I was shooting a “ball and dummy” drill at the 2024 Pat Rogers Memorial Revolver Roundup when I first met Steve Shields. Our instructor, Bruce Cartwright, had directed us to load our cylinders at random with live rounds and spent cases, and we were working our way through the chambers with a bit of a surprise each time. As we paused to load our cylinders for another turn at the drill, Steve approached and complimented me on my trigger press, telling me, “your sights didn’t move at all when you landed on the empty chambers. That’s a thing of beauty right there–good work!”

I didn’t know who Steve was, but was grateful for the kind words from someone who was obviously an instructor observing the class. It wasn’t until the next day, when we had a more formal introduction, that I realized my new coach was also the owner of an ammo manufacturing company that I’d been hearing lots about, lately—High Desert Cartridge Company.

The Best Part

Longtime readers of the blog know that I enjoy telling the stories of the people in our gun world as much as I enjoy telling the stories of the products, themselves. We’re all nuts for the guns and gear here, and I’m no exception, but ever since I became part of the industry, I’ve found the people to be the best part of it. Gun folks are special, I think, and I firmly believe that our industry generally attracts people who are a cut above (especially on the revolver side).

It was quickly apparent to me that Steve is one of these great folks, and as we talked about his ammo and the work that goes into manufacturing it, it occurred to me there were two stories to tell—the first, about the ammo itself, and the second about the journey Steve took to making it.

I’ve entrusted Top RevolverGuy Kevin McPherson to work on the first story, and he’s diligently testing the entirety of Steve’s product line in a variety of guns, as we speak. You guys know how thorough Kevin is, and I’m excited to share his report about the performance of the High Desert Cartridge loads in these pages, soon. I know you’ll be excited to read it, too.

Meanwhile, I’d like to invite you back to the mid-80s in Washington state, where the beginning of the High Desert Cartridge story was taking shape.

LE Roots

In 1986, Steve Shields was working as a dispatcher for the Forest Service, and saw there was an opening in the Recreation Department for a campground and back country wilderness ranger. This position required candidates to be graduates of the Park Service Academy’s training program, since they would be doing law enforcement work as part of the job. In March of 1987, Steve began the Department of the Interior’s Park Service Academy in Washington state, and upon graduation he went to work in a seasonal ranger position, where he was assigned to patrol campgrounds and also to enforce back-country ordinances in a designated wilderness area. He did the latter work on horseback for two years, and spent the off-season working as a reserve police officer in a neighboring small town.

In 1989, Steve got hired by a sheriff’s office, where he’d spend the next twenty years working a variety of details, including stints as a firearms instructor for the agency. Later, he took a position at the state’s Criminal Justice Training Center, where he taught firearms to the recruits. During his three years at the academy, he was on a small team that rewrote the firearms curriculum for the state’s basic academy program, and for post-academy training.

Around 2015, when he was working with a new agency in a small town, he contacted a small, local ammo company to see if they could fill the agency’s ammo needs. They invited him to the facility to take a look at the operation, and he found it so interesting that before long, he was volunteering his time to help them make ammo. The owners of the business made their primary living as HVAC guys, an appreciated Steve’s interest and help. Over time, as Steve learned more about the machines, manufacturing, and the business, the owners made him an offer to run the whole business for them upon his retirement for law enforcement.

When he retired in 2015, Steve took over full operation of the ammo manufacturing business, and managed the company until he moved further east, making it too far to commute. The owners eventually shut down their business, rather than move it to Steve’s new home. However, a friend with some vacant buildings and an offer of financial backing encouraged Steve to start up his own ammo manufacturing business, and High Desert Cartridge was born in 2019.

Getting Started

Steve’s experience with the business helped him get things started fast. He already had established contacts at all the suppliers of components and machines, and was able to set up new accounts quickly. He ordered three Mark 7 reloading machines, powder from Hodgdon, primers from CCI, and bullets from Berry’s, and he was off to the races.

High Desert Cartridge started with reloading cartridges in 9mm, .45 ACP and .223 calibers in once-fired brass from trusted sources (law enforcement ranges, and a commercial range that required its customers to shoot ammo supplied by the range). The 9mm catalog started with a single, 115 grain load, but expanded to 124 and 147 grain cartridges loaded with both TMJ and JHP bullets, as orders continued to increase.

The 2020-22 ammunition panic killed a lot of ammo businesses, as components (especially primers) became difficult to source and more expensive, but High Desert Cartridge continued to thrive. “We did really well during Covid,” said Steve, “and usually had 40 to 50 orders going at a time.” Getting primers was a full-time chore though, and Steve often found himself setting an alarm to wake up at 0300, so he could get first crack at each days’ new inventory, when it was first posted online by the suppliers. “I’d order the maximum of 25,000 primers and watch the computer just spin forever, before the order finally processed, then I’d switch accounts or go to the next place and order 25,000 more,” said Steve. The effort paid off though, and High Desert Cartridge kept its doors open throughout the ammo panic.

Because powder supplies could also be irregular during the panic, Steve had to develop more loads for each cartridge, based on what powder he could acquire. Some of his cartridges had as many as five different loadings, but he was able to keep up with the growing demand for High Desert ammo.

A New Opportunity and Direction

Steve met Darryl Bolke (“DB”) in the 2020/21 timeframe at the Primary & Secondary Training Summit, and began to follow him on his Facebook page, DB’s Shooting Adventures. In one of DB’s posts, he expressed disappointment with the .357 Magnum ammo he’d been shooting in his K-Frame Magnums, noting that it suffered from a high rate of misfires, and the recoil and blast were too excessive for the guns and his needs.

Steve recognized this as an opportunity and began developing a reduced recoil loading in the caliber that would shoot softer in the medium frame guns. He sent samples to DB for testing, and after three or four attempts, the pair settled on a formula that checked all the boxes for blast, recoil, and point of impact for the K-Frame sights.

Since the ammo panic had made it impossible to get a regular supply of Speer Gold Dot bullets for loading, Steve settled on using the 158 grain Hornady XTP, as it was normally available. To achieve the desired blast and recoil characteristics, Steve loaded the bullet to around 925 fps muzzle velocity, which was well short of the typical 158/.357 standard (which runs around 1,240 fps).

With a suitable JHP recipe established, DB urged Steve to develop a matching load with a less expensive bullet than the XTP. The idea was to have a more economical training load that would recoil the same and shoot to the same point of impact as the JHP load in the caliber. Steve liked the idea and cooked up a match for the XTP load, using a 158 grain Total Metal Jacket (TMJ) bullet. “Lead shoots dirty,” explained Steve, “and it’s also hard on loading machines. I didn’t want any pure lead bullets going through my machines because I didn’t want to spend all my time cleaning them, so I went with a TMJ bullet for the practice load, and it was great for both me and the customer.”

It took a bit to realize it, but Steve and DB had just developed the foundation for an entire line of revolver cartridges that Steve would eventually load. The High Desert Cartridge model that evolved from their work on the .357 Magnum is based on a matching set of controllable loads in each caliber—one topped with a Hornady XTP at moderate velocity, and the other with a coated or jacketed bullet in the same velocity range, to match the XTP load’s performance. The formula of a moderate defense load and training load that recoil and bark the same, and hit to the same point of impact, is the basis for every revolver caliber that Steve now loads for.

Ballistics and Tradeoffs

It’s important to note that these are purpose-driven cartridges, which deviate from industry norms. Most Magnum revolver cartridges are loaded to much higher velocities, and have correspondingly increased levels of blast and recoil. That’s not what DB and Steve wanted, however. Instead, they sought reduced levels of blast and recoil to enhance the shootability of these loads, especially when fired from smaller medium frame guns and snubs.

The only way to do that was to buck the industry standard, and load the ammo to reduced velocity. That would lessen the recoil and blast, but Steve was concerned that it might also ruin the performance of the JHP bullets, since the .357 Magnum had built its reputation on pushing bullets at fast speeds.

To find out, Steve mixed up some calibrated, 10% ballistic gelatin (the real stuff, used by the FBI and industry, not the Clear Ballistics product which has different properties, and gives different results) and started testing loads that developed circa-925 fps with the Hornady 158 grain XTP bullet. Pleasantly, he discovered the XTP did expand, yet still penetrated 20” in the calibrated gelatin, when fired from a Model 19 with a 2.5” barrel.

This was not the kind of performance he’d been conditioned to expect from 85 years of writing and reporting on the .357 Magnum. The gun press had always focused on the high-speed nature of the Magnum, but was the velocity really necessary to extract suitable performance from .357 caliber bullets?

Not in Steve’s opinion, which has been forged by the experience of observing more than 40 autopsies of people who died from gunshot wounds, while he was a law enforcement officer. With the help of the examining doctors, Steve collected detailed data on each of these shootings (about calibers, bullet weights, bullet types, intermediate barriers and clothing, shot placement, distances involved, and other factors) as part of an effort to ensure he was issuing the best available duty ammo to his deputies, and he told me that, “what I saw in actual shootings was different than what people were writing and talking about. Some of the ‘best’ loads didn’t do as well as they said they would, and some of the performance differences which looked so big on paper didn’t translate into real world effects.”

Steve’s experience matched that of DB’s, who also studied these things closely as a police officer in Southern California. Both Steve and DB are satisfied that a 158 grain, .357 caliber bullet that penetrates 20 inches in calibrated ballistic gelatin will do a reasonable job of stopping threats, especially if the shooter can place his hits better, as a result of improved controllability. If they pushed the XTP bullet faster, they would eventually get greater expansion and terminal effect, but at what cost in recoil and diminished control?

As it turns out, the circa-900 fps range that Steve and DB settled on for enhanced controllability is the “sweet spot” for generating the first bit of expansion with the durable XTP bullet. Below 900 fps, you’re unlikely to get any expansion at all, but the bullet starts to open up a little around 900 fps. Unfortunately, there is little additional expansion of the XTP until you reach velocities in the 1,400 fps range, where the bullet really begins to mushroom significantly. Between 900 and 1,400 fps, the increase in velocity doesn’t provide a correspondingly meaningful increase in bullet expansion, but you do suffer an increasing amount of recoil.

So, the circa-900 fps range is a good target for the XTP bullet, as it provides an excellent balance between recoil and expansion, controllability and terminal ballistics. It’s the perfect place for a purpose-built load, that’s designed to shoot comfortably through the smaller guns that are carried so frequently for self-defense.

Big Guns Too

It’s also a great place to stop for bigger guns. The moderate recoil generated by a High Desert load makes it pleasant to shoot in larger L and N-Frame guns, and extends their service life.

Steve recalls that in the late 1980s he was issued a Smith & Wesson 686 by the sheriff’s department he was employed by, and that agency required deputies to shoot full power duty loads in all firearms training. The agency conducted quarterly qualifications and biannual in-service training where deputies would shoot between 100 and 200 rounds each time. Each deputy was also issued 50 rounds of ammo each month, to encourage extra training on their own time.

Steve said he shot a lot of the monthly allotment ammo that wasn’t claimed by his fellow deputies, and in the course of three years, he broke two Model 686s, which had to be sent back to Smith & Wesson for repairs. When the second of these was returned by the S&W Warranty Department, it was accompanied by a note asking the department to treat the guns more gently, as they were not designed to digest a steady diet of full house .357 Magnum loads!

You won’t have to worry about breaking your revolver with the High Desert Cartridge loads, which will be gentler on both the gun and the shooter.

Growth

With the High Desert Cartridge “formula” established, Steve spent most of 2023 developing additional loads in .38 Special (a 125 grain XTP at around 820 fps from a Model 10, a matching 125 grain TMJ, and a 148 grain plated HBWC from Berry’s at around 725 fps) and working up a load for the test and evaluation work on the Lipsey’s Ultimate Carry J-Frame prototypes in .32 H&R Magnum.

Along the way, Steve found that he was getting some splits in the once-fired nickel cases he was reloading (he identified the problem during testing, and none of the ammo got out to the public), so he changed over to using brand new brass cases for all of his revolver loads. He used some primed Winchester cases in .357 Magnum, and a few in .38 Special, but mostly relied on new Starline cases to manufacture his ammo.

The .32 H&R Magnum load development was interesting because he wasn’t NDA’d with Smith & Wesson, and there was no gun to give him for testing. He bought a Ruger LCR in .327 Federal Magnum and developed his .32 H&R recipe in that, then sent the ammo to DB for testing in the prototype 432/632 UC revolvers. It took about four attempts before Steve had a load that was calibrated to the UC’s sights, and when the dust settled, it was a coated, 98 grain wadcutter from Missouri Bullet Company at about 825 fps that got the nod.

More Growth

In 2024, Steve expanded the catalog even more, developing additional loads in .32 H&R Magnum, .32 S&W Long, .41 Magnum (in conjunction with esteemed, former Gunsite instructor, Giles Stock), .44 Special, .44 Magnum, and .45 Colt, including:

A .32 H&R Magnum 100 grain XTP load, at around 880 fps;

A .32 H&R Magnum 100 grain RNFP, at around 880 fps;

A .32 S&W Long 98 grain coated wadcutter, at around 815 fps;

A .41 Magnum 210 grain XTP, at around 925 fps;

A .41 Magnum 210 grain TMJ, at around 925 fps;

A .44 Special 200 grain XTP, at around 860 fps;

A .44 Special 200 grain FP TMJ, at around 835 fps;

A .44 Magnum 240 grain XTP, at around 1,200 fps;

A .44 Magnum 240 grain FP TMJ, at around 1,150 fps;

A .45 Colt 250 grain FP TMJ, at around 790 fps;

None of these loads are “hot” for caliber. They’re loaded to moderate velocities that won’t stress the brass, the gun, or the shooter. But even at these moderate speeds, the bullets have been doing good work in the hunting fields. Friend and trainer Chuck Haggard shot a deer with one of the .357 XTPs and it mushroomed beautifully out of his levergun, stopping the deer in its tracks. Similarly, friend and fellow Shootist Shane Jahn took a deer with one shot, using the .41 Magnum XTP load in a handgun. These loads will do, if you will do!

Frustrations

One of the most common misconceptions about operations like High Desert Cartridge is that they’re “reloaders,” and their products are more closely aligned to the rounds made by hobbyists in their garages, than the factory cartridges loaded by the “big boys,” like Winchester, Remington, Federal, Speer, Hornady, and others.

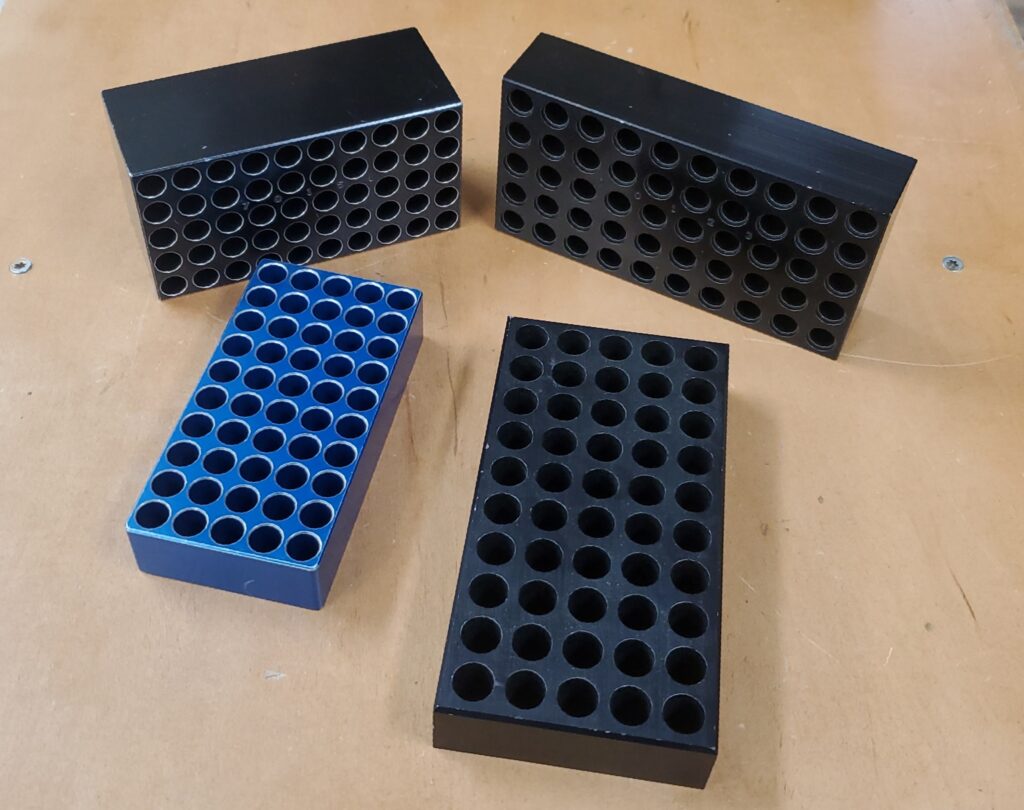

“You won’t find anyone pulling a handle on a press at High Desert,” says Steve. “We’re running six commercial-quality, automated reloading machines—Mark 7s, the best machines available for the money. A hobbyist press like a Dillon won’t stand up to the rigors of what we do. I’ve loaded over two million rounds on several of our Mark 7s and they’re in great shape.”

Steve explains that presses like the popular Dillons are excellent machines for their intended use, but they just aren’t robust enough to handle the stress of commercial production, and their manual design makes them unsuitable for manufacturing the quantities of ammo that someone like Steve is looking to produce. It would take an army of laborers pulling handles on reloading presses to create the output that a single Mark 7 is capable of, and you wouldn’t have the benefit of the automated quality controls/inspections that come with the commercial-level equipment.

High Desert Cartridge uses factory-new components in all of its revolver ammunition (only the 9mm, .45 ACP and .223 cartridges are remanufactured products, using once-fired brass), and adheres to rigorous quality control procedures on par with the majors. Loads are carefully developed and tested, and samples from each batch are tested to ensure they meet standards. “I’m not a ‘reloader,’ I’m an ammunition manufacturer, just like the majors,” says Steve, “I just don’t load as many rounds as Winchester does in a day. Some people think we’re making hobbyist-quality ammunition, just like their buddy in his garage, but we’re making professional-quality ammunition here.”

It’s taken a lot of work to get there, too. The Mark 7 machines are excellent tools, but some of the accessories that Steve needed to manufacture rounds like the .32 H&R Magnum and .41 Remington Magnum are not available from Lyman, the manufacturer of these machines. “They don’t make a conversion kit for .41 Magnum,” Steve explains, “so I had to have a machinist friend manufacture a .41 Magnum shell plate and modify the ram so I could load .41 Mag.”

Similarly, Steve says they had to manufacture a shell plate and bullet dropper for the .32 H&R Magnum, so he could load that caliber on the Mark 7 machines. The conversions worked great, and Steve is proud to say he’s got the only Mark 7s in the country that are set up to load .32 Mag and .41 Mag ammo.

Whereas primers were the most difficult thing to source during the 2020-22 panic, powder seems to be the limiting factor in the current market. The wars overseas in the Middle East and Eastern Europe have strained the powder supply, and that shows no sign of easing anytime soon, but Steve is still getting what he needs to keep up with demand, so far.

Looking Ahead

Steve told me that when he attended the 2023 Pat Rogers Memorial Revolver Roundup, nobody knew him or his company, but that all changed by the 2024 Roundup. “Everyone there had heard about High Desert Cartridge from Darryl, Bryan, and others” he said—a positive sign for the young company.

Steve is dedicated to continuing that growth, and introducing more shooters to High Desert Cartridge. To do that, he’s always talking to shooters, and trying to identify new opportunities to satisfy an unfulfilled ammunition need. “I want to build the ammo that shooters want, but haven’t been able to get anywhere,” he says.

To illustrate the point, Steve has expanded the High Desert Cartridge catalog to include popular levergun calibers . The .35 Remington, .30-30 Winchester, .45-70, .444 Marlin and the .32 Winchester are all being loaded, and Steve is open to adding other calibers, if there’s sufficient demand. He’s even added .243 Winchester loads for you boltgun fans, in both 100 grain and 85 grain varieties. All of them follow the High Desert formula, and shoot to moderate velocities for caliber. “They’ll have enough energy to make great hunting rounds,” he says, “but they won’t beat up the shooter like some of the full house loads in those calibers.”

It seems to me like that’s a winning idea, and I’m excited to see Steve and his company thriving and growing. The shooters at the 2024 Rogers Revolver Roundup had nothing but good things to say about the High Desert ammo they were shooting, and it seems like the company is on the right trajectory for 2025. This is going to be fun to watch!

Thanks for showcasing what High Desert is doing, Mike. I am very impressed with the ammo that I have shot to date and will have a full report soon. I’m very impressed with the consistency of Shield’s ammo in the calibers I have fired so far, and the commonsense velocity levels to which it is loaded. He is filling a long overdue void for Revolver Guys with his offerings. Rah!

Good news, Kevin. I’m excited to see your report when you’ve finished all the testing.

Kevin,

Impatiently waiting for your article.

Steve

I met him briefly at the roundup, picked up two boxes of .32 long WC, but then got busy… I’ll be trying it out at the outdoor range soon (my shooting picks up when the weather is nice). I do like the idea of custom .357 loads for the K frames. I can imagine the bullets hit harder at 1400 fps, the hp expands larger, transfers energy faster, etc, but a 900 fps .38 125 grain is nipping the heels of 9mm, so a 158 grain at those speeds is definitely no joke. I will be a repeat customer.

Riley,

Thank you for the words of encouragement.

I learned with the DB 357 load that one doesn’t need to push pills at Mach 85 to get solid performance. Bullet tech and even the raw materials have come a ways since having to go with +p and +p+ stuff.

I’ll be a fixture at the PRMRR, hope to see you again!

Steve

I’m curious; i’ve seen this website mention how much the old school guys liked Nyclad ammunition back in the day, has anyone ever attempted to bring it back in the modern era?

The equipment for making those nylon coated bullets has all been eliminated at Federal. Honestly, the bullets aren’t worth bringing back, in light of the better tech we have now. Check out the gel testing we did in our .38 Snubby Ammo article.

Jeb,

As Mike pointed out, bullet tech has progressed to the point where older designs don’t measure up to what we’re seeing today.

We can now push a 357 Magnum 158gr JHP at 935fps and get great expansion and surpass the FBI protocol for penetration. That says a lot about where we’ve come, but I always remember where we’ve come from as to bullet design and the velocities that used to be so heavily thought of as necessary.

Things have changed for the better…as to bullet design.

Steve

Dear Santa – forget everything else (except Jeep parts) – I want one of those Mark 7 loaders for .38 Specials !

It is always good to see commercial ammunition production expand in both quality and quantity. There had been a trend for a few decades to try and push bullets faster in the belief that raw energy translated directly to more effective ‘stopping’ power. I remember the early 1970s and our department transitioned from Winchester’s 158 grain Lubaloy SWC .357 to the newfangled 125gr JHP ammo. For a time, there was a race between Federal, Remington and Winchester to see who could market the hottest .357 125gr JHP loads. The highest number I remember seeing on a chrono in those days was just over 1450 fps out of one of our 5 inch barrel duty guns. It was that loading that seemed to ruin more than one S&W K-frame magnum, especially when one had to qualify with their duty ammo.

It wasn’t just with handgun rounds. Just because you can push a bullet faster does not automatically mean it’s going to work better. In many cases, the reverse is true. Hollowpoints pushed too fast may mushroom violently, but not penetrate to a desired depth. Varmint hunters quickly learned that a bullet well designed for a .222 Remington would come apart going up to 700 fps faster in a .220 Swift. A 125gr JHP .357 that works well in a 4″ revolver might not work so well out of an 18″ barreled rifle. Application dictates components. That might explain why cartridges like the .30-30, .30/06, .308 are still strong in hunting rifle calibers, and why the .38 Special / .357 Magnum still dominates the revolver world.

The 158 grain .357″ bullet at 950-1000 fps is really a gentle load and makes the .357 Magnum something of a gentle, yet potent giant. The hollow point should mushroom, not explode. Slowing down to about 900-950 fps would also serve the .38 Special defensive loadings rather well. My old Model 10 seems to like my 158gr SWC reloads that speed along at the blistering speed of around 750 fps. No paper target has yet survived hits from this load. At the other end, a defensive 148-150 grain .38 wadcutter at 900 fps would ruin any perp’s day. Projectiles like Speer Gold Dot and Federal’s HST show that velocity alone is not the most important factor.

Which brings me to what I found curious: “When the second of these [S&W 686] was returned by the S&W Warranty Department, it was accompanied by a note asking the department to treat the guns more gently, as they were not designed to digest a steady diet of full house .357 Magnum loads!” Alas, was that not the claim about the K-Frame Magnums in the late 1970s ? The 686 was allegedly created for an unlimited diet of .357 Magnums, or at least that what S&W advertised. Apparently not. What else is S&W not telling us (asking for a friend). I’m trying to imagine a Ruger .357 with a caveat of “please treat the guns gently”.

Ruger: “Please treat our guns gently. Using them as a hammer to drive railroad spikes will void the warranty. Limit use to home and commercial building construction.”

L M A O

I have about 65,00 38spc 158 LSWC out of a 686-1. The full diameter forcing cone lends it to be an exceptional 38spc. The old 686’s werent as grand w 357’s and I saw a number of them take a dump. Not nearly as bad as the old 65-2/3’s. I have trashed more K frame barrels than anything else even shooting 38’s. They seem to have about 45k before they’ll give up the ghost and less with +p’s. The new Smiths are far superior in strength to the vintage ones. The only guns I have found that will take regular diets of 357 are N Frames and GP100’s.

Y

Bryan, thanks for the super info–it’s great to see you here! I think the new K-Frames are probably stronger than the L-Frames now, due to that full profile barrel extension and the yoke lockup.

I’m shocked that 686s couldn’t handle a lifetime of hard 357s, I thought that’s what they were designed for, though I guess 10s of thousands is well above my anticipated usage rate.

I’m also thinking now my recently acquired Highway Patrolman isn’t too big for 357s, maybe it’s just right. I’ll need to get one with a 4” barrel.

Is there an article on the newer K-frames? I’m curious now as to how much stronger the new Classic Model 19s are compared to the older ones. I’ve not shot 357s from my old K-frames models (19 & 66s) as I bought them used. I don’t know how hard they’ve been used, though they look well cared for.

Gregory, our best article for info on the new K’s is this one here:

Evolutionary Improvements in S&W Revolvers

We haven’t done a review of any new K-frames because I had no interest in obtaining one with a lock, but now that S&W has some no-lock K-frame SKUs, we’ll be getting some for T&E. Stay tuned for more.

Gregory,

I think for the average shooter, the original L Frames will be fine with full magnum loads. Average meaning range time 3-5 times a year with 100 or so rounds per session.

I, on the other hand was an anomaly. Not only did we shoot full magnums for quals and training, but were also given 50 rounds as month for practice as well. Most didn’t use their 50 round allotment, so I was gobbling up everything I could find. I was young, had a hand of steel back then, and loved to shoot.

The first one was slightly used, but in excellent condition, the second was new in the box. Not sure of the round count on the first, but the second was around 15k+

N frames and Ruger is the way to go. As for Ruger, if you need it to pound fence posts, the manual has a specific section on that.

Steve

As pointed out before…Ruger is a farm tool as well.

s. bond

I have personally put a bug in old St. Nick’s ear for you!

Steve

Very nice writeup, Mike. I recently discovered High Desert Cartridge via a reference from either the American Fighting Revolver site or the Snub Noir Facebook group, don’t recall which.

My primary carry piece lately is a 1990s-vintage S&W 632 Airweight and I’ve settled on High Desert’s 98 grain wadcutter .32 H&R Magnum for the carry load. It shoots accurately and with the powder coated bullet it shoots as clean as jacketed loads.

If Steve is looking for new options to offer, I can think of two: First, .38 Special FBI loads using a powder coated soft cast or swaged bullet. That would approximate the old Nyclads. Second would be a .38 Special “full charge” wadcutter, as written about by C.E. Harris.

Dave, I like those suggestions a lot! The trick with the FBI Load would be to find a good bullet manufacturer. I’m not sure who’s building projectiles like that? I see plenty of LSWCHP projectiles, and plenty of coated solids, but who’s making a coated LSWCHP? Might have to do a secondary coating operation on somebody’s LSWCHP bullet.

Glad those .32 WCs are working so well for you. Thanks for the report!

Dave M.

Hmmmmm let me ponder those loads.

Although the LSWCHP was and still is touted as a great load, it had to be pushed to +p pressure/velocity. Which tells me the original load for that bullet failed at something, so upping the velocity solved something…expansion and/or penetration.

I’m not against lead, it just gums up the bullet feed system and the dies, so stopping the machines every 1,000 round or so is a bit counter productive, which is why I don’t load lead.

As Mike pointed out, finding a coated SWCHP is going to be different than the original because the coating will make the bullet perform different than the original. But I have enough interest in it, that the round is on the back burner for research.

As for the wadcutter, my currect wadcutter load runs at 750fps, and gets consistent 18″ of penetration in bare gel and 4 layers of denim.

Steve

Thanks for the reply, Steve.

BTW, I ran 10 of your .32 H&R Mag 98 grain wadcutters over a Garmin Xero C1 chronograph from my new S&W 432UC the other day and got an average MV of 811 FPS. Compared with some older Black Hills 85 grain JHPs that gave about 950 FPS it was much more pleasant to shoot in the little Airweight.

Re the “full charge wadcutter,” one of Ed Harris’s stated goals for the load was something that could break a deer’s shoulder. It wasn’t just for defense against criminals, it was a general use load suitable for both defense and hunting in a survival situation. I’ve been able to duplicate the load with a 148 grain wadcutter over 3.5 grains of Bullseye or 2.9 grains of Accurate No.2. Guys who don’t handload might be interested in it, though, which is why I suggested it.

Good stuff Sir!!! I recently started carrying the Speer Gold Dot 135gr Short Barrel load in my K frames because I wanted something that met the same criteria as the High Desert loads, low recoil, and easier on my older frames but still a potent load. They advertise their velocity to be in that same ballpark as the High Desert loads, but its a lighter bullet. I really like the idea of the 158gr rounds and would gladly switch as soon as I can get my hands on some. 20rnd of Gold Dots are almost $40.00 and I am curious how much the High Desert loads cost and how big is the box? Thank you for the great content!

Mark, each one of the underlined phrases in the article is a hyperlink that will bring you directly to the High Desert Cartridge website, where you can find that info. Click on the underlined “125 grain XTP” for example, in the first paragraph of the “Growth” section of the article, and it will bring you to the HDC website page for their .38 Special 125 grain XTP load. Hope that helps!

I attended a one day revolver class a month ago. I used the S&W 432UC running Mag tech and PPU through it. The instructor, Kyle turned me on to High Desert and I bought 250 rounds of the .32 wadcutters. I signed up for the Revolver Fest and will be using the UC and an older 19. Going to be buying more ammo from High Desert for that class.

Bruce, I look forward to seeing you there. A 19? We’ll get along, just fine! 😁

Bruce McCarthy,

Thank you for thinking of our ammo for your needs.

I will be working with AFR to provide students that attend the Revolver Fest to have ammo shipped to that range, so students can pick up their order when they arrive.

Steve

I never heard of High Desert until last year when the UC J-Frames were released. I finally bought a box of their 98gr .32 H&R wadcutters a few weeks ago, and I’ve been satisfied enough with them to make them my carry load (I still keep 85gr JHPs in my speed loaders).

The 98gr wadcutter is actually kind of painful to shoot out of my LCR (the .32 H&R one, not the .327 model); probably because I put a Hogue G10 grip on it. Out of my Taurus 327, no issue, and I also swapped the grips on that (I put on an older Taurus boot grip from the 85). It shoots very accurately in both, and I appreciate the polymer coating on the bullets.

I will be a repeat customer, and already ordered another 50 round box of the .32 H&R wadcutters. I like that they sell them for $42 for a box of 50. That makes them more affordable than wadcutters from Lost River and Buffalo Bore, even after shipping.

Thanks for the great report, Axel! It’s always interesting how much influence a set of grips has on our perception of recoil. Ones that don’t fit can become torture devices, real fast, can’t they? I like your practice of carrying JHPs in the speedloader.

Axel,

Thank you for your trust in our ammo.

We try our best to keep the overhead low. One thing is the packaging. Plain, not flashy but it ends up in the garbage anyway.

Steve

No, thank YOU sir. I very much appreciate both your production of .32 H&R and .32 Long ammo, as well as the price. The no-nonsense cardboard packaging is also welcome, and easy for me to recycle once I no longer need it.

I bought your .32 H&R JHPs recently, and will also be sourcing my .38 Special and 9mm defensive ammo from you in the future.

Thought I’d join the happiness hog pile…

Tried a box each of their Long and H&R wadcutters. I couldn’t tell them apart, in my 432 UC or the demo LCR or SP101 at the Roundup. I’ve adopted the 32 H&R wadcutter for the cylinder of my UC, and the XTP load for the recharge.

Just started working with their sensible 357 “DB Loads.” Shooting my GP100 revolvers is now a pleasure rather than a chore. Trying them in the S&W M19-7 2.5 inch next. Expecting good things.

I also appreciate the simple, no-nonsense packaging – a compact, nondescript, brown box. Why spend money on a fancy carton and cartridge tray bound for the trash bin?

Carry on, High Desert Cartridge Company!

PS, Primary & Secondary ModCast No.419 features a trademark long form conversation with the proprietor, Steve Shields.

Michael Brady,

Thank you for the vote of confidence.

I’ve been told more than a few times from marketers that we need to upgrade the packaging, but I’d rather keep the prices lower.

Steve

If only I had known; I might have saved myself a little work. This is the first I’ve heard of High Desert Cartridge; I’ve book marked their site and will need to try some.

But I’m thinking that great minds think alike. I’ve just finished loading 1100 rounds for a friend of mine, that I’ll be delivering to her soon. She is not a big fan of recoil, so we are setting her up with an SP101 in 327 Fed Mag. I’ve loaded 550 rounds of 327 Fed Mag powder coated, Lyman #2 alloy, 98 gr DEWC running at 1050 fps. I’m also giving her 550 rounds of 32 H&R Mag powder coated, #2 alloy, 98 gr Keith LSWC, running at 1050 fps, that she can use for reloads. Both loads are hitting the targets at approximately the same place.

Out of the SP101 there is (relatively anyway) not much recoil at all. The best part of it is, with the 327 load, I’m seeing an Extreme Spread of 21 fps and Standard Deviation of 7 fps. Nice tight groups with holes touching each other.

I’ve measured Underwood XD, Federal HST, and Amreican Eagle JSP. The best of those was the HST load with an ES of 78 and SD of 21. Those loads averaged 1357 fps. I don’t really see a need to go that fast if I can get the job done with less recoil and blast, with better accuracy to boot.

billmc,

You can lower those 32 Magnum loads down to a bit over 800, and they’ll still surpass the FBI protocol for penetration.

The DB 357 load taught me a lot about getting my mind out of 1970’s and 80’s thoughts on velocity etc.

Steve

I have become a big fan of the High Desert stuff. I have been shooting a lot of the 158gr 357 loads – both XTP and TMJ – in my M66, Speed Six, and Rossi RP63. I have never once enjoyed shooting magnums in any of the those guns, but now they are reasonably pleasant. Well, the RP63 is not “pleasant” with those loads, but they are doable as a carry round if needed.

Steve is doing great stuff. Now, if he will only listen to me and start loading 30-40 Krag! LOL

Steve’s a busy guy these days, and doing great work! Your .30-40 Krag order is currently being held up as he works on reloading some .41 Action Express for the fans who still wear parachute pants and sport mullets. 😆

…and the 45 GAP

Cecil,

Will see what Santa has to say about 30-40 Krag come PRMRR time…stay tuned.