If you’re like most shooters these days, your interest in the revolver as a defensive weapon centers around small frame guns that are easily carried and concealed. While a medium or medium-large frame revolver is still an incredibly effective gun for self-defense inside and outside the home, it’s the smaller “snubby” that gets called on the most for concealed carry and law enforcement backup needs.

Unfortunately, the main feature that makes the snubby so attractive as a carry gun is the same that robs the gun of some of its power. The nominal two-inch barrel that hangs off the end of most snubs helps to make the gun disappear nicely in a waistband, pocket, or ankle holster, but it also exacts a penalty on bullet velocity and energy. The service-length guns, with their four-inch and longer barrels, can generate more velocity and energy with the same cartridge than the shorter snubs do.

How much?

How much more? That depends. We know that some individual guns are “faster” or “slower” than their peers, based on variables like barrel-cylinder gap or bore dimensions, but in general the difference between a 1.875” barrel on a Smith & Wesson 642 and a 4” barrel on a Smith & Wesson 686 can account for about 75-150 feet/second (fps) of velocity, and at about 40-80 foot-pounds (ft-lbs) of energy in a cartridge like the .38 Special.

That may not sound like much, but the difference can have a very significant effect on the terminal ballistics of a hollowpoint handgun bullet, because it can take the bullet outside of its designed “operating window.”

Flowers and Fungi

To explain, hollowpoint bullets are designed to expand by virtue of the pressure that is generated inside their hollow nose cavity. The mechanical or hydraulic forces which build up inside the cavity exert outward pressure on the inner walls of the cavity, and force the bullet to open up, or expand.

If the bullet is pre-stressed with cuts in the cavity walls and jacket (called “skives”), the bullet will ideally open up along those fault lines and the final bullet shape will resemble a flower with multiple petals radiating out from the core. If the bullet cavity is not pre-stressed, then the soft lead walls will ideally curl back and the final bullet shape will resemble a mushroom cap, of sorts.

The key here is that a certain energy threshold must be reached to begin this expansion. If the minimum threshold is not met, then the pressure within the hollowpoint cavity will not be sufficient to initiate and promote expansion. Bad things can also happen if the pressure exceeds design values, but we won’t concern ourselves with that now—the most critical extreme, for our purposes, occurs on the low end. If we can’t meet the minimum threshold for cavity pressure, then the hollowpoint won’t open up and the slug’s ability to create damage along the wound track will be reduced, by virtue of its smaller frontal area.

The Rub with the Snub

The difficulty we face in making defensive ammunition selections for snubby revolvers is that the shorter barrels on these guns can steal enough velocity from a hollowpoint bullet that it’s difficult to achieve the minimum energy required to initiate or promote bullet expansion.

Consider, for example, a hypothetical cartridge whose hollowpoint bullet needs to be travelling at least 750 fps (I’ll just use this for the sake of comparison—please don’t read more into it than that) to generate the hydraulic force necessary to reliably initiate cavity expansion, and continue expanding to its planned diameter (current industry standards favor bullets that expand to at least 1.5 times their initial diameter, so that’s a common goalpost for ballistic engineers) as it slows in the target.

If we shoot this cartridge in a service-size revolver with a 4” or 6” barrel, we can be reasonably assured that the bullet will strike in excess of this minimum velocity, and achieve the necessary energy to expand as desired. From these longer tubes, the bullet will probably hit something close to 1,000 fps at the muzzle, and even as it slows inside the target, it will still be traveling fast enough to generate the cavity pressure necessary to promote expansion.

If we shoot this cartridge in a snubby revolver with a 1.875” barrel, however, we can’t necessarily expect the same results. The shorter barrel might rob 150 fps worth of velocity at the muzzle, leaving us with an initial impact velocity of only 850 fps. While this velocity is enough to start cavity expansion, our theoretical bullet will rapidly slow in the target and the forces inside the cavity will drop off quickly, curtailing expansion. The same bullet which opened up so nicely out of the gun with the longer barrel may barely expand at all out of the shorter gun, leaving a slug that is much smaller in diameter, and potentially less damaging.

Lower the bar?

Why not lower the bar, then? If our theoretical bullet needs 750 fps to expand, and a snubby can’t deliver that with reliability, why not lower the minimum threshold to 550 fps?

We could do that, but we might create some new problems. First, if we made a bullet that readily expanded at the lower velocity, it might be too fragile to stay together. To get the bullet to open at low velocity/energy, we would have to weaken the structure, and if we weaken the structure too much, then we risk having the bullet explode and break apart on impact, or have large segments shear off as it expands.

When a bullet sheds weight, it decreases the energy of the bullet, and it may not retain enough energy to penetrate to an appropriate depth. This risk is increased if we fire a fragile bullet from a gun with a longer barrel, generating a higher velocity and greater impact forces.

A second risk is that a bullet designed to open at low velocity/energy can run out of steam too fast. When a bullet opens up, the additional drag slows the bullet down quickly. If the bullet didn’t have much energy to start with, it won’t go very far after opening. Once again, we’re left with a bullet that’s a shallow penetrator.

Expansion is good, but a bullet that doesn’t penetrate deep enough is of little use to the defender. Bullets that expand too quickly and shed weight, or expand too quickly and slow down too fast, won’t reach the vitals. They create nasty, but shallow wounds, and fail to reach the structures that must be damaged in order to stop the aggressor.

There has to be an adequate balance between expansion, penetration, and retained weight, and if we lower the threshold of expansion too much, we upset that balance.

I feel the need

Over the years, there have been several ways that engineers have tried to address the problem of creating a bullet with a larger “operating window,” that will continue to expand and penetrate as velocities drop off.

The most popular method has always been to push the bullet faster from the start. A bullet with a higher muzzle velocity will have a greater surplus of energy to do work, and even as the velocity of the bullet bleeds off (due to shorter barrels or drag in the target), there will still (ideally) be enough energy to promote sufficient expansion and penetration.

One strategy to achieve this has been to reduce bullet weight, since a lighter bullet can easily be driven to higher velocities without exceeding pressure limits, particularly if different powders are used.

Another strategy to boost velocity has been to increase internal cartridge/chamber pressures beyond normal Sporting Arms and Ammunition Manufacturers’ Institute (SAAMI) standards for the caliber, venturing into a new category of elevated, SAAMI “+P” pressures. In some cases, manufacturers have even disregarded the enhanced SAAMI +P limits, and loaded cartridges to their own “+P+” pressure limits that went beyond any published industry standard—SAAMI or otherwise.

These higher pressures deliver higher velocities, but they come at the cost of increased wear on both the gun and shooter. Shooting “+P+” ammunition increases recoil, can rapidly accelerate gun wear, and almost always violates the terms of a manufacturer’s warranty agreement. The same can often be true of shooting ammunition loaded to SAAMI +P standards—even if the manufacturer allows the use of +P ammunition, it will recoil more and it frequently accelerates wear on your gun.

More Workarounds

There’s a number of other methods that don’t rely on boosting velocity to solve the problem of expansion.

One method has been to change the properties of the bullet’s material. In some cases, the antimony has been reduced to create a softer lead that would expand more readily, while in other cases, the shape, thickness or hardness of the bullet’s jacket was tailored to increase or decrease the resistance it offered to bullet expansion. Some projectiles have even been machined from solid copper, allowing engineers to carefully control expansion in ways they can’t (or, at least not as easily) with lead projectiles.

A more difficult approach has been to engineer the shape of the hollowpoint cavity for better results. Rather than using a simple, cylindrical-type cavity in the bullet’s nose, engineers have applied the principles of fluid dynamics to create shapes that more efficiently harness and direct energy to promote expansion. These more advanced cavity designs are often combined with pre-stressed cores and jackets to control the separation and expansion of the bullet’s petals.

Some increasingly sophisticated attempts at managing expansion have involved the use of polymer plugs in the nose cavities of bullets, which exert mechanical, rather than fluid, pressure on the inside of the cavity walls when they are compressed. The elastic properties of the plug can be managed to generate the necessary force to start expansion, and open the cavity far enough for building fluid pressure to complete the task. The plugs work to open the bullet even when intermediate barriers (like clothing, bone, or other obstructions) might otherwise clog the cavity and defeat expansion, and they also help to reinforce the cavity to prevent it from collapsing when robust intermediate barriers (like auto glass or steel) are encountered on the way to the target.

Of course, any of these various techniques can be used in combination with each other to achieve the best performance possible for the bullet, and that’s what most manufacturers are doing now—at least in their premium products. The best bullets are always a sum of small changes in each of these areas–design, materials, construction, powders, pressures . . . the whole gamut of variables available to an engineer.

What’s special about the Special?

It’s a difficult task for ballisticians to squeeze much juice out of a cartridge that doesn’t have a lot of energy to play with.

This is a particular problem with the most popular snubby cartridge of them all, the .38 Special. First designed as a black powder cartridge, the .38 Special suffers from a maximum average pressure (MAP) limit of only 17,000 psi. Even in its boosted +P form, the cartridge is still capped at only 20,000 psi MAP. By contrast, the standard pressure 9mm Luger and the .357 Magnum each operate at 35,000 psi MAP, giving engineers a lot to play with.

There’s only so much you can do within those physical limits. You can only push a bullet so fast while keeping the internal pressure safely under 20,000 (or 17,000) psi. You can only tweak a cavity shape or play with materials so much before you run into practical limitations. You can only lower a bullet’s weight so much before you sacrifice the momentum necessary to guarantee penetration.

As such, the .38 Special is one of those cartridges (like the 21,500 psi MAP .380 ACP) that just doesn’t give ballisticians a lot of breathing room. In a cartridge like the .38 Special, the shooter often has to choose between expansion or penetration. You can get a little of both, but if you want more of one, you’ll probably have to sacrifice some of the other.

If you truly want to have it all, you’ve got to step up to a high energy cartridge like the .357 Magnum, with all of the attendant penalties in recoil and blast that come with loading the same bullet at twice the MAP.

Jello Shooters

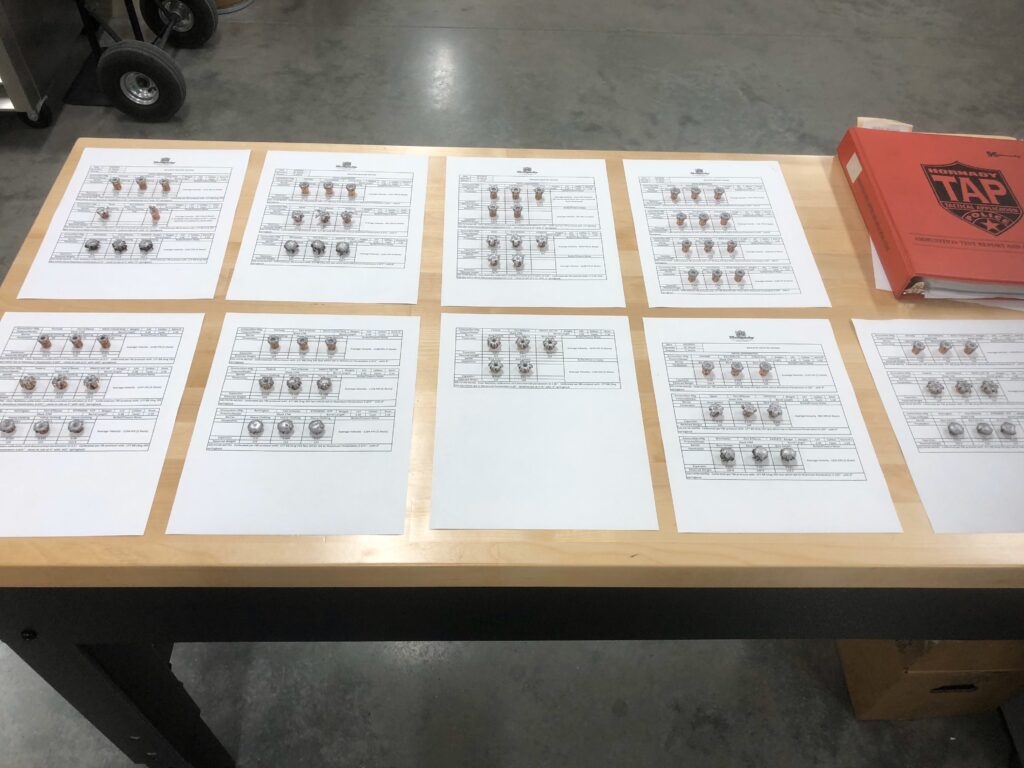

In August of 2019, I had the opportunity to work with friends at Hornady Manufacturing on a project that evaluated the suitability of a new, clear synthetic gelatin product for ballistics testing. Our task was to compare the results obtained from shooting a variety of 9mm loads into both the synthetic product and calibrated organic gelatin, to see if the two test mediums were comparable.

You can read the results of that test in a three-part series of articles that were published in my column at Police1.com here, here, and here. There’s a lot of good information about ballistics testing standards and protocols in that series, and I think you’ll find the test results very interesting, but for you bottom-line folks out there, here’s what we learned: While the clear synthetic gelatin offered many advantages and conveniences, bullets fired into the product tended to underexpand, and overpenetrate, in comparison to the same bullets fired into calibrated gelatin.

At the completion of the test protocol, we still had a bit of calibrated ordnance gelatin and a little more range time available, so I took advantage of the opportunity to test a small selection of .38 Special loads in the bare gelatin. I regret that I didn’t bring a greater variety of loads to test, and acknowledge there are some unfortunate gaps in the selection of bullets we tested (I really wish I’d had some 158 grain +P LSWCHP, some Gold Dot, and some of the new HST to test), but we were still able to generate some interesting data for a cross section of old favorites and new loads. I think the results will help to illustrate some of the concepts we’ve talked about here, and may help you to understand how different .38 Special loads achieve a balance between expansion and penetration.

Technical Details

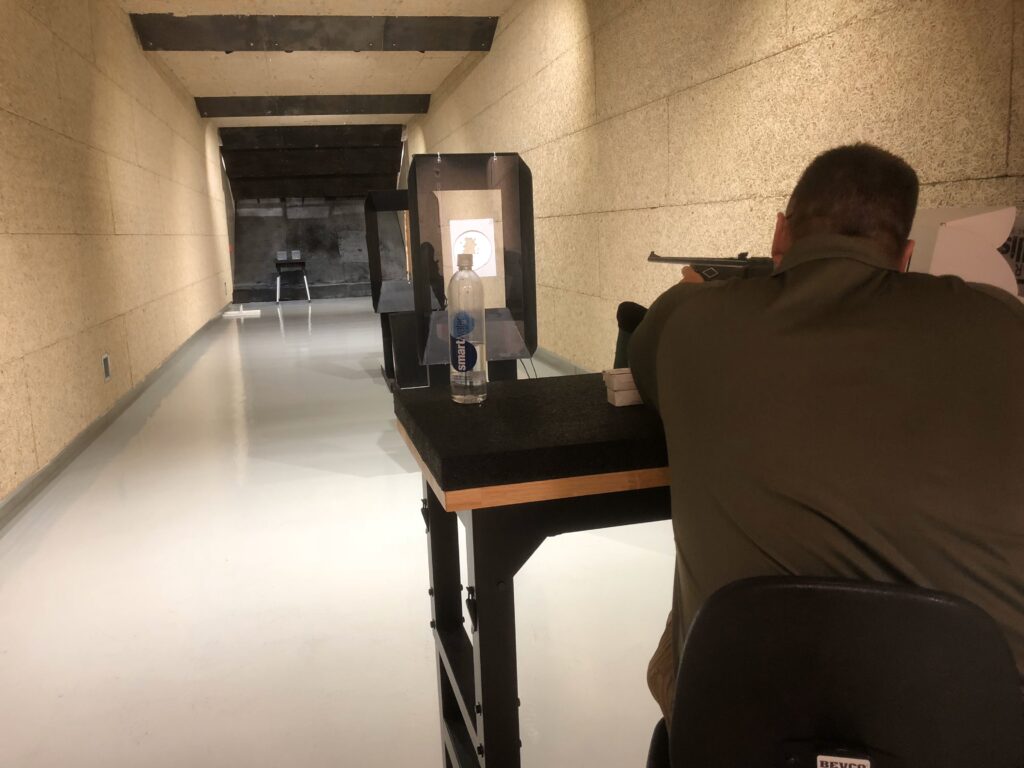

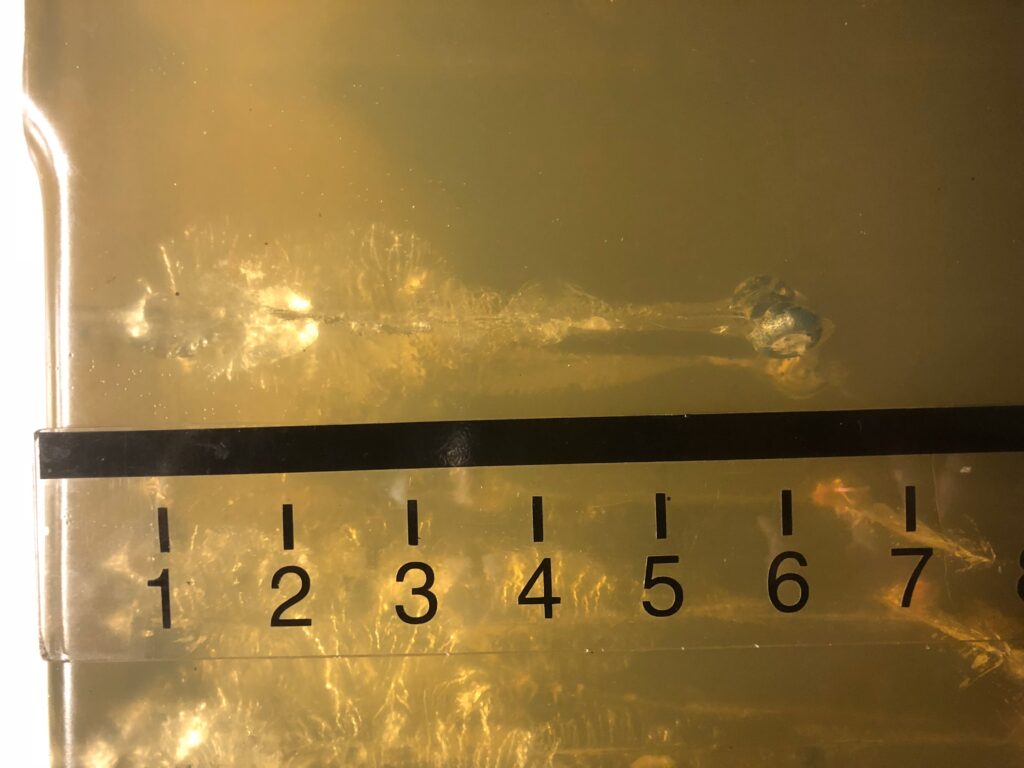

The tested .38 Special loads were fired into bare, (nominal) 10% calibrated ordnance gelatin blocks, that were calibrated with a 0.177” BB fired at 592 fps to depths ranging from 3.125 to 3.375 inches into the gelatin (FBI specifications call for 590 +/-15 fps, penetrating to a depth between 2.95-3.74 inches).

Regrettably, I didn’t have enough ammunition, time or gelatin to repeat the test with FBI standard “Heavy Clothing” in front of the gelatin, but the bare gelatin results gave the bullets the best chance to expand. Putting heavy clothing in front of the gelatin would likely have plugged up a lot of the hollowpoint cavities, retarding or preventing bullet expansion. That would have been useful data too, but I’ll have to schedule another test in the future to capture it.

A Smith & Wesson Model 638 revolver (1.875” barrel) from Hornady’s reference library was used to make all the shots from a measured distance of 10 feet. Because we were rushed for time, we did not chronograph the rounds fired in this test. I wish I’d had more time to set up the chrono, but this was a real push to get everything done by closing time.

Although industry standards usually call for five rounds, we only fired three rounds of each load into the gelatin because we didn’t have enough time or gelatin to do more. This smaller sample size could potentially make the numbers we are about to discuss look a little different from the data derived from a full, five-round protocol, but I saw enough consistency from the bullets in the three-round test that I don’t believe it would have changed things appreciably. I only mention it to be thorough and transparent.

With that out of the way, let’s take a brief look at the results, and what we can learn from them.

Federal Nyclad

The Federal Nyclad is a discontinued bullet, but it was popular from the late 1970s through the early 2000s as a carry load for guns that were not rated for +P pressures. The standard pressure Nyclad (there was a 158+P in the early S&W days, and I seem to recall a 125+P in the Federal days, as well) offered a 125 grain JHP bullet with a blue-colored nylon coating in lieu of a copper jacket, and developed a reputation as a soft-shooting cartridge.

The Nyclad was originally designed by Smith & Wesson as a target shooting round, and the nylon coating was intended to reduce lead fouling in guns and airborne lead in indoor ranges. The design was later purchased by Federal when S&W ceased to manufacture ammunition, and it was under the Federal banner that it achieved its greatest notoriety as a defensive round.

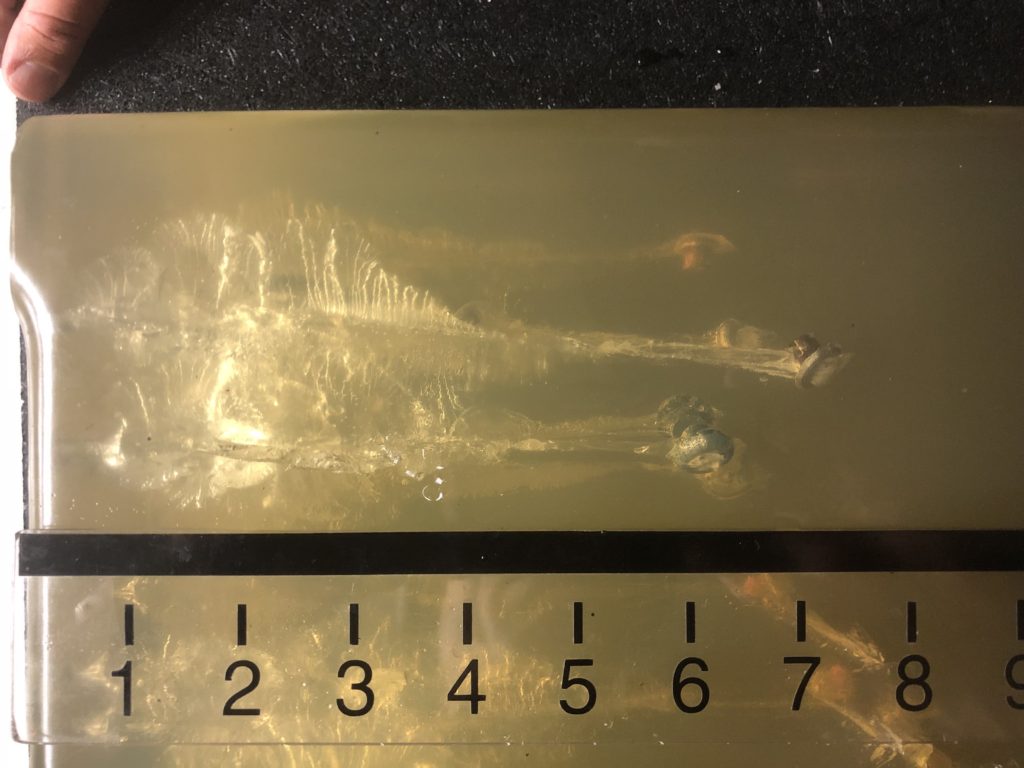

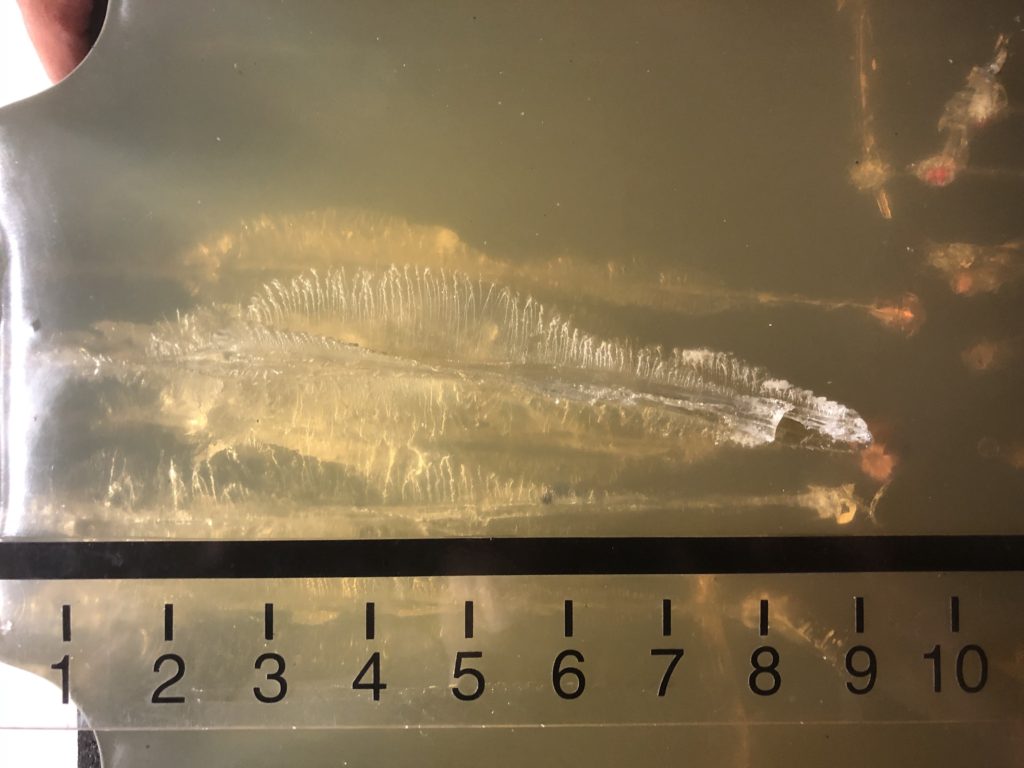

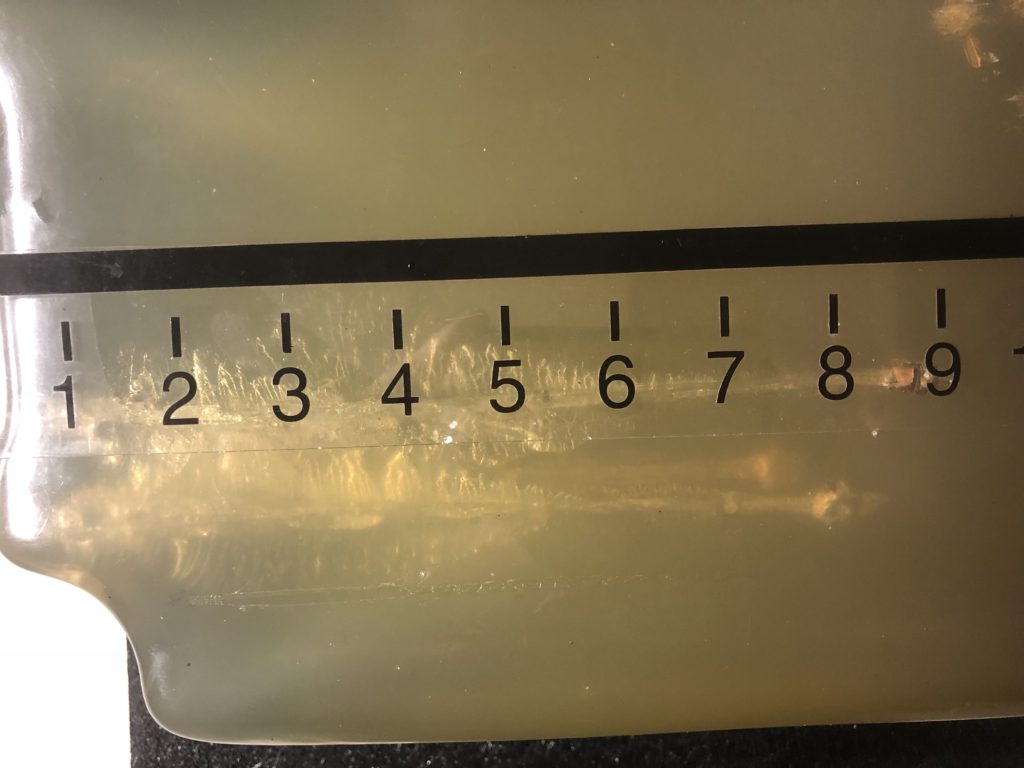

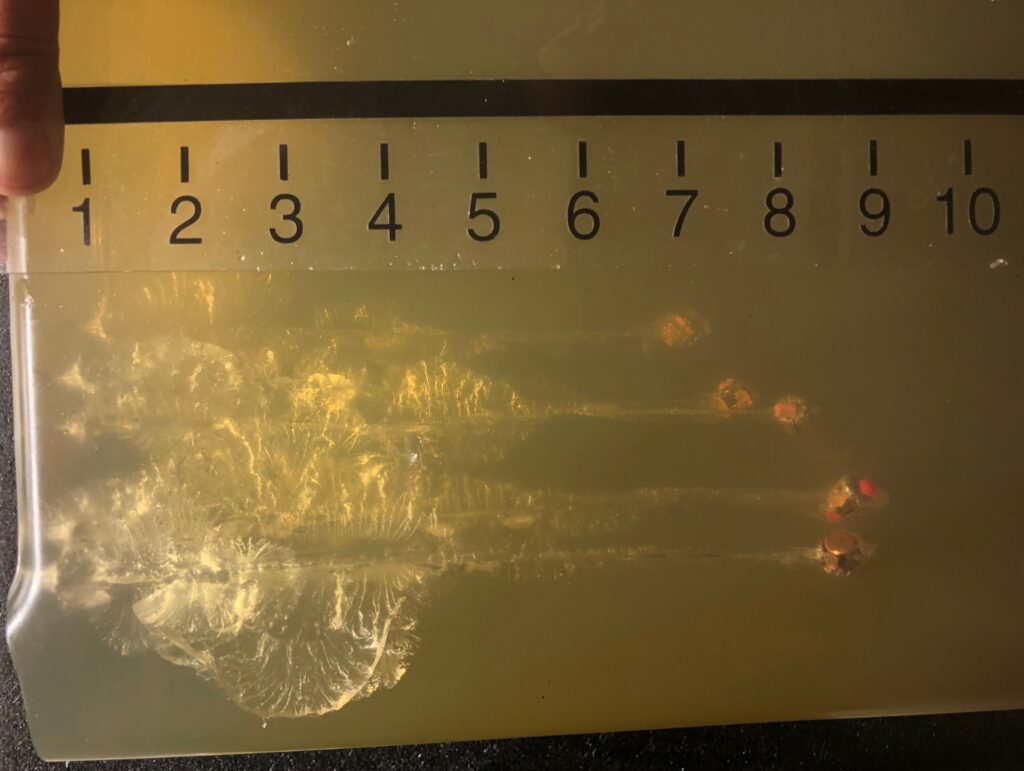

Law enforcement users found that the softer nylon coating and softer lead alloy allowed this bullet to expand to large diameters, even when fired at standard pressure. In our test, the round did indeed mushroom to some impressive diameters (0.653” average for three rounds), but it also failed to penetrate very deep into the gelatin, going only 7.16” on average.

The newly-released Federal Syntech Defense load follows the Nyclad model in some ways (and even retains its traditional blue color), but fans of the old Nyclad should be aware that the new bullet works very differently. The Syntech Defense bullet (only offered in auto chamberings, as of this writing) is a pre-segmented hollowpoint, which is designed to break up into pieces upon impact. After it expands, the three nose segments break off and are thrown out radially from the main path, to form additional wound channels that run about six inches deep in calibrated gelatin. Meanwhile, the reduced-weight core plows straight ahead, seeking deeper penetration than the nose segments–about 12 to 18 inches in calibrated gelatin.

The upshot? The new Syntech Defense might look like a Nyclad, but it doesn’t act like one. Actually, it’s a much better bullet in almost every respect, because the core penetrates deeper than the Nyclad ever did. Unfortunately, Federal has not built a .38 Special Syntech Defense cartridge, but you could use the 9mm version in a gun like the Ruger LCR 9mm if you desired.

Don’t give up hope, though . . . I happen to know that Federal is due to release another .38 Special option that will be very exciting. I’ve talked to Federal about this load in detail, and know you’ll be impressed with it. More details to follow, when the embargo is lifted!

Winchester “Treasury Load”

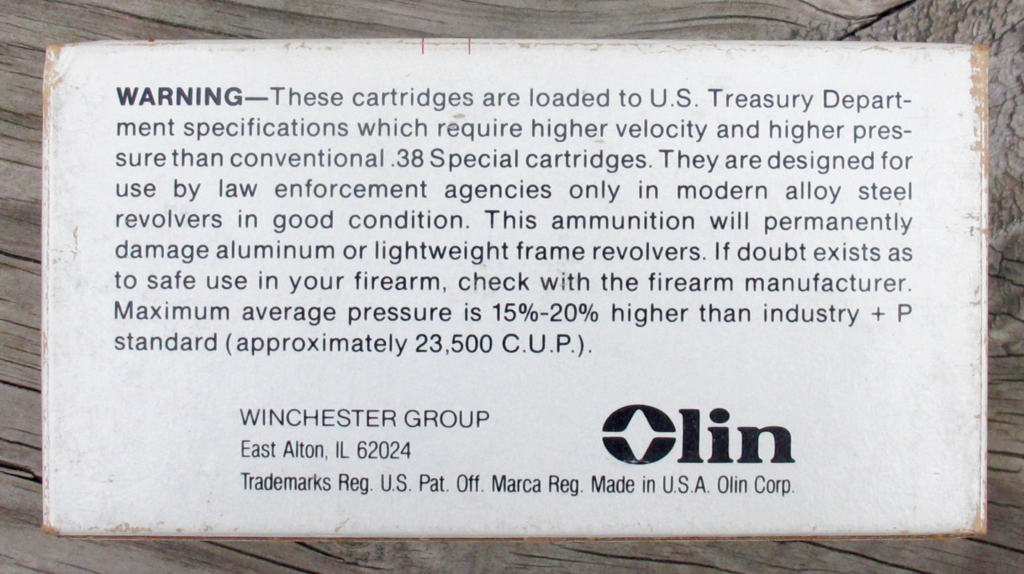

The Winchester Q4070 (later Q4169) load was adopted by the U.S. Treasury Department in the early 1970s and by the California Highway Patrol in 1976, along with many other agencies throughout the nation. A competing product from Federal (their 38F-TD load) was generally loaded to slightly lower pressures, but was similar in form and function.

Whereas the Federal Nyclad sought to achieve expansion through the use of a softer lead alloy and the absence of a jacket, the Treasury load relied on raw energy to expand its semi-jacketed bullet. A simple cavity in the exposed lead tip was forced open by virtue of very high impact velocities, achieved by loading the cartridge to pressures in excess of SAAMI +P standards.

At the time, SAAMI used a non-linear unit of measurement known as a “copper unit of pressure” (c.u.p.) to evaluate internal case pressures (now superseded by the more precise pounds per square inch, or p.s.i.). Standard pressure .38 Special was capped at around 18,900 c.u.p. and the higher pressure .38 Special +P was capped at about 22,200 c.u.p.. However, even the +P limit was insufficient to achieve the desired velocity for the little 110 grain bullet, so Winchester and Federal took the unprecedented step of loading their cartridges in excess of the SAAMI +P standard, going into uncharted, “+P+” territory. In the case of the Winchester product, the cartridge was loaded about 15% – 20% above SAAMI +P standards, or around 23,500 c.u.p..

All that pressure leads to large amounts of flash and blast. Muzzle rise isn’t too bad, by virtue of the lighter bullet, but the muzzle flash and the blast are excessive, and can contribute to the perception of increased recoil. This is especially true in a gun with a shorter tube, because the powder charge hasn’t fully burned before it exits the shorter barrel, and there’s a big fireball that comes out of the gun.

The cartridge offers good expansion, but also limited penetration. In our test, the round opened up to 0.597” (average of three rounds) and penetrated to 7.83”, on average. That’s pretty good performance from a .38 snub, but it’s interesting that the standard pressure Nyclad expanded 9% more and only penetrated 9% less, without the harsh blast and the excessive wear generated by the +P+ load. The temporary cavity of the Treasury Load is much larger than the Nyclad’s, but the expansion and penetration were very close between the two.

CorBon DPX

The CorBon DPX line of ammunition is based around highly-engineered, hollowpoint bullets that are made from 100% copper.

Making a bullet from pure copper offers several advantages. Since copper is a harder metal than lead, it’s much less likely that segments of the expanded bullet will break off, robbing mass and energy from the core of the bullet, which helps to guarantee adequate penetration. Additionally, the increased strength of copper allows the manufacturer to create larger hollowpoint cavities, because less material is needed in the walls for structural integrity. This, in turn, helps to ensure expansion, even after penetrating through intermediate obstacles (clothing, building materials, etc.) that could plug up a reduced volume cavity.

Engineers can also “program” all-copper bullets to expand to a desired size and stay there. This is more difficult in lead projectiles, as expanded segments can often curl back and flatten along the side of the core, reducing the frontal area of the bullet, but an all-copper bullet can be more easily designed to expand and hold a larger diameter.

On the downside, an all-copper bullet is very expensive to make, and the reduced density of copper compared to lead results in bullets that are generally towards the lighter end of the spectrum. The lighter weights can cause sight regulation issues (where point of impact does not match the point of aim for fixed sights) and may also influence penetration depths.

It appeared from our test that the engineers who designed the .38 Special +P version of the DPX did an excellent job of balancing requirements. The .38 +P DPX expanded to 0.572” (disappointingly, one of the three bullets significantly underexpanded and brought the average down—the average of the other two was 0.647”) and penetrated to 10.83” on average, garnering the deepest penetration of the hollowpoints we tested in the little snubby.

Winchester Ranger Bonded

The Winchester Ranger Bonded (formerly Ranger T Bonded) is the lineal descendant of Winchester’s infamous Black Talon bullet, which was a refined, second generation hollowpoint design.

The Ranger Bonded is a jacketed, bonded lead hollowpoint in which fingers of the copper jacket pour over into the hollowpoint cavity. When the pre-stressed, petal-like segments of the core and jacket begin to expand, these copper jacket fingers help to control expansion and keep the lead segments connected to the main body of the bullet, for weight retention.

Because the jacket fingers terminate in a triangular point, they give the appearance of sharp talons, hence the original namesake. As the lead core petals curl back, the jacket fingers remain extended, to cut through tissue and provide the greatest frontal cross-section for the bullet.

In our testing, the 130 grain, .38 Special +P Ranger Bonded expanded to 0.642” on average, and penetrated to a uniform 9.25” depth, giving Nyclad-type expansion but with much greater penetration. The all-copper DPX beat the Ranger’s penetration and (in 2 of 3 bullets, at least) expansion, but it’s also more expensive and it doesn’t hit as close to the sights as the 130 grain Ranger bullet does. In the author’s S&W 640, the lightweight DPX hits several inches low, while the 130 grain Ranger hits where you aim.

The Ranger Bonded (RA38B) is sold as a law enforcement product, and is not found in the commercial catalog. The Winchester Defender (formerly PDX1 Defender) cartridge is the same technology, offered in commercial packaging.

Hornady FTX

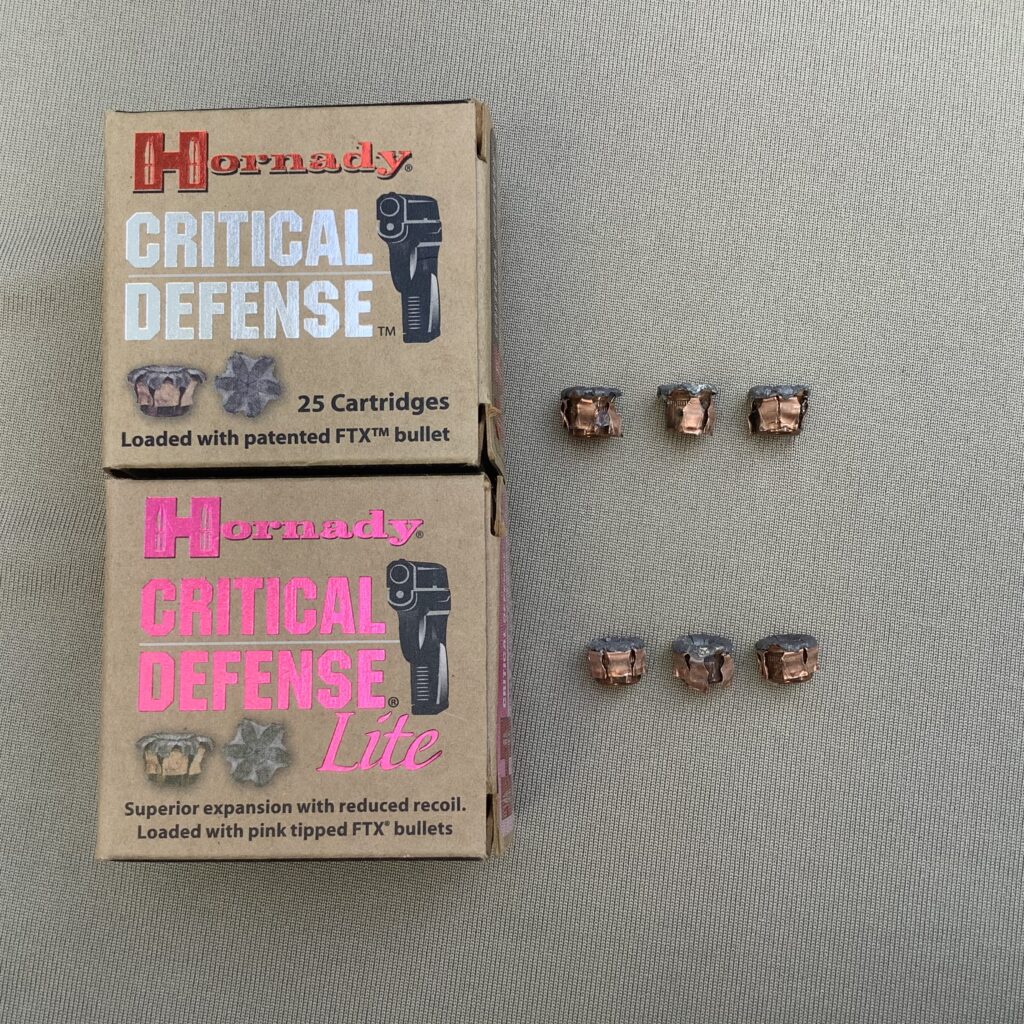

The Hornady FTX bullet is loaded in their Critical Defense line of cartridges and incorporates a polymer plug in the nose cavity to initiate and promote expansion. Hornady engineers designed the FTX bullet for maximum reliability, creating a projectile that would give consistent expansion regardless of clothing barriers. Many other bullet designs can fail to expand after their hollowpoint cavities get plugged with clothing fibers, but the polymer plug in the FTX ensures reliable expansion, no matter what kind of clothing is worn.

This enhanced reliability comes at the cost of expansion, however. The FTX bullets, regardless of caliber, tend to expand less than premium hollowpoints from other makers. When they work as designed, the other bullets will usually expand more, but they also carry a greater risk of not opening at all. Hornady figures that consistent and reliable expansion outweighs the amount of it.

Hornady offers two bullet weights in the .38 Special caliber, with a 90 grain, standard pressure, Critical Defense Lite load for recoil-sensitive shooters, and a 110 grain, standard pressure Critical Defense load for those wanting a heavier bullet. There is also a +P loading of the 110 grain Critical Defense available for shooters who want a faster version, which gives about 80 fps and 40 ft-lbs of extra energy at the higher pressure.

We shot the standard pressure 90 and 110 grain bullets because I was interested to see what kind of difference 20 grains and 190 fps made (the lighter bullet is faster). I was rather surprised to see that the difference was minimal. The 90 grain Lite load expanded to 0.500” and penetrated to 8.75” on average. In contrast, the 110 grain standard pressure load expanded to 0.497” and penetrated to 9.75” on average—basically the same expansion, but 1” greater depth.

Although I didn’t shoot it, I suspect the +P version would expand more, and penetrate less than the standard pressure 110 grain load. Hornady’s testing seems to bear that out, as well.

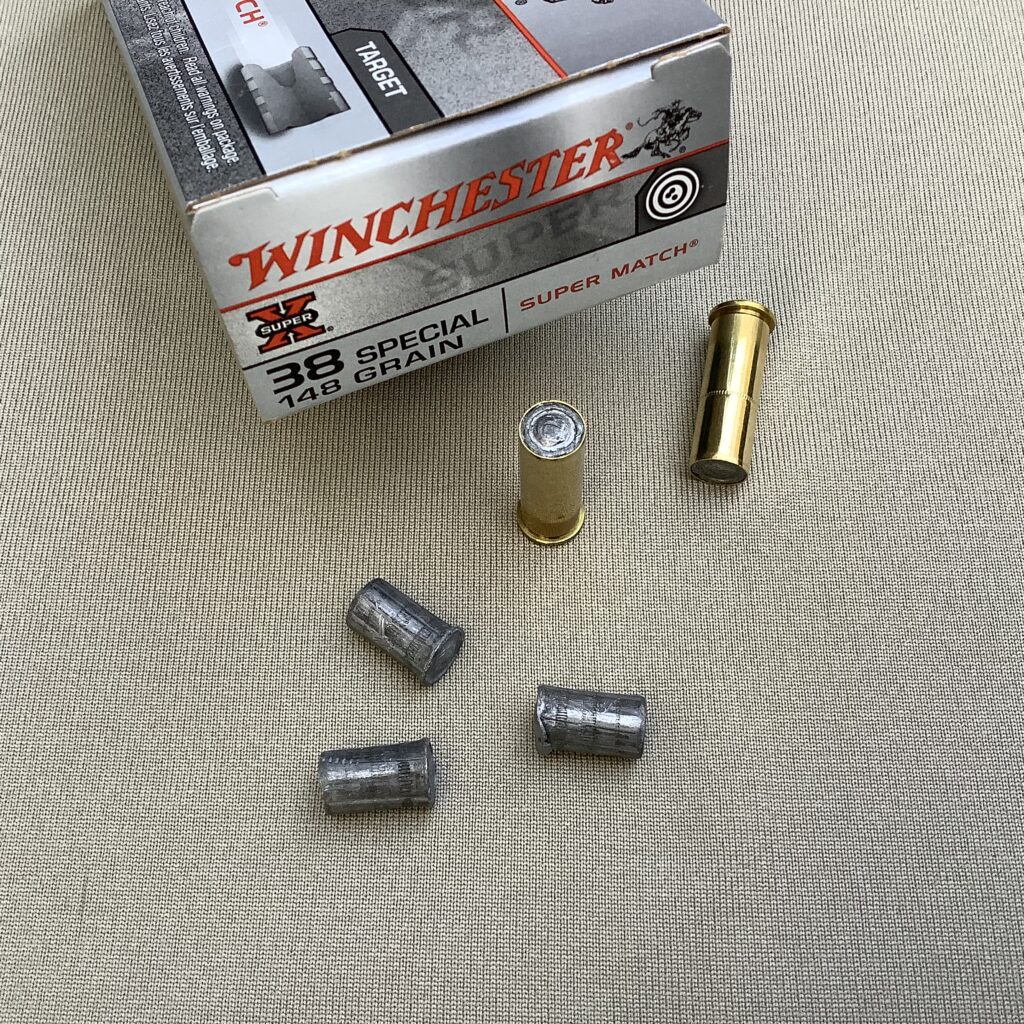

Winchester Wadcutter

The last load we tested out of the snub was a 148 grain, lead wadcutter. This one was loaded by Winchester, and it represents the classic target load in the .38 Special, designed to cut nice clean holes in paper for easy scoring.

The 148 grain lead wadcutter is a low energy, non-hollowpoint load that produces very little recoil, and it seems to hit right to the sights of most fixed sight guns. Those are nice features for target shooting, but why would a defensive shooter want to load up with such a low energy, solid bullet?

It comes down to penetration. As we’ve seen, many .38 Special hollowpoint bullets simply don’t penetrate very far. The .38 Special lacks sufficient energy to both expand and penetrate deeply–particularly out of snubbies–so ballisticians and shooters are left to find an appropriate balance between the two. In the lead wadcutter, a shooter knowingly sacrifices expansion for penetration, figuring that a small bullet that reaches the vitals is better than a larger bullet that does not.

In our test, the Winchester 148 grain Super-X Match wadcutter expanded to 0.397” and penetrated to 15.83” on average in bare gelatin out of the snub. It was the best penetrator in our test, by far.

The Winchester Super-X load is sedate, clocking only 710 fps out of a factory barrel (and probably less out of a snub), and the lead is soft. There are other companies, like Buffalo Bore and Underwood, which are loading hard cast wadcutters to higher velocities (in the vicinity of 1,000 fps, advertised) in an attempt to provide an even more useful defensive round, and these would be better choices than the Winchester target load we tested, for those inclined to carry wadcutters.

Summary

This may have been a deeper dive than some of you anticipated, but I think it’s important to understand how the unique qualities of the snubby revolver can influence your ammunition choices. It should be obvious by now that all .38 Special loads are not the same, and those differences can really be exaggerated when you’re launching them from a short barrel.

Recoil, point of impact, expansion, penetration and retained weight are all factors that you have to take into account and balance when you’re choosing the best load for your snubby. There’s no free lunch in ballistics, and that goes doubly so for .38 Special snubby loads, so do your homework, make an educated choice, and be safe out there.

I, for one, very much appreciate the deep dive. Good information on ammo performance from 1 7/8 inch barrels is scarce and this article provides some much needed data. Regarding wadcutters, other researchers have found that, in addition to improved penetration, the sharp, flat shape of the bullet causes more tissue damage than a round nosed bullet (or a JHP that fails to expand) so one more point in their favor.

Indeed, back when all handgun ammo was solid point, the sharp corners and wide meplat of wadcutters and semi-wadcutters were considered to deliver more “shock” to the target. Some big game hunters held similar views.

Mike,

Thank you for putting this information out there; it’s of great value. Thank you also for including Nyclad ammo in your tests. That was like a time warp to better days, it gave me a bullet nerd’s moment of warm fuzzy nostalgia!

Haha! I know what you mean, Kevin! Me too!

It’s interesting to test the old favorites sometimes, and see if the legend lives up to reality.

Great write up! I’ve been using Buffalo Bore 150gr wadcutters in my 642 since I read Jim Cirillos Tales of the Stakeout Squad and his success with wadcutters. I also like Remington, or Buffalo Bore 158gr +P LSWCHPs as well, they aren’t the end all just my preference.

I can’t argue with either of those choices, Robert! I’ve been interested in trying that Buffalo Bore load for some time, now. An honest, 850 fps wadcutter out of a snub is compelling.

Hi Mike,

Thanks for your work on the interesting article. In light of the fact that none of the hollow points met the 12” FBI standard, how concerned would you be about under-penetration in a “real world” defensive scenario? Do you think wadcutters might be the safest bet(at least you would ensure adequate penetration)?

Thanks

Brendan

It’s a tough call, Brendan. We should remember that the FBI’s standards are specifically designed, first and foremost, for the FBI. They use the protocol to measure LE duty ammunition against their personal standards, and those standards may or may not be reasonable to apply to a non-LE scenario. You kinda have to decide if your needs align with their standards, and that’s an individual choice.

We should also remember that there’s a lot of ammunition out there which “fails” the FBI Protocol, but still manages to stop bad guys in their tracks. A favorite example of mine is the Federal 9BPLE, which is a very basic, cup and core, 115 grain, 9mm JHP loaded to +P+ pressures. That round usually doesn’t penetrate far enough in calibrated gelatin to get a PASS by FBI standards, but there’s an impressive number of bad guys who have been permanently reformed by this lightning bolt, over the past three to four decades. It was a leading law enforcement favorite for decades, even after the FBI developed its protocol and “failed” it.

I guess the bad guys didn’t get the notice that it flunked?

In the service calibers, I see no reason to select ammunition that doesn’t do well in the FBI Protocol, but as we discussed in the article, calibers like the .38 Special require a little adjustment in our expectations, and I don’t have a concern with carrying a round that “only” goes 9” to 10” in jello. In fact, the S&W 640 I carried today was loaded with the 130 grain, Winchester Ranger Bonded load that you saw in the article—a load that went 9.25” in our test. I’m OK with that.

Does that mean I would pooh-pooh someone who placed a premium on 12” minimum? Absolutely not, and I’ve written previously in these pages (search for “wadcutters for self-defense” and you’ll find it) that I think a hard cast wadcutter makes a heckuva lotta sense in a .38 snub. Some VERY savvy gun guys wouldn’t carry anything else, and I’m not going to argue their sensible choice. I’d be perfectly content with carrying a wadcutter load in the gun, but would like a JHP with a pointed ogive for my speedloader.

Remember, penetration is just one of many selection criteria. Reliability is most important, and accuracy is next. An appropriate balance between controllability and power is important. In the current environment, availability and economy cannot be ignored, either. There’s lots to consider when choosing ammo.

In the end, I think there are more important things than ammo. Your mindset, awareness, tactics and training are all MUCH more important factors in your survival than your ammo. Even the most basic bullet will work if you can put it in the right place. As friend Evan Marshall says, “the three most important factors in terminal ballistics are Placement, Placement, and Placement!”

That’s a long-winded answer to your question, but I thought it was important to provide some insight on my perspective, rather than just give you a direct answer. Is 12” minimum a show-stopper for me? Absolutely not. I’d like it if I can get it, without sacrificing other things that are important to me, but I won’t use 12” in jello as Go/No-Go criteria by itself.

I hope that helps more than it hurts. Perhaps some of the other RevolverGuys here can chime in and offer their perspectives.

Thank you! I appreciate the detailed reply

I think the FBI standard includes barrier penetration like glass or car doors. Thats why a lower penetration than 12 inch is in a regular case still deadly without any barrier.

Thanks Lars. Yes, the FBI Protocol includes auto glass (Test #6) and sheet steel (Test #3), in addition to wallboard and plywood (#4, #5). The 12” minimum is applied to bullet performance in each of these tests, and this is why so many .38 Special bullets fail the protocol—they just don’t have what it takes to get through those barriers and still meet FBI requirements for penetration and expansion. The manufacturers I know best don’t even bother trying to run their .38 Special loads through the full FBI Protocol—they simply focus on Bare Gelatin (Test #1) and Heavy Clothing (Test #2). That’s probably sufficient for most users of the .38 Special.

Mike,

I just really appreciate the time and effort you put into these write-ups, excellent stuff.

Like Robert, I have been carrying Buffalo Bore 150gr hardcast wadcutters as well, and my reloads are their 158gr (non +P) LSWCHP. Both seem to have similar velocities, so I don’t get any surprises and shoot close to point of aim for each other. However, they have a bit more recoil than the standard 148gr wadcutters, but quite manageable.

A company who I have some wadcutters from is called “Choice Ammunition” out of Western Montana, I have no affiliation with them. Their wadcutters are Hi-Tek coated, 148gr and hard cast. I emailed them last year and they said they did not have chronograph info out of a 1 7/8″ inch barrel but guessed 700fps. I’m guessing less because they probably test out of 4″ or 6″ barrels for the advertised 800fps.

They “feel” about like Remington Target Match and Winchester Super Match, since I don’t have a chrono it’s about “feelings, nothing more than feelings”. But what interested me was the hard cast properties AND they always have them in stock.

Of note, they used a picture from Chris Baker’s article at Lucky Gunner on wadcutters for self defense from November 10, 2016. They did leave the Lucky Gunner name on the bottom of the picture so all is well.

Thanks again!

Mike (nMW)

It’s always a pleasure to hear from you here in the comments, Mike, and I appreciate your kind words about my work. It really does help to keep me motivated when I get great feedback from the gang. This hobby has turned into quite a commitment and demands a lot of my time, but the positive feedback keeps me going and lets me know that I’m on track. I’m happy to know that you’re getting something useful out of it.

I’m not familiar with Choice Ammunition, but appreciate the steer. I was curious about the Hi-Tek coating and followed some links to the company that makes it, as well as a guy with an excellent video on how to apply it. That looks like a REALLY neat coating! I bet it shoots super clean in your guns, without the lead fouling you’d normally get from a wadcutter. I can see why you’d like those cartridges so much. A clean-shooting, hard cast wadcutter would be a great round, indeed. I like the BB cartridges for the added velocity though, and would prefer them for self-defense chores, as you do. You’re probably getting another 150 fps from the BB cartridges.

Thanks again for writing in!

This is really interesting. I knew from other sources that the clear gel allowed more penetration, but I was under the impression that it was a couple inches or so. In comparing your results to the Lucky Gunner tests, they generally had about 5 inches more penetration. They used a 2 inch barrel for the tests I was looking at, but I don’t think that would matter too much, and the fact that they used heavy clothing shouldn’t make that much difference with at least some of these loads (wadcutters and the FTX bullets in particular). If nothing else, this gives me a more informed basis for looking at those test results. Thank you very much.

Thanks Greyson, great to hear from you, as always.

The articles I wrote over at Police1, which were hyperlinked in this article, should disabuse anyone of the notion that the two products give similar results. We had some of the bullets in our testing penetrate in excess of 50% more in the Clear Gel, than in the calibrated gelatin required by FBI specs. They did this, in part, because they also underexpanded by 8% to 11%, on average, in the Clear Gel, compared to the real stuff.

You’ll see the same things at play in the stats you referenced from the other source. Their bullets underexpanded and penetrated deeper in the Clear Gel, compared to what we got in the calibrated gelatin.

There’s no fidelity between calibrated gelatin and Clear Gel. It’s really an apples-to-oranges comparison, and any attempt to apply FBI standards, designed to apply to calibrated gelatin, to the Clear Gel product is . . . misguided.

I’ll also note that at the time we were testing the Clear Gel, the company wouldn’t warranty it past the second remelt, because the product’s qualities would change and influence the results obtained. However, I happen to know some of the popular places on the web were publishing data obtained from Clear Gel blocks that had been remelted over a dozen times. This makes the data even more unreliable.

I hope it changes someday, but there’s currently no substitute for calibrated gelatin that provides equivalent performance, so if you’re going to judge a bullet by the FBI’s standards (i.e., 12” to 18” penetration, with 14”-16” preferred, and 1.5x expansion) then you have to use the FBI’s test medium. Otherwise, you’re wasting your time. The analogy I’ve used is that it’s like trying to apply braking standards derived from a dry surface to stopping tests on a wet track.

Thanks for yet another informative article, Mike.

Your continuing dedication to providing practical, helpful information— about the guns we carry, and the best loads to feed them— is much appreciated.

I come away from each of your articles a little more better-informed than I had been. So thanks again, and please do keep up the good work.

Thank you Sir! Always great to see you here!

Another excellent article with superb analysis. The performance of the .38 Special in a snub has been a dilemma since the Dick Special appeared on the scene. It’s a problem of physics that really can not be realistically solved. You either opt for high speed and low penetration (along with rapid expansion) or you go for low speed with deep penetration. Think Aircraft – a Boeing 737 cruising level at Mach 2 just ain’t happenin’

Your observation about the Federal 9BPLE load is an example of a round that is still in production, is still used on the street, still will cause bad guys to assume room temperature, and still fails the ‘magic numbers’ of gubm’t tests. On the other hand, you have the humble wadcutter and semi wadcutter hollow point loads that apparently never got the memo that they were ill equipped to do the job, yet they still work on the street and cause bad guys to get cold. The street results show that the WC and LSWCHP work out of snubs . . . you don’t need Mach speed to do the job.

BTW, I still have two full boxes of Federal Nyclad .38 Special 158gr LSWCHP +P . . .

Hmm…if I get my hands on some more jello, we’re gonna have to break open one of those boxes!

I’ve got another article coming soon about a 2021 product release that may thread the needle better than it’s been done, before. Federal has a new load that promises to give the vaunted 12+ inches with reasonable expansion from a snub . . . more to follow, soon.

Great info, thanks! This is anecdotal, but we had a guy suicide rather than surrender to SWAT a few weeks ago. He shot himself in the heart and was transported to my Precinct’s hospital, to be pronounced dead. Now I haven’t a clue what he shot himself with, but the wound was on the nipple line, clipped the left edge of the sternum, and entered the heart. I had the opportunity to observe this wound in the trauma bay with it’s excellent lighting, and could see the pericardial sack about three inches in. I imagine six or seven inches of penetration will work fine in a frontal shot.

Excellent info Riley, many thanks! Yes indeed, the vitals aren’t very deep on a frontal shot. Be safe out there.

Mike,

I have shot several hundred .45 ACP 225 grain truncated flat point cast bullets from Missouri Bullets that are coated with Hi-Tec coating in both a 1911 and Smith&Wesson 625. They produced significantly less smoke than traditional lubed cast bullets and no leading. Definitely worth looking at bullets with the Hi-Tec coating. Due to demand Missouri Bullets has limited their available bullet choices at this time. Once they get back to normal I’ll try some of their coated .41 bullets in my Model 58. Should be great for “. 41 Police” loads! Thanks for the great article!

Best,

Morgan

Thanks Morgan, glad you enjoyed it! I really appreciate the feedback on the Hi-Tek coating—that stuff sounds pretty amazing. I’m not a handloader yet, but have been fascinated by it for decades and enjoy keeping up on the latest in that world. I see tremendous advantages to a coating like that. I’m actually curious about how it would bond to a copper jacket.

Great article! I have been a police officer for three decades and a “gun guy” longer than that. As such I agonized over ammo selection for a long time, until I attended some training. After a heated discussion on ballistics the instructor said, “Just get a bullet in him [the bad guy] and he will be easier for the rest of us to deal with.” Since then I’ve picked what I thought was the best ammo I could then I planned to follow the above advice.

KEEP UP THE GOOD WORK, MIKE

Thank you BC! Glad to have you here. Be safe up there.

PS. I’d also like to thank you for including the NYCLAD. Those of us who used it miss it. We carried the non +p in ours snubs.

I can definitely understand why everyone misses that load! Fortunately, the standard pressure Hornady FTX does a real good job, as a substitute. If I wanted a standard pressure JHP, that would be the one I would select.

Mike –

Thanks for a well researched, well written article on this topic. In my brief time as a visitor to this blog, I’ve found a wealth of great information!

As You mentioned in Your summary, “There’s no free lunch in ballistics.”…and that’s the .38 snubby dilemma. I read Your article with great interest, as I’m a new owner of a Kimber K6S, having added it to my possible carry gun list which has had .44 Special as my preferred caliber. While the Kimber is a 357 Magnum, the info shared on this blog mention that, heavy grain bullets fired from this gun, or any small frame snubby to be punishing. I have had the Kimber to the range twice now, and it shoots very nice with 38 spl standard and +P. Finding 357 of any type locally has been impossible.

With the current ammo shortage greatly limiting choices, something that might continue for some time to come, finding any good options is a challenge. Being armed with good information is a great starting place. While I sort this out, I’ll keep carrying my CA Bulldog in 44spl.

Looking forward to Your next contributions!…

Kevin Massey

Thanks Kevin! We’re glad to have you aboard, and I appreciate the kind words. Your .44 Spl Bulldog will hold you in good stead while you work out the details on a good load for your Kimber. I can’t imagine any self-defense snubby chores that a .44 can’t handle.

One plus to the heavy .357 loads in the K6s is that they will probably hit very close to the sights. We had a difficult time getting the lighter bullets to do that on the K6s. The heavy loads will definitely extract a toll in recoil, though. If you could find some of the Speer Gold Dot Short Barrel in .357, you might be happy with that level of recoil, but I understand that they are tough to locate right now. Good luck on your search.

I’ve been carrying Super Vel’s 90gr +P load in my 642. It’s the only self-defense load for .38 Special that I’ve been able to reliably get.

Axel, that one’s a screamer, and you’ll probably get performance very close to what you see with the Treasury Load in our test–large expansion and about 7″ of penetration in calibrated gel. I’ll warn you that shooting that load regularly in your 642 will cause some wear in that gun, and will eventually give you some cylinder endshake. Keep the round count down with that stuff and you’ll be OK . . . not that you could afford to shoot a lot of it anyhow!

Mike

I am confused with the fbi penetration. The depth to vital organs is 6in max, even with a heavy person . Thanks for the great article I like the federal micro load and good old wadcutters

Dave,

Law enforcement shootings are frequently at odd angles where the bad guy presents his side as he is shooting at the officer and/or running or some other strange thing. Officers need bullets that will get through an arm and into the torso deep enough to reach the vital organs. This is much less common for citizens who are defending themselves from someone facing them.

Hi Dave, thanks for writing in. Let me see if I can help clear things up.

To start with, the calibrated gelatin is designed to replicate tissue–it’s a tissue simulant. As we know, a human body is composed of many different components, each of which has different degrees of elasticity, tear resistance, and strength. Skin, for example, is very tough stuff, but organs may be more fragile. Tissue might tear, but bones won’t–they’ll break and shatter.

So, the body isn’t homogenous, but calibrated gelatin is. In order to account for the varying resistance a bullet might encounter in a body, we don’t use a 1:1 ratio between the actual depth of a vital organ, and the amount of tissue simulant (gel) that must be penetrated to simulate reaching that organ.

Additionally, there’s the matter of oblique shots and intermediate barriers. A vital organ may only be 6 inches below the surface when viewed from the front, but if a threat is turned sideways to you, then the bullet might have to travel through a lot more of the body to reach that same organ (i.e., through a shoulder, across the width of a chest, and then into the organ). Additionally, if the threat’s arm gets in the way, then you might have to shoot through that intermediate barrier before the bullet ever enters the front of the chest.

For these reasons, the FBI standard of 12″ in gelatin exceeds the nominal depth of vital organs in the body, when viewed from the front. I hope that explanation makes sense.

Edited to add: Oops, sorry Riley! You were responding as I was typing! If I had seen your reply, I would have just let you handle it, since you said the same thing in fewer words!

Thanks gentlemen that makes sense

Bravo, Mike! As usual, job well done. As I age and am semi-retired, I’m beginning to appreciate the simplicity and reliability of a good snubbie. I keep my LCR stoked with HSTs and was able to shed about an ounce from the 13 oz. by swapping out the grip to a Hogue bantam grip. I thoroughly enjoy the articles and the comments. Thank You!

Thank you sir! Those HSTs are excellent and should do the job very well. Be safe out there.

Excellent article Mike. I know we all really appreciate you providing us with such in depth information. Thank you for all that you do here at Revolverguy.

I had always known that the 38 spcl was under-powered, especially in a snub nose revolver, but your results were still a little sobering. Without throwing them under the buss, would you say that LG’s ammo tests using clear gel do not provide us with any real information about how these defensive rounds will perform in the real world? Do you think the best performers in their tests would still perform well in calibrated gelatin?

What do you carry when you do carry your Smith model 640? I have Winchester PDX1 130 grain +P on hand (though sadly not much left) and some old school Remington Golden Saber 125 grain +P (which was actually the top performer in LG’s test).

Thanks again for sharing your knowledge and experience.

Hi Sean, good to hear from you. I’m glad you enjoyed the article so much. Thanks for your kind words.

I appreciate all the hard work that LG (and ATG, and a legion of YouTubers) did with their ammo tests, and I think there’s still useful information that can be gleaned from them. However, I think they’re fundamentally flawed, because they try to apply the FBI’s criteria for penetration and expansion to a test medium that acts very differently from the real gel used in FBI tests.

You just can’t do that. You can’t judge a cartridge as “Good” or “Bad” using the FBI criteria, if you’re not going to follow the FBI’s instructions on how to conduct the test. It’s like judging the results of a cake recipe, when you don’t follow it, and use your own ingredients, measurements, times and temperatures.

In the context of ammo testing, if you don’t follow the instructions on how to conduct the test, you’ll wind up “passing” some loads that would normally fail, and “failing” some loads that would normally pass. Unsat.

The analogy I like to use is trying to apply dry pavement automobile braking standards to a braking test conducted on wet pavement. The grading standards don’t match the test conditions, and any conclusions you draw from the test will be flawed. As the computer nerds say, “garbage in, garbage out.”

There is utility in comparing Clear Ballistics test results to other Clear Ballistics test results, but you have to suspend the use of the FBI’s yardstick, which was designed around calibrated, organic gelatin, mixed to a nominal 10% concentration. You can’t judge Pass/Fail based on a 12”-18” penetration window, for example—a new standard is required for measurement.

Unfortunately, I’m not seeing that from anyone in the industry, yet. Nobody has developed a new standard of measurement for Clear Ballistics results. As a result, I think the data is largely unhelpful, and only good for relative comparisons (“x” tends to penetrate deeper than “y” IN CB GEL).

If you can’t agree on the standards of measurement, then measuring does you little good. I’m VERY hopeful that the industry will develop a useful yardstick for measuring performance in CB gel, because it’s so MUCH easier to use, but nobody has done it yet, unfortunately.

I’ve mentioned it before, but there’s also the additional complication of reusing the CB gel over and over and over. At the time I was evaluating this product, the manufacturer would not warranty the product beyond the second remelt, so after 3 uses, there was no guarantee that your test medium was acting the same way, or that the data you derived from it was comparable.

Unfortunately, I know that the same CB gel was used far in excess of 3 times in some of these tests. Would it be reasonable or meaningful to either “Pass” or “Fail” a particular round that was fired into CB gel that had been remelted a dozen times, when the manufacturer only warrantied the product to be consistent and repeatable for three attempts? Not by scientific standards.

One can argue whether or not the FBI standards are meaningful, and I’ve found myself on both ends of that discussion over the years. I’m not going to address that argument here.

Instead, I’ll just say that if the FBI’s 12”-18” standard is important to you, then there’s only one acceptable way to test ammo, and that is to shoot it into the type of gelatin required by the FBI’s protocol, in the manner that the FBI describes. Period. Anything else is not useful.

Please understand that I don’t think LG or anyone else who has used CB gel is trying to be deceitful. I think they trusted the manufacturer’s assertion that the product gave equivalent results—heck, the blocks from CB even come with a “calibration” card that states the block meets FBI specs.

Unfortunately, this was not correct, at the time I last tested the product. My testing in 2019 indicated there was a significant difference between CB gel results and real gel results. I worked closely with CB after the test to explain this to them, and in the process they realized they had misunderstood how to apply FBI calibration standards, and were doing it wrong. An honest mistake, but one which resulted in them marketing a product that “met FBI specs” when it actually did not.

So, I don’t hold this against LG (or the others—ATG, YT, etc.) and I’m not trying to disparage them. They’re good people, with good intentions, trying to provide a useful service. Unfortunately, they just used the wrong test medium and/or the wrong standards of measurement, so the data isn’t particularly helpful. It may be someday, if a new standard can be developed for measuring CB data, but it’s not currently.

Now, as to what ammo I personally use, I’ll say that I’ve carried a wide range of ammunition over the years, ranging from 110 grain lightweights, to 158 grain heavyweights, at all kinds of speeds. If I had to carry any of them again, I wouldn’t be concerned. I can make any of them do, if I do my part.

But of course, I do have preferences. For the last decade or so, I’ve preferred the 130 grain, +P Winchester Ranger Bonded (equivalent to the PDX1) or the 135+P Gold Dot. I think these loads offer a good balance of control, penetration, expansion, and accuracy. Importantly, they hit close to my sights—they’re well-regulated in elevation, which is often difficult to achieve in a snubby. I have the skill to hit with my snubby out to 50 yards, so I want ammo that will facilitate that, if necessary.

I’ve mostly carried the Winchester, because I was able to buy a sizable quantity at a very affordable price several years ago, but I’d trade it for the Gold Dot without hesitation. I actually think the Gold Dot is a marginally better bullet, but alas, my logistics favor the Winchester right now. Doesn’t bother me a bit. I carry it with all the confidence that is due to a .38 snub.

If I couldn’t get either of those, I wouldn’t sweat it too much. I’d be happy with a 158 +P LSWCHP, or a 148 wadcutter (hard cast preferred, if I could get it) instead. If I couldn’t get those, there’s a number of other choices that would do the job. Some of them would require more effort to recalibrate my holds, though (like the excellent 110+P Corbon DPX, which is a great bullet, but hits really low in my 640).

There’s a new product from Federal that you’ll see in these pages next month which is exciting. It promises to do things that previous .38 Special JHP bullets were unable to achieve, and if it performs as advertised, it will be a compelling choice. Stay tuned for more.

Hope that helps, more than it hurts.

Federal micro hst .38 penetrate about 13″ in gel, and is only about 2 years old. Interesting they have another round coming out so soon

We have a big story on this in the queue for May. Stay tuned.

Good info, thank you. I would be curious to see a write-up of both Underwood’s and Lehigh’s “Defender” and “Penetrator” line-ups, as they have taken the hollow point aspect out of the equation.

I am a convert.

Thanks sabasarge. I don’t have any personal experience with the fluted solids yet (which also include the Black Hills Honey Badger, Inceptor ARX, and NovX projectiles), but the concept interests me. I’m honestly not a big believer in temporary stretch cavity as a primary wounding mechanism for handgun bullets, but would like to learn more about these rounds and see their performance in gelatin before I pass any judgments. I’ll definitely look for opportunities to get smarter about these, and will pass along what I learn to the RevolverGuy audience.

Thanks Mike, I will look forward to your impressions. Keep well and stay safe.