We recently discussed the ins and outs of .38 Special ammunition for snubby revolvers here in these pages, and described the challenges involved with trying to make the most special of revolver cartridges perform from abbreviated barrels, which rob velocity and energy from the bullet. As a moderate energy level cartridge, the .38 Special doesn’t have a surplus of energy that it can afford to lose, and when you shoot it in the small guns, it can lose just enough energy to have a dramatic effect on terminal performance.

Because the .38 Special doesn’t give ammunition companies a whole lot to work with, they have to make very deliberate choices to eke out the best performance from this cartridge. Bullet weights, materials, designs, hardness, and velocities all have to be carefully tailored to obtain the best performance, particularly from a smaller gun. To date, the tradeoffs associated with these choices have dictated that most of the .38 Special loads which expand well, don’t tend to penetrate very deeply in industry-standard test mediums. Conversely, the ones that can be relied upon to penetrate deeply, don’t tend to expand.

Expanding the envelope

The engineers at Federal are smart guys though, and always eager to tackle unique challenges like this. In the past several years, we’ve seen them tinkering with the old .38 Special quite a bit, releasing new loads for their Personal Defense line such as the 130 grain, .38 Special +P HST Micro in 2017, and the 120 grain, .38 Special +P Punch in 2020. While these two bullets are very different in their design, materials, construction, cost, and target market, they’ve been well received by shooters.

Federal already had good .38 Special loads in these products, particularly the HST, but their work on another project opened up some new opportunities to address the delicate balance between penetration and expansion in a cartridge like the .38 Special. Based on the success of their new bullet design, they felt it was now possible to push the accepted bounds of .38 Special performance, and develop a .38 caliber bullet that would both reliably expand, and still penetrate to distances of at least 12 inches in bare, calibrated ballistic gelatin, and gelatin covered in clothing.

The 12-inch standard was important to them, because it represents the minimum acceptable penetration depth for a law enforcement duty round, according to the FBI’s protocol for testing ammunition. While the FBI’s standards are clearly designed to address law enforcement requirements, and a person could argue that 12 inches of ballistic gelatin penetration is an unnecessarily high bar for the typical snubby revolver engagement, there’s a number of folks who are so comfortable with the FBI’s 12-inch standard, they’re hesitant to carry a load that won’t meet it, regardless of mission.

Unfortunately, Federal didn’t have a .38 Special product that could do that reliably. Their premium .38 Special load, the .38 Special +P HST Micro, gets to (exactly) 12 inches in bare, calibrated gelatin, but the sizable expansion of the HST bullet (almost 1.7 times the original diameter, in bare gelatin) prevents it from going any deeper. This is unsurprising, considering the HST Micro bullet was designed to favor large expansion over deep penetration.

Surprisingly, adding FBI-standard Heavy Clothing in front of the gelatin doesn’t help the HST Micro to reach deeper. Many hollowpoints tend to penetrate further after going through heavy clothing, because their hollowpoint cavities fill with clothing fibers, and the bullets either under-expand, or fail to expand at all. This is not the case with the .38 Special +P HST Micro, however, which expands so nicely after FBI Heavy Clothing (about 0.677 inches in Federal’s testing—nearly 1.9 times the original diameter!), that it runs out of steam by 11.1 inches, according to testing done by Federal.

So, Federal had a round that expanded exceptionally well, and approached the FBI’s favored 12 inches of penetration, but it didn’t have a bullet that would reliably reach and exceed that distance after opening up. To fill this gap in the product line, they’d need to build a new bullet—a bullet that would give them close to the FBI’s required 1.5 times expansion, but also routinely penetrate beyond 12 inches in both bare, and heavy clothing-covered gelatin.

To do this, they turned to one of the most popular bullets ever invented for defensive use, Federal’s Hydra-Shok.

Going Deep

For several years, the team at Federal had already been engaged in updating the classic Hydra-Shok design, starting with the service calibers (like 9mm, .40 S&W, and .45 ACP). The intent of this work was to improve the classic Hydra-Shok’s ability to penetrate at least 12 inches in ballistic gelatin after upsetting to around 1.5 times the starting diameter—something which the old load did not always achieve.

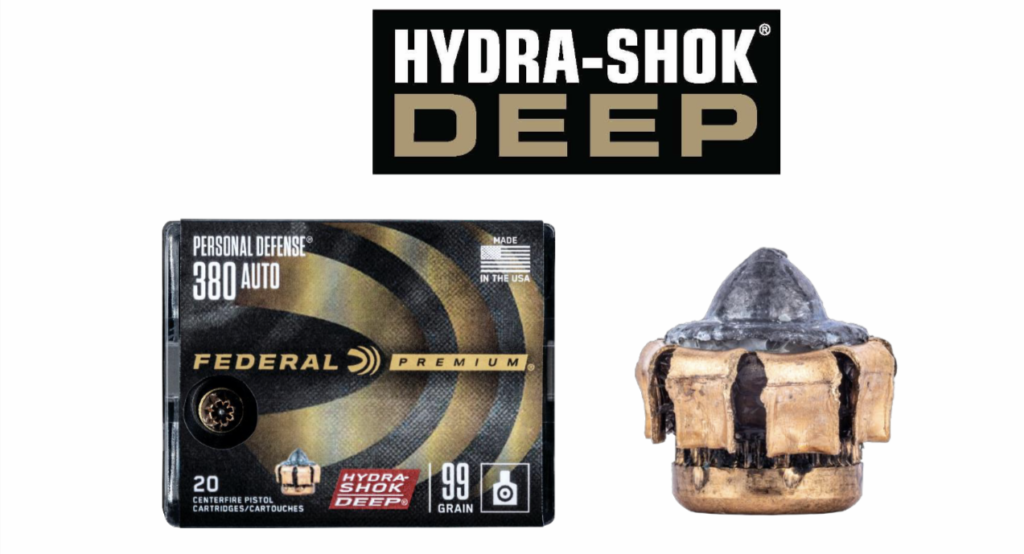

The new formula was labeled Hydra-Shok Deep, reflecting its deep penetrating performance. While the HST would remain the premium law enforcement bullet in the Federal lineup, with its excellent expansion and optimum penetration in all stages of the FBI protocol, the Hydra-Shok Deep would offer a substantial improvement over the classic Hydra-Shok, which some law enforcement agencies had become stubbornly allegiant to. The Hydra-Shok Deep doesn’t expand as much as the HST, but it expands better than the classic Hydra-Shok bullet did, and penetrates appropriately into the 12-to-18-inch range (and optimum 14-to-16-inch range) outlined by FBI standards. In fact, the Hydra-Shok Deep boasts a 70% improvement over the classic Hydra-Shok bullet across all stages of the FBI protocol, according to Federal, and will be a much better choice for those agencies and officers who won’t give up the Hydra-Shok for the premium HST load.

After tackling the service calibers, the Federal team turned their attention to the .380 ACP version of the Hydra-Shok, which had become one of the longtime favorites in this caliber. While Federal had no intention of pitting the .380 ACP version against the full battery of FBI protocol stages, they were interested in improving its performance in the bare gelatin and heavy clothing stages of the protocol, which were most appropriate for the conditions where a .380 ACP would most likely be used.

They succeeded handily. Federal reports that in bare gelatin, the new .380 ACP Hydra-Shok Deep bullet, weighing 99 grains, penetrates to 13 inches and expands to 0.496 inches (about 1.4 times the original diameter). In FBI-standard Heavy Clothing, they say the same bullet penetrates to 13.5 inches, while expanding to 0.514 inches (about 1.45 times the original diameter).

This is exceptional performance from a .380 ACP bullet. By comparison, the classic, 90 grain, .380 ACP Hydra-Shok bullet–which was well-respected for its performance in the category–penetrates about 30% less in bare gelatin with only 3% larger diameter, and penetrates about 13% less in FBI-standard Heavy Clothing, while expanding 9% less. The next-best performing .380 ACP bullet from a competing brand penetrates 32% less in bare gelatin, while only gaining 5% in expansion, and in FBI-standard Heavy Clothing, it penetrates 19% less, and expands 6% less than the new .380 ACP Hydra-Shok Deep, according to Federal’s numbers.

This is important to us as RevolverGuys, because the .380 ACP and the .38 Special have a lot in common, from the standpoint of terminal ballistics. Both of these calibers are moderate energy cartridges, in which the performance traditionally drops off rapidly as you chamber them in shorter and shorter barrels. Shooting a .380 ACP in a compact auto delivers performance that is similar to shooting a .38 Special in a snubby revolver, so if the Federal team could dramatically enhance the .380 ACP’s performance with their Deep formula, then it was tempting to see if they could accomplish the same with the venerable .38 Special.

So, with the .380 auto project complete, the Federal guys turned their attention to the .38 Special version of the Hydra-Shok.

Back to the future

Ironically, this was a path that brought them full circle, as the Hydra-Shok family of cartridges originally started out as .38 Specials.

The Hydra-Shok design was created by Thomas J. “Tom” Burczynski. Burczynski was a technician at Westinghouse Electric Corporation, and studied mechanical engineering and metal fabrication techniques during his employment there. As an avid shooter and handloader, he had a strong interest in ballistics and some unique ideas about how to achieve better performance from handgun bullets.

After almost six years of work, Burczynski filed a patent application for his expanding bullet design in February of 1974. Burczynski’s patent (assigned US Patent Office number 3,881,421) was approved in May of 1975, and paved the way for him to join forces with a local businessman, and form the Hydra-Shok Corporation (derived from the term, “Hydraulic Shock”), where he served as Vice President.

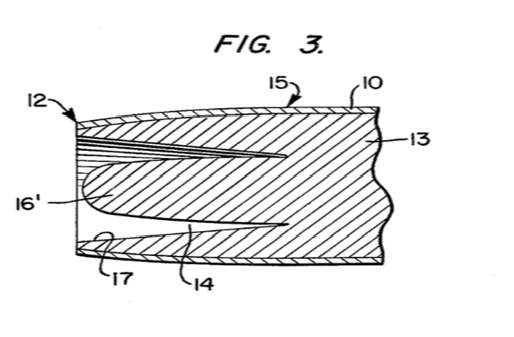

Burczynski’s patented bullet design incorporated a hollowpoint cavity with a tapered post in the center of the cavity. The purpose of the post was to serve as a simple machine–a wedge which would redirect the fluid forces inside the hollowpoint cavity so they were focused on the interior walls, rather than the base of the cavity. By applying this outward, radial force to the cavity walls, the bullet would be forced to expand by hydraulic pressure quite early, even before the pressure inside the cavity peaked. As the bullet continued to penetrate the target, the annular forces inside the cavity would grow and accelerate the bullet’s expansion, increasing the bullet’s frontal area, so the bullet could damage more tissue and deliver more shock to the target. As the bullet mushroomed and curled away from the post, the post would stand firm and act as a penetrating probe at the front of the bullet, piercing new tissue as the bullet plowed forward.

Burczynski’s research showed that variations in the shape and size of the central post, as well as the size of the cavity’s opening, could be used to control the pace of bullet expansion. Over time, he discovered that a broad, conical post was most effective at redirecting forces, and, when used with a large cavity opening, could encourage even heavy and slow projectiles like the .44 Special and .45 ACP to expand rapidly. In contrast, bullets like the .38 Special often performed better with a tapered post, built with a hemispherical tip, in a smaller cavity opening. In this case, the smaller opening and hemispherical post slowed the rate of expansion just enough to allow adequate penetration from the smaller bullet. Burczynski found that the more efficient conical post would have opened the bullet up too soon, and the resulting drag would have limited penetration.

Hurdles

Burczynski’s prototype Hydra-Shok bullets were very promising, but he had two main technical problems that were preventing his newly-formed company from manufacturing them. The first was the lack of a robust die that would withstand the rigors of mass production. Since his bullet had a pointed ogive, the cylindrical die used to cold press the bullet had thin walls near the base, and they would crack prematurely. Despite diligent work at the drafting table, and the skillful work of his machinist uncle, Stan, Burczynski was unable to design a cylindrical die for a pointed ogive bullet that would go the distance.

The other problem is that his bullet making operation was set up around manual methods that didn’t translate well to mass production. He needed to create a system that would automatically eject the bullet from the machine after it had been formed and punched with the press. In the manual process used to create his prototype Hydra-Shoks, it had been necessary for Burczynski to manually free the bullet from the punch after striking it. This was OK for his small-scale R&D efforts, but it wouldn’t work for large-scale manufacture.

The latter problem proved easier to fix. Burczynski was soon able to design a system that safely ejected the bullet, using inertia, after the forming and punch operations were complete. As a result, the press’ operator was no longer required to manually remove it from the die.

The dies though, continued to be a problem. In an effort to resolve it, Burczynski sought outside help from industry expert Jerry Alberts, of the Alberts Corporation. Alberts was a talented tool and die maker who manufactured his own bullet making machines and ran a successful business manufacturing lead bullets. Alberts initially told Burczynski that it would be no problem to manufacture a set of suitable dies for him, but after several months of trying, he was forced to admit that he couldn’t find a solution, either. The punches he made for the ogive bullet were breaking too often, and the bullets were sticking to the post-forming punch so badly that they wouldn’t come free.

Alberts suggested to Burczynski that he should abandon the vexing ogive bullet and make a cylindrical one–a full wadcutter, with the patented post design. It would be easy to design and build the dies and punches necessary to manufacture a bullet like this, and it could easily be put into mass production.

The idea didn’t appeal to Burczynski, as he wanted to go with an ogive bullet for its better performance and compatibility with speedloaders, but he finally agreed to proceed with the idea, in order to get a product on the market. Thus, the first Hydra-Shok bullets looked like a .357 caliber, hollow-base wadcutter, with a small post in the center, instead of the pointed ogive bullets that Burczynski had planned. Alberts manufactured the 146 grain bullets for Burczynski, and they were loaded at a facility near the Hydra-Shok company headquarters in New York.

The loaded .38 Special ammunition was sold to distributors and to law enforcement agencies as the “Hydra-Shok Scorpion.” It didn’t last very long, because Burczynski was bound and determined to bring an ogive bullet with his patented post to market. He finally succeeded in designing an appropriate die, which would withstand the stress of high volume operations, and the wadcutter-shaped Scorpion quickly disappeared in favor of a .357 caliber, 125 grain, jacketed hollowpoint with an ogive profile. This bullet was quickly adopted by the U.S. Department of State, in both .38 Special and .357 Magnum loadings, starting around 1977. The so-called, .357 Magnum “State Department Loading” (SDL–alternatively, “Super Defense Load”) penetrated to 8.5 inches in 20% ballistic gelatin (a military standard which was adopted by several federal law enforcement agencies of the era) and expanded to between .55 and .60 caliber. It was the product that really put the Hydra-Shok Company on the map.

The State Department contracts (Burczynski was eventually awarded 13 different contracts to produce the SDL) generated lots of interest in the Hydra-Shok design, and led to requests from the FBI and others to supply them with ammunition. The Hydra-Shok Corporation couldn’t fulfill all these requests with their small manufacturing operation, and this led to Burczynski selling an exclusive license to Federal Cartridge to manufacture the Hydra-Shok product, around 1984.

Federal at bat

The timing couldn’t have been better for Federal. After the horrible, April 1986 FBI gunfight in Miami, the FBI hosted a series of Wound Ballistics Workshops that resulted in the FBI protocol for ammunition testing. The new protocol emphasized deeper penetration, and Federal’s new Hydra-Shok bullet was well-suited to meet the demands of the test.

In fact, the Federal Hydra-Shok did so well in FBI testing that it eventually became the preferred FBI duty load in multiple calibers. The Winchester OSM, 147 grain, 9mm JHP may have been the first 9mm load adopted by the FBI to replace its now-disfavored, 115 grain Winchester Silvertips, but the 147 grain, Federal Hydra-Shok soon replaced that load in FBI service, and Hydra-Shoks became the Bureau’s standard in .38 Special as well.

To create the FBI’s .38 Special Hydra-Shok duty load, Federal loaded one of their 9mm, 147 grain Hydra-Shok bullets in a .38 Special case at +P+ pressures, to generate about 950 fps out of a 3” Model 13 revolver. Even though this 9mm bullet was only 0.355 inches in diameter, the accuracy was good enough to meet FBI standards in their .357 caliber revolvers. The Federal 147 grain, .38 Special +P+ Hydra-Shok replaced the legendary, 158 grain, .38 Special +P lead semi-wadcutter hollowpoint (LSWCHP) that was originally designed for Saint Louis PD, but later popularized as the “FBI Load,” and served until the FBI formally retired its revolvers in the 1990s.

The special production, 147 +P+ Hydra-Shok disappeared from the Federal catalog shortly thereafter, but Federal still continued to build two versions of the .38 Special Hydra-Shok for consumers. The first of these .38 Special Hydra-Shoks is a full-power, 129 grain load at a published muzzle velocity of 950 fps, and the other is a 110 grain, low-recoil load at a published muzzle velocity of 980 fps. While these have been good performers, neither can reliably reach 12 inches in bare and heavy clothing gelatin after expansion, as a growing number of consumers have demanded.

The very new Hydra-Shok

All of which brings us back to the present task of applying the Deep “magic” to this venerable favorite.

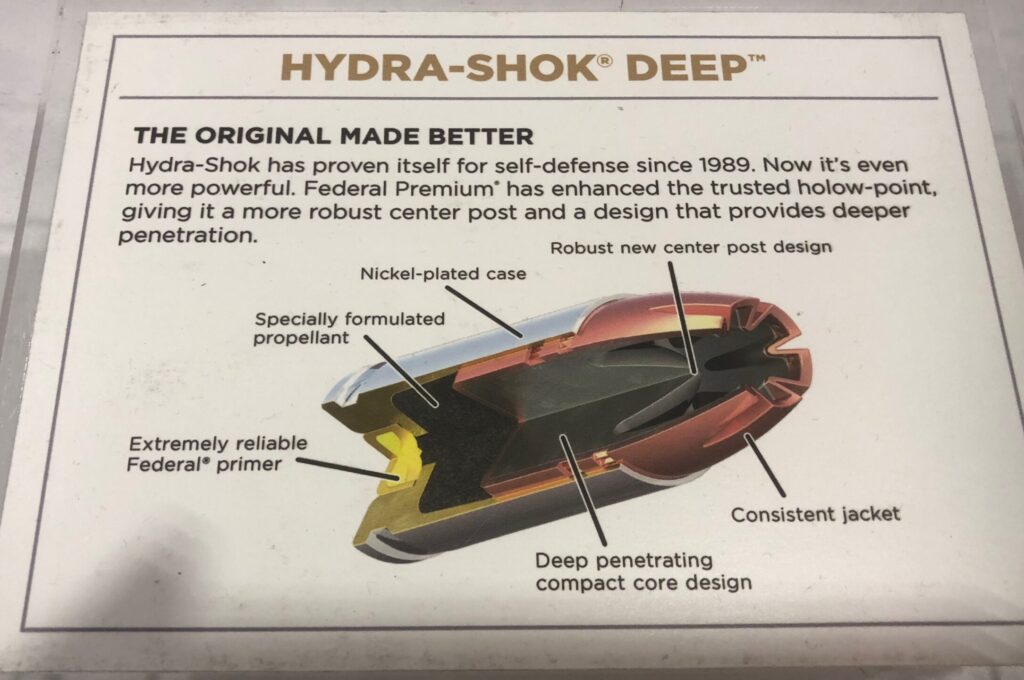

The new Hydra-Shok Deep bullet shares the concept of using a central post to redirect fluid pressure inside the hollowpoint cavity, but aside from that, it has very little in common with the Hydra-Shok bullet of old. The Federal engineers who built this bullet clearly weren’t constrained by the previous design in any way, and had freedom of movement to change all aspects of the bullet—design, shape, weight, materials, hardness, skiving . . . the whole works. When I asked Federal’s Chris Laack why the 130 grain weight was chosen for this bullet, for example, he simply replied, “because that’s the bullet weight that worked best in our testing—we didn’t plan it that way, we just settled on it, based on what we discovered.”

Only the objective remained inflexible: Build a bullet that will achieve 12-plus inches of bare and heavy clothing gelatin penetration, while opening up to 1.5 times the diameter (or as close as you can get, without sacrificing penetration).

Simple, but not easy.

Changes

Our tour of the new Hydra-Shok Deep starts with the most visible difference of the new bullet, the folded jacket design.

The folded jacket gives the new Hydra-Shok Deep a very unusual appearance, and is a critical element of the new design. Unlike the old Hydra-Shok, the jacket is not simply a cover for the lead core of the bullet. Instead, the jacket is the primary structure in the forward section of the bullet—most of what you see exposed beyond the shoulder of the case is nothing but jacket.

In the old Hydra-Shok, the lead core ran all the way to the mouth of the bullet, and the jacket just wrapped around it, but in the new Hydra-Shok Deep, the lead core only climbs the walls a little bit before it runs out, and all that’s left is jacket material to complete the pointed shape of the bullet and create the mouth of the cartridge.

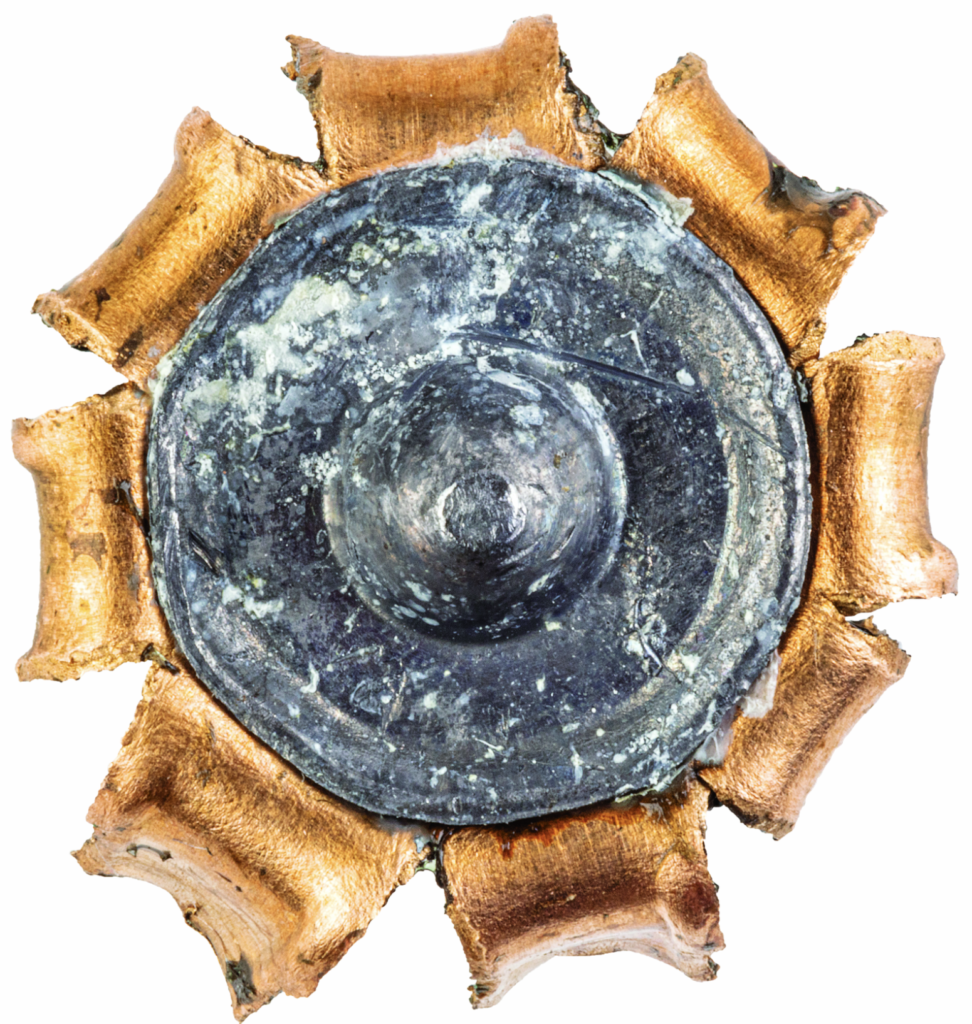

This heavy copper jacket (which is reminiscent of the scored jacket concept used in Burczynski’s earliest HST prototypes) is what does most of the bullet’s mushrooming. When the new Hydra-Shok Deep strikes the target, fluid forces are redirected by the central post to begin unfolding the jacket and expanding the bullet. Since the copper jacket is skived, it opens up along those fault lines into a series of eight petals (in the .380 ACP and .38 Special bullets—other calibers have different numbers, such as the 9mm, which has six) that expand, then fold back, to form the mushroom.

The short section of lead core that extends up the inside of the cavity walls stops near the bottom of the bullet’s cavity. This lead ring will mushroom as well, and curl over the base of the expanded petals, at the bottom of the cavity. This lead mushroom is much smaller than the copper jacket mushroom, but it serves an important purpose, to protect the integrity of the expanded jacket. The lead ring at the bottom of the cavity prevents too much energy from acting on the base of the copper petals, which in turn prevents them from over-expanding and separating from the projectile—it’s basically a shield for the base of the jacket.

We mentioned the central post briefly, but didn’t explain how it differs in the new design. In the old bullet, the post was a slightly-tapered cylinder, with a hemispherical tip. It was quite thin, looking a bit like a section of pencil lead with a rounded tip, sticking up in the center of a relatively small, cylindrical cavity. This narrow post served to slow the rate of expansion, to allow the bullet to reach adequate penetration depths, and also simplified production, because the reduced surface area (compared to a larger post) decreases drag, and allows the bullet to be stripped off the punch more easily.

On the new Deep bullet, the post is conical and very large. Its base is very broad, and looks to be about four to five times the diameter of the tip, which sits appreciably below the mouth of the cavity. As Burczynski noted in his original development of the Hydra-Shok, a conical post is much more efficient at redirecting the fluid in the cavity, and it appears that Federal is taking advantage of that, to help open the heavy copper jacket on this new bullet quite rapidly.

Assisting that rapid expansion is the larger mouth on the Hydra-Shok Deep. The folded jacket design increases the surface area of the cavity mouth, and allows fluid pressure to build more rapidly in the (comparatively) much larger cavity of the new bullet. Interestingly, while the new Deep bullet has a larger mouth, the folded jacket and conical post design do a better job of preventing the cavity from becoming plugged with clothing fibers or other material (such as drywall—a real hollowpoint killer in FBI protocol testing).

More differences

Since the Hydra-Shok Deep is mostly comprised of copper jacket near the tip, the bullet’s overall length is longer than comparable 130 grain bullets of traditional manufacture, where the lead core reaches the cavity mouth.

The core and jacket in the Hydra-Shok Deep are mechanically bonded, and the bullet features a pair of cannelures that help to lock the components together and keep them from jumping the case crimp under recoil. The mechanical bonding of the Hydra-Shok Deep will prevent the core-jacket separation that can reduce penetration, by virtue of the energy loss that comes with shedding mass.

The jacket thickness and hardness are specially tailored, along with all the other elements of this bullet, to “program” the bullet’s expansion. When a Deep bullet expands, the petals fold back to a point that they’re parallel to the shank of the bullet, but the tips don’t contact the shank itself. It takes a lot of work to design the petals to bend this far, but no more.

If you compared an expanded Deep bullet to an expanded HST bullet, you might be tempted to think it’s a shame the Deep petals bend past 90 degrees, instead of remaining roughly perpendicular to the bullet’s shank, as they are on the HST. There’s no doubt the HST’s traditional, “starfish” expansion pattern is impressive, but it’s that large surface area which acts like a drag chute, and prevents the HST from penetrating further. The Deep’s petals fold back more, which gives the bullet a smaller cross-section when expanded, but the decreased drag allows the bullet to use its energy for deeper penetration, and sail past the HST in the target.

Amazing job

The Deep bullet looks unique when it’s expanded, sort of like a sunflower, or a lead sombrero perched atop a bird bath. Fortunately, it’s performance is unique as well.

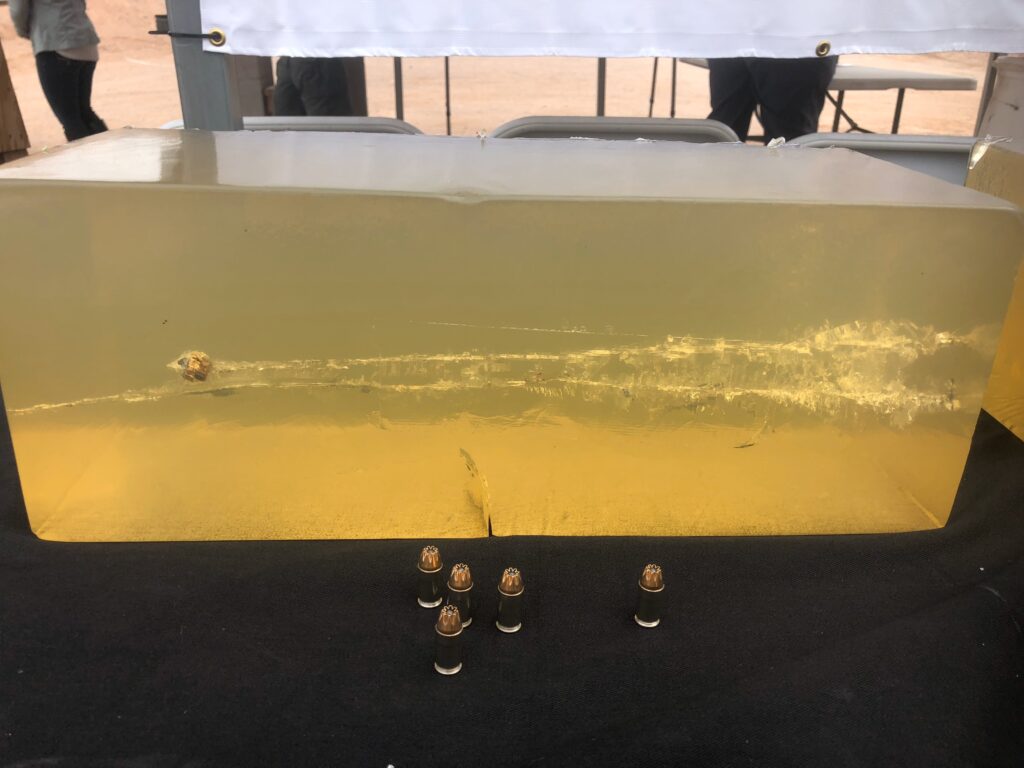

When fired from the 1.875” barrel of a snubby revolver, the 130 grain, .38 Special Deep bullet clocks about 800 feet per second at the muzzle, as a result of careful powder selection. According to Federal’s Chris Laack, this energy allows the bullet to penetrate 13.2 inches of bare ballistic gelatin, and expand to 0.551 inches (1.54 times it’s starting diameter), according to Federal’s numbers. In FBI-standard Heavy Clothing, the bullet is said to penetrate 13.4 inches and expand to 0.548 inches (1.53 times it’s starting diameter) from the same, short barrel.

I’ve fired the .380 ACP version of the Deep on paper, but have been unable to test any of the Deep bullets in gelatin yet. However, I’ve worked with Chris before on a project, and respect and trust him very much, so I’m confident in his numbers. Looking at the supplied .38 Hydra-Shok Deep data, I have to say this is extraordinary performance from a snubby revolver. As we previously discussed in these pages, most .38 Special and .38 Special +P loads struggle to get beyond 9 inches of penetration in those test mediums, with only a select few going as deep as 11 inches, but the .38 Special +P Hydra-Shok Deep does it regularly, while expanding to over 1.5 times the original diameter. This is really super, and it represents a new benchmark for this legendary chambering.

Importantly, the .38 Special +P Hydra-Shok Deep performs very well from a service-size gun, as well. From a 4-inch barrel, Chris says the load clocks about 900 feet per second at the muzzle and penetrates 14.6 inches of bare gelatin while expanding to 0.584 inches, according to Federal. In FBI-standard Heavy Clothing, the bullet reportedly penetrates 16.1 inches and expands to 0.562 inches.

Sometimes engineers are forced to make choices that actually decrease performance out of a longer barrel, to ensure a bullet will work well at the lower velocities encountered in shorter barrels, but the Hydra-Shok Deep bullets seem rather indifferent to velocity changes and work very well in anything you chamber them in. As a matter of fact, Federal engineers have tested the 9mm Hydra-Shok Deep in a 16-inch carbine, and found that the bullet performs nearly the same as when it’s fired in a 3-inch pistol barrel, achieving the same expansion, and about 0.75 inches more penetration. This is really amazing consistency from a handgun bullet.

New bar

This performance puts the .38 Special +P Hydra-Shok Deep in a unique position in the market. There really isn’t another hollowpoint bullet out there which reliably goes beyond 12 inches in gelatin, with good, consistent expansion, when it’s fired from a snubby revolver.

There are other .38 Special bullets which expand better than the Hydra-Shok Deep, such as Federal’s HST, but none that travel as far in the target. The Deep’s closest competitor is probably the excellent, 135 grain, .38 Special +P Speer Gold Dot Short Barrel, which expands equally as well, but still penetrates about an inch less than the Deep in both bare and heavy clothing gelatin. As a bonded bullet, the Gold Dot may have some advantages against other barriers, like steel or glass, but in the arena it was designed for, the Hydra-Shok Deep should rule the roost.

The best part for us RevolverGuys is that we now have a choice. We previously had bullets that could expand nicely (like the HST), just as we had bullets that could penetrate (like the wadcutter). On balance though, the market was skewed towards expansion. Now, with the Hydra-Shok Deep, a shooter that wants to tilt the scale in favor of penetration, without giving up reasonable expansion, has a dog in the fight.

A closing word

As this article goes to press, we’re deep in the middle of the worst ammunition crisis any of us can remember—perhaps since World War II. The demand for ammunition is at record levels, as a function of political instability, security concerns, a skyrocketing population of buyers which grew by an estimated 9 million in 2020 alone, and a global pandemic that has interrupted the supply of raw materials used by ammunition manufacturers, and had meaningful impacts on the labor force they rely on to make the product.

It’s tough to find ammunition right now, and I know a lot of RevolverGuys are frustrated by the lack of availability. Please don’t think we’re tone deaf to the situation, by running an article on the latest and greatest ammo product from Federal! We feel your pain, too. We don’t have any ammo sponsors here at RevolverGuy, after all. Every round that gets fired in support of a RevolverGuy article comes out of our own stash, and our own pocket. We’re just as concerned as you are about our ability to replace what we shoot, or find new products that we want to try out.

Rest assured that manufacturers like Federal (and their sister companies under the ATK umbrella, Speer and Remington) are working 24/7 to produce ammunition, pushing machines and employees to their limit. They are actually making more ammunition than ever before, and are aggressively getting it to the market. The problem is, there’s just a lot more people chasing the product, and they’re buying a lot more of it than they did in the past.

Federal has already made a bunch of .38 Special +P Hydra-Shok Deep, and they will continue to make more, as quickly as they can. You may have to wait a while–or just get lucky in your timing–to find it, but I think you’ll find it will be worth the wait.

Good luck on the search, and be safe out there!

*****

RevolverGuy would like to thank the following individuals for their invaluable assistance with this article: Tom Burczynski (creator of the Hydra-Shok, and industry consultant), Chris Laack (Federal Centerfire Handgun Product Manager), Evan Marshall (Detroit PD, Retired, world-class law enforcement trainer, purveyor of StoppingPower.net, and author of the books Handgun Stopping Power, Street Stoppers, and Stopping Power), and JJ Reich (Communications Manager, Firearms and Ammunition , Vista Outdoor). Thank you gentlemen, for your contributions!

Thanks Mike, for the excellent article on this promising new bullet. Thanks for the history behind the Hydra-Shok, too. I’m looking forward to a day when we can walk into a local gunshop and pick up a box of these bird bath perching lead Sombreros!

Haha! Me too, brother!

Hey Mike, can you do a bone test on the 9mm 135 Gr Hydra Shok Deep out of a 3.5-3.8″ Barrel (M&P9 M2.0 3.6″ Compact, Canik TP9, etc.)? No one has tested the expansion ability through bone yet, and I feel this is most often missed, yet most relevant to simulating real life as close as possible.

Maybe you could use pork ribs, one of those kinda big “dog” bones, etc. Thanks.

Hi James, great to hear from you. Unfortunately, I don’t have a good lab setup to conduct my own testing, so I won’t be able to help here unless I can get access to a professional facility again. If I do, I’ll certainly make sure to include the 9mm Hydra Shok Deep.

Regarding bone, a good friend who works in the industry tells me that their experience has been that “dead bone” (like you would find in butchered meat) doesn’t have the same qualities as “live bone.” The bones in a living animal or human are rather pliable, and not as brittle as the “dead” bones where the marrow has dried up without active blood flow. As a result, he thinks calibrated ordnance gelatin does a better job of replicating “live bones” than using “dead bones” as a test medium. I know there are folks out there using beef ribs or other butchered meat bones as a ballistic test medium, but I’m honestly not sure how valuable the results are from this kind of effort. As I quipped to “not Mike” earlier, it may be that these tests are just a waste of good BBQ material!

On the bright side, my friends at Federal have tested the 9mm HS Deep extensively in their own labs, and the bullet has proven to be very insensitive to barrel length. It is penetrating to the same distance, plus or minus an inch, from compact pistols (in the 3.5” range you specified) and pistol caliber carbines (16”)! It’s a VERY consistent bullet, reaching that 14” to 16” desired range of penetration in calibrated gelatin with regularity.

Ah ok. So it would be easier for a JHP to expand through a dead bone than proper 10% FBI gel? I’ve seen tests on YouTube, where a bullet expanded in gel, but not through dead bone, at least not fully opening up. If you’re up for it, it’s still be nice to see a bone used in a test, maybe even put inside the gel block to simulate a bullet first hitting soft skin, and then bone, and then more tissues. Just an idea. Thanks for replying!

Ah ok. If you’re up for it though, it would still be nice to see a “dead” bone test with the HSD from a 3.5-3.8″ barrel. Maybe putting the bone inside the gel, to simulate the bullet hitting skin, then bone, then tissues. Just a thought. Thanks for replying!

I’ve seen these in the shop and felt like “why mess up a good thing?” so I’m glad you wrote this up! Thanks, Mike, for another fascinating article!

You bet! Thanks for reading!

I’m happy to hear you’ve actually seen this stuff in the wild. I imagine it wasn’t cheap, given the current circumstances.

Thanks Mike for the great article.

Ammo will eventually come back as in the past, well …. if the trend stays the course. Until then …. “Don’t stop believin’ – hold onto that feelin'” Ok, end musical interlude.

“Every round that gets fired in support of a RevolverGuy article comes out of our own stash, and our own pocket. ”

Shameless plug time — cough …. Patreon, cough, cough ….. everyone cough, go to Patreon. Cough, cough, donate today, cough, hack, cough.

Thanks again!

Mike (nMW)

Haha! Thanks Mike. I wasn’t fishing, but do appreciate the thought.

On a musical note, Journey sure struck a goldmine with Arnel Pineda, didn’t they? That kid is fantastic. Don’t Stop Believin indeed!

That .38 Special +P Hydra-Shok Deep sounds like an excellent choice, but because of the current scarcity of (and exorbitant prices for) just about all quality ammo, I’ll stick with .38 Special lead wadcutters for my snubby. It’s a cartridge that offers relatively low recoil, accuracy, and good penetration. No much expansion, though, but bullet placement is paramount in my view.

Can’t go wrong with those, Spencer. An excellent choice. Twelve to eighteen inches? Yeah, we can do that. No problem.

Very informative as usual. I was most impressed with Federal’s 130gr. +P HST when it came out. I carry them in my LCR. I’ll contact Lucky Gunner and humbly request some testing on this round. I’ve seen it advertised lately and was/am curious as to it’s terminal ballistics. Thanks, Mike.

With respect to our friends at LuckyGunner, you won’t get better data from them than you’ve already got in this article, Jack. This data comes from calibrated ballistic gelatin, while LuckyGunner conducts their testing in Clear Ballistics gelatin, which doesn’t accurately depict performance in calibrated gel. If gelatin data is important to you, don’t use the Clear Ballistics numbers.

I love reading articles like this, heavy on the factual history and technical details. It takes a lot of work to get all this info packed into a single article. Well done!

Informative, as always. Eyes wide open, but for now, as above, wadcutters will do the trick.

Thanks.

Great, informative and well written article, thank you for the effort!

The history of Mr. Burczynski and how the Hydra-shok was developed was of particular interest.

I have carries the 38+p HST Short Barrel, I found it to be reliable and very accurate in my revolvers . It only had two drawbacks due to its design, 1 it could not be used in a speed loader, and 2 it would not function in my 77/357 or my 1894C… which in fairness, it wasn’t designed to be used in.

When I find some of the new Hydra-Shok I will defiantly give it a look.

Tom is a real gentleman and a ballistic wizard. The PMC Starfire, Remington Golden Saber, Federal HST, and some other well-known, high-performance bullets are all beneficiaries of his work. I was super happy to get the opportunity to help tell a small part of his story. Evan Marshall deserves the credit for being the first to write extensively about Tom’s work, and I thank him for introducing us. I also thank Tom for his time and help in assembling this abbreviated history of the Hydra Shok!

Oh, do I now feel crotchety. I remember when Black Talons and Thunderzaps were top of the heap. You had to “know somebody” to get them, back then. I still prefer LSWCHP for daily carry.

Thunderzaps. I’d almost forgotten about those. I wasn’t sold on the idea, but it was definitely interesting ammo! In today’s age of advanced polymers and powders, it would be interesting to see what could be done with the old concept.

I still have a left over fresh box of .357 Black Talons. I have no idea why they have such a mythical stigma.

Tim, I remember standing at a crowded gun counter in the early 90s and some guys were talking about the pile of Black Talon boxes stacked up on the counter with hefty price tags on them. The media rush to discredit this ammo was in full swing, and the prices were significantly marked up. Shockingly so.

One of the customers was trying to convince everyone in earshot that the Black Talon was so superior to everything else, that it was still a bargain at the inflated price. I wasn’t convinced, and the clerk I was working with must have been good at reading body language, because he rolled his eyes and said in a hushed tone, “it’s just ammo.”

“It’s just ammo.” Indeed!

I’ve thought about that comment a lot over the years. I admit I’m an ammo nerd, and enjoy getting lost in all the details, but in the end, it’s all just ammo. Our ability to put it in the right place is much more important than the technology!

The stigma came from a killer at 101 California St in San Francisco. He used Black Talons in his shooting spree, and the media found out about it.

Yep, and a few others around the same time. The media latched on to some of Winchester’s marketing and declared it a menace to society. That shooting in SF added a lot more fuel to Senator Feinstein’s anti-gun fire. “Never let a crisis go to waste,” eh?

Interestingly, that bullet performed very well in some calibers, and less impressively in others. The later SXT was/is an improved bullet, minus the “evil” black oxide coating. It’s in my snubby right now.

Thank you for another great DEEP dive (sorry, couldn’t resist). Seriously though, I found the history of this bullet development very interesting and very much appreciated the testing data from 1 7/8 inch barrels. As others have said, it looks like I will be replacing my wadcutters with this load when it becomes available. It is because of articles like this that I became and remain a patron.

RBO

Thank you Sir! We appreciate the support and the great wit!

I’m also excited to get my hands on some of this in .38 Special. I think Federal really knocked this ball out of the park.

Let’s see . . . 800 fps from a snubby, with a 1:18″ twist for S&W gives a rotational speed of the bullet at @ 533 rpm – approximating that of a chain saw at full speed. (I’m guessing at the math folks)

So just maybe it’s like getting hit with a chain saw ? We’ll have to interview the recipients of these projectiles to get their feedback, assuming they’re around to tell us. ;-P

Groo here

That is 800 fps or 9600 inches per sec.

Devided by 18 is 533 inches per sec or 31980 rpm…

That is some chain saw!!!!!!!!!!

Told ya I was guessing at math, got the 533 right, just wrong measurement. . . yeah, that’s a turbo charged chain saw with nitrous boost. ; )

A little bit of history and a whole lot of edumication there Mike! Thanks!! I’m currently running a dwindling supply of the 135gr GDHP and an even smaller supply of the 130gr Winchester Defender. Hopefully these will show up soon.

Those two loads are my go-to JHPs as well, Jim. Like you, I’ve been rationing them.

I’m comfortable with carrying the SXT or GDHP, but must admit I’d love to buy a sizable quantity of these Deeps when they become available. I think they would be an excellent choice.

The article begins with a good summary of the .38 Specials limitations in short-barrels and of the efforts by manufacturers to overcome those limitations by designing specialized projectiles and “short-barrel” powders/loadings. I don’t mean to come off sounding like a Wise Guy…or to re-iterate what many here already know…but it is a lot easier to just buy a .357 Magnum snub nose. Lackluster ballistic problem solved…and all the better if you are a handloader because you can tweak your own loads for optimal performance. By “optimal performance” I mean developing a load that works respectably and does not duplicate having an M-80 go off in your hand. AND you can also fire that mediocre performing .38 Special if forced by necessity.

Brian, there’s no doubt the .357 Mag is ballistically superior, but allow me to play counter-point with your argument that maximizing the .38 Special isn’t worth the effort, when you could just step up to the Maggie.

As you recognize, the Magnum recoil is strong to excessive in the small frame guns. The .38 Special +P is simply the upper limit of what many shooters can handle, or are willing to experience. Given this energy cap, it makes sense to develop ammunition that is most effective, within the given limits, doesn’t it?

Only the tiniest number of shooters are handloaders, so factory ammo is what the overwhelming majority of shooters will be limited to (and there’s a reasonable argument that even if you ARE a handloader, there are legal pitfalls associated with using handloads for defensive purposes that argue against doing it). This factory .357 ammo is often just too powerful to shoot efficiently and effectively in the small frame guns. Even the “light” .357s can be too much candy for a dime, sometimes.

Yes, as a handloader, you could download the .357 to make it more controllable, but now you’re dancing at the edges of .38 Special performance anyhow—-a lot of extra work for no practical gain, and again, we have the possibility of legal issues surrounding the use of handloads for defense.

Lastly, many small frame revolvers are limited to .38 Special, and upsizing to .357 Magnum is simply not an option. If you own/want an aluminum frame S&W Airweight, a Detective Special, or one of the newer Cobras, the .38 Special is your limit. In some cases, the manufacturers have enlarged their .38s to turn them into .357s (thinking of the new, Magnum J-Frame, for example), but a shooter may not have one, or they may prefer the smaller, trimmer, .38 Special version. If all you have is a .38, then you need to find good .38 ammo for it!

I’m all for these efforts to squeeze as much juice as we can out of the mild .38 Special!

Brian,

While you have a valid point, I have to counterpoint along with Mike. If I’m reading you correct, your premise is based on a one shot encounter. In that case, you’re right that a well placed .357 round will do just nicely, but reality is that handgun rounds are pathetic manstoppers (compared to a 12 gauge slug, or 5.56m/m round). This is why we practice followup shots: I can tell you from experience that you’ll rarely get a one shot stop on a crack head or gang banger.

A snub .357, whether S&W or Ruger, or even Colt, is going to be a handful to shoot well in the first place, not to mention followup shots. A 2.5″ S&W Model 19 is wonderful to carry on a belt, but it’s lousy in a pocket. It’s very easy to handle and get followup shots when shooting .38 Specials, even the +P and +P+ rounds.

There is a reason the .38 Special thrives, and that in the five shot snub guns: It packs the most power for the least bulk that is controllable in both initial and in followup shots.

Mike and “S” I meant to imply that it is hard to believe that we are still trying to milk more out of the .38 Special when it should be well know at this point that limitations are limitations and eventually one arrives at the beating of a dead horse. We’ve gone +P combined with lightweight bullets and faster burning powders. I don’t know of any remedy beyond that. My main point is we’ve already been down this road some 90 years ago when the .357 magnum was borne out of the same frustration with the .38 Specials lackluster performance. And to “S” I fully understand your statement on how “the .38 Special thrives, and that in the five shot snub guns: It packs the most power for the least bulk that is controllable in both initial and in followup shots.” But I would like to point out that there are other options today like .327 Federal…and if cut for moon-clips I see no reason why 9mm +P could not be chambered in a snub-nose. The latter would allow the user to own both a polymer semi-auto like a G19 AND a J-Frame. Two guns one ammo.

Well Brian, the whole point of this article was to point out that it’s possible to move the goalposts sometimes—that “limitations are limitations” isn’t necessarily true, and with some creativity, technology, and advanced manufacturing, we can sometimes achieve what we previously thought was not possible. If you “don’t know of any remedy” beyond lightweight bullets and faster burning powders, then I have to ask, “did you even read the article?”

I don’t know if you’ve fired the .327 Federal Magnum yet, but it’s definitely in the .357 Magnum class. I know the .327 was initially marketed as a “.357 without the kick,” but that is certainly NOT the case. The .327 barks and has hefty recoil, particularly in small frame revolvers, and is not the light-kicking alternative that some people mistakenly believe it to be. Everything that makes the .357 Magnum a poor match for most snubby shooters applies to the .327 Fed Mag.

I’m glad you mentioned the 9mm. There are several revolvers chambered in this cartridge already, and we reviewed one of them extensively in these pages—check out our review of the 9mm LCR. The 9mm snubs are a good solution for many shooters, but do kick more than a .38+P in a gun of similar size, weight, and shape. The +P and +P+ loadings in 9mm are even more spicy in these small revolvers.

Please understand, I’m not trying to be argumentative, just trying to say that we’re not ready to give up on the .38 Special around these parts, and see the effort to improve its capability as a worthy effort. We don’t think the horse is dead yet!

; ^ )

Thanks for reading!

I own several .327 fed. Mag and 32 h&r mags. And there is no comparison between full power .357 and .327. .327 is certainly not “kick” free but is considerably less and carries one more round. NonHandloaders can purchase any level cartridge they like because of the multiply cartridges available. Great article, great comments, but I couldn’t let that one slide!

Dan, I disagree. We may be talking about different.357 loads, though. If your reference is 158 grain .357s, then yes, they are not comparable, but the .357 loads often recommended for use in small revolvers (110s, 125s, or reduced recoil 125/135) have a lot in common with the .327 FM.

Consider Speer’s Gold Dots in .327 Fed Mag and .357 Mag, if you will. The 100 grain .327 at 1,500 fps produces 500 ft-lbs of muzzle energy, compared to 584 ft-lbs for the full power 125 grain .357 load (125 grains at 1,450 fps), and only 294 for the reduced power, 135 grain Short Barrel .357 load (135 grains at 990 fps). That puts the .327 Fed Mag squarely into full power .357 territory, and well in excess of the reduced recoil .357 Mag.

Beyond parsing the numbers though, my point is that the .327 recoils much more than consumers were led to believe, in the initial marketing of that round. There was a mistaken impression, amongst those who had never shot it, that the .327 FM delivered .357-like performance “without the kick,” and that’s just not true. If you shoot a .327 FM in a Ruger LCR, you’ll soon understand that the .327 deserves the “Magnum” label in a way that the .32 H&R Magnum never did.

Great article Mr Mike

Thank you Sir! Much appreciated!

A quote from an online gun magazine from 2013 …… “And if you think center-punching a miscreant through the sternum with a 158-grain lead round nose is an inconsequential wound, you’ve been watching too many vampire movies.”

I believe this could also be used to describe a simple wadcutter. The old reliable family station wagon of .38 special rounds. It’s not glamorous, it’s not the newest wiz-bang technologically advanced round on the planet, it has it’s shortcomings, but if I do my job it’ll probably do it’s job.

Now, having said that ….. this newest offering from Federal has my interest. With new technologies and manufacturing techniques it’s good news that a major ammunition manufacturer would look to advance a very popular self defense round.

Truthfully, flawed reasoning and logic is that we’re stuck with anything old and that we should not look into improving it.

Again, great article Mike!

Mike (nMW)

Spot On, my friend. Placement is King, but we should never give up trying to build a better widget!

Mike if you can please remind the good Folks at Federal not to forget us old Fellows who like the .32 Mag. and that it could use a bit of magic.

Sure seems like lots of people buy Js in .357 Magnum and might shoot a cylinder full before switching to .38 Special.

Nice article.

I agree Tony. The .32 H&R Mag seems overlooked and under-appreciated. One thing that has helped revive interest in this great cartridge is the .327 Fed Mag—once folks get a taste of its hefty recoil, they start looking for other options, and the sweet-shooting .32 H&R Mag often gets the nod. That cartridge is due for some attention, and I’ll recommend it to my friends behind the scenes.

.32 H&R is one of my favorite calibers!

“Since the Hydra-Shok Deep is mostly comprised of copper jacket near the tip, the bullet’s overall length is longer than comparable 130 grain bullets of traditional manufacture, where the lead core reaches the cavity mouth. This gives the bullet an improved sectional density, in comparison to these other bullets…”

That is false.

Sectional density is calculated by dividing the bullet’s weight (in pounds) by its diameter (in inches), squared. Thus any two .38 bullets, both of which weigh 130 grains, will have the same sectional density, regardless of material or length differences.

Thanks Jeff. I was thinking more about ballistic coefficient with the longer projectile, I think, and used the wrong term. Good catch.

Great article. Now we just need someone to do gel tests on federal deep, micro, and punch. Throw in speer GDSB+p and and hornady CD+p for reference as well ;). I suppose lucky gunner could expand their existing testing with clear so we can get relative penetration between ammo types. It seems everything penetrates slightly more in the clear ballistics blocks.

Thanks for the writeup, great article! I am one of the many who has a 357 J-frame and carries ammo loaded to 38spl energy levels in it. The gun is capable of handling more energy than I am, and I like the safety margin that gives me with loads, not to mention that it will likely extend the operational life of the gun.

I definitely appreciate any effort made to increase the effectiveness of a cartridge at lower energy levels… because honestly, if 22LR was good enough, that’s what I would carry all the time.

Thanks for another great piece Mike. I’m still hoping one day you’ll review the “fluted” ammo offered by Underwood and Lehigh. I’ve come to rely on it, and am extremely impressed.

https://www.underwoodammo.com/38-special-p-100-grain-xtreme-defender.html

Thanks Sarge. I’d definitely like to work with this ammo and test it appropriately. Maybe I’ll get the chance to do it someday. I’ll certainly write it up here, if I do.

I must admit that I’m hesitant to get excited about the concept of temporary stretch cavity being a primary wounding mechanism at handgun velocities, but honest enough to say that I can’t form an educated opinion about these loads yet, because I haven’t worked with them. I know Jeff Hoffman is sold on the concept of fluted solids, and he’s a real smart guy when it comes to ballistics. That makes me curious . . .

Realistically, how much penetration in gel do you think is necessary for “civilian” (police are civilians, too) CCW?

It’s a hard question to definitively answer, Brad, because we just don’t know what the task will look like, and ballistic gel is an imperfect test medium anyhow.

However, I will say that I don’t buy into the concept, which is often suggested by well-meaning folks, that armed citizen shootings and police shootings are different enough to justify different terminal performance criteria.

Tell me if you’ve heard these before:

“Armed citizen shootings normally involve attackers who face you head-on, so the ammo doesn’t have to penetrate as deeply as a police bullet, which might have to penetrate from an angle”

“Police shootings frequently involve barriers—cars, walls, etc.—that armed citizen shootings do not, so a police bullet has to perform through glass, steel, wood, drywall, and other materials that we can dismiss in armed citizen shootings”

Frankly, I think statements like those are nonsense. There’s nothing we see in police shootings that make them materially different from what we see in armed citizen shootings, when it comes to the issue of terminal performance. Armed citizens get into shootings around cars and in buildings, and sometimes need to shoot bad guys at oblique angles, where the bullet needs to penetrate through an arm and across the width of a torso before it gets to the vitals. Sometimes, armed citizens even need to shoot bad guys wearing LBE full of spare mags (active shooter, anyone?), too. So, I think their ammo should be capable of handling these circumstances just as effectively as a police officer’s ammo.

Therefore, if you accept the FBI’s standard of 12 inches minimum for a police bullet, then I think it makes sense to hold an armed citizen’s bullet to the same standard. We don’t get to choose the circumstances for our gunfight, eh?

Please note, I’ve discussed in these pages that 12 inches may disqualify some really great ammo with excellent, real world street creds, so I’m not in the camp that 12 inches is absolute. The Federal 9BPLE, for example, often stops short of 12 inches in various stages of the FBI protocol, but has permanently reformed a large number of miscreants over the course of about three decades. Do I worry that it “only” does 10 inches? Not really.

But then again, if you can carry a load like HST or Gold Dot, which gives you a 12+ inch guarantee, even through a hard barrier like auto glass, then why not carry it, instead (assuming you can get it—a big assumption in times like these we’re currently in)?

No easy answers here, but I’ll leave you with this. In .38 Special, I typically carry 130+P Winchester SXT Bonded or 135+P Speer Gold Dot in my snub. Neither of these bullets is a 12 inch bullet out of the snub in bare gelatin or heavy clothing, but they’re close enough that I don’t fret about it much. They do about 9-10 inches and that seems like a reasonable expectation from a .38 snub—a gun that is far from being Thor’s Hammer.

So, I’m comfortable with 9 inches of gelatin penetration, but that doesn’t mean I wouldn’t like to have 12+ if I could get it. I’m eager to get my hands on this new ammo and see how it compares. If it performs as I hope it will, it may just become my new baseline.

Mike,

I’ll throw in another perspective: there IS a difference between police shootings and citizen shootings. As a citizen defender, you look to protect you and yours, driving off the threat. As a cop, you must effect an arrest, and the suspect knows it. You may well need a more effective round against those that would resist that arrest. Some people will absolutely die before going back to prison.

Hi Riley, good to hear from you. I absolutely agree there are significant differences between the two, but I don’t think they significantly differ in the area of terminal ballistics—-at least not with enough reliability to make dangerous assumptions about what our ammo needs to do.

Armed citizens face those same bad guys, with the same motivations. If a homeowner is holding a bad guy at gunpoint, and the police are on the way, the bad guy knows he’s going back to prison. Nothing changes in his motivation or resolve. He’ll fight the homeowner with the same vigor as the cops, in order to get away.

Same thing for an active killer—I don’t think it matters to him whether it’s a cop or an armed citizen that points a gun at him, he’ll react similarly, and our ammo will need to accomplish the same job.

I have a friend who got involved in a gunfight in a parking lot, with bad guys hiding amongst the cars. That fight didn’t look any different, from a ballistic standpoint, as a trooper making a vehicle stop.

We would like the armed citizen to act very differently than the police, and make different tactical choices, but I think it’s safer to assume the ammo will need to perform the same in each type of shooting. At least that’s how I see it.

Fair points. The parking lot scenario sounds particularly bad. Any place I could look that up in detail?

Not really. No reporting on it of any value, unfortunately.

Maybe the Brazilian reality could be different. Most “armed citizens” are off-duty LE or military personnel. And, statistically, police officers are more subject to gunfight off-duty than on-duty.

Hi Mike,

Just outstanding information here, both in the article and discussion. Now, for the $64,000 question …….. which ballistic medium should be considered legitimate? We have clear gel, then calibrated (darker) gel, clay (yes, modeling clay!), 2 layers of denim, 4 layers of denim, water jugs, wet newspaper, and of course Paul Harrell and his as of yet not patented meat pack.

Myself, I like Harrell’s dryyyy sense of humor and the meat pack. Scientific, maybe ….. maybe not. But it sure is fun, so he gets style points …. there I said it, ‘style points’ dog gone it!

Also, I wonder if people who do accuracy and speed drills with their carry ammo have ever considered trying out factory wadcutters paired with say factory lswc or lswc-hp’s in their speed loaders? See if they have better accuracy and if they run a bit faster than their normal carry ammo. If so …. then the question becomes, is better accuracy and speed preferable to being slightly less accurate and slightly slower? Just a question, perhaps not a good one, so feel free to ignore it.

Anyhow, thanks again Mike for your time and effort to put these articles together and answer questions.

Mike (nMW)

Thanks Mike, I appreciate the kind words!

I think the best test medium right now is (nominal) 10% ballistic/ordnance gelatin, but I don’t think it’s perfect. The best thing about it is that it’s reasonably consistent and repeatable, and we have a lot of data that compares how bullets perform in it, to how they work in the real world.

I’m not a fan of 4 layers of denim, the IWBA protocol. I think it’s very unrealistic and too extreme of a test. Water, clay, wet pack, and all the other stuff is ok for a hobbyist to play with, but doesn’t give meaningful results (water, incidentally, is REALLY tough on bullets). Clear Ballistics gel offers several advantages, but will only be truly useful when we develop a new set of criteria for judging performance—trying to apply the FBI standards, which were developed around ordnance gel, is a no-go with the CB product because it reacts differently.

On the downside, ballistic gel is a pain to work with, and it’s homogeneous, while a human target is not. Knowledgeable industry friends say that 10% gel does a reasonable job of replicating skin, muscle, fat, and living bone, but I think it’s awfully tough for one substance to accurately simulate all these disparate elements. Unfortunately, there’s nothing else that gets us any closer.

Harrell’s meat pack? Well, living tissue and bone react differently than butchered meat, so I pretty much view that exercise as good TV, but a waste of good BBQ components! ; ^ )

I think Col. Cooper had it right with his DVC model, and we’re all tasked with trying to balance Accuracy, Power, and Speed. There’s no doubt that ammo selection has a big influence on how all that balances out, and the humble wadcutter is a reasonable attempt to tip the scales in our favor when shooting a difficult gun like a snub. Personally, I’m happier with a well-placed, lower-powered bullet, than a poorly-placed barnstormer.

Mike

Mike,

Now THAT’S an excellent answer! If I had the resources, I would find several types of accepted self defense ammunition for snub nosed revolvers, line up and start shooting into the different test media that’s currently available. Just to see if any of them actually do correlate to one another.

At least that way, when people use water jugs, meat packs, layers of denim, clear gel, calibrated gel, lumber, etc, etc, etc ……. we would have a better idea of what we are seeing.

Or, I suppose we could just practice more to get better at shot placement. Sigh ……… ok, I’ll just do that.

Have a great rest of your weekend!

Mike(nMW)

Mike,

Back in the early ’90s I worked in a cafe that made homemade fudge weekly. When the old stuff got rotated out it was free to employees. Of course, a lot was thrown out because we tired of it quickly. Eventually, a buddy got the bright idea to shoot it with various bullets to compare different rounds and calibers in a consistent medium… We had, of course, just read Marshall’s book- this was tongue in cheek but a lot of fun! Sometimes I miss being that dumb kid. These days it might make good YouTube material.

Riley, I gotsta know . . .

Did walnuts make any difference? Marshmallows? How about Maple versus Chocolate?

I’m not showing your response to my wife, because she’d cry at the pure savagery of “wasting” good fudge. She has no appreciation for the scientific quest!

Now you’ve got me thinking about flan leftovers . . . 😉

Great article! I cannot wait until ammo becomes plentiful again and I can get my hands on some of this Federal ammo…until then I tend to go old school and if I carry a 38spl I use either Buffalo Bore wadcutters, in the snub, and Remington or Buffalo Bore SWCHPs in the Model 10 . Of course I’d rather carry a 357 Mag with either Remington 125gr SJHP or 125gr Buffalo Bore JHP, I’m not recoil sensitive however there’s just something about carrying a 38 special that’s pretty cool

Nothing wrong with wadcutters in the snub, R.M.

I’ll likely continue to use Federal’s 130gr HST in my 642 and 12 due to the mild recoil (and mild pressure, despite the +P designation). I’d be interested in checking out this new Hydra-Shok load, whenever the stars align. Might be good as a personal defense load for my Model 10s.

On an unrelated note, I’d love to see this kind of development put into making new self-defense loads for the .44 Special, as well as new firearms chambered for it. Yeah, you probably couldn’t get .44 Special into a J-Frame sized package, but it’d be interesting to see something that isn’t a Bulldog.

Agreed, Axel! I’d love to see revolver ammo get some more attention, especially calibers like the .44 Special and .32 H&R, which have been ignored too long.

Good article, enjoyed the read. My question is, are we every going to see this ammo? A recent response from Federal states that there are no current plans to put this into production.

Greg, my sources inside Vista tell me they have already manufactured some of this ammo, and will certainly make more of it when market conditions allow. Currently, all production lines are dedicated to making the ammunition that’s in highest demand (calibers like 9mm, .223/5.56, and the hunting ammo everyone will need soon), and they can’t afford the downtime required to retool for a big run of .38 Special, but when things settle down, we’ll certainly see them making more of this ammo again. Believe me, I’m anxious for it, too! We all are, even the guys at Federal!

This is the best gun blog I have seen keep it up

Thanks Mark! Appreciate it!

Mike,

Which of these loads would you prefer for for a J-Frame ?

Corbon DPX 110 grain +P

Double Tap Barnes 110 grain +P

Buffalo Bore Barnes 110 grain +P

Speer Gold Dot SB 135 grain +P

Federal Hydra Shock Deep 130 grain + P

Thanks,

Shane

Shane, those are all potent loads, but I’d lean towards the Gold Dot 135+P or the Hydra Shok Deep 130+P because bullets in that weight range and velocity print much closer to my point of aim in my S&W 640 than any of the 110 grain loads. I carried the CorBon DPX 110+P and think it is a good round with good terminal ballistics, but it prints significantly below point of aim in my 640. I would presume the similar loads from Doubletap and BB would do the same.

Thanks Mike for your response.

If I may ask a follow up question; if accuracy was the same would the DPX/Barnes round ( DT/BB get about 75 fps faster out of my guns than Corbon) be more effective ballistically than the GD or HS round? Is it just a six in one hand sort of thing? I have ample supplies of all those rounds and keep the Barnes loads in the speedloaders because they are faster to load but am still waffling a bit on which load to keep in the gun. I do notice that the Barnes loads to hit a little low in my gun but not so bad at the most likely ranges I’d need the gun for in a self defense encounter.

Since a pair of 442’s makes up my EDC and they are on the lower end of adequate I just want to make sure I am squeezing out all it has to offer.

Try as I might I just haven’t been able to stay with any flat pistol for any length of time. I always revert back to my J’s. I make up for the capacity issue a bit by carrying two ( 3 in bad areas ) and a couple of reloads.

Thanks. I appreciate your time for n answering my questions.

Shane, you’ll see some info on how the DPX load stacked up against the Winchester Ranger (which offers performance similar to what you might expect from the Gold Dot) in calibrated ballistic gelatin, in this article, here:

https://revolverguy.com/38-snubby-ammo/

My takeaway from that comparison is that there’s not a lot of meaningful difference between the two of them. You’ll be able to discern some differences in both expansion and penetration between them, but I doubt they will translate into substantially different terminal effects.

Short version? I’d be confident in any of those loads, from a ballistic standpoint. I might lean towards the HS-Deep because it promises to penetrate a little deeper than the others, but the most important thing to me is how the ammo shoots. Is it reliable in my gun? Can I control the recoil and shoot with appropriate speed and accuracy? Does the ammo shoot to point of aim?

Regarding the latter, don’t be too quick to assume that you will be shooting at close range with your snub. Changes in point of aim/impact won’t be significant at close distances, but by 15-25 yards, you should see some meaningful changes. It’s not unreasonable that you might need to shoot at those distances, so be sure to check that far out. I’m pretty sure that you’ll start to see at least 3-4 inches worth of difference with the 110 grain loads.

Thanks Mike! I appreciate your time and insight. Take care.

Finally seeing this load for sale at some outlets. Interesting design and performance, but it’s a weak load. The laughable “+P” designation gets you only 800 fps with a 130 grain bullet for a paltry 185 ft lbs of energy. I have .32 Auto loads that beat that. Plain ole .38 Special 158 SWCHP +P loads from nearly 50 years ago have 50 fpe more out of the 2″ revolver. Of course any wound can be lethal or effective, but there’s better choices in .38 Special. So much for Federal’s “high-tech” engineering. I’m unimpressed.

The 130 grain Micro load gets you more expansion and adequate penetration if one is looking for a low-recoil load. Haven’t seen a box of that in over 3 years…

PC. thanks for the report. I’m glad to hear this load is finally making it out into the marketplace.

I think it’s important to remember that the velocity isn’t as important as what the bullet can do with it. In the old days (thinking of that 158 LSWCHP) the way to boost bullet performance was to boost velocity, because the bullet designs were pretty unsophisticated. Today’s bullets are more sophisticated though, and you can extract better performance at lower velocities.

The design goal for HS Deep was 1.5x expansion and at least 12” of penetration through heavy clothing into gel, and I’m told that Federal was able to do that at 800 fps from a snub with this new bullet, so that’s why it’s loaded to that level. Even though the older 158 LSWCHP was loaded faster, it still couldn’t achieve that kind of performance, often failing to expand.

I can see how 800 fps with a 130 grain bullet might underwhelm you, if you’re interested in raw energy, but energy is just the ability to do work, and if this new bullet can do the work with less energy, then I think that’s a good thing. Remember, this ammo was designed for snubs, where a softer-shooting load is a huge advantage.

The 130 Micro HST was discontinued by Federal, because of ongoing accuracy concerns. They tried several redesigns, but couldn’t fix the issue to their satisfaction. The HS Deep has replaced it, as a low recoil, snub performance load. That’s why you’re not seeing it.

Back in the day… I loaded that Alberts Hydra-Shok wadcutter bullet – I believe it was 146 grains – in .38 Special as defensive load. It was also variously marketed as “Taurus Bullets”. No ballistic jelly outside .gov readily available in that bygone era, but tests @ ~830 fps out of the Colt Detective Special in the usual media of soaked newspaper and duck seal were impressive. The bullet was also accurate at that speed, and the ballistics were better than the .38 Short Colt blackpowder-level loads that Federal currently sells as “+P” loads. Miss that bullet.