RevolverGuy readers will recall that I had a favorable opinion of the Taurus Model 856 Executive Grade revolver when I reviewed it back in October of last year, but felt the gun could stand some upgrades in critical areas like the grips, sights, and trigger. The gun had good bones, but needed a little bit of help to reach its full potential.

Recognizing this, I enlisted the help of some friends of RevolverGuy, to see if we could give the Taurus 856 Executive Grade a do-it-yourself (DIY) upgrade, of sorts. I’ve been pleased with the results and want to report them so you’ll be encouraged to give your own 856 a little bit of attention, if it needs it.

ACTION

The first place I started was with the action. Readers may recall that I thought the 856 Exec’s action was quite smooth, but the trigger pull was heavy enough that it affected my ability to shoot it well, particularly in slow fire. My initial estimate of 14 – 15 pounds, out of the box, led me to disassemble the gun, lubricate the action with some Lubriplate, and test it with my improvised “water bucket method,” since the factory pull weight exceeded the 12-pound maximum on my trigger pull gauge. My workaround method indicated the trigger pull weight was slightly over 13 pounds, after lubricating the gun and exercising the action in dry and live fire.

I found I could shoot the gun pretty well in fast-paced shooting drills with that trigger, but the heavier weight foiled my attempts to extract tight groups from the gun during slow fire accuracy work. Additionally, the gun repeatedly failed to fire when loaded with Armscor ammunition, despite the heavy pull weight. It ran with 100% reliability with all other brands I tested, which made the Armscor ammunition the culprit, not the gun, but I was still a little unhappy to experience the failures.

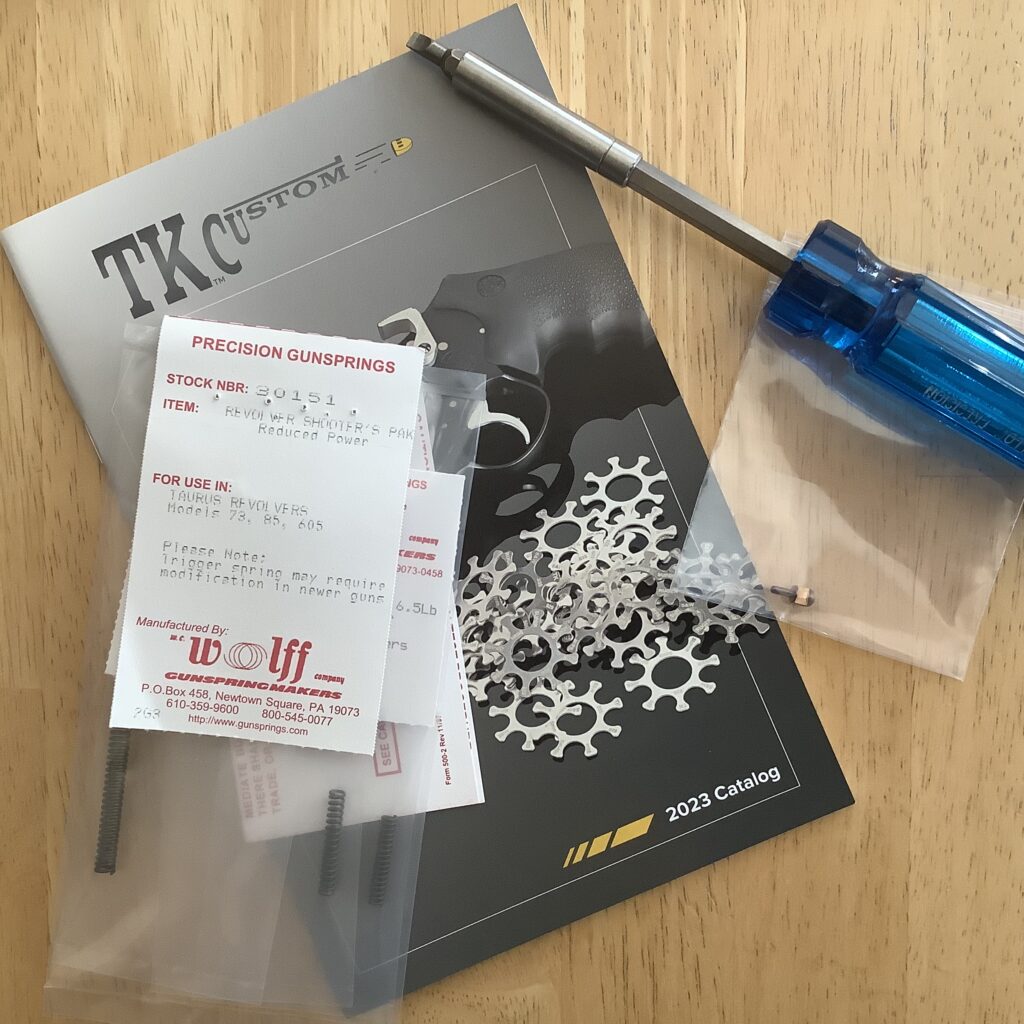

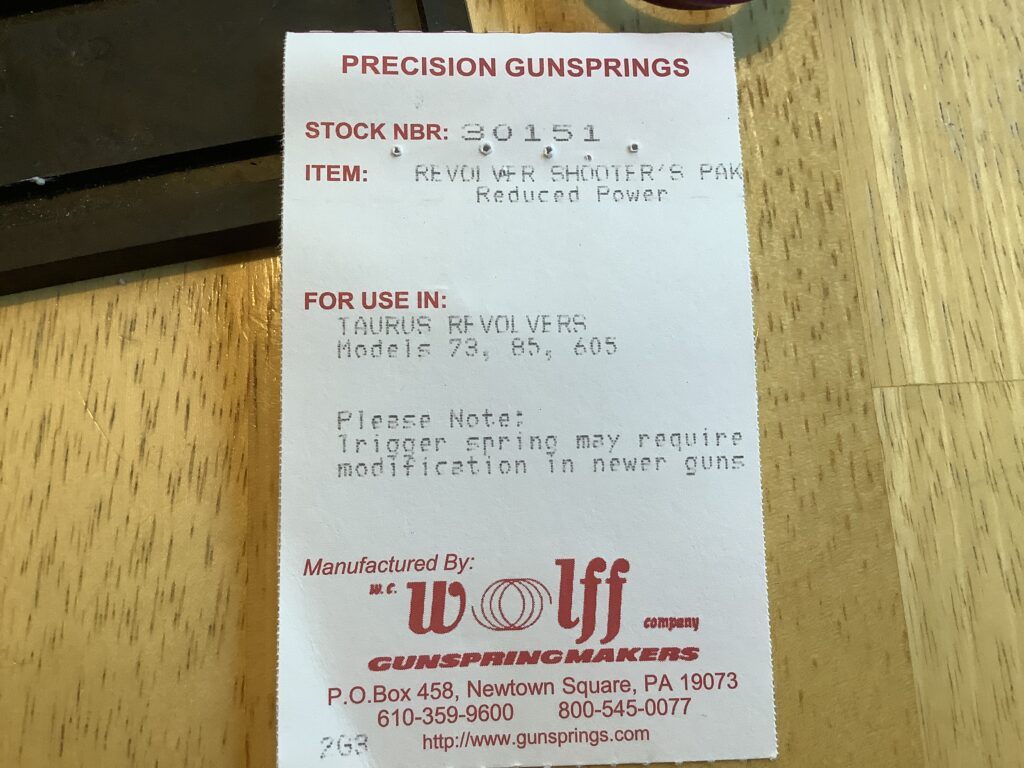

To help remedy these issues, I reached out to Revolversmith Eli Johnson at TK Custom, and asked what he’d recommend for my DIY project. Eli suggested re-springing the gun with a kit from Wolff Gunsprings to help reduce the pull weight, and adding one of their extended firing pins to help improve reliability with the Armscor ammunition. He sent the parts along to me and I got to work.

The Wolff Gunsprings Revolver Shooters Pak for Taurus small frame revolvers is aimed at the Model 73, 85, and 605 revolvers—there isn’t a Model 856-specific kit. The kit includes a 9# reduced power hammer spring, a 9# reduced power trigger spring, and a 6.5# reduced power trigger spring.

It was easy work to disassemble the gun and install the hammer spring, but both the 9# and 6.5# trigger springs were too long to fit on the Model 856’s trigger spring strut.

Wolff’s instructions with the kit advise the trigger springs may need to be modified for “newer guns,” which presumably includes the Model 856 with its short strut. I could have started cutting coils off one of the Wolff springs (they would have needed at least two or three removed, just to fit the strut), but since I like a more positive trigger reset anyhow, I decided to keep the OEM spring in place, and see if the reduced power hammer spring would provide enough relief on its own. If I wasn’t happy with the result, I could always go back and start fiddling with the trigger spring, but if the reduced power mainspring could do the job by itself, that would be great. I honestly found it was a bit of a pain to remove the OEM trigger return spring from the strut and then reassemble it, so if I could skip doing that several times over while I tried to find the sweet spot with cutting coils off the Wolff part, I’d be fine with that.

The TK Custom extended firing pin and spring were an easy replacement on the gun, and looked identical to the S&W part I’d previously installed on my set of Kimber K6s revolvers. Eli warned me that Taurus has used several different firing pin designs on the Model 856, and his part only fits some of them. He wasn’t sure if this TK part would be compatible with my gun, but it fit the gun perfectly, and looked smoother and more robust than the OEM part. It also looked to be a smidge longer than the Taurus firing pin.

SIGHTS

The sights on the Taurus 856 Executive Grade were another area that needed improvement. The combination of the black ramp up front and the satin stainless notch in the rear was better than you’ll find on the average snub revolver these days, but the rear window was still a little crowded and shallow, and it prevented me from seeing much of the front sight. To Taurus’ credit, the sights were well-regulated (an uncommon thing on new revolvers, it seems), but it was hard to see that front sight, particularly against a black bullseye.

To help remedy this, I reached out to Monte Long at XS Sights, who I’d had the pleasure of shooting with at the Lipsey’s Ultimate Carry Revolver event in February. Monte is a Marketing and Sales Engineer at XS Sights, and he knows everything there is to know about making good sights. He put a Standard Dot Tritium replacement sight in the mail for me, and I was eager to get it installed on the gun.

The XS Standard Dot Tritium sight has a green tritium lamp surrounded by a photoluminescent orange or green “Glow Dot” ring (mine is green) to make it really “pop” in all light conditions. The high-visibility sight measures 0.140” in width, making it substantially larger than the 0.120” wide OEM 856 front sight. It was going to be interesting to see how this sight would look through the tight 0.130” rear notch on the 856 Exec.

Fortunately, XS Sights drills the sight tenon for the roll pin that secures it into the sight base. This made it an easy proposition to tap out the roll pin, pull the old sight out, then replace it with the XS sight and tap the roll pin back into place. The holes lined up nicely, demonstrating that XS Sights really did their homework to make the installation as easy as possible.

Following the directions supplied by XS Sights, I cleaned and degreased the sight channel and replacement Standard Dot Tritium sight, after getting the old sight out. I also applied some of the red thread-locking compound supplied by XS to both the sight channel and the sight tenon, before inserting the XS sight in the base and driving the roll pin back into place.

It was an easy installation, and the sight looked really good on the gun when I was finished. I was really pleased at the increased visibility afforded by the Standard Dot when I lifted the (empty!) gun into firing position the first time.

I would like to have a larger rear notch on the 856 (about 0.160” minimum would be a good target), but there’s no good way to do it without a mill, and I have neither the machine nor the skills to do it. So, in the spirit of a DIY project, I left the rear notch alone, save for darkening it with a black Sharpie, to enhance the contrast with the front sight.

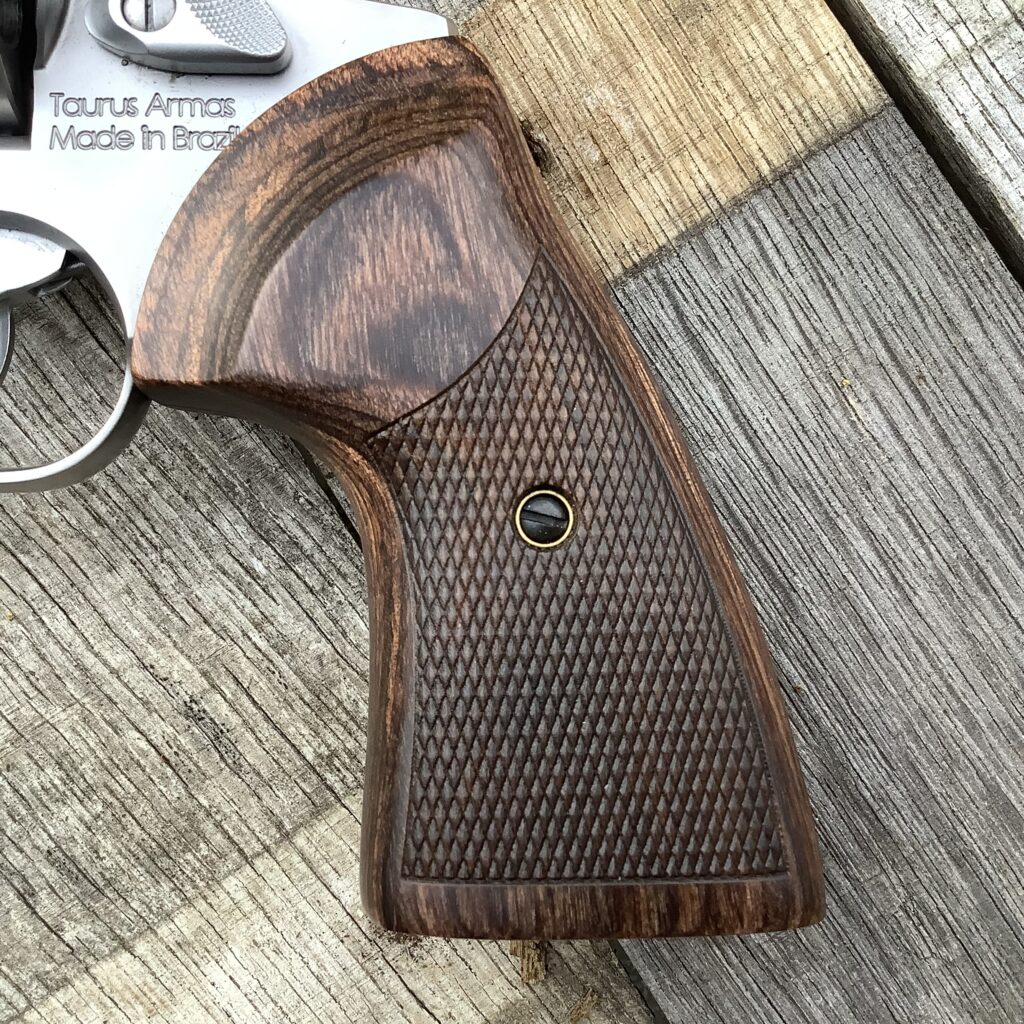

GRIPS

The Presentation-style, wood OEM grips on the Taurus 856 Executive Grade were handsome, but suffered from a complete lack of speedloader clearance, and a square butt profile that made them less suitable for the concealed carry mission that the rest of the gun is designed for. I had briefly considered getting my files and sandpaper out to fix the loader clearance, but wasn’t sure if I’d do a credible job of round-butting them, so I decided to look for an off-the-shelf solution, instead.

Blake Cremeans, the Marketing & Sales guru at LOK Grips, bailed me out by sending a set of their 3-Finger Carry Veloce grips for the 856. The LOK grip is machined from G10, and features attractive texturing and borders, finger grooves, enough room for all three fingers on the front strap, and a round butt profile at the rear, to reduce printing under cover garments. The back strap is enclosed, and there’s a speedloader relief built into the grips.

The Veloce grips feature two indexing pins along the front strap, to make sure everything lines up properly, and they’re secured by a cross-screw (with a rubber O-ring, to prevent cracking the G10 grips). Mounting the grips was easy, but did require a T20 Torx bit for my screwdriver to secure the grip screw. Once installed, the grips are rock-solid on the gun, with no slop (the OEM grips did allow the gun to rock a bit, inside them—another issue I had with them).

A GREAT HOLSTER

I’d tested the 856 Exec with a repurposed DeSantis holster that was originally made for the 3” Kimber K6s. The fit was reasonably good, and the holster was made of quality materials, like DeSantis products always are, but I didn’t care for the design. The holster collapsed when the gun was withdrawn, and its single point mount on the leading edge didn’t keep the gun’s grip in a consistent position for me, as the weight of the gun made it rotate around the clip. I knew I needed a better option for the upgraded Taurus, if it was going to get a fair evaluation.

Harrison Jones, owner of Harry’s Holsters, is no stranger to RevolverGuy readers after Kevin’s detailed reports on Harry’s Icon and Monocle holsters. Those rigs earned Kevin’s praise for their intelligent design, comprehensive feature list, and excellent build quality, and my 856 Exec upgrade project afforded an opportunity for me to try out a new design called the Masterpiece, which Harrison had in the developmental test and evaluation stage.

The Masterpiece is a Kydex holster designed for inside the waistband (IWB) carry. Because Harrison understands the needs of shooters who carry in the Appendix IWB (AIWB) position, as I do, he tailored the holster body of the Masterpiece to have a profile consistent with that special mode of carry. Many makers will mistakenly repurpose their normal IWB holsters, with their wide skirts, as AIWB holsters, but Harrison understands why holsters with that kind of profile don’t work in AIWB, and has designed the Masterpiece to work in any IWB carry mode.

The Masterpiece has smooth and rounded edges throughout, to make it comfortable for carry, and includes a raised surface in the trigger guard area (a built-in “wing”) that helps to cam the butt of the weapon in towards the body, courtesy of the belt’s tension over the top of the wing, to enhance concealment.

The Masterpiece’s dual clips are made of tough spring steel, and do an excellent job of securing the holster in place–this holster won’t rotate unpredictably on the belt like the one it replaced. The clips are adjustable and allow you to shift the ride height of the holster by more than an inch, to find the right balance between concealment and grip access / draw speed for your individual needs. The clips are attached in a way that you can wear the holster under a tucked-in shirt, with just the tongues of the clips being visible, and if you desire to change the straight-draw orientation of the holster, you can remove one of the clips and set the holster to provide up to 20 degrees of cant.

As a fan of the Crimson Trace LaserGrips, I was also pleased to learn the Masterpiece is compatible with those grips, offering additional clearance for the laser unit at the top of the right grip panel. That’s an exceptionally thoughtful design touch that you don’t see in many holsters.

TO THE RANGE!

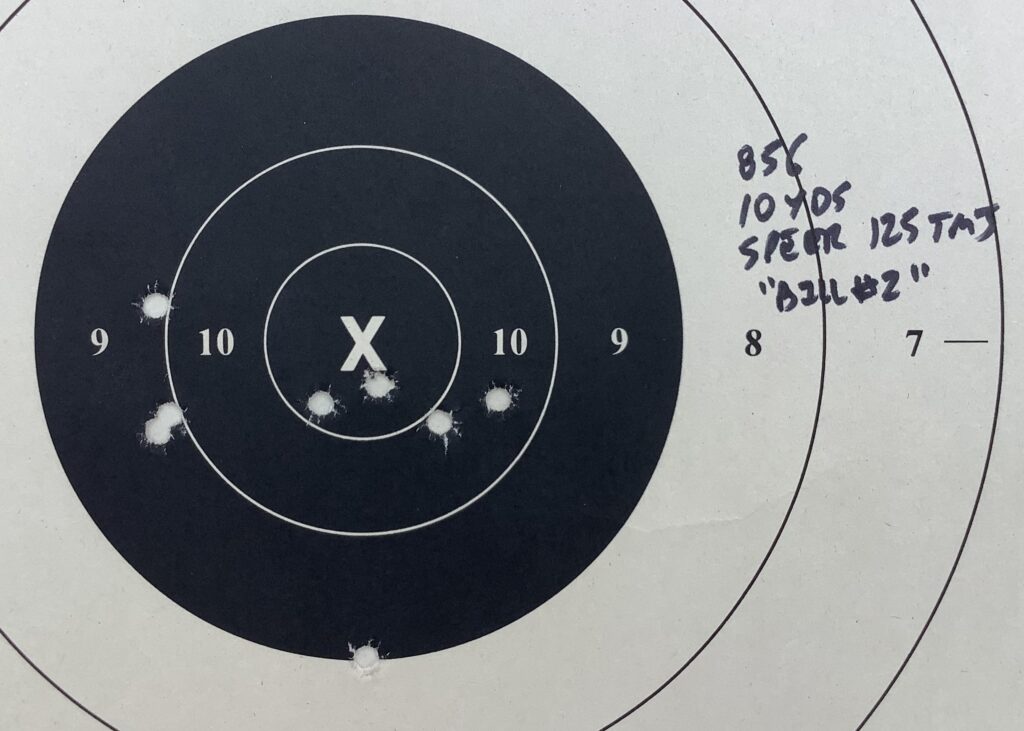

When I shot the upgraded 856 at the range, I was left with the impression that the mainspring change didn’t affect the trigger pull very much, so I was surprised to discover the Wolff spring had actually brought the pull down to just over 10.5 pounds (from circa 13 pounds, with the stock spring). If I had modified the Wolff trigger return spring to make it fit, I might have been able to reduce the pull weight further.

I experienced no failures to fire with the new mainspring and TK Custom extended firing pin installed. I didn’t have any of the troublesome Armscor ball ammo left to shoot (and frankly didn’t want to buy any, just to test it), but the upgraded 856 ate through a hundred or so rounds from three manufacturers with nary a problem.

I shot the upgraded 856 much better than the stock version, and I think both the grips and the sights played a big part in that. The Wolff mainspring was definitely a help, but I think the enhanced grips and sights may have been even more helpful.

The LOK Grips Veloce grips were very comfortable in my hand, and were much more substantial than the target-style OEM stocks. The enclosed backstrap and ergonomic palm swells positioned my hand very nicely to do good work on the trigger, and gave me very good control of the gun in recoil. The traction on the grips helped me to get a very positive grasp on the gun, and lock it into my hand (“LOK” it?).

I was especially pleased that the LOK Grips Veloce grips were compatible with the HKS #10 speedloader that I was using to feed the 856. I had a few times where the loader wanted to pull a single round out of the cylinder when I removed it, but I attribute that to the HKS #10 being an imperfect fit for the Taurus’ chamber spacing. I think the HKS #10 is probably the closest fit I’ve found for the 856 (the HKS-DS is also close), but it’s not exact. Either way, the LOK Grips Veloce grips were not an impediment to using the loader, which I appreciated very much.

The XS Sights Standard Dot was a tremendous and dramatic improvement over the OEM front sight post. While the rear notch was still too tight on the 856, the big dot grabbed my attention so readily that I didn’t feel as handicapped by the rear sight as I did before. I hardly paid it any notice, as my focus was definitely on the front sight.

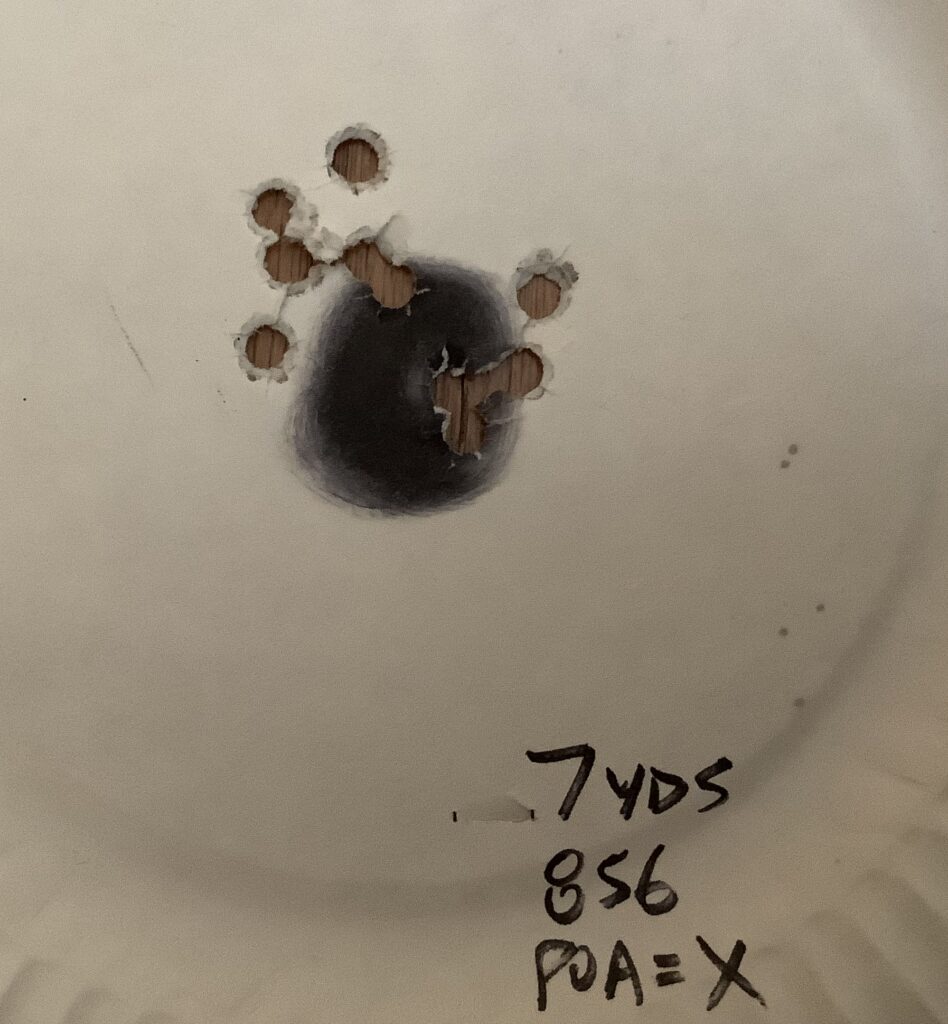

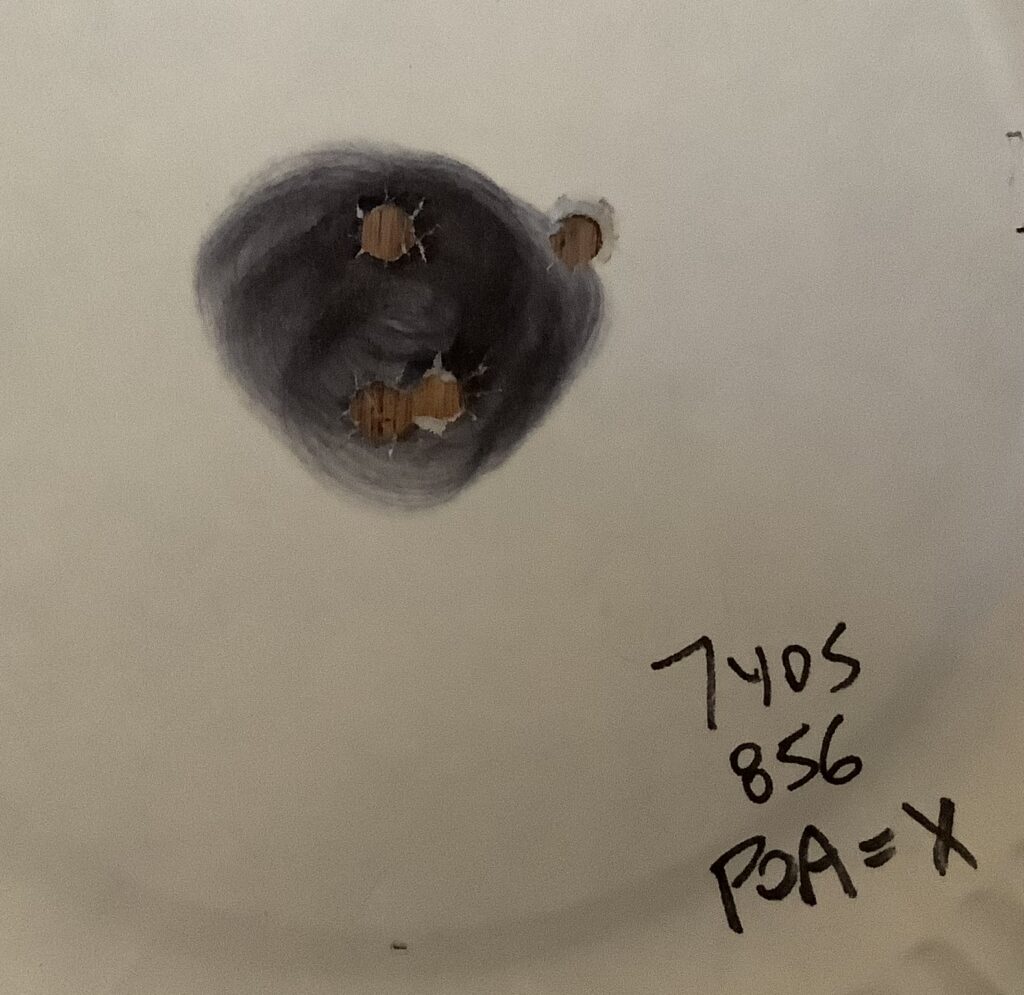

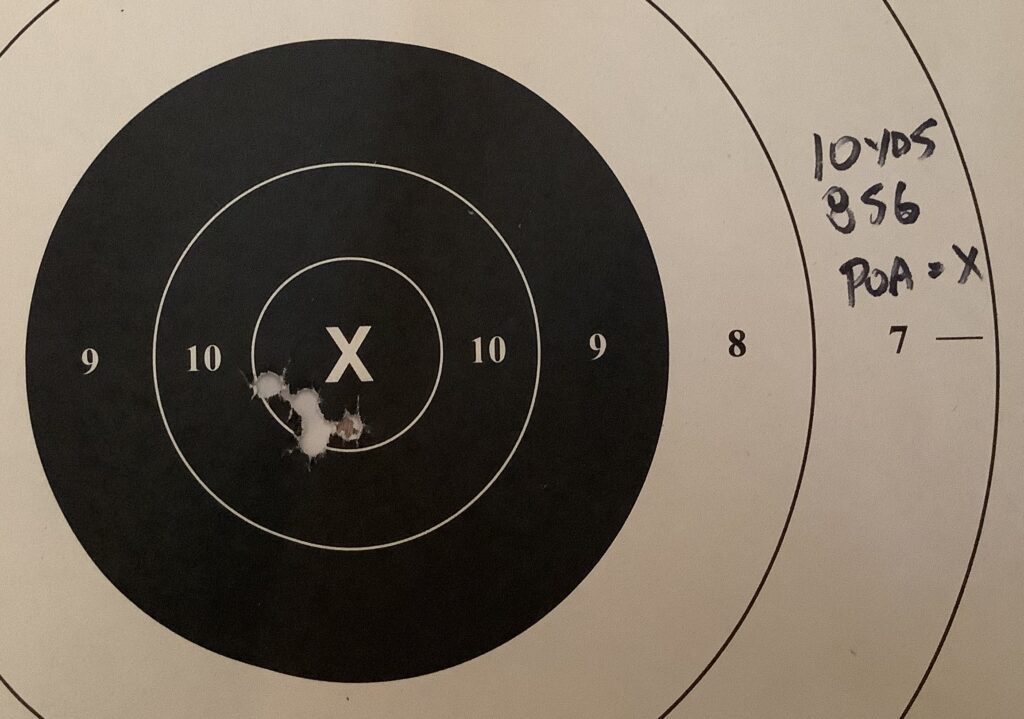

Monte advised that the Standard Dots are regulated so that rounds will impact behind the dot out to 10-15 yards in typical snub installations, and I found that to be the case during my range visit. I placed the Standard Dot directly on top of where I wanted to hit at 7 and 10 yards, and was rewarded with tight clusters that beat the pants off all my prior efforts with the gun. I’ve never shot this gun with greater accuracy, and I was really pleased–especially since I was a little fatigued when I first started shooting it, as I’d been shooting a S&W 642 for an extended period prior to that.

As things turned out, I never got the chance to shoot paper at 25 yards with it, but I was able to shoot a half-size IPSC steel target (38 x 19 x 6 in.) at 40 yards, and found it easy to make hits with the standard dot planted in the middle of the steel. I was typically getting five to six hits from each cylinder at this distance, without breaking a sweat—a performance I would not have expected with the OEM configuration.

A Masterpiece

The Harry’s Holsters Masterpiece has been an excellent holster for this gun. It arrived with the clips adjusted for a fairly deep ride, with the rear edge of the cylinder positioned below the top edge of the belt. This deeper ride can crowd the grip area and slow the draw, but I found it didn’t interfere, and it allowed for very good concealment. I normally use a foam wedge at the bottom of my AIWB holsters to cam the gun’s grip into my body and reduce printing, but this was unnecessary with the Masterpiece, as the holster body was long enough to accomplish this by itself, and the combination of the deep ride, the integrated wing, and the rounded profile of the LOK Grips stocks made the medium(ish)-sized gun all but disappear under my light shirts.

The draw from the Masterpiece is excellent, as the holster affords a full firing grip on the gun, and its molded retention doesn’t interrupt a smooth presentation. I must admit I have not been a fan of metal clips as holster attachments in the past, and prefer to have dual belt loops on my rigs, but the metal clips used on the Masterpiece completely anchor the holster in place, and I’m very impressed with them.

LOOKS FAMILIAR!

After I completed my upgrade of the Taurus 856 Exec, it struck me that it bore a striking resemblance to Taurus’ Defender version of the 856, with its high-profile Ameriglo front sight and black-gray, VZ G10 grips. However, my gun had additional features that the Defender lacked, by virtue of its Executive Grade pedigree, like lightly-chamfered chambers, a gentle bevel on the cylinder’s leading edge, a bobbed hammer, and a beautiful satin finish.

In effect, I’d created an “Executive Defender,” a gun that was very well suited to concealed carry and self-defense chores, with an extra touch of class over the standard matte stainless Model 856.

This DIY project took a little extra work, but the result was definitely worth the effort. If you want to upgrade your own Taurus 856, and make it even more capable, I’d highly encourage you to reach out to these same vendors for the parts and information you’ll need. I know they’ll take care of you, and you’ll be happy with the results.

*****

Train with revolverguy!

As a reminder, Mike will be teaching a Defensive Revolver class in Northern California in October. See this post for additional details.

Excellent job !! For Taurus to call this revolver ‘Executive Grade’, yet totally drop the common sense ball on basics makes one wonder who is running their R&D and production operations! If Taurus really intended this to be a top tier revolver:

a. Perhaps making sure your product will fire 100% of the time – like maybe in house loading .38 Specials with small rifle primers to test your product and verify it will set off even the crappiest primers . . . and make sure the firing pin is long and strong enough to fire anything. Testing in real life beats computer models every time.

b. Make the sight picture actually useable, practical, and effective rather than just digging a trench in the topstrap and calling it a day. Good enough for government work does not cut it. Hey, Taurus – how about contracting with XS to provide your front sight units for this revolver ?

c. Design realistic grip panels that actually facilitate speed reloading, concealed carry profile, and fit human hands. I look at those factory wood stocks and I envision trying to conceal an N-frame, square butt S&W with target stocks.

The Devil is in the Details. Details matter . . .

They’re all doing it, but things are getting better, now that they’re starting to listen to RevolverGuys! We’re making progress.

Yes they do.

Two of my pet gripes with Taurus–and I carry one as a BUG daily–

1. Why all the sharp edges? I don’t understand why, for example, the top rear of the frame isn’t gently radiused like that on a Smith or Colt. I’ve stoned the “points” there and will smooth them even more.

2. Why not get the recoil shoulder of factory grips squarely behind the frame instead of stepping it down? Both LOK and VZ do the same, to a lesser degree. The higher the grip on the gun, the better. I’ll gladly give up some trigger leverage. It’s why my 856 wears a set of cheap Tillanders cut to boot length.

It appears that the newer Executive Grade revolvers (the 605, 692, and Judge) have a gold rod front sight (it looks like a fiber optic sight, but I am pretty sure it uses a gold rod). That seems like a nice compromise on the sights that they should retroactively apply to the Executive Grade 856.

I’ve thought the same, Greyson! Or just use the Ameriglo unit from the Defender series.

Taurus is using a brass rod now on the EG finish guns. This first started with their Executive Grade Judge, and is now bleeding over to other EG lines. I first noticed it at SHOT 2023, and asked Caleb Giddings about it, who confirmed. I really like the brass rod front sight, though I haven’t gotten the chance to try it out under low light conditions.

I saw it on the Judge Exec and 605 Exec at SHOT. It appears the 692 Exec, released since, also uses it. The 856 Exec is the only one with the plain black ramp.

Thanks, Mike. Good shootin’! And great info.

The XS sight may be a good compromise. My primary EDC has a flat-t0pped blade with a green tritium doughnut, and I prefer that color combo to the orange Ameriglo on my 856. I find the dot on that sight is mounted low on the sight blade, causing me to shoot high if I get hasty.

The LOK grips are begging to be cut down to boot length. Can’t wait for them to build a “2-finger” variant.

Had the same problem with Armscor in my 856. Murdoch’s had it on clearance. Wonder why.

The extended firing pin looks like the answer to hard primers. I’ll order one, see if I get reliability with the Galloway hammer spring I was using.

The Masterpiece may be a great alternative for the XO, if not with an 856, with a J 2″.

Thanks again!

Lobo, you read my mind about the grip length. Might become another project for me!

Wait till you try Armscor in an auto loader. 9mm and 40 will not fire in Beretta 92,96…Glock19,17 or 23 and lets not forget Sig 225 or 228.

Good grief!

What’s this stuff good for? Colt blowback SMGs and single action Ruger Blackhawks?

Hey Mike, thank you for the excellent write up! I’m glad you took the time to make the DIY tweaks to the “good bones” of the 856 Executive. Your finished product strikes me as a very capable carry gun. The fact that it’s all steel allows it to be an all-day range gun, too. It would be cool if Taurus could mill out the frame to provide a slightly wider U notch cut for the rear sight window- and supply the Exec with the excellent XS standard dot that you used. I have had similarly pleasing results with the XS standard dot on my Ultra Lite Defender. Points to Taurus for making the swap easy, and to XS for the excellent fitment. Those LOK grips would also be a better choice for the gun’s intended mission. Harry’s Masterpiece is just that. You now have a set up to ride the river with, I think. Good show!

Is XS Sights now shipping all tenon-mount front sights with the tenon drilled? A Little over two decades ago, I put the older white Big Dot with tritium insert on three S&W 640-1’s and had to find someone who could drill the tenons for me.

No, this SKU is pre-drilled for the Taurus, but most of their products are not.

I’m going to speculate this is the direct result of manufacturing processes and tolerances. The Taurus method must be consistent enough, or the tolerances large enough, that pre-drilled front sight tenons will work well. There must be more variation in the S&W method, or tighter tolerances, that require each replacement sight to be individually drilled.

Ordered the XS sight, and the firing pin and springs. Worst case, I’ll have spare parts for my 642, and a sight upgrade for my next 856.

And there will be another one.

The days when good quality firearms generally performed well new out of the box are long gone. Decades ago, the very thought that one would have to invest time and money in spring kits and other upgrades just to have a decent action and make the guns light off cartridges would have been a nonstarter for most customers. Nowadays, it’s the norm.

Sure glad I bought the vintage good stuff long ago, but I feel sorry for today’s first-time buyers.

What size punch worked for the front sight pin? The narrowest one in my set was too fat. I’ve got Taurus’ Ameriglo on 2 of my 856s, may try the XS at some point. I’ll echo other folks’ preference for a deeper and wider rear notch.

My preferred grip is the Crimson Trace LG-385. Beyond that I’m not tempted to make any changes to it.

Lee, I used the PP-1 punch from my Grace USA set–looks like that’s a 1/16″ punch. I would have preferred a slightly smaller punch, but made it work.

The LG-385 looks like a great grip, just a little pricey.

I looked every where for the right size punch online and no one was selling them. Then I went back to Ebay a couple of days ago and “bingo” they had what I thought would work for sale. I bought them and they worked perfectly and to my surprise the one I used didn’t bend while I was hammering in the roll pin for the front sight in my 856.

Tom thoughtfully provided a link for the product but our security settings deleted it. Readers should search for “10pcs 1mm Dia Tip Watch Band Strap Link Pin Remover Punch Repair Tool” on the Ebay site to find the product. Thanks Tom!

I really like your changes, especially the three finger grips that cover the back strap and give a little long trigger reach.

My gunsmith installed Galloway reduced power spring kits in my two 856 revolvers that did not require any modification to fit. My Lyman gauge shows trigger pulls now of about 8 lb DA and 3.5 lb SA and so far the springs are providing 100 percent reliable ignition with Federal, Remington, and CCI Blazer ammunition.

Thanks Steve, great info about the Galloway springs!

The 856 Executive isn’t perfect, but I feel that it’s one of the better choices on the market right now. In late 2022 I got together with the folks at Primary & Secondary and we put about 1,000 rounds through one in roughly 24 hours with no issues. I’ve reviewed the standard 856 and 327 Defender TORO guns over the past year, and there’s a noticeable difference between the typical Taurus offering and their Executive lines. They’re certainly not on par with the handcrafted guns of yesteryear, but a big step up from what we’ve seen in years past.

Over the past few months I’ve had some serious issues with Armscor ammunition. In January I encountered my first squib of my life when using their .357Mag loading, which got seriously stuck in the barrel of my 66-1. Required a solid brass rod (courtesy of Greg Ellifritz) and a 1# rubber mallet to remove the stuck projectile after several failed attempts with other tools. Gun survived unscathed and has made its way to several local matches since then.

Later I traveled to another state to AI for Tom Givens in his Shotgun instructor course. While there I took a rental 686 for a spin at the host range after class. About 20% of the rounds in the box of .38 Special I picked up failed to fire despite several attempts to re-strike the primers.

After those experiences I tossed out all of the ammo I had from them. Wasn’t much, but with ammunition prices today, it still hurt a little.

Dan, thanks plenty for your report. Very helpful to have another set of eyes looking at the same guns and gear, and add more data points. The Armscor ammo seems to use harder primers for sure. Disappointing to hear about your squib load, but in fairness, I’ve encountered those from all the big makers too (the last was a round from Federal). The quality control on ammo still hasn’t fully rebounded since the 2020-22 ammo crisis, I think.

Great posting! I’ve been a Taurus revolver fan for years now. Bought the first one because I couldn’t afford a S&W or a Colt. Bought the rest because they satisfied my revolver needs.

I have a 856, but mine is an early 2″ Plain Jane model. I did have an issue with the factory rubber grips, though. I have hand that run to the largish size, and as a result my middle finger knuckle was pressed against the lower rear corner of the trigger guard. I looked for a set of grips that covered the back strap in order to move my hand back a little. I finally ran across the Pachmayr “Renegrade” grips for the small frame Taurus (Model 85).

I am very happy with them, as they fit the 856 perfectly, they move my hand back just enough that they no longer interfere with the trigger guard, they have adequate clearance for an HKS Speedloader, and the checkered rosewood looks great! (They also are available with a smooth finish as well.)

I bought mine from Amazon (but for some reason they don’t list the price!) Whodathunkit!

Tom, I haven’t tried the Pachmayr Renegade grips yet, so I’m glad to get your positive report on them!

Mike:

Greg Ellifritz at Active Response Training lately reports that many American ammo manufacturers are producing substandard cartridges. Some of that ammo is dangerous and could explode firearms and injure shooters. Sounds like a quality control problem.

Really interesting article Sir! With Taurus being the focus of several articles now, I searched back and re-read the “Guns of Brazil” article. I couldn’t help but wonder if our Brazilian brother and sister Revolverguys and Gals like Erik have provided any updates or reviews on the newer offerings of Taurus wheelguns. I know at that time, he was using an older Taurus 66 and I couldn’t help but wonder if the newer 38s and 357s were seeing hard use. Thanks again for all the content you bring us!

Great write up on the 856 EG. I did the Wolff springs and Ameriglo front sight on my 856 ULCH along with a set of Byron’s grips. With a 1791 OWB holster it’s now a great conceal carry revolver.

It sounds like those discontinued Byron’s Grips are becoming quite popular!

Terrific article. This gives me some more ideas for my 856 Defender Ultra Light, which has become my preferred day to day revolver in a simple Tulster holster.

Interesting you reached the same conclusion I did on the trigger spring. The more I trimmed the Wolff spring, in quarter coil increments, the less confidence I had, so I left the OEM spring in place. I’ve not had a single failure to fire with the Wolff hammer spring, but changing out the firing pin seems like relatively cheap insurance.

The OEM Hogue combats on the Defender were a disappointment. I have them on other guns and have had good success but on the Defender they just didn’t set up for me. I’ve tried a couple others but am still in search of “perfection”. I was next going to try Hamre Forge, I hadn’t thought of LOK so your endorsement on that grip is timely.

The only other thing I am going to tackle is, as you did, the front sight. The OEM Ameriglo unit is okay, but the angle of the face keeps it from really popping visually. I’ve had very good results with XS dots, so that will likely be how it goes.

Thank you! It’s nice to have these options available for the upgrade. It doesn’t take much to get the 856 where you want it for a nice carry gun.

Mike,

I think I may need to stop reading this site. Here recently, it seems each time I log on I end up spending more money. First it was the Blue Wonder (that stuff works great), then a book, and now a set of grips (just ordered those LOK grips). I currently have the Pachmayr Renegade grips on my 856 Defender but I’m not sure those are “the ones” (as was mentioned they do look good though; I did need to relieve them a little for the speed loader). Who knows, maybe the 27th try will actually work (at this point I think I’ve spent more money on grips than I did for the actual gun). I also have the Wolf hammer spring installed and left the factory trigger return spring in place.

The firing pin will probably be next. My 327 locked up on me. Couldn’t pull the trigger, cock the hammer, nor open the cylinder. Sent it back to Taurus; when they returned it to me they said they replaced the firing pin and the firing pin spring. Well it just did it again, same symptoms. I haven’t had a chance to open it up yet and see what is going on, but its not giving me the warm fuzzies at this point. Seeing as how the 327 and the 856 are the same gun, its got me wondering if these should be relegated to range use only.

Sorry about that, Bill! I think there’s a lot of households where I’m considered a bad financial influence, but I promise to keep at it. ; ^ )

Also sorry to hear about your 327. I can’t diagnose it without seeing it, but I wouldn’t have expected the fix for a locked-up gun to be a firing pin replacement–my first inclinations would have led elsewhere. I hope you’ll get a better resolution when you send it back. I hear Taurus has been good about sending replacement guns when they can’t fix the old ones.

You weren’t experiencing primer flow on that 327, were you? That could lead to a firing pin repair, I suppose, but ammo would be a culprit too. A sticky firing pin that wouldn’t retract might also lead that direction, I guess.

I haven’t put large quantities of ammo through my 856 yet, but it’s been reliable so far, after about 400 rounds, and I wouldn’t hesitate to carry it, now that I have it set up the way I want it. It sounds like your 327 still needs some work to get it there, but I wouldn’t give up on it yet. I know how a bad experience with a gun can erase your confidence in it, so I understand if the 327 will never get back into the carry rotation, but I’m confident Taurus will get it fixed for you.

FWIW, the DS HKS speedloader fits the 856 perfectly. A little more clearance, no hang up on the single cartridge, issue.

FYI: The TK firing pin I received does not resemble yours or that in my gun, but I tried to install it anyway. The front stop prevents it from fully retracting into the breechface, and the body is overly long, resulting in a failure of the hammer to properly reset. Email sent to see if I screwed up in ordering and if they have one that looks like the one they sent you.

For those considering this swap, I’d suggest contacting TK by phone first. I’ll advise here of their response to my questions.

Eli Johnson at TK got hold of me. Looks like I screwed up the ordering. He’s sending a couple of firing pins my way to see if any fit the 856. Package already shipped.

Quick, courteous response!

Couple of days should see results. Will post ’em.

I knew he’d take care of ya, Lobo. Thanks for letting us know, and keep us posted.

Eli Johnson at TK sent me two Taurus firing pins, one brass-colored and one blue. The brass was closer in configuration to the OEM, so I installed that-under five minutes, by the way. I took my remaining Armscorp 158 gr FMJ–38 rounds–and fired 18 rounds with the OEM hammer spring and the rest with the Galloway reduced weight spring. The initial 18 fired first strike, with decent impressions. The next 20 had multiple failures to fire and light strikes, with some rounds needing one or more restrikes.

All shot high, some as much as 6″, at 10 yards, regardless of hammer spring weight.

Comparison rounds–Underwood hard cast 150 gr coated WC–shot a little high, too, but the firing pin impressions were deeper and wider and there were no malfunctions with the lighter spring.

I may try the blue pin, just to see if it’ll work, but for now I’ll run the brass one: I’m out of Armscorp and darned if I’ll buy more.

Thanks to Eli Johnson at TK!

A great report Lobo, thanks for that. I’m not surprised Eli and TK took care of you–they’re great folks.

Sounds like the Galloway spring just doesn’t have the oomph necessary for the hard Armscor primers–my OEM spring didn’t either, with the bobbed hammer on my Exec. Your test confirms the OEM spring and spurred hammer will do the job though, with the TK pin installed. Good stuff.

Sorry–I should have been more clear–all results above were obtained with an OEM bobbed hammer, which makes the firing pin swap all the more useful.

Mike-

Got back this afternoon from the range with my 586EG and was still “Meh” after three round sessions with it. Love the size, the appearance and accuracy but that trigger, grips and front sight!

Google search and your work on the very issues you ran down in your DIY 586 EC fit the bill. Small shopping list and I’ll wait for the big brown truck to deliver.

Was good seeing you again this year at the PRMRR- thanks for the feedback and ongoing work…

Hi Bill! Great to see you again, and I sure enjoyed the visit! Glad the article was a help. Let us know what you think, when you get yours gussied up.

Hi,

I had just purchased an 856 E.

I ran across this article and followed the advice with the upgrades with great success.

I see this article was written last year. My question is about extended use since the article was written. How has the revolver been holding up? Any issues that came up since?

I ask because I plan to rotate this into my EDC carry and prior to this only ran SW’s or Rugers.

Thanks in Advance

David, I haven’t been working with the Taurus very much since this article was written–I’ve been busy with other projects. If your other guns are working well as carry guns, I’d probably just run the Taurus as a training gun for a while, and see how it holds up for you. I’ve got friends who run theirs pretty hard and they’re happy with them, but I’ve also seen some failures. I think the failures usually tend to show up pretty early, so if you can get past the 500 mark without issues, I think you’ve got little to worry about.

Much thanks on the reply….. I was thinking the same thing.

Keep up the great work and I look forward to reading more articles from you guys

Thank you Sir! We’ve got plenty more on tap, ready to go. Lots of good stuff coming. Drop us a note later, and let us know how your Taurus is doing.