The Merriam-Webster dictionary defines serendipity as “the faculty or phenomenon of finding valuable or agreeable things not sought for.” Serendipity occurs when you unexpectedly bump into a long-lost friend, or find a $20 bill under the sofa cushion when you’re fishing for the nickel that just fell between the cracks.

Serendipity also occurs at the Shooting, Hunting, and Outdoor Trades (SHOT) Show, when you blindly stumble into a quiet, non-descript display booth, and discover the world’s most highly-engineered and precisely-manufactured wheelgun—The Janz Revolver.

From fruitless search, to happy discovery

I was ignorant of the Janz design until I discovered their tiny little booth just a few months ago at the 2019 SHOT Show. To be honest, I wasn’t looking for revolvers as I stalked the German portion of the international zone of the show floor. Instead, I was on the prowl for a clue that might lead me to the elusive SL Variant speedloader, whose import had been unceremoniously interrupted years before. If there was an SL Variant trail to pick up, the first sign would be located somewhere in this island of lightly-trafficked booths in the middle of the chaotic trade show.

A similar search had led me to the combined Nighthawk Custom – Korth display at the 2018 SHOT Show. The announcement by the Arkansas-based custom house that they would be teaming up with the legendary German revolver manufacturer to produce a selection of tuned revolvers drew me to their adjoining booths like a moth to the light.

At the Korth booth, I got to handle samples of the revolvers that I had only heard about in whispered, reverent tones. In the American gun community, the Korth (pronounced, “court,” in German) revolvers are often regarded as the pinnacle of revolver design, and I certainly enjoyed getting a chance to handle these beautiful guns and talk to the gentlemen who designed and built them. The Nighthawk Custom Korths were equally nice, but less artistic, since they were equipped and finished to standards that would enhance their appeal to the American market.

The guns were great, but my search for someone who could provide information on SL Variant production in Germany came up short. Thus, I was still on the hunt for current intelligence on the unicorn loader at the 2019 SHOT Show when I locked eyes with Mr. Till Hezel, of Janz Revolver USA.

The Janz Story

Till’s welcoming smile encouraged me to stop and talk to him about the revolvers in his display. As I neared the case, I was dumbstruck by the first price tag that caught my eye–it’s not every day that you see a $14,000 price tag on a revolver! I knew immediately that there was something special going on here, and I had to find out more.

Till explained that the revolver in front of me had its roots in the Korth story, but represented a refinement of the design. As I whipped out my notepad and pen, he began to fill in the details.

In the late 1940s, Willi Korth began his work to design a revolver that would be the best in class. By the mid-1950s, he had founded the Korth company, in Ratzeburg, West Germany to produce the design.

Korth manufactured the guns for decades with assistance from various suppliers, including the Janz Technik & Labor company of Malente (about 50 miles North of Ratzeburg), who provided a variety of high quality parts for the Korth concern. In the 1990s, Korth’s business model was failing, and the company went through a bankruptcy. After the reorganization, Korth struggled to gain a footing and went through a second bankruptcy process, leaving Janz Technik & Labor with a supply of revolver parts and a bunch of unpaid bills.

The natural solution was for Janz (pronounced, “Yahnz,” en deutsch) to go into the revolver manufacturing business. As a precision engineering and manufacturing operation, with experience building Korth revolver parts, they were in a unique position to pick up where Korth left off. Thus, in 1997, the decision was made to assemble a team to produce a revolver under the Janz Revolver marque.

Janz hired Rene Ganz–the last personal apprentice of Willi Korth–to help with the technical effort. Ganz would provide critical experience and know-how with the Korth design, and enable the new company to step into the revolver manufacturing arena. But Ganz’s work wouldn’t be limited to helping Janz Revolver recreate the Korth design—instead, the management at Janz Revolver wanted to improve on it, and expand the versatility of the platform. To that end, Janz proposed the following improvements to the basic Korth design:

Increase the range of calibers. The Korth revolvers were chambered in .22 Magnum (with an additional .22 LR cylinder), .32 S&W Long, and .38 Special/.357 Magnum (with an additional 9mm cylinder). The Janz company wanted their revolver to handle calibers up to .44 Magnum, and by 1999, the goal had increased to include the .454 Casull;

Improve the trigger. The Korth revolvers were known for their quality single action triggers, but the double action trigger had an unpredictable sear release, which made it difficult for shooters to anticipate the break. Janz wanted to reengineer the trigger for a more predictable double action release;

Increase versatility. The first Janz revolvers, like the Korths before them, were fixed caliber designs. However, by 2000, Janz Revolver introduced an interchangeable caliber gun, wherein the barrels and cylinders could be easily replaced by the user in just a few seconds. This allowed the user to not only change calibers, but select from a variety of barrel lengths in the same caliber. These capabilities were particularly important in Germany and other parts of Europe, where legal and practical restrictions limit the quantity of firearms that can be registered and possessed by a shooter. With a multi-caliber Janz, a single serial number could be transformed into a wide array of revolvers.

It was understood that these improvements would be made without sacrificing the quality of materials, design, and manufacturing that had established the Korth as the world’s premiere revolver.

First things first

With a goal of improving on the basic Korth design, the Janz Revolver team went to work.

One of the first challenges for the team was to map the trigger geometry and timing of the Korth. Willi Korth had never recorded any details about his trigger design, so Uwe Janz—the owner of Janz GmbH—set out to decipher the system. Uwe Janz was trained as a Master Gunsmith and Master Precision Engineer, and used his talents to break the code of the Korth trigger. His important work in this arena was published in the book, Willi Korth – His Guns, by Verlag Veith Morgenroth.

Once the Korth trigger was understood, it could be improved upon. The timing of the double action trigger was completely redesigned by the Janz Revolver team, resulting in a trigger that could be “staged” much like a Smith & Wesson. Instead of breaking without notice, the Janz trigger could be staged just short of sear release, then carefully squeezed for a more predictable break.

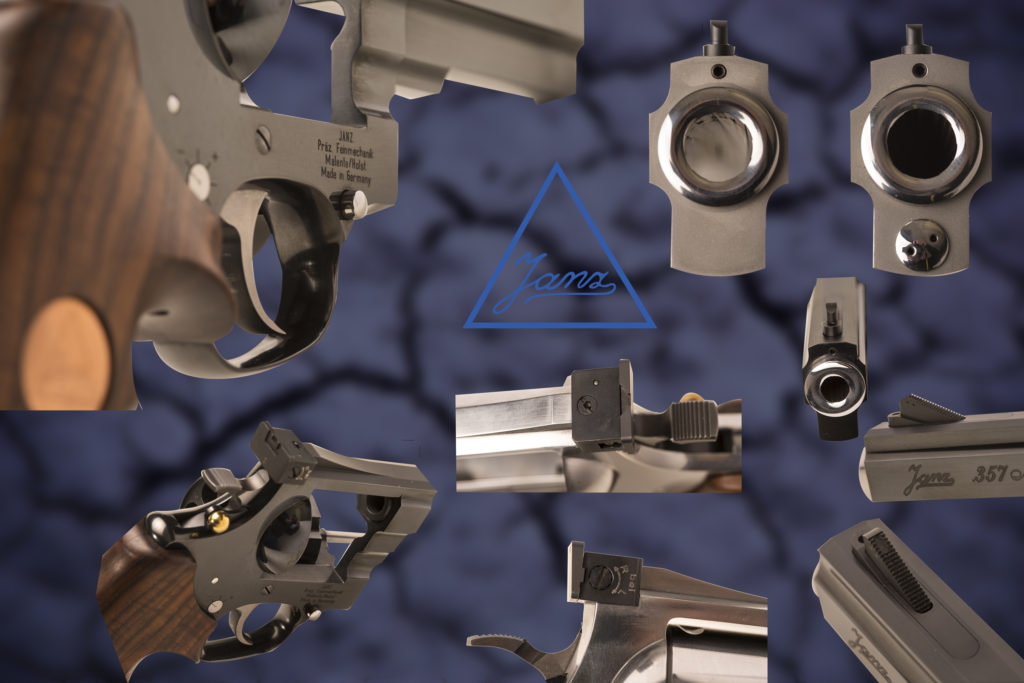

Like the Korth, the Janz trigger uses a roller/disc to bear on the double action engagement surface of the hammer to reduce friction. In the Korth system, the disc can be replaced to change the trigger pull, and while this is possible in the Janz system, it’s not necessary. Instead, in the Janz system, trigger weight adjustments are made without disassembling the gun and trading parts. On the Janz Revolver, a tool is used to externally select trigger weights ranging from 1,000 grams to 2,000 grams in single action (2.2 to 4.4 pounds), or 4,000 grams to 6,000 grams in double action (8.8 to 13.2 pounds), and the setting can be read by an indicator located on the right side of the frame. There is a trigger overtravel stop at the rear of the triggerguard window that can be precisely adjusted as well.

The first Janz Revolver prototypes and production pieces were all built by hand, but around the middle of 1999, production methods changed to include precision CNC methods. There is still a lot of hand work that goes into the fitting and fine tuning of the revolver, though.

Other features

The top strap of the Janz frame became stronger as the design matured to accommodate more powerful chamberings, and the cylinder lock control (located to the right of the hammer spur, and actuated by the shooting hand thumb) was redesigned to incorporate a lighter spring, making it easier to open the cylinder.

As a safety measure, the Janz uses a hammer block which only allows the hammer to contact the frame-mounted firing pin when the trigger is held to the rear.

The mainspring of the Janz Revolver looks very much like a piston, and must be compressed and captured by inserting a pin (like some 1911 guide rods) to remove it from the gun. When the mainspring is removed, a threaded base remains behind, attached to bottom of the grip frame. If the shooter desires, a screwdriver can be inserted through the bottom of the grip frame to change the height of this base, which in turn changes the mainspring tension. This system facilitates fine tuning of the mainspring to ensure reliable primer ignition.

The front sight on the Janz is interchangeable, and shooters can choose from a variety of ramp, Patridge, and other blade designs. Additionally, there is a front sight with a bead that is height-adjustable. On the aft end of the gun, the rear sight is fully adjustable for windage, and can be easily exchanged for various styles and heights.

A selection of compensators with 3 or 4 vents–either angled or straight–is available to mount on the end of 4 inch or longer barrels. The comps are precisely machined to fit over the crowned muzzle and secure to the underlug with a bolt that passes through the front and is secured with a special wrench.

The Janz revolvers are produced in a variety of finishes. Some are highly-polished stainless, while others are finished in a bead-blasted, matte stainless that is both beautiful and functional. There are high-gloss blue finishes, matte blue finishes, and even a vacuum plasma coating that looks dark blue in the shadows, but turns into a rainbow hue of colors in direct light.

Foreign exchange

The construction, fit and finish on the Janz revolvers is exemplary, reflecting the utmost of care and precision, but a true appreciation of the engineering and machining accomplishments on these guns starts with an examination of the Janz Quick Change System for barrels and cylinders.

On the right side of the frame, at the forward, lower corner of the cylinder window, is a push-button release for the cylinder. When the cylinder is opened and this push-button is depressed, the cylinder and yoke assembly can be pulled forward off the frame, and set aside.

Once this is done, a special mounting tool is inserted into the yoke tunnel in the frame. The tool has a post on it that’s machined just like a yoke axle, and two fingers to lock the tool in place on the frame. The purpose of this tool is to provide a mounting point for a wrench that will unlock the barrel from the frame.

When the barrel wrench is mounted to the installed tool, the pair looks like a set of pliers. When the two levers are squeezed, the wrench turns the barrel about 30 degrees—just enough to break the grip of the barrel threads. The wrench and mounting tool are then removed, and the barrel is unscrewed from the frame by hand.

When the barrel wrench is mounted to the installed tool, the pair looks like a set of pliers. When the two levers are squeezed, the wrench turns the barrel about 30 degrees—just enough to break the grip of the barrel threads. The wrench and mounting tool are then removed, and the barrel is unscrewed from the frame by hand.

At this point, the shooter is free to select from a variety of barrel lengths and calibers. Depending on the model, the shooter can install anything from a .22 caliber barrel, all the way up to a .454 Casull, with tubes measuring from 3” (in the USA, and 2.5” in Europe) to 12” long.

When a barrel is selected, it is threaded onto the frame by hand until a pin at the chamber end of the shroud approaches a machined detent in the frame. The barrel and frame threads are carefully timed so that this pin is perfectly indexed to interrupt further hand-tightening of the barrel. At this point, the mounting tool and wrench are installed back on the gun, and the handles are squeezed together once again to snug the barrel into its final resting place. The tools are removed from the frame, leaving you with a tightly-fitted barrel with proper headspacing.

The appropriate cylinder for the caliber is selected and installed onto the frame by sliding the yoke axle into the frame until it locks in position. The cylinder is carefully machined in a way that prevents it from closing if there is a mismatch between the caliber of the barrel and the chambers of the cylinder. This safety feature prevents you from trying to launch a .44 caliber slug down a .357 inch bore, for example.

The whole process of removing a barrel and cylinder, then replacing them with another set, takes just over a minute to accomplish—possibly less, if you’re fast.

Teutonic engineering

The precision necessary to machine these components so that the barrel is properly indexed each time is awe-inspiring. The barrel has to fit the same way, every time, to ensure that the front sight is true and the headspacing is exact.

In other barrel change systems, like the Dan Wesson design, a two-piece barrel is used. The rifled barrel is screwed into the frame and a headspace gauge is inserted between the face of the cylinder and the forcing cone to signal when the proper depth is reached. A shroud is then fitted over the barrel, and locked into place with a tensioned nut at the muzzle end, which is wrenched into place.

The system works well, and there’s evidence that the tensioning of the barrel helps to eliminate vibrations that could affect repeatability and accuracy, but it takes a lot more time and effort than the Janz system, and is rather unsophisticated by comparison. The Janz Quick Change System doesn’t require a special gauge to time the barrel, because all that work has been done by the machinist that made the gun—simply screw it in until it doesn’t go any further, then snug it up with the wrench. It’s simple, elegant, and perfect every time. Marvelous.

There’s some other neat engineering at play with the barrels and cylinders. Take the .22 caliber barrel, for instance. Since the Janz Revolver frame is designed for centerfire cartridges, the chambers of the .22 cylinder cannot be centered on the firing pin. Instead, the chambers are bored on a longer radius than normal, so that the firing pin contacts the rim of the cartridge, instead of the center. This means that the bores in the .22 caliber barrels have to be drilled offset as well, to match the “higher” chamber in the cylinder. It looks a little weird to see the .22 caliber bore crowding the top edge of the barrel extension. In any other gun, it would be an indicator of poor quality control, but in the Janz, it’s evidence of precise engineering and machining tolerances.

The 9mm and .45 ACP cylinders are similarly unique, in that the ejector star is carefully machined so that it rests a few degrees out of alignment with the chambers. This slight offset allows the ejector to slide into the extractor groove on the autopistol cartridges, and hold them in place for firing and ejection without the use of a separate clip. In practice, the autopistol cartridges are inserted until they click into place on the offset ejector, and when it comes time to dump them after firing, all it takes is a push on the ejector rod to send them flying from the chambers.

Till advises that the hands and ratchets on these guns are mated. If a gun is sold as a kit with multiple cylinders, then each of those ratchets has to be carefully fitted to the hand in the gun’s frame.

Models

The Janz revolvers are built in three different sizes, and two of those sizes offer a choice between a fixed caliber gun, or one that includes the Quick Change System.

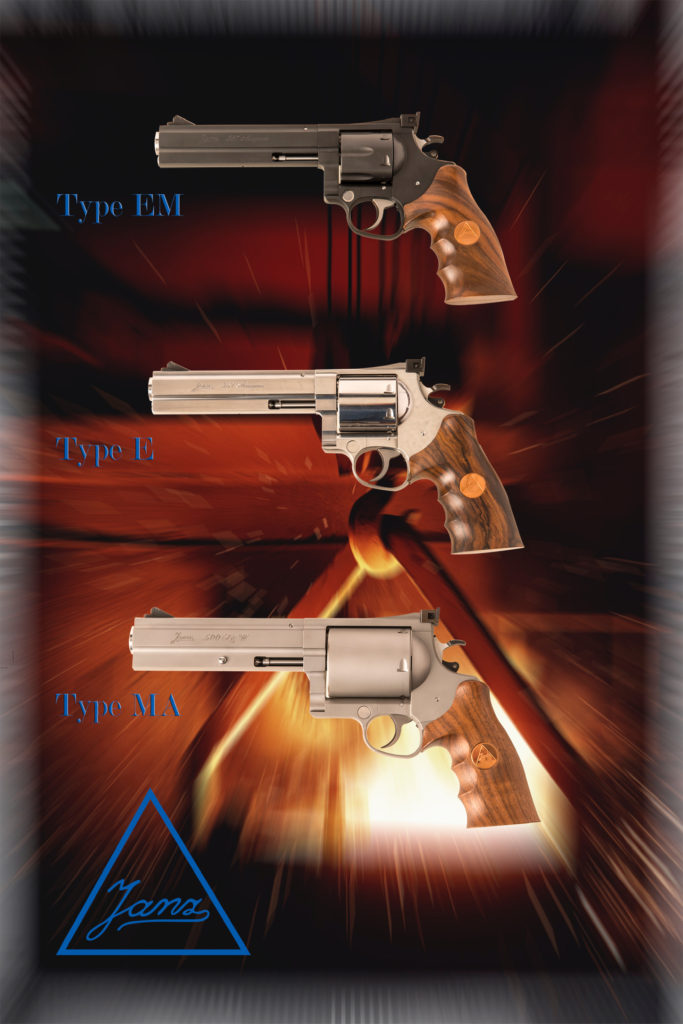

The Type EM is the smallest of the Janz frames, and is available in fixed calibers from .22LR to .44 Magnum. The frame is compatible with Smith & Wesson L-Frame grips, and barrel lengths from 3” to 12” are offered.

The Type EM-S is the same as the Type EM, but features the Quick Change System to allow users to convert between the different calibers.

The Type E is the medium-sized, fixed caliber frame. It can be chambered from .22LR to .454 Casull, and is compatible with Smith & Wesson N-Frame grips. Barrels range from 3” to 12” in length.

The Type E-S is the same as the Type E, but features the Quick Change system to allow users to convert between the different calibers.

The Type MA is the largest of the Janz frames. It’s a fixed caliber gun, available in either .460 S&W or .500 S&W, and is compatible with Smith & Wesson N-Frame, round-butt grips. Barrels range from 4” to 12” in length.

The Type MA is notable because it has an additional lock that the Type EM/EM-S and E/E-S do not. In the smaller guns, the cylinder is locked at the front by a spring-loaded plunger that bears on the tip of the ejector rod, and at the rear by a piece that goes through the recoil shield. On the Type MA revolvers, an additional push-button lock is installed on the barrel underlug, which locks the forward, spring-loaded plunger in place on the tip of the ejector rod, until the button is pushed to release it. This extra lock is necessary to withstand the forces generated by the .460 S&W and .500 S&W cartridges, which could easily overwhelm the spring-loaded plunger, absent the additional lock.

An unexpected wrinkle

Till was already 30 minutes into his demonstration of the Janz Revolver system when I asked him if there were any commercially-available speedloaders that would fit these fine guns. “I don’t know about other loaders,” he said, “but we do have a prototype of our own.”

With that, Till reached under the counter and grabbed a sample, which he placed on the table before me. To say I was shocked would be an understatement. After years of searching for SL Variant bread crumbs, I was now looking at its kissing cousin.

The Janz Speedloader, like the gun that it feeds, is an over-engineered piece of precision craftsmanship. The body of the loader is a polymer cylinder, which is capped on top by a plate that incorporates a release knob, and on the bottom by another plate that hosts the release mechanism. The knob and release mechanism components are a mix of brass and hardened steel.

It’s when you turn the loader upside down to look into the chambers that the magic starts to unfold before your eyes.

Each chamber in the Janz speedloader has a spring-loaded plunger to power the cartridge out of the chamber. Cartridges are held in their respective chambers by a pair of hooks that capture the rim and hold the base against the compressed plunger until the loader is mated to the cylinder, and the central stud in the face of the loader is depressed by the raised post in the center of the cylinder’s ratchet.

Sound familiar?

Yes, like the revered SL Variant loader, the Janz speedloader is a push-feed design in which each chamber is individually spring-powered to launch the cartridges into the cylinder! Can I get a RevolverGuy “Amen?”

The Janz loader is robust, with steel, brass and polymer components joined by no less than 14 (!) screws. It’s obviously designed for sport and competition, not for concealed carry. There’s more material there than necessary to get the job done, and you’d probably hesitate to drop such a fine piece of gear on the ground.

However, the guts of an excellent concealed carry speedloader are there! A slightly more streamlined version, executed in polymer, would launch it to the fore as the best speedloader on the market. The SL Variant uses uncapped coil springs in each chamber, but the Janz goes a step further with its plunger system, which is less likely to kink in the tube. The SL Variant uses a single plastic hook to hold each cartridge, but the two fingers of the Janz hold each cartridge with greater security.

After the initial shock of discovery, I told Till with an earnest voice that, “this loader could be a business all by itself!” I don’t know if the proud Germans who engineered this precision tool could bear to see it “dumbed down” for mass production, but if they could be convinced, it would all but erase the SL Variant from memory. A partnership with a company like Magpul could blow up the speedloader market.

Unlikely perhaps, but a RevolverGuy can always hope, eh?

Window shopping

A set consisting of a black plasma-finished Janz Revolver with four barrels, four cylinders, and six calibers (the .357 Magnum and .454 Casull barrels can shoot 9mm and .45 ACP with the proper cylinder installed) stared at me from the shelf with a $30,000 price tag. Less elaborate caliber conversions halved that, and some of the fixed caliber guns were even less, but I knew that even the most affordable Janz was out of reach for me and the majority of people that shuffled the halls of SHOT Show.

There’s no doubt that the Janz Revolver is aimed at a select segment of the market. Most RevolverGuys will never spend this kind of money for a single gun–even if it can be readily converted into a variety of calibers and barrel lengths—but all of us can appreciate the talent, skill, effort and artistry that goes into making a beautiful, precision instrument like this.

All of my firearm needs can be met by revolvers that are less sophisticated and expensive than the Janz. In truth, I’m not still not skilled enough to outshoot any of them—there is more inherent accuracy in any of my mass-market revolvers than I’m capable of extracting. Additionally, I have simple tastes, and don’t need fancy engraving, exotic finishes, or custom touches to stoke the wheelgun fires in my heart. I’m the kind of guy who still gets excited by the lines and beauty of pedestrian guns, like a blued Model 10 Heavy Barrel with checkered walnuts.

Still, it’s heartwarming to know that this kind of craftsmanship and precision hasn’t disappeared from the firearms world. In an age of indistinct, polymer guns with unfitted MIM parts and ugly matte finishes, it’s refreshing to let your eyes rest on a refined, highly-polished, hand-fitted, engineering marvel like the Janz Revolver. It’s even better to hold it in your hands and feel the steel parts smoothly glide across each other and make mechanical music as you pull the trigger.

I’m not the kind of guy who will ever own a Janz Revolver, but it makes me happy to know that it’s out there.

For more information:

Till Hezel

Janz Revolver, USA

Mike,

I want to thank you for your hard work on this wonderful article!

Like most of you guys I’d never even heard of the Janz until Mike excitedly called me from SHOT to tell me he’d found something unique! This is an impressive looking piece of revolver engineering and I can’t wait to read the range report!

Thanks again, Mike!

Thanks Justin, it was my pleasure! We’ll try to get some rounds through these later this year.

RevolverGuy readers might be interested to know that this is the first-ever feature report on this gun in the U.S. gun media (electronic or print)! We’re proud to be leading the way on revolver-oriented coverage here at RevolverGuy!

Both the Korth and Janz definitely have some novel features to be sure and the finish on each of them are magnificent – too bad we have lost that with our firearms over here.

I do have a question or two about these revolvers for those that own them or at least have spent some time on the range with either. What I am wondering about is the cylinder release.

First, it look like the release would be ambi friendly but on closer inspection of the photo taken from the left side of the frame it appears that the hammer would actually be in the way of the left thumb activating it. Am I right or wrong in this observation?

Second, it seems to me that there ‘could’ be a fatal flaw even with a right hand shooter in regards to the placement of the cylinder release. What I mean by that is that it seems that unlike with other revolvers where the thumb (for right handers) remains ‘wrapped’ around the grip to activate the release, on the Janz or the Korth, the shooter is required to ‘raise and move’ their thumb around the back of the grip to the right side, or at least directly behind the grip, to activate the release. It seems to me that this maneuver weakens the grip as the thumb is removed from the equation to activate the release while the trigger finger is also extended outside the trigger guard (for safety) and thus leaving the middle, ring, and pinky finger as the remaining gripping ‘structures’ of the hand to maintain a grip on the revolver? Again, am I right or wrong in this observation?

In a self defense situation, or in a match especially like USPSA or the equivalent where running reloads are allowed, I can see someone losing their grip resulting in a match DQ, or a very nice revolver skipping across a parking lot or street while moving to cover marring the revolver, or losing their defensive weapon in an encounter resulting in a Class I download in their drawers after disarming themselves in a gunfight.

The Korth and Janz are beautiful weapons, but if my observations are correct then they are probably more suited as informal plinkers and or safe queens.

Steve, after handling both designs, I can say that your gut instincts are pretty good. It’s not as awkward as it may look, but you definitely sacrifice a little grip strength to do it. In the end, it’s not really a player though, as these guns are intended as bullseye guns, or hunting guns. They are not intended to serve as defensive guns or “practical” sports guns. When used for their designed purpose, the design of the release isn’t a hindrance.

If you are reloading a revolver single-handed, something must have gone terribly wrong. You cannot operate the ejector rod on a swing-out cylinder with the shooting hand without breaking the shooting grip anyway. So the cylinder release placement to the right of the hammer is a non-issue.

Korth and Janz revolvers come a bit short of a full length ejection stroke. That is detrimental to social work.

Stunning. But then so is a Porsche 911. I would love to own one, but given my budget for a car I can flog, I’ll be buying a $6000 used Miata this summer, and having 90% of the fun with 10% of the worry. And I can work on it myself.

I approach my guns (well, I don’t do home gunsmithing) the same way. I don’t exactly flog them, but they get a workout. The fanciest wheel gun I’ll probably ever own is a Dan Wesson 715, as my retirement present to self.

Yet if the money did grow on a tree in the yard…I’d love to own a Janz.

Absolutely fascinating! Thanks for the write up! Also not in my future, but I’m glad to know they are out there.

Mike,

Excellent article, you left no questions unanswered and yet it was still easy to read.

Wow, I would love one of the these. The L frame-sized with just a few barrels and cylinders would be just fine with me, thank you. .22, and .357, yes please! 6″ for the .22, 2.5, 6, and 8″ for the .357. This is like a dream gun for me. I’m the kind of person who loves fine watches that are incredibly accurate, so this level of crafmanship and precision are what I covet.

Someday maybe….

Better start saving now! ; ^ )

Glad you enjoyed it, Sir! We’re making plans to shoot one later this year, so we’ll be back with a range report.

Really superbly fun and interesting Mike! Like you said, it’s just nice to know it’s out there even if I never own or shoot one.

Pinned, recessed, and tensioned; this revolver has it all and more. Unfortunately, the CFO would not be pleased if I purchased one.

Pretty guns. I really like the grips.

I would love to drive one of those Porsches sometime, maybe for a long weekend. Would also love to shoot one of those Janz revawvers, maybe a .44Magnum on a pig hunt. But somebody else would have to pay for it, or loan them to me. Neither will ever be owned by me, but getting to use them just for a few days would be a grand experience.

Got a pig hunt coming up in April. If anyone would care to loan me their Porsche and Janz for the weekend, I’d be glad to provide contact information. Ace

Ace,

Unfortunately all RevolverGuy can promise you – eventually – is a limited range report. Mike is going to try his best to get to Texas for a range day with these guys, and I’m going to try my best to join him! Stay tuned!

Justin

Would you go for an ‘89 Ford and a sharp stick?

Thanks for the offer; I pretty much got that covered.

Glad there’s a sense of humor here. Ace

I own 11 Longwitz SL speedloaders that feed about as many Ratzeburg Korth revolvers. I have handled Janz revolvers at SHOT and IWA shows, but never had a chance to fire one one with live ammo. I disagree with the notion that Korth revolvers have a double action trigger with an unpredictable sear release that makes it difficult for shooters to anticipate the break. To the contrary, when set up with the #3 sear wheel, the Korth trigger can be easily and consistently staged just short of sear release, then squeezed for a very short final travel stage with a crisp and predictable break. Also, the trigger spring preload is adjustable externally on all Korth revolvers. Lastly, the original revolvers that were made by Willi Korth through 1981, prior to the sale of his company to outside interests, had all of their steel components made in-house out of forgings that were hand ground in the course of hard fitting. Uwe Janz came on board as a subcontractor at the behest of Willi Korth’s successors. I am nowise convinced that his design changes amount to any kind of improvement. Admittedly, it is nice to have the big bore option available, but the switch caliber functionality is an expensive gimmick in jurisdictions that place no limits on the number of guns that one can own.

https://larvatus.livejournal.com/401890.html

My personal preference in sixguns tends toward the Mulhouse Manurhin MR73, the best fighting revolver ever made. But that is another story.

https://larvatus.livejournal.com/520133.html

Mike

It’s been awhile. I’m the officer in Idaho who sent you the articles from the 1971 Gun World Magazine looking at the changes implemented by the CHP in the months following Newhall. Anyway it’s good to see that Janz is still making revolvers. I first learned of Janz in “The Complete Encyclopedia of Pistols and Revolvers” by A.E. Hartink. That book was published in 2002 and I couldn’t find anything about the company back then. Of course that was sixteen years ago and times change. That is one beautiful piece of machinery, but beyond my budget. The revolver equivalent of the beautiful British double rifles I think. Thanks for the great photos though.

I remember you Jeff! Glad to see you here, enjoying all the great articles we’ve prepared at RevolverGuy! Welcome aboard, friend!