back again.

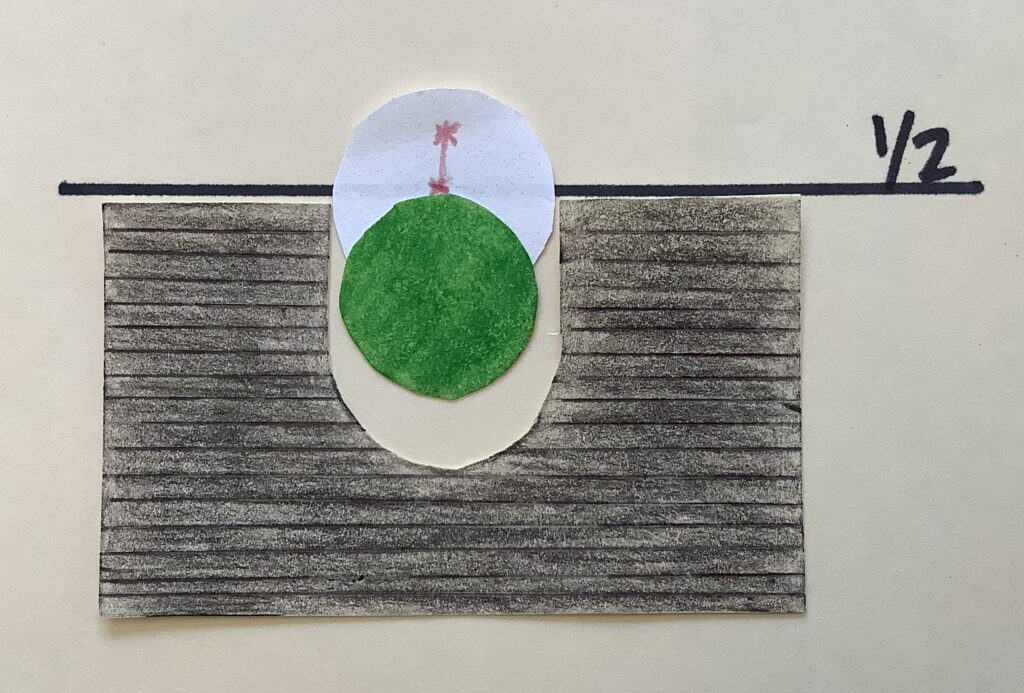

At 25 yards, I maintained the same sight alignment and placed it on the lower third of the 10” plate, like this:

Once again, the hold piled my 130 grain FMJ bullets in the top half of the plate. It’s important to note that the plate was starting to be covered by the dot at this distance, and if I wanted to see much of it in my sight picture, then I had to hold the front sight a little out of the notch, as I was doing. If I had put the ball in the bucket, I would have begun to cover most of the plate with the dot.

At this distance of 25 yards, I was routinely putting five out of five rounds on the plate—something I would not have expected from myself with my Model 640, which has a better trigger than the UC (after some custom work and thousands of rounds downrange), but worse sights (OEM, with a little orange paint dabbed on them).

A couple of us were feeling frisky at this point, and we pushed the line back to 50 yards. I continued to use the same sight alignment at 50 yards, but placed the top edge of the front sight about a quarter of the way up from the bottom:

At 50 yards, the 10” plate would have been mostly, maybe totally, occluded by the XS dot, and it would have been difficult to use the “ball in the bucket” alignment with a center hold, but my tall front sight alignment allowed me to see the target and put the 130 FMJs in the top half of the target when I did my part. At this point, I’d been shooting .38 Specials through the aluminum frame guns for about four hours, and was starting to get fatigued, but could still put five out of five rounds on the target occasionally, although most of my attempts were normally three to four hits out of five.7

For grins, I began shooting strong hand only at 50 yards and was typically rewarded with two to three hits per cylinder at that distance. It didn’t take long before my tired hand needed a break, so I began shooting weak hand only, and was very pleased to find I could still land two to three hits on the steel per cylinder, even as a Southpaw. That’s about half of my rounds hitting a 10” steel plate, weak hand only, at 50 yards, after shooting all day long!8

I was impressed. I don’t think I could do that with any other factory snub on the market.

RELIABILITY

I need to comment about the reliability of the guns we shot, because they gave an impressive performance.

Counting the writers, the staff, and other attendees, we had about 20 shooters working with fourteen guns (eight in .38 caliber, six in .32 caliber), and the group fired an estimated 3,500 rounds through them, in total.9 None of the guns were cleaned or lubricated during the shoot, yet we didn’t have a single stoppage. That’s pretty darned good for a bunch of small frame revolvers!

I’m only aware of two, possibly three, mechanical issues with the guns. Rich Grassi had a thumbpiece screw start to back out on him, which was easily fixed with a screwdriver. Likewise, a 442 UC I was shooting had the rear sight set screw start to back out, and block my view of the front sight. RevolverGuys are used to checking and tightening screws regularly on their revolvers, so these issues weren’t too far outside the normal revolver experience, but we’d like to avoid them anyhow. Andrew Gore agreed, and got on the phone with Smith & Wesson Lead Product Engineer Andrew Foley right away, and before we’d left the range, Foley was already drafting a running change to put thread locker on the screws, to remedy the issue.

I mentioned a possible third issue: In the afternoon, I started to shoot some Clear Ballistics gelatin with .32 and .38 caliber UCs, and I had one 632 UC spit some fouling back into my face when I shot it. The gun had been shot hard all morning (the .32s were in high demand and were never idle) and may have developed a small timing issue, but it also could have just been dirty from shooting a steady diet of soft lead wadcutters and not being cleaned. I only fired a few more rounds out of the gun, and didn’t get back to that particular chamber, but the gun didn’t give me any additional problems, so I’ll call this a wobbler, for now.

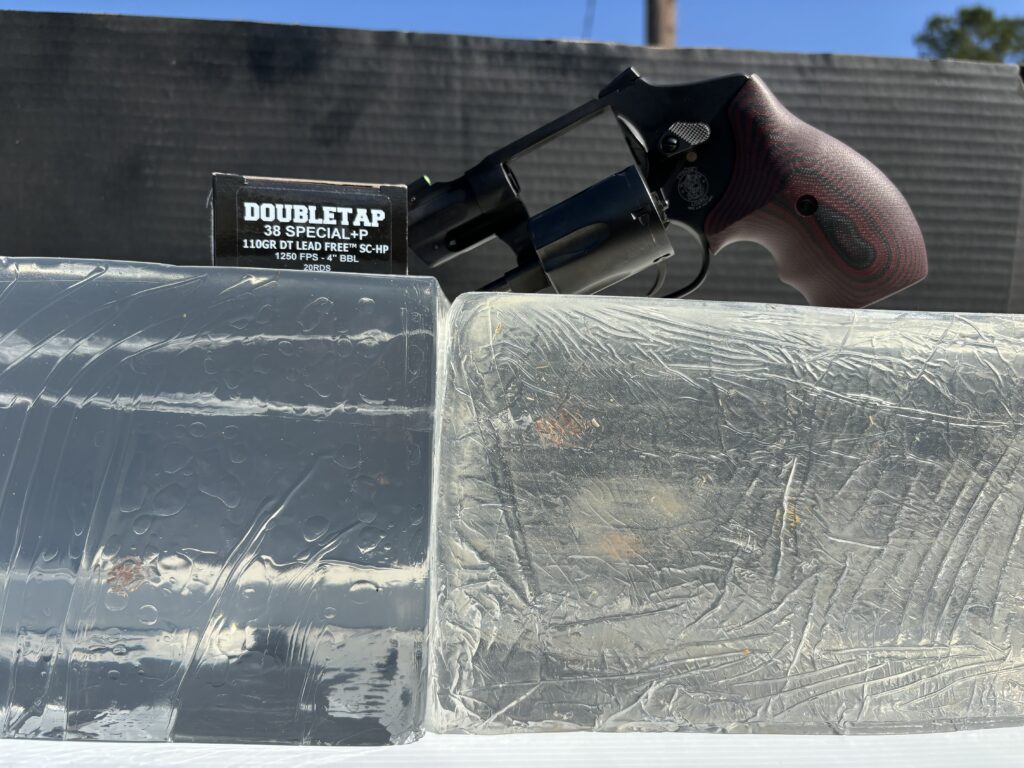

I personally shot somewhere north of half a case of ammunition through four different guns at the media event. I started with approximately 66 rounds through a 432 UC (about six rounds of Doubletap SnakeShot, 36 rounds of Lost River Ammunition Company wadcutters, and 24 rounds of Federal Personal Defense JHP), then changed to a 442 UC, which went about 120 rounds (100 rounds of Federal 130 FMJ, and 20 rounds of assorted JHPs) before that rear sight set screw began to walk out. I traded the gun for a 642 UC that I shot for the remainder of the day, putting at least 360 rounds though it (about 300 rounds of 130 FMJ, 40 rounds of JHP, and 20 rounds of wadcutter), if not slightly more. On top of all these rounds, I shot a few dozen rounds into Clear Ballistics gelatin, using the same 642 UC and a different 632 UC.

I shot that one 642 UC hard, and it got so hot on a few occasions that I could barely hold it for reloading without burning my hand.10 The gun shrugged it all off and ran like a top, never once slowing down or burping. The timing remained perfect, and the barrel-cylinder gap was set so perfectly on the gun that the cylinder never rubbed on the forcing cone, as I’ve experienced so many times with other snubs.11

I was mightily impressed with the fleet of UCs that we shot, and not surprised to learn that Bryan Eastridge measured extremely uniform barrel-cylinder gaps on all of them, when he checked them later.12

ABOUT THAT .32 H&R . . .

All the reporting on the UCs is replete with praise for the .32 caliber guns, which really seemed to steal the show. As I mentioned, I only shot the 432 UC for a short while in the morning before I traded it off for a 442 UC, and I stuck with the .38 Special guns for the remainder of the day, with the exception of a few .32s I fired as part of ballistics testing.

My general impression of the .32 H&R Magnum UCs is very favorable. It shoots very soft, particularly with the 100 grain Lost River Ammunition Company .32 H&R Magnum wadcutters that averaged about 795 fps in the gun, but even with the more energetic hollowpoint loads from Federal and Doubletap. This is not a combination that will beat you up or scare off the recoil conscious. If you can handle the .22 Magnum, you’ll have no problem shooting the .32 H&R Magnum in these aluminum-framed guns, or any of the lesser .32s (.32 S&W, .32 Long).

BALLISTIC TESTING

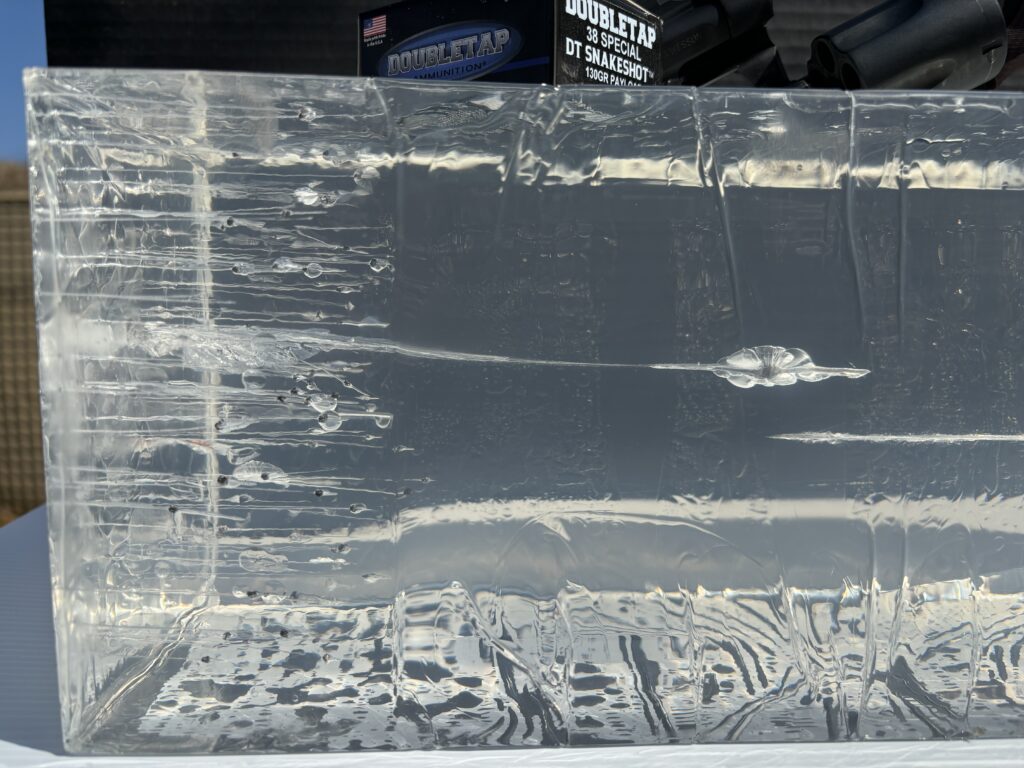

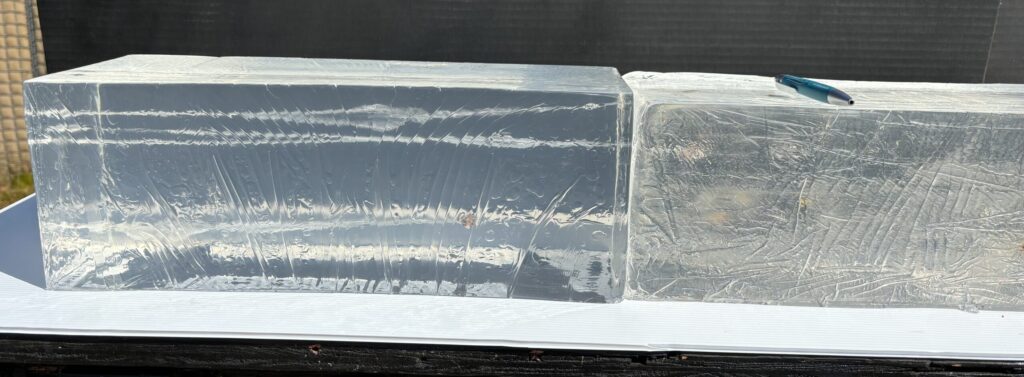

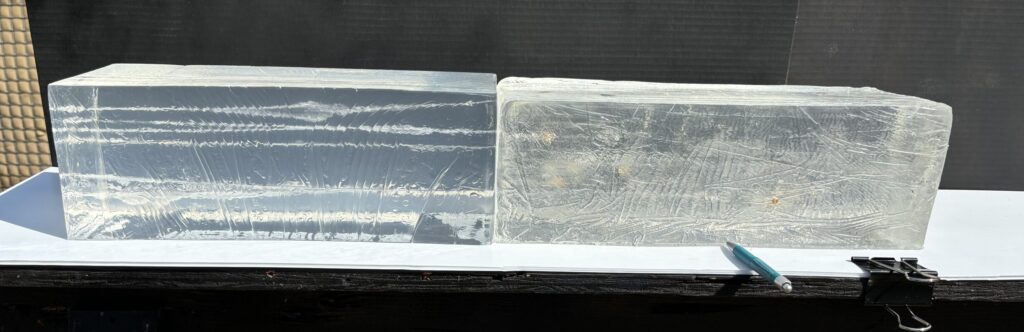

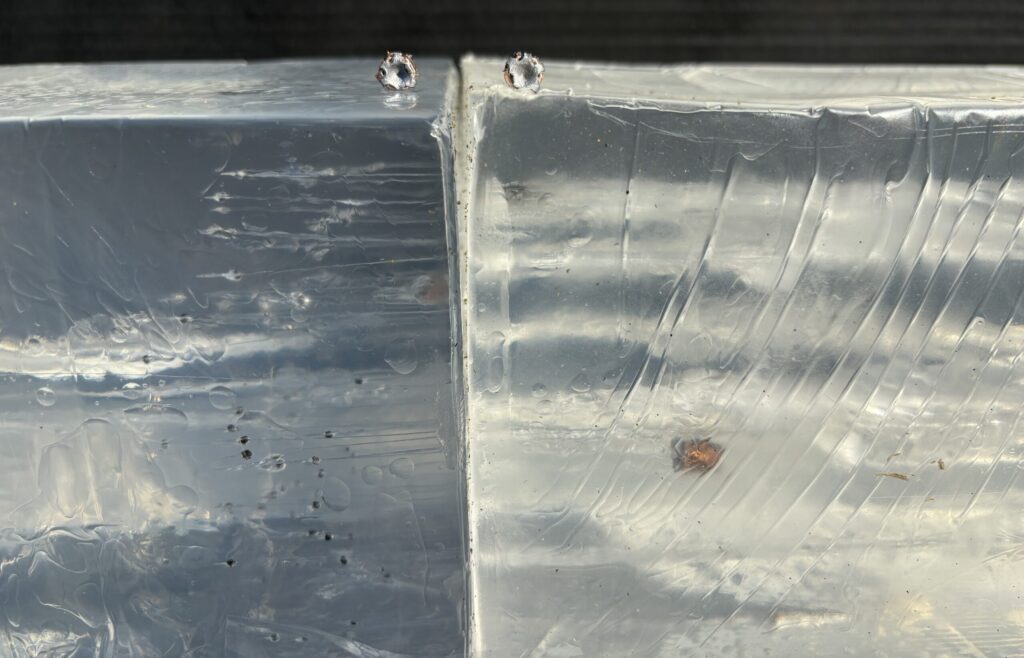

Mike McNett of Doubletap Ammunition brought a variety of .32 and .38 caliber ammunition to the range, as well as some 16” blocks of Clear Ballistics gelatin.

Longtime readers of RevolverGuy will recall that I did an extensive test of the Clear Ballistics product, in conjunction with Hornady Manufacturing, back when I was still writing for Police1 magazine. We determined that, despite Clear Ballistics’ marketing, their synthetic gelatin did not perform like the organic, calibrated 10% ordnance gelatin that’s specified by the FBI for use in their ammunition testing protocol. The Clear Ballistics synthetic gelatin tended to retard hollowpoint bullet expansion, and increase hollowpoint bullet penetration, in comparison to the calibrated organic gelatin.

However, the Clear Ballistics product boasts several advantages that makes it useful. It’s already mixed, is temperature stable, less messy, and allows better photography. It’s much easier to use than organic gelatin, in every way.

The synthetic gelatin doesn’t allow an apples-to-apples comparison to calibrated 10% organic gelatin, and you can’t use the FBI’s yardstick (i.e., 12” minimum penetration depth, and 18” maximum) for measurement in the synthetic gelatin. However, the Clear Ballistics gelatin still produces valuable data to consider, when compared against results from other Clear Ballistics testing, and as the database of Clear Ballistics test data continues to grow, it will become even more useful as a standalone tool to measure ballistic performance.

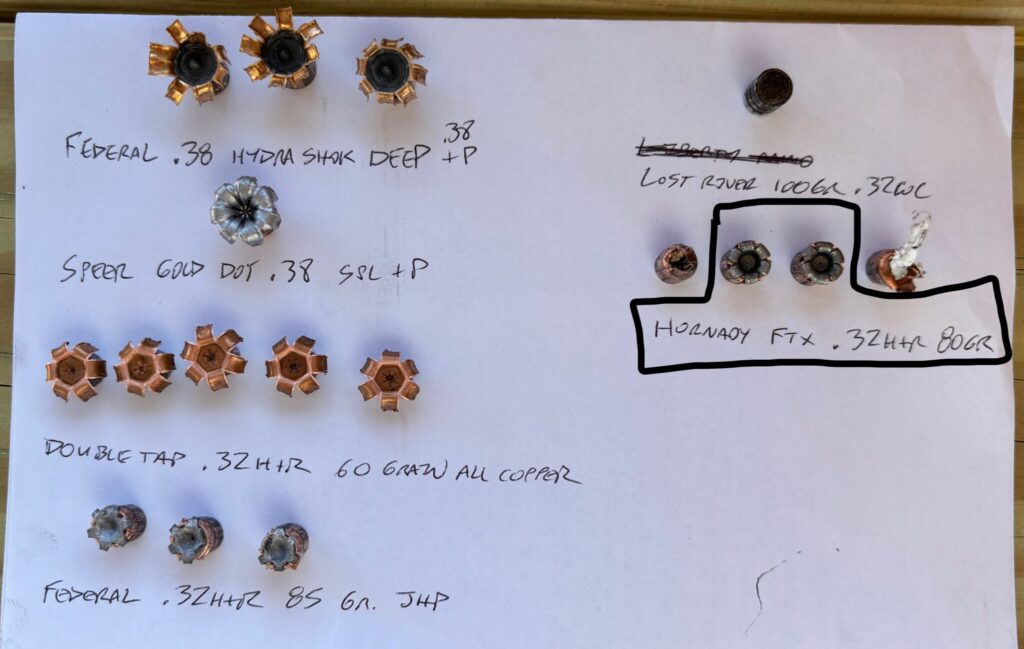

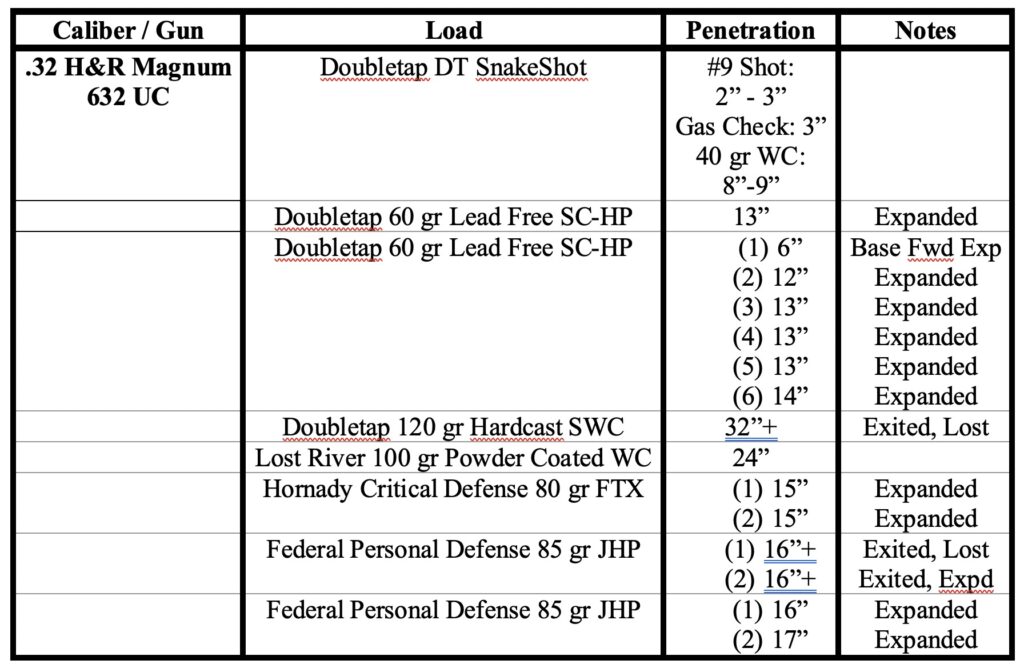

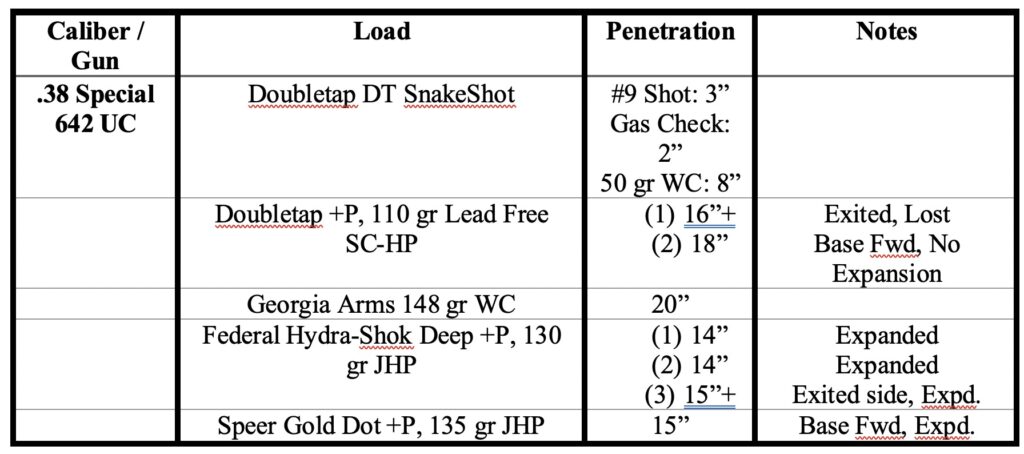

With this in mind, I shot a variety of .32 and .38 caliber loads into the bare synthetic gelatin, including the following loads:

-

- Doubletap .32 H&R Magnum DT SnakeShot. This is a new specialty load from Doubletap, which features 70 grains of #9 shot (about 140 pieces) and a 40 grain hardcast wadcutter, topped by a gas check. Because there is no plastic shot capsule to take the rifling, Doubletap believes their shot load will create denser, more uniform patterns without the “donut hole” effect common with other shotshells. Doubletap SnakeShot is designed to provide an effective snake load, while still offering a useful payload for a surprise attack by a larger animal, including the two-legged variety. There’s no time to change out your ammunition when you come under attack, and DT SnakeShot will make that first trigger pull much more effective than if you just fired a traditional shotshell;

-

- Doubletap .32 H&R Magnum 60 grain DT Lead Free SC-HP. This is an all-copper hollowpoint with deep skives that help it to open up reliably;

-

- Doubletap .32 H&R Magnum 120 grain Hardcast Solid. This is a hardcast lead semiwadcutter that’s a fairly hot load for the .32 H&R Magnum;

-

- Federal Personal Defense .32 H&R Magnum 85 grain JHP. This load has been the standby for defensive use in the caliber since the 1980s. The bullet is a standard, cup-and-core JHP—it’s nothing fancy, but it works;

-

- Hornady Critical Defense .32 H&R Magnum 80 grain FTX. This is a highly-engineered hollowpoint with a polymer plug in the nose that’s designed to promote reliable expansion after barrier (heavy clothing) penetration;

-

- Lost River .32 H&R Magnum 100 grain powder-coated wadcutter. This is a soft lead wadcutter that’s powder coated to prevent fouling;

-

- Doubletap .38 Special DT SnakeShot. The .38 Special version of McNett’s new snake load features the same 70 grains (140 pieces) of #9 shot, but adds a heavier, 50 grain hardcast wadcutter to the mix;

-

- Doubletap .38 Special +P 110 grain DT Lead Free SC-HP. The all-copper hollowpoint in this cartridge is loaded to a higher pressure to generate greater velocity and energy;

-

- Federal Hydra-Shok Deep .38 Special +P 130 grain JHP. This fantastic successor to the storied Hydra-Shok line, previously explored here at RevolverGuy, achieves greater penetration depth, allowing it to pass the FBI Protocol Bare Gelatin and Heavy Clothing tests from a snub;

-

- Georgia Arms .38 Special 148 grain Ultimate Defense wadcutter. This wadcutter load, previously reviewed by Kevin, is designed to provide a good balance of controllability and terminal performance from a snub;

-

- Speer Gold Dot .38 Special +P 135 grain JHP. The banner defensive load in the caliber, and the baseline chosen for .38 Special UC sight regulation.

Jello junkies

We didn’t have sufficient time or gelatin to do a comprehensive test of each load, and often just fired a single round. We’d normally like to fire at least five rounds of each load to get a useful data set, because bullets often behave unpredictably in gelatin, and it’s risky to make judgments from just one or two samples.

Additionally, it would have been useful to fire these loads through an FBI Heavy Clothing barrier, to see what effect it would have on performance, but we lacked the time and resources to do it.

Despite this, RevolverGuys may still find the results of our efforts interesting, so here’s what we found when we shot these loads into the synthetic gelatin (all shots fired from the reader’s left):

I think the attendees at the media day were rather surprised by the penetration numbers from the .32 caliber solids, which went deep into the synthetic gelatin (and sometimes, all the way through). Frankly, I was more surprised to see the penetration depths achieved by the .32 caliber hollowpoints, even after they expanded. The little bullets gave a credible performance from the UCs, matching the expansion ratios and penetration depths of some of the best .38 Special +P loads available. The .38s obviously delivered more energy on target with their heavier projectiles, leaving larger temporary stretch cavities and ever-so-slightly bigger permanent wound channels behind in the bare, synthetic gel, but from the perspective of penetration depth, you don’t seem to be sacrificing anything with the .32s, in the absence of a barrier.13

I FEEL THE NEED . . .

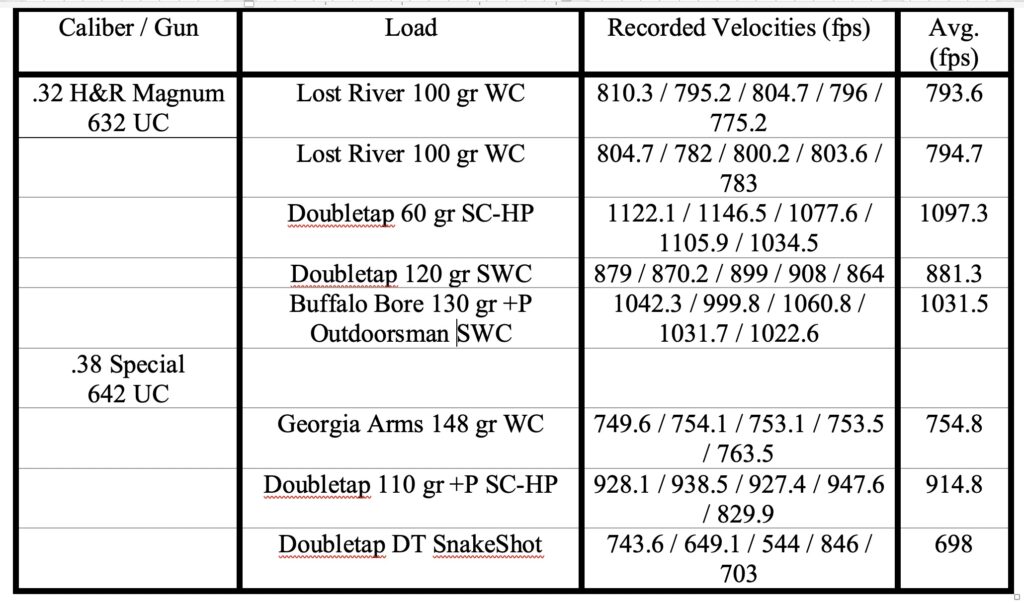

Incidentally, Rich Grassi brought the new Garmin Xero C1 Pro chronograph and measured some loads with the assistance of Rob Garrett. They recorded the following velocities:

That Buffalo Bore .32 H&R Magnum +P 130 grain Outdoorsman load was a real barn burner in the 632 UC, and definitely belongs in a different class than the other .32s out there. I didn’t shoot this one, but both Rich and Rob reported that it really thumps your hand in the aluminum frame guns, and wouldn’t be a pleasant load to shoot much of.

The .32 H&R Magnum Doubletap 120 grain load wasn’t as stiff, but still recoiled more than rest of the other .32 selections we fired. This was the hardest kicking load I shot in the .32 UCs, and I’d rate it similar to a standard pressure 130 grain .38 Special load, as a comparison.

The .32 H&R Magnum Doubletap 60 grain SC-HP load shot a bit faster than the 130 grain Buffalo Bore load, but at less than half the bullet weight, it still remained very controllable. Despite its louder bark, I thought it shot softer than .38 Special 148 grain target wadcutters in the 642, and was impressed with its uniform performance in gelatin.

ROUNDUP

I think that’s a pretty complete survey of my experience shooting the UCs. I didn’t get a lot of time with them, but still managed to squeeze a lot of juice out of the lime—frankly, I probably shot more rounds through these guns in 5.5 hours than most J-Frame owners would in a lifetime of owning them.

As mentioned, Kevin’s been working with a production 432 UC and a pile of ammo, so he’ll have one of his excellent field reports to share with us soon. I’ll be interested to see how the production gun stacks up against the pre-production samples that I shot.

By now, some of you have your own UCs in hand, and I’ll be interested to hear your thoughts on them too, here in the comments.

As always, be safe out there, and thanks for reading!

*****

ENDNOTES

1.) I will note that the guns I shot were pre-production models, which likely benefitted from extra attention during manufacture and assembly. I haven’t been able to shoot any of the production models yet, as they’re still not legal to sell in California, and will caution that the first production run of any gun, by any maker, will usually have a few discrepancies that need to be addressed, as the manufacturer works out the kinks in their manufacture and assembly processes. Fortunately, Kevin has one of the production 432 UCs and is doing a T&E as we speak, so he’ll be able to fill in the gaps, and let you know what the production models actually look like, very soon.

2.) As longtime RevolverGuy readers probably know, I tend to place the web of my shooting hand up very high on the back strap of a Centennial-style gun, often with a little bit of the web overlapping the recoil shoulder itself. I find this high grasp does an excellent job of reducing muzzle flip and keeping the gun flat as I’m shooting it. It also changes the angle my trigger finger approaches the trigger, and allows me to comfortably engage it with the distal crease on my long finger, without getting cramped up on the small gun.

3.) I tend to migrate back and forth between Mas Ayoob’s Stressfire Reload technique and the reloading technique that I grew up doing before that, which is based in 80s-era police training, and called by various names. In the latter technique, the opened gun is held muzzle up by the support hand, and the shooting hand slaps the extractor rod to clear the cases, then moves to fetch the spare ammo.

The weakness of the technique lies in the fact that the gun cannot be comfortably held in a pure vertical position for reloading, and usually winds up with the muzzle angled about 30 to 45 degrees away from the body. This interrupts gravity from doing its thing, and sometimes the newly-released cartridges from a speedloader don’t fully seat without an extra push. It’s actually kind of helpful though when you’re feeding the gun with strips or loose cartridges, as I spent the morning of the media event doing, because the gun is held at a more natural angle for your primary hand to feed it.

With the HKS loaders that I used in the afternoon, however, the Stressfire technique is superior, as it holds the gun in the vertical plane and takes full advantage of gravity to seat the payload

4.) I have really come to appreciate and like the Ruger LCR revolvers, but one of the things I dislike most about them is their weaker trigger reset, which is powered by a small torsion spring. The LCRs have a light pull that makes them pleasant to shoot, and the tiny torsion spring contributes to that, but I find myself more likely to short stroke the LCR than any other snub when I’m shooting fast, because the trigger reset is not as strong. Fortunately, the new UCs don’t have a problem with this.

5.) RevolverGuy Dean Caputo has introduced a lot of police officers to the Kimber K6s with the same results, and notes that the sights are often their biggest takeaway about the gun, garnering more attention than other features like the excellent factory trigger, and the six-shot cylinder.

6.) Even after I made the correction, the sights still aren’t ideal. I could only take so much material off before I began to crowd the tritium lamp on my K6s DC, so the front is just a tad higher than I’d like. Additionally, it’s a little distracting to have the dot sitting up near the top edge of the sight, where I’d like to have a little more bare metal to focus on, when trying to get a precise alignment.

Fortunately, the Kimber K6xs that I shot in January at the SHOT Show didn’t suffer this malady. I think Kimber did a much better job on the sight regulation on the aluminum-framed guns. Now if we could just talk them into fixing the steel ones . . .

7.) I’ve got a witness! Even though I didn’t bribe him to say it, Rob Garrett reported a 70% – 80% hit rate, which may have been slightly generous, particularly when I was shooting with one hand, but it wasn’t far off. (See the P&S Modcast #378 at 41:58)

8.) I wasn’t the only one, either. American Rifleman’s Justin Dyal, who’s a much better shooter than I am, was shooting a .32 H&R on my right, and kept cleaning a six-plate rack out at 50 yards, shooting six for six. Some of the other guys on my left were getting good hits, too.

We kept the steel ringing at 50 yards, much to the delight of the proud parents of the UC, Jason and Andrew, and much to the amazement of some spectators. At one point, Jason remarked to an observing Smith & Wesson employee, “I bet you guys don’t normally hear this much steel ringing with J-Frames at your media shoots,” to which the employee responded, “we don’t even hear this much steel ringing when they’re shooting [.22 LR caliber] M&P15-22 rifles!” (See the P&S Modcast #378 at 58:25)

The guns can shoot!

9.) See the P&S Modcast #378, at 48:30.

10.) See the P&S Modcast #378, at 51:15 and 54:40

11.) Readers will recall my ongoing battle with my 3” Kimber K6s, which was set too tight and frequently bogged down inside of 75-100 rounds. Even my pet Model 640 wouldn’t have lasted as long as that 642 UC did. I probably would have felt the cylinder rubbing inside of a few hundred rounds, with that one.

12.) See the P&S Modcast #378, at 53:15.

13.) It’s not clear that energy, in itself, really contributes much to the nebulous “stopping power” that shooters are always chasing. I know there are people who strongly believe in wounding mechanisms like “energy transfer,” “shock,” or temporary stretch cavities, but I’m personally skeptical of them. Handguns are generally poor stoppers, regardless of caliber, and I think we’d be wise not to expect too much from any of them, but particularly from .38 and .32 caliber snubs, which live in the shallow end of the energy pool.

That doesn’t mean we can ignore energy though, because it allows a bullet to do work—to expand and penetrate. Our brief and incomplete experience with the bare synthetic gelatin indicates that the .32s have sufficient energy to expand and penetrate on par with the .38s in that medium, which is promising, as far as it goes.

But I would have liked to shoot through some barriers, to see how it would have changed things. It would have been illustrative, for example, to see how FBI Heavy Clothing affected the outcome. The blunt wadcutters which did so well in bare gelatin would have had a tougher time getting through the layers of heavy clothing, and it would have been interesting to see what kind of penalty it extracted on bullets of this type in the two calibers. Similarly, some of the hollowpoints we tested may not have expanded as well with a snoot full of fibers, possibly resulting in deeper penetration than they normally achieve in bare gel. Would the .32 hollowpoints have fared better or worse than the .38s here? I don’t know.

So, it remains to be seen if the .38 Special’s extra energy would give it a significant edge in barrier penetration and post-barrier terminal performance over the less energetic .32 H&R Magnum, or if the .32’s smaller cross section would help it overcome its energy deficit through reduced drag. It seems like the .32 can hang with the .38 when there’s no barrier (at least as far as penetration is concerned), but will that change with a barrier in place? I don’t know, but we’ll probably have some good answers to that question before long, since the engineers at Federal Ammunition are going to be working on .32 H&R Magnum cartridge development, using the information and experience gleaned from their previous .30 Super Carry work. We’ll probably see some optimized ammo, like a .32 H&R Magnum Federal Punch load, in the catalog before too long, if we’re lucky.

In the meantime, it’s good to know the .32 H&R can poke holes in bare gelatin on par with the .38 Special. It indicates that if you can put one of these tiny slugs in the right place, it will probably do the job as well as a .38 Special can be expected to.

As law enforcement trainer, writer, and friend Evan Marshall once observed, “the three most important factors in ‘handgun stopping power’ are shot placement, shot placement, and shot placement.” In this sense, the improved controllability of the light-kicking .32 H&R in these lightweight snubs may give it the edge over its Special competitor, regardless of what the comparative data says about expansion and penetration. Good hits win battles, and it’s easier to make good hits with the milder .32 H&R—for everyone, but particularly for those shooters who are more recoil conscious, due to injuries, impairments, inexperience, or demeanor.

It’s definitely something to think about, and having that extra round doesn’t hurt, either. Being honest though, I’m still not sure I’m personally ready to trade my .38+P for the .32 H&R. I’m open to the idea, but this is going to take some more work, to figure out.

Thank you the write up, sir. It’s good to hear that Lipsey’s work on these new J-Frames appears to have paid off, and I hope they help spur further interest in .32 H&R Magnum. I LOVE shooting the .32 H&R, and it is my new carry round. I definitely can’t go back to .38 Special in a snub now that I’ve had a taste.

That being said, I don’t know if I will picking one of these up for myself. Shooting .327 Federal out of the Taurus 327 was a lot more manageable than I was expecting, and I think I’d like to keep the option rather than switch to a pure .32 H&R.

May still get a 632/432 for my mother, although we recently found a S&W 30-1 in .32 S&W Long (old enough it has the flat cylinder latch) in a pawn shop in very good shape for $500. She’s become quite happy with that, so I guess we’ll see if she’d be open to another .32.

Also, if I may, I would like to mention that the guys over at Steinel Ammunition recently introduced defensive loads for .32 H&R Magnum and .327 Federal Magnum earlier this week. The .32 H&R load sounds like a duplicate of Federal’s JHP load, but is likely a bit hotter. I already ordered some myself, and I anticipate trying them. I’ve had good results with their .38 Special Snub load the past several years.

Axel, there’s certainly nothing wrong with the .327 FM if you shoot it well, and it’s nice to have options. I’m one of those guys who prefers to carry a steel frame snub, so it wouldn’t bother me a bit to carry a steel 327, but I’d probably still feed it with .32 H&R.

I appreciate the point out to Steinel and their new loads. I’ll reach out and see if we can arrange a test for Kevin.

Mike, maybe we can convince Kimber or EGW to make an optic plate for the 3” K6s DAO. That’s solve the sight issue and better take advantage of the excellent trigger.

I too have cut my thumb (and bled all over my grips) during qualification with a j frame… which makes me wonder why Smith did away with the flat latch. Perhaps they saved some money or something.

While I’d say energy on target is not as important as some people think, I still want the three inch barrel for a little extra. It could mean the difference between a hollow point expanding or not quite- especially in Ohio winters with all the coats and flannel associated.

Sure wish my agency would authorize .32 for off duty carry, but we did away with .380 recently because “ FBI protocols” so I don’t expect that to happen. Sometimes those standards are NOT what I’m looking for.

As always, thank you Sir, the article was great to read.

Riley, I don’t have any meaningful experience shooting the flat latch guns, but I think the flat latch was considered difficult to operate because the thumb could slip on it, and the new concave piece was designed to provide better leverage and purchase. I gather there were about three different generations of flat latches, with the last one including a bit of a “ski jump” near the cylinder, to give the thumb better purchase on the part, but even this fix was deemed insufficient. The rounded, concave piece that replaced it is easy to use, but also stands prouder and has sharp edges that result in J-Frame Thumb. I always have to polish mine smooth to reduce that possibility.

10-4 on the FBI Protocols! They were designed for evaluating law enforcement ammunition, but were truly focused on service pistols. It’s probably not a fair application to subject off duty or backup guns to the same standards, across the board. The Bare Gelatin and Heavy Clothing stages seem appropriate, but not necessarily the rest. Even if we just look at those two standards, there’s lots of great ammo that can be disqualified by the FBI’s yardstick. My favorite example is 9BPLE, which doesn’t fare well in the protocol, but has an excellent track record in the real world, where it counts. In the end, there needs to be some subjectivity involved in the process, so good and valuable options don’t get disqualified.

Thanks Mike, for another good one. It was cool to hear of your (and the other writer’s) experiences with the UC’s. Your diagrams to help the reader picture the sight alignment and sight pictures you used to get missiles “on” at various ranges were very helpful. Neat stuff, man! I’m getting trigger time and gathering data and hope to have a “.32 postscript” to your excellent series on these little guns soon.

Thanks Kevin! My time with the .32 UC was brief, so I’ll be very interested to learn more about your experience with it!

Thanks for this one, especially the ballistics.

Not yet able to obtain a production 432, I’m looking forward to Kevin’s evaluation with great interest.

He always does great work, and we’ll be excited to share it with everyone when it’s ready. I burdened him with three different evaluations at once, so he’s a busy man these days. I might push him to finish testing the other guns first, just to mix up the content a little bit. I’m afraid 25K-plus words on the UCs in the last month might have some readers looking to change the channel!

Another outstanding review Mike!! I picked up my 442UC about two weeks ago. During some dry fire draws with snap caps, i discovered the front sight pin had walked out slightly. I tapped it back in and after firing about 200 live rounds though it, it has not repeated that issue. I have nothing but love so far for my UC. It fits a well used Galco Combat Master I have, as well as my Desantis FLETC holster. I strictly use Safariland Comp 1 speedloaders and they work beautifully with no hang ups. When i fired it, I didn’t have much in the way of “carry” ammo and only had UMC 125gr +P semi jacketed hollow points, as well as Blazer Brass 125gr fmj. At 15yrds, it fired those to the sights and I had no problem keeping them in a 6in circle at that distance. I tried 158gr lead round nose and 158gr semi wadcutter ammunition just to see where it prints. They shoot a few inches high, with a 6 o’clock hold. I dont feel they are out of the question but one would need to practice and get used to that. For some odd reason, the semi wadcutters printed a little bit lower then the round nose but not much. I intend to get more range time and shoot it at further distances if the NM wind would allow it.. I was really excited to read about these snubs and I am not dissapointed at all with mine. Thank you for all of this great content!

Mark, thanks for the valuable report on your gun! My experience with these is strictly limited to the pre-production versions we shot, so it’s very helpful to hear reports from owners of the real deal. We all know there can be quite a gap between pre-production, and production!

It sounds like the 158 SWC might be loaded a little differently (velocity) than the 158 RNL, which would cause the difference in POI. I’m super glad to hear your available 125s shot right on—I would have expected that, but it’s good to get the confirmation that the sights on the production guns are properly regulated.

Thanks for presenting the very thorough evaluation of these guns. Your time and effort are greatly appreciated. My wife is slowly getting into shooting and has her own GP100 and SP101. She enjoys our range outings and is not recoil shy with the steel frame guns but I advised her not to shoot my 642’s yet. I don’t want her to develop a flinch. The .32 H&R is a better suited cartridge for an aluminum frame gun for new shooters. If she ever gets to the point that she wants to carry concealed, the 632 UC will be at the top of the list of light weight carry options.

Derek, you’re a wise man, and your wife is lucky that you’ve been so thoughtful about it. We’ve all seen how that story plays out when a new shooter is given too much gun, too early. Nothing good comes from that. These .32 UCs were designed for someone just like her, and I think she’ll be very happy with one.

It is very encouraging to read of these lightweight guns holding up under the number of rounds put through them in one sitting. That is quite the workout. I doubt the average ‘joe’ or ‘jane’ puts 600 rounds through an airweight J frame in a lifetime. I’m sure a Motrin and some Maker’s Mark will make your hands feel better in short order. Give a wheelgun to us Revolver guys and if we can’t break it before we go broke, the gun likely can’t get broken, which is more than can be said of the wallet. Which presents a dilema – just how many J-frames is too many; or, is there such a thing as too many J-frames ???

I had to smile at your comment about the Federal 9 BPLE (115gr +P+) not so hot on paper but devastating on the street. That’s been my go-to load since the mid 1990s, and is reknown for stopping fights. So, too, the humble 148 grain .38 Special wadcutter doesn’t make many waves, but I’ll wager I wasn’t the only guy on the street that had them in their J frame backup gun. Jim Cirillo proved the humble wadcutter was more than a match for any job it was deployed for.

Evan Marshall was spot on in his observations on where to plant your shots -location, location, location. It parallels a Native Indian saying that it’s the archer, not the arrow.

I was definitely sore the next day! I wouldn’t want to do that much shooting through an Airweight very often. There’s a reason I prefer a 640 over a 642!

How many J-Frames? Just one more!

9BPLE: Killing bad guys like cancer, since the 1980s. RevolverGuy approved.

Well stated, s. bond. A J-frame snubby topped off with .38 wadcutters is my bag.

I’m glad to be seeing nothing but stellar reviews of the UC’s. The only issue I’ve heard of is a batch with dimly tritium installed but some teething pains are to be expected.

We had a reader complain about a trigger reset issue in the comments to Part II, and I’ve seen some other isolated complaints elsewhere, but it seems like most are happy with their guns, as it should be. The dim front sight issue seems to be the most common complaint—likely an installation process bug that needs to get worked out.

Great to see more info on the 442/642-UC variants. Most of the articles out there focus on the 432/632 UCs and for good reason. I figured the .32 caliber versions would be mild mannered but was very curious about how the VZ stocks would affect recoil distribution in a .38 Special Airweight.

I won’t lie, Carlo. I like the stocks a lot and think they do a very good job, but the hard G10 can be a little unforgiving during high volume shooting with an Airweight gun like this one. Most folks will never shoot these guns that much in a single session.

3x thoughts:

1. I can’t say it enough, the quality of writing on this site is fantastic. Very well done!

2. After shooting both which do you plan to carry, 32 or 38?

3. I had no idea a company was producing 32 duplex loads. I carried an LCR in 327 for several years. I live in snake country and often work or hike out in the sticks with young kids. This article inspired me to roll my own duplex loads:

https://loaddata.com/Article/BenchTopics/Snake-Loads-for-the-327-Federal-Magnum/138

Following that I wrote up my amateur thoughts here:

https://www.thetruthaboutguns.com/what-i-carry-and-why-the-327-federal-magnum-ruger-lcr/

My duplex loads were decent, very low recoil and good enough for snakes at about 10ft. The bullet hit pretty close to POA and the shot penetrated a couple laters of cardboard. That’s enough so I called it good. But someone producing a factory load gives me a better option, I’ll have to try them out.

I only fired a half dozen of the DT SnakeShot loads, but the WC hit true each time and the patterns seemed good within 5 yards. I’ll be interested to hear what you think of them, after trying them.

As I mentioned in the Endnotes, I’m not personally ready to give up the .38+P for the .32 H&R yet. The .32 H&R solution looks very promising, and I think it might be a perfect solution for people who need a low-recoil option, but I still have the ability to shoot .38+P well and still have unanswered questions about .32 H&R performance after light barriers. Additionally, I’m already heavily invested in .38 Special ammunition, and have limited access to .32 H&R ammo here in California, because of unconstitutional restrictions that complicate buying it. I’m not ruling out the .32, pending further investigation and court rulings, but will stick with my .38+P for now.

I only fired a half dozen of the DT SnakeShot loads, but the WC hit true each time and the patterns seemed good within 5 yards. I’ll be interested to hear what you think of them, after trying them.

As I mentioned in the Endnotes, I’m not personally ready to give up the .38+P for the .32 H&R yet. The .32 H&R solution looks very promising, and I think it might be a perfect solution for people who need a low-recoil option, but I still have the ability to shoot .38+P well and still have unanswered questions about .32 H&R performance after light barriers. Additionally, I’m already heavily invested in .38 Special ammunition, and have limited access to .32 H&R ammo here in California, because of unconstitutional restrictions that complicate buying it. I’m not ruling out the .32, pending further investigation and court rulings, but will stick with my .38+P for now.

Anner, thanks for those links — if something like your dream LCRx .327 ever gets produced I’d buy one too!

For what it’s worth, lipseys, shows a talo LCRx 327 3 inch coming.

Jason

What?!?! Oh boy, saving my pennies now

Good article/series of articles Mike, as per normal. As a man who has carried a J frame Smith almost every day for the last 35 years, and shot them a lot, I believe the best most important thing Smith and Wesson did with these guns is to upgrade the sights. I think a lot of people will be surprised at what they can do with a snub with those sights and some practice. Oh, and that other stuff, that usually cost a lot from a gunsmith, probably won’t hurt either.

I hope Smith and Wesson makes all these upgrades, but at least the sights and missing lock the new standard.

Keep up the good work.

Thanks BC! Yes, the lock and sights are a huge win, and I hope they’ll translate to other models.

I recently purchased a 442UC.

First thing I did was replace the grips with NOS Uncle Mike’s boot grips; Because, that is what I’ve had on my decades old Model 42. (and the VZ grips have a sharp edge near where they don’t quite meet the trigger guard that caused a pain on every rapid draw from IWB or OWB holsters with the bottom of trigger guard exposed). No one else complains about this – I get it, grips are a very personal thing. Also, I have decades of muscle memory for the smallish Uncle Mikes boot grips sadly no longer manufactured.

At any rate, old Model 42 and new 442UC had very near identical trigger pull feel: 42 after 1000s of rounds, 442UC right out of the box. Now the same grips are on both. Ready to test with same Ammo.

Went to range. Only perceptual difference was the sights. At 7 yards 42 and 442UC seemed to shoot almost to an identical spot (center of group a bit above point of aim). However, 442UC had a much tighter group (often three holes touching with slow fire). Cylinder lock up and play seems about identical. The grips are identical. Ammo from same lot. Therefore the difference seems to be principally in the sights.

I think the sights are really really well thought out – an excellent choice for a small defensive side arm. The sights just work! The round bottom of the rear sight provides enough of a circular pattern to utilize the intrinsic human brain process that automatically seeks symmetry and concentricity. Brilliant!

After two trips the the range and some dry fire I believe the 442UC is smoothing out. So I expect the trigger feel to improve with some use. (I believe I can tell it is already happening).

I concur with BC above. S&W needs to make this sight system available across the J frame line up.

AND, No internal lock!

The other engineering improvements (Ti thru frame pins, new spring rates, indexed shroud over barrel, recessed barrel bore , chamfered chambers, beveled cylinder…did I miss anything?) add up to an exceptional value. For a serious personal defense EDC this is an exceptional value. This sights alone make it just about worth the premium price. The whole package is amazing.

I am thrilled to have such a well thought out ‘custom pistol smith grade’ revolver that can be carried all day, everyday! Lipsey’s and S&W brought their “A” game together to produce this “E ticket” ride.

Colonel, thanks for the constructive feedback and the comparison between the two guns. That’s much appreciated. I’m glad the new gun is performing so well for you!

As always, another outstanding piece of editorial brilliance.

Thanks Mike

Rob

Thank you Sir! Much appreciated!

Mike, I very much have enjoyed and appreciated this three part series on the new ultimate carry j-frame! Thank you.

I was lucky enough to get a 632-UC about a month ago and my first impressions of this snubby are very good! Mine, like some others I have read about on the web, came with a dead front sight. However, Smith & Wesson quickly sent me a replacement.

I’m on the fence concerning the grips. My hands are slightly smaller than average and my fingers don’t quite wrap around as far as they do on the more standard S&W boot grips. And the grip texture is not as sticky as I like. Overall I’m very pleased with this new J-frame and all of the “custom gun” features and I will likely purchase one of the 642-UC versions all so.

Thanks again for your excellent writing!

Thanks Glenn, I’m glad it was helpful to you, and appreciate your kind comments.

I’m disappointed that you experienced the sight issue, but I know S&W has been working to correct the installation process that was breaking them during assembly, and hope this will cease to be an issue soon.

The grips may not be a good fit for a smaller than average hand, but you’ve got some good alternatives out there, and I suspect you won’t have any trouble finding an interested buyer, should you choose to sell them!

Those grips would look great on my old PC 442. Just sayin’.

I hope Smith and Wesson can fix their quality control. That’s the only thing keeping me from buying a 442UC.

They’re working on it Steve, and I hear you loud and clear!

Months after this series of articles, and about 1mo of EDCing my 632UC:

It’s fantastic. Buffalo Bore WC hits exactly to POA at 5-10yds, perfect. Recoil with that excellent load is still lighter than any .38 Special load I’ve ever shot through a 642 (almost identical weight, grips). The one exception is powderpuff .38 cowboy loads, a handloader’s attempt at having the bullet barely squeak out the muzzle and dribble onto a steel target—obviously not a factory load, and an instant blocked barrel in a carbine.

The DT snakeshot duplex loads are excellent. The bullet hits to POA and the shot pattern seems usable to about 5-10ft, which is all I’ve ever expected from any snakeshot load (CCI factory and my own handloads). They penetrate layers of cardboard the same as .38 Special snakeshot loads.

I shot a variety of .32S&W Long and .32 H&R Mag loads, all quite accurate and hitting at POA.

Sights: the best I’ve seen on a pocket revolver yet. Better than my previous favorite (front fiber optic rod, rear square notch). My only complaint is the finish on the XS steel: it’s August, I sweat, and I’ve seen some light surface rust. A little rubbing with an oiled cloth and it disappears, but it’s disappointing to now wipe down sights regularly when the rest of the gun is so corrosion resistant. A nitride finish or cerakote would probably solve this.

Grips are slightly shorter than other G10 grips I have on J-frames and LCRs. I can barely get my pinky anchored on the bottom, but given the light recoil it’s not a concern. The grips suit this gun (in this caliber) perfectly.

I added a TechnaClip pocketclip for AIWB carry and alternate between that and pocket carry (Blackhawk pocket holster) depending on dress code.

This was a refreshing change: for a stock J-frame I’m accustomed to installing better sights, grips, deleting the lock, adding a pocketclip, dry-firing, and tweaking action springs. The UC arrived 99% ready to carry as-is, just a pocketclip for my personal carry preference. That is fantastic.

All in all, this is now my primary EDC and my #1 recommendation to folks looking for a no-frills, self-contained entry to the world of concealed carry.

I stand by my previous comments, I think in previous articles: if S&W made a “632UC-PD” in .327 Fed Mag I’d absolutely buy one, but I understand that a scandium frame and pricetag only appeals to 2% of their customer base while the airweight frame and pricetag appeals to a broader audience. The ability to scrounge 4x SAAMI cartridges to feed it is enough for me to pay extra; being able to carry potent .327 FM loads (GoldDot, Underwood XD) is a bonus.

As is, I load my 340PD with 1x snakeshot (a DT duplex load), 3x .38+P (PDX-1), and 1x .357 Mag (125gr Golden Sabre, the last chamber since recoil mgt is moot on the last round…and if I get to 5rds fired then I may be needing that extra oomph). I’d do something similar with a “632UC-PD”, but have 4x Buffalo Bore WC in the middle chambers.

Thanks for the great report, Anner! Disappointingly, the only reports I’ve been getting on the UCs have all involved complaints about broken night sights, sight regulation issues, stuck cylinders, and action gripes, so it was encouraging to get your generally positive review.

I appreciate the data point about the rusting on the front sight, as I hadn’t heard that one yet. It’s a good thing to look out for.

I wouldn’t hold my breath waiting for a .327 FM version from S&W, but Lipsey’s will soon be selling a six-shot, .327FM SP-101 exclusive with an upgraded front sight that I think will interest you very much. Same for the TALO 3” LCRx in .327 FM.

For those interested in a lighter kicking gun, we’ll also see a .32 H&R version of the LCR soon. The .32s are definitely getting a lot of renewed interest!

I’m loving this revival in .32’s!

I see Lipseys and Talo have several DA revolver options available now or soon. I’ll have to check out that SP101. A commenter here drew my attention to the LCRx 3” in .327 FM; I have my name on the books at my local FFL for the first one they get, that’ll be my “perfect packin” trail gun.

Asking for some advice please. Loved the three articles on this revolver and bought the 432 for a carry arm then went to the range today. Sights were perfect, trigger was excellent but that’s where the problems started. I fired 60 rounds from 5 different manufacturers ranging from LWC Longs to H&R mags. For the 60 rounds I had 8 light primer strikes with no ignition. Six of the rounds fired the second time around but 2 would not fire even after running them thru 3 times. Obviously I’ll be talking to S/W in the morning but I’ve never had to return a firearm to a manufacturer. Any words of wisdom from you experienced revolver guys? Thank you

Eddie, I’m sorry you’re having those issues. Unfortunately, the light strike issue has become a common complaint with the .32 H&R UCs, and you’re not alone–many folks are running into the same.

I think there are two, possibly three, factors at play.

The first is the ammo. The most readily available .32 caliber ammunition on the market right now tends to be .32 Long, from foreign companies like Magtech, Sellier & Bellot (a sister company of Magtech, under the CBC umbrella), and Prvi Partizan. These companies have reputations for using hard primers in their ammo, and they can really give a lightly-sprung revolver like your 432 UC a rough time.

Unfortunately, things aren’t always better on the American front. The high global demand for ammunition components has put a strain on the supply chain, and American companies are having to source primers from a bunch of new sources in order to keep their machines running. The result is that even companies that have traditionally used soft primers, are now using some hard ones in their ammo. Your Federal or Remington .32 H&R Magnum ammo may fail to pop from a hard primer too–much more frequently than we’ve ever seen in the past. Still, you’re bound to have better luck with Federal, Remington, and Hornady than you will with Magtech, S&B, and Prvi.

So that’s the first thing, ammo. The second thing is the light main (hammer) spring on the UC revolvers, which was chosen to make the trigger pull as light as possible, without sacrificing reliability. I’m starting to think they cut it a little too close on the .32s, and the mainspring is too light. I won’t be surprised to see S&W adjust the spring rate upwards, to fix the reliability issue, in the future. In the meantime, you may have to replace your mainspring with a standard (8.5#) or extra power (9.0#) hammer spring to get better ignition reliability. You can obtain them from sources like Brownells or Wolff Gunsprings. Folks may not like the increased pull weight these heavier springs generate, but it’s more important for your trigger to be reliable, than light.

The last potential item is the firing pin. Decades ago, S&W developed a shortened firing pin to help their revolvers pass the drop tests mandated by states like CA with better margin. I think it’s possible this shortened pin became the new standard, and might (!) be contributing to the ignition problems in the UCs. You can source replacement extended-length firing pins from our friends at TK Custom, or from other vendors like Apex Tactical and Brownells. I’ve encouraged some .32 UC owners to give them a try, and have received positive reports back–the longer firing pins seem to help with ignition reliability, even with the more troublesome ammo, like Magtech.

Once again, it’s disappointing to hear you’re having these problems, but you’re not alone. Try tackling these three areas, and I think you’ll see improvements with your gun.

Of course, you can also return your gun to S&W for warranty service. They’re receiving a number of them back for this light strike issue, and probably have a standard fix in place for it (maybe a change to the hammer and rebound slide springs). If not, they will soon!

FWIW, the .38 caliber guns don’t seem to be suffering the same issue with light strikes. All the complaints I’m hearing are coming from the .32 owners, which lends more credit to the ammo being a principal cause.

Good luck, and please let us know how things turn out for you, especially if you return the gun for warranty service.

Thank you sir for the detailed response. I’ll stay away from Magtech, S&B and Provi. Does Fiochi fall into this group as well? Currently my trigger pull is a little over 7 pounds so hopefully they won’t raise that a huge amount with a heavier spring. When you get a longer firing pin, is there a risk of piercing primers? Lastly, can you recommend a very good revolver gunsmith in the DFW area? Thanks again and I thoroughly enjoy Revolver Guy. For a novice like myself, it’s a godsend.

Eddie, I suspect Fiocchi would be similar, based on some reports I’m hearing.

Seven pounds? Whoa, that’s light. No wonder the gun is struggling to pop primers. The typical J-frame is much heavier. I know you don’t want a heavy trigger, but I do think a heavier mainspring is in order. You could still do good work with a trigger pull that weighed several pounds more.

The extended firing pin should not give you a problem with pierced primers. I’ll assume the headspace on your new gun is correct, and the .32 H&R (and Long, and Short) is a relatively low pressure round.

I don’t live near Dallas and don’t know the lay of the land. Perhaps another RevolverGuy reader can chime in with a good recommendation for you? Barring that, I’d ask the trainers at Palisade Training Group (you can find them on the web) if they can provide a recommendation. They’re respected instructors in the area, and I’d trust their opinion.

Having said that, changing the springs and firing pin in your revolver is an easy task, definitely within the realm of an average gunsmith, or a handy enthusiast. You don’t need a top shelf ‘smith to do that job.

Mike – per your suggestion my 432UC is now back at S/W. I’ll let you know what they say. Yesterday my dealer received another 432UC that I had ordered and upon inspection I found the front of the cylinder was dragging on the forcing cone. I declined that one and they are sending back to Lipsey and having them send me a replacement. That’s two for two returns. I feel snake bit on this revolver but I love features so I’ll keep trying.

Thanks Eddie, I’ll be interested to hear your report on the warranty service.

How disappointing that the replacement gun was a mess, too. It shouldn’t be this way. I know S&W and Lipsey’s are working on it, and hope they’ll get it fixed before this gun develops a reputation it can’t recover from.

I just wanted to thank you for this series. I just brought home my very own 642UC (would have preferred the 442, but I’ll take what I can get!), and I’ve been loving it so far. I can’t wait to get out and shoot it some more, other than the 14 rounds of Federal Hydra Shok Deep I used just to make sure it hits where it’s supposed to. Its been with me just about 24/7 for the week I’ve had it so far, and after a couple hundred reps of dry fire, I keep enjoying it more and more. I’m looking forward to many years of having this, and it definitely lives up to its name!