I haven’t had much direct experience with Taurus revolvers over the years. I’ve shot a handful of them in .22 LR, .38 Special, .357 Magnum, and .44 Magnum, but outside of the .22, I’ve never fired more than a few cylinders through each. However, I’ve grown increasingly interested in the brand and their products over the past several years, so when the opportunity came around to test the premium version of their popular Model 856 revolver, the 856 Executive Grade, I was eager to do it.

Our History With The Bull

Longtime RevolverGuy readers will remember that we’ve evaluated several guns from Taurus over the years. Including the 856, the 942, and the 856 T.O.R.O.. Honestly, the guns received mixed reviews from our staff, who appreciated some of the features, but found others lacking. The Model 942 was disappointingly unreliable, but the two Model 856 revolvers were solid in that regard, and performed relatively well, particularly for the price point. The 856 T.O.R.O. model was definitely the most interesting of all of them, since it was the first revolver designed to accommodate a reflex sighting system, direct from the factory.

I’ve been intrigued by some of the Taurus guns I’ve handled at SHOT Show over the years, and have been even more intrigued by recent proclamations from a bushelful of industry writers who’ve proclaimed that the “New Taurus,” with a new USA headquarters in Bainbridge, Georgia, was making much better guns than they used to. I was willing to believe it, but wanted to see the proof before I jumped on the bandwagon.

This would call for a product test, and it seemed there was no better gun to judge (no pun intended) the new operation by, than their premium offering.

First Blush

I met the Taurus 856 Executive Grade at the 2023 SHOT Show, and I’ve got to say I was pretty impressed with what I saw. The gun was attractive, and the sample I fired had a smoother action than I remembered from previous Taurus guns. It looked like this gun was indeed an upgrade over previous efforts, and I was eager to obtain a sample so I could get to know it better, and develop a more informed opinion of it.

Taurus Media Relations Manager Caleb Giddings was happy to make that happen, and also got a pair of T.O.R.O. revolvers to us to test as well. You’ve already seen Kevin’s article on the 856 T.O.R.O., and Justin’s article on the 605 T.O.R.O. will follow soon in these pages.

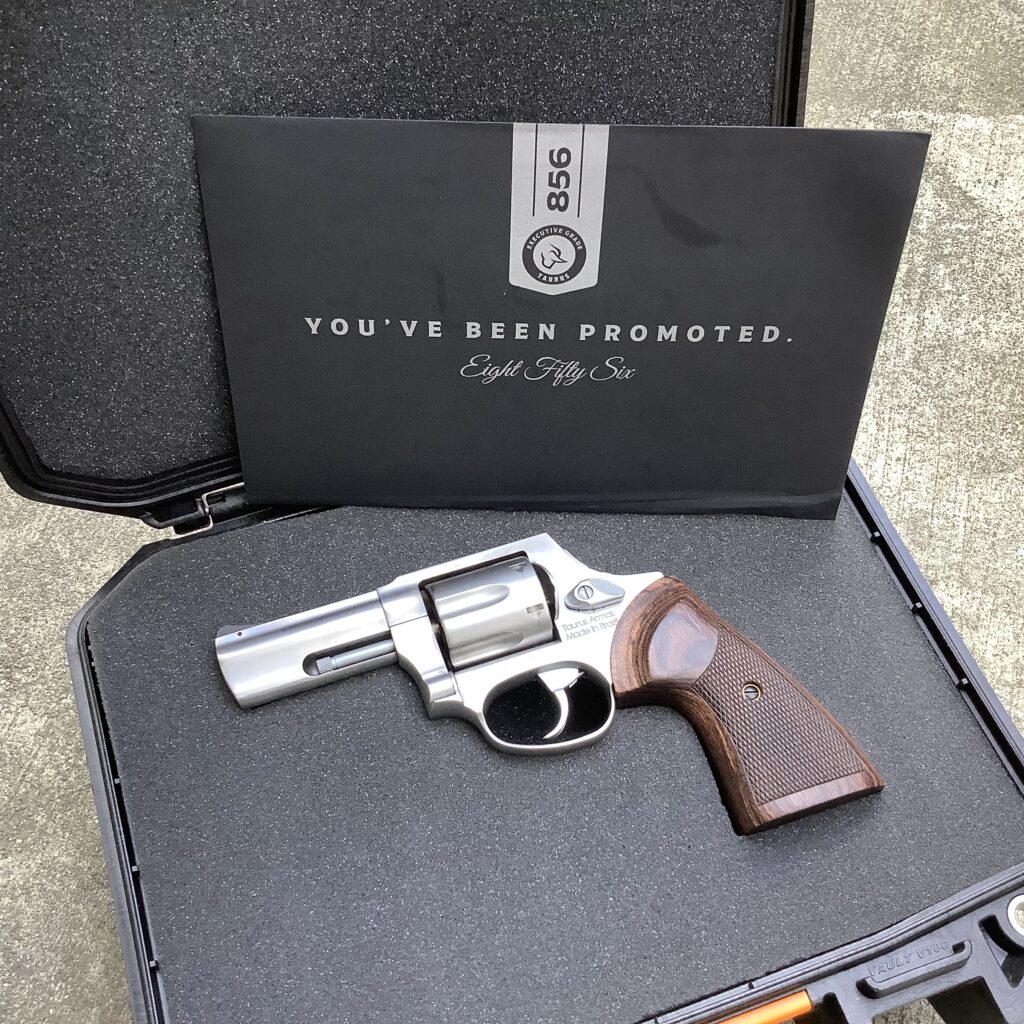

The “elevator pitch” on the 856 Executive Grade goes like this. Taurus has taken the basic 856 platform, and enhanced it with a menu of factory-custom touches, to include a hand-polished satin finish, a checkered walnut grip, and unique badging. The gun’s hammer has been bobbed and the action rendered double action only. The chambers have been chamfered, the forward cylinder edge has been rounded, and the trigger has reportedly received more attention (more on this later). Instead of the standard cardboard box, the 856 Executive Grade ships in a rugged, Pelican-brand case.

The Book’s Cover

The satin finish on the 856 Executive Grade is indeed pretty handsome. You can’t get lost in it, like with the deep blues of old, but in a world of matte black semiautomatics, it looks downright luxurious. It’s definitely an upgrade over the matte stainless, matte black, and Cerakote finishes found on other 856 models in the catalog, as well as many of the finishes found on stainless revolvers from rivals Smith & Wesson, Ruger, and Colt (excepting the much more expensive Python and Anaconda models, which are extensively polished). I thought it was handsome, and liked it very much.

I didn’t like the special Executive Grade badging as much, however. Where other Taurus revolvers have the company’s simple bull logo on the right sideplate of the gun, the Executive Grade guns have a more elaborate Executive Grade seal in the same place. It’s not unattractive by itself, but the right side of frame is already marked in heavy font with the model number, the serial number (which is repeated on the right side of the barrel too, for reasons I don’t quite understand—maybe an export or import requirement?), and the maker’s info (“Taurus Intl Mfg, Bainbridge, GA”), so it looks a little cluttered even before the large, round, Executive Grade seal is added. Thank goodness that Taurus moved the caliber designation to the underside of the barrel, or the whole thing would look like a stuttering engraver got his hands on it.

We’ve all got different tastes, but I think Taurus should have taken a cue from some of the European automakers, who tend to use less badging on their top-of-the-line models than they do on the lesser trim packages. Simple can be elegant, and all the business on the right side of the gun tends to distract you from enjoying the gun’s handsome profile, enhanced finish, and upgraded walnut grips, in my opinion.

Get a Grip

Speaking of those grips . . .

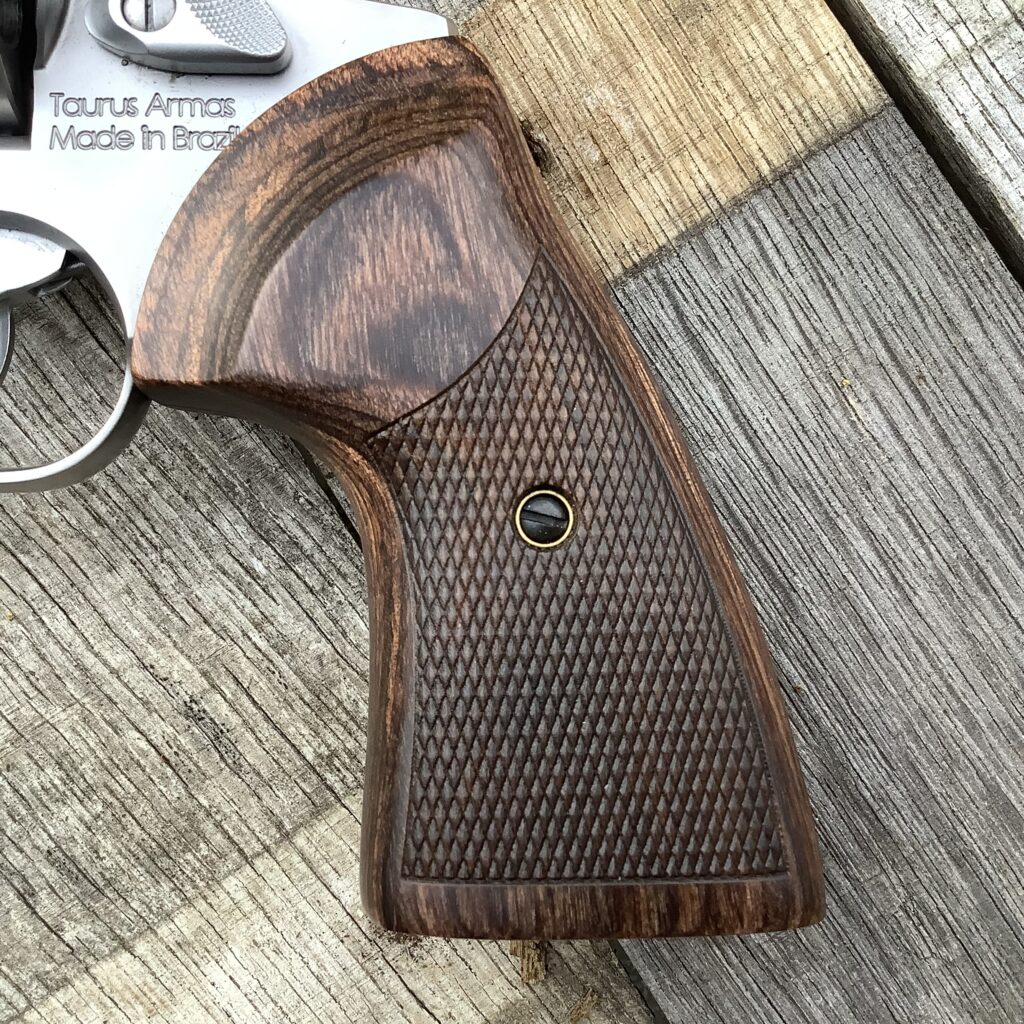

The checkered walnut stocks were a mixed blessing on this gun. Mine had some nice grain, and I thought the checkering was pleasing to both the eye and the hand. They were attractive and offered a nice contrast to the metal’s satin finish, which definitely gave the gun an “Executive” look. High scores for aesthetics!

Function-wise, I had some complaints, though. My biggest beef (and you veteran RevolverGuys can see this one coming from a mile away) is that the left stock was insufficiently relieved to accept a speedloader. My HKS, Safariland, Dade, and SL Variant speedloaders were unable to fit past the upper part of the grip panel, leaving me quite dissatisfied. After all, the 856 Exec is designed to serve in a defensive role, and it didn’t make much sense to equip it with grips that prohibited the owner from using the most efficient means to reload it.

In my initial shooting with the gun, I kept it fed using loose rounds and occasionally an inline strip loader (my preferred Bianchi Speed Strips), but I really wanted to use a round body speedloader. I thought about relieving the grips, like I’ve done on so many other guns, but since I wasn’t sure if I’d be returning the gun to Taurus yet, that option wasn’t on the table.

Fortunately, I remembered something else that might work. After a little bit of searching, I located a pair of Zeta6 K-CLIP loaders in my stores, and filled them with dummy rounds, to test. As it turned out, the K-CLIPs still had to be forced past the proud grip panel, but once the plastic rims of the K-CLIPs cleared the grip panel, they fed the cartridges nicely into the chamfered chambers. The Zeta6 clip’s S&W K-frame spacing was a good fit for the 856’s cylinder.

There was still some pesky interference, but with the K-CLIPs, I thought I could fill all six chambers faster than I could with my Speed Strips, or even with Zeta6’s flatter K-PAK loaders, which also fit the Taurus. The K-CLIPs weren’t perfect (we’ll talk about that more, later), but they seemed to be the best option for keeping the 856 Executive fed.

I thought the square-butt, “Presentation” or “Target Style” grips were a little bit of an odd choice on this gun, given the mission. The 856 Exec’s frame has a round-butt profile, and I think it would have made better sense to fit this spurless, abbreviated-barrel, carry gun with a grip that followed those lines closely. Round-butt grips tend to hide better under concealment garments, and can be a little more forgiving of hand placement errors that are committed during a rushed draw from concealment, so they would have been preferred, from a functional standpoint. Additionally, a square-butt profile is unnecessary to control and support the short, three-inch barrel of the 856 Exec—this is not a heavy, large frame target gun, which needs the square corner to help cam the barrel up when a firing grip is acquired, particularly with one hand.

On the plus side, though, I liked the symmetric thumb rests on the stocks, which gave the gun a balanced look, and (more importantly) also gave my shooting hand thumb an excellent purchase, even when firing left-handed. I think the shelves helped me to fight the muzzle flip by locking my thumb down upon them, and the one on the left side also did a nice job of keeping my thumb knuckle away from the nearby thumb piece. I especially liked the fact that the relief arced across the entire top of the grip panel, terminating right behind the trigger guard, because it gave my long thumb a perfect shelf to rest upon for its full length. Some makers just dish out a little area on the stock for a speedloader (although it’s never enough for that), and it’s not as functional, nor as comfortable, as the thumb rest is on this stock.

One other thing worth mentioning about the grips: They’re secured, in part, by locator pins that align and join the two halves together. These pins create a very tight fit from the factory, and complicate grip removal, as part of routine maintenance and disassembly. Honestly, it was a bit of a pain to take them off the first time. I was trying to be patient, and did not want to pry them off the frame, because I knew it would damage them. However, it took a whole lot of tapping on the frame with my plastic mallet to finally walk them apart. Unfortunately, the grips never fit as tightly after that first removal, and now the gun rocks a little bit inside the grips when they’re on the gun, which I find unsatisfactory.

Controls

Going back to the thumb piece, it’s common for that part to cut or abrade my right thumb knuckle under recoil (especially on the classic, pre-MIM S&Ws with the old-style latch, but the Ruger LCR’s push button release will occasionally bite my thumb knuckle, too), but I didn’t experience this discomfort with the 856 Exec. The Taurus thumb piece is similar in appearance to the current S&W style, and they’ve done a nice job of rounding the edges, so it’s not as sharp as the parts I’m used to from Springfield, MA. The thumb piece is comfortable and convenient to operate, and I appreciated the fact that it didn’t draw blood. Again, I think the generous grips helped with that, by keeping my knuckle well clear.

The cylinder on the 856 locks up at the rear in the typical S&W manner, with the spring-loaded center pin engaging a hole in the frame. Up front, the cylinder locks up on the yoke, instead of on the tip of the extractor rod, with a spring-loaded plunger in the yoke nestling into a machined cut in the underside of the frame, right below the spot where the barrel screws into the frame.

This locking arrangement allows Taurus to use an extractor rod with a solid, slightly domed tip that is very easy on your hands when you slap it to extract cases. With the older S&W-style extractor rod, the tip is hollowed out to accept the forward locking bolt, and it can act a bit like a cookie cutter on your hand. The Taurus part is comfortable to operate though, and a nice improvement.

The hammer on the 856 Executive Grade is bobbed to prevent a hammer spur from snagging on clothing—a nice feature for a gun that will be carried concealed. It does not have a firing pin or “hammer nose” in its face—instead, the firing pin is mounted in the frame, and energy is delivered to it via a transfer bar that rises into position as the trigger is pulled. Disassembly of the gun proved that this was one of many MIM-manufactured parts used to build the 856 Exec, and I’ve got no problem with that. It’s a good use of the manufacturing technology.

The trigger is also one of those MIM parts, and I was very happy with its shape and contours. Using S&W vernacular, this is a “Combat Trigger,” with a medium-width shoe that is smooth, without grooves. The trigger face is slightly rounded, and there are no annoying square edges where the radiused face meets the sides. I felt this trigger was very comfortable to pull on, and was set up for good double action work. In fact, it’s the best feeling trigger I’ve encountered on a DA test gun in some time, after disappointments with the triggers on guns like the Ruger LCR (too narrow, with a peaked crown that focuses too much pressure on a small surface area), Colt Cobra and King Cobra (too narrow, with square corners), and even the Colt Python (too narrow, square corners, and grooves). Well done, guys.

Action

However, the flip side of the trigger coin is that it’s heavily sprung—probably a little too heavy, in my opinion.

At first, I was surprised by the weight of the trigger pull on my gun, because I remembered a lighter pull on the sample I’d fired at SHOT Show. It’s certainly not unheard of for a manufacturer to put some extra TLC into the guns that media and VIP customers are going to handle and shoot at SHOT Show, so it’s possible that Taurus slicked them up a bit to make a good impression. However, to be fair, that display gun had been through a lot of hands, had been dry-fired a bunch, and had fired a lot of rounds, so it’s also possible it was just well “broken in.” Either way, I wrote in my notes that I thought the trigger on the display gun that I fired at Media Day hovered around 10-11 pounds.

The T&E sample I received from Taurus felt heavier than that, however. I estimated 14-15 pounds when I first started dry-firing it. It was heavy enough that my right hand’s trigger finger quickly got fatigued during my first shooting session with the gun, and I had to switch to shooting left-handed before I even got through a box of 50 cartridges. I’d been shooting other guns for about four hours at that point, so I wasn’t exactly fresh, but I still felt like the gun’s pull weight was the problem, not the previous exercise my finger had received.

The trigger pull was actually quite smooth on that first outing, but it just felt heavy. When I got the gun home and disassembled it to inspect and clean the innards, I took the opportunity to add a little Lubriplate to all the right areas, in the hopes it would help slick things up—the revolver equivalent of the famous “25 Cent Glock Trigger Job.” It certainly couldn’t hurt.

Subsequent trips to the range confirmed the gun’s trigger pull was a little heavy. When I started shooting 25 yard groups for record, my trigger finger got so tired and cramped that I was having to use my other hand’s index finger to give it a little assist at the end of the stroke. The pull felt a little smoother after adding the Lubriplate, but that heavy trigger was still very fatiguing, and negatively affected my ability to run the gun (more about this, and my journey of self-discovery and enlightenment, later).

My mechanical trigger pull gauge doesn’t read over 12 pounds, and this gun’s pull was heavier than that, so I borrowed some weights from my gym and suspended them from a thin nylon strap to evaluate the pull weight the old-fashioned way. Ten pounds of weight would not trip the trigger when the weight was applied at the center of the trigger’s face (where your trigger finger rests, and where we usually test), nor would 12.5 pounds. When I tried 15 pounds, it would trip the trigger if I positioned the strap closer to the bottom of the trigger, where the mechanical advantage is greatest, but wouldn’t do it reliably, in the center.

Concerned, I decided to try my water bucket “gauge” instead, and see what I could measure with that. I took the wire handle off and filled the bucket with water. I inserted the wire handle into the trigger guard and positioned it across the trigger face, then reconnected it to the bucket. Holding the gun steady, to keep the pressure centered on the trigger and aimed straight to the rear, I began to lift the bucket with the gun. I removed water until the gun’s trigger would support the weight of the bucket.

This method gave me a little over 13 pounds for the trigger pull on the 856 Exec, which was a more reasonable value than the circa-15 pound estimate I got with the strap and gym weights. Frankly, I was a little surprised the weight wasn’t higher, but 13+ did seem more realistic.

So, it’s a relatively heavy pull, but it’s also quite smooth. I didn’t see any evidence of focused polishing on the contact surfaces of the hammer and trigger, nor on the struts that supported the mainspring and the trigger return spring, so I’ll have to attribute the smooth pull to the smooth, even surfaces of the MIM parts used in the action.

One thing I have to point out is that the timing on this gun was very good, despite the fact that the ratchet looked kinda rough. I didn’t experience any spitting or other signs of improper timing, which was really great news. I’d just finished shooting another revolver that did have timing issues, straight from the factory, so this solid performance from the 856 Exec was really welcome.

Reliability

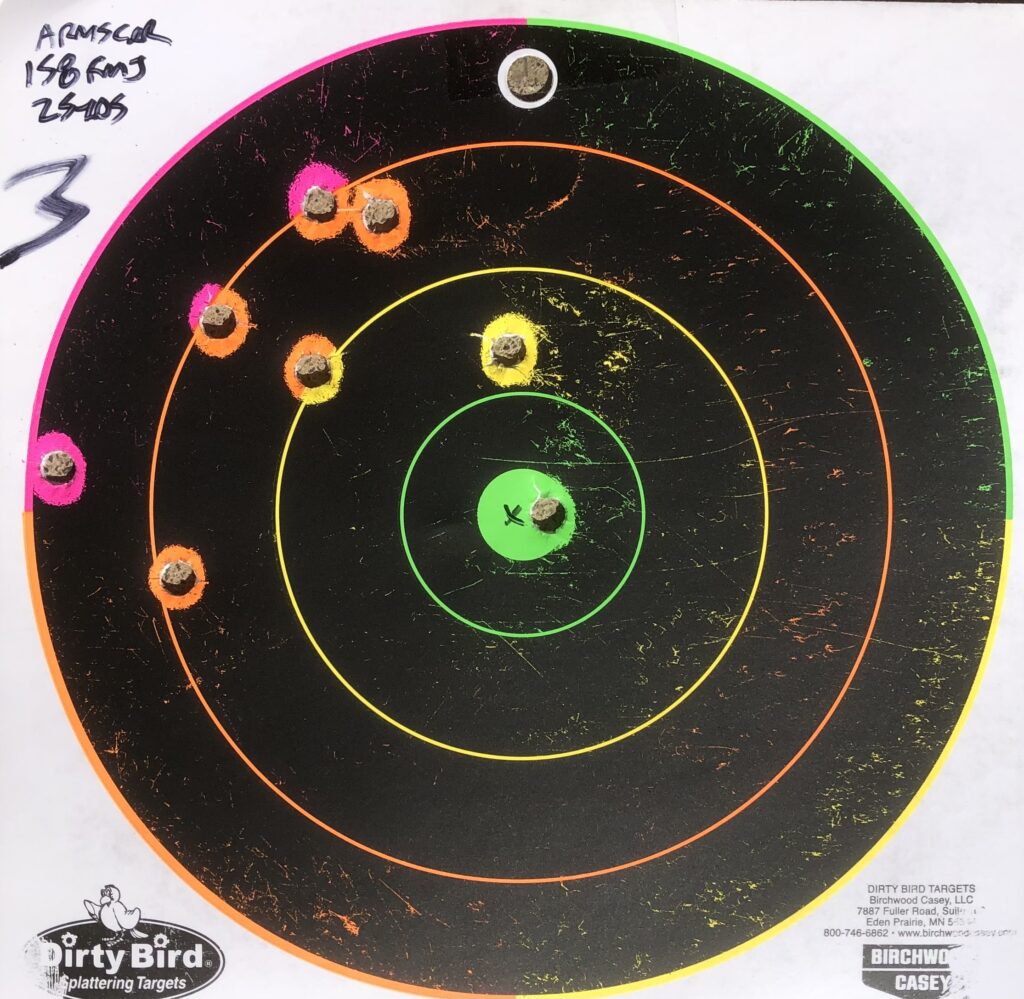

I wish I could say the heavy pull weight gave me 100% ignition reliability with the reduced-mass, bobbed hammer, but I did experience repeated light primer strikes with Armscor 158 grain FMJ ammunition. This was my first experience shooting Armscor ammo, and I’m not sure if the brand has a reputation for tough primers, but I can tell you with great assurance that this gun did not like it.

At first, I thought I could attribute the light strikes to staging the trigger (pulling it straight through to the natural pause, then gradually applying more pressure for the short remainder of the stroke, until the hammer falls), which I had been doing while shooting groups for record at 25 yards. This is the toughest scenario for any hammer, because it’s taking a short fall from a paused condition, without the inertia that’s normally generated by a continuous double action stroke.

This happened twice while I was shooting the 25 yard targets, and I took pictures of each failed round. You can see in the photos that each round has a very light strike on the primer. After the photos, I tried each of the failed rounds a second time, and they both fired normally after a continuous trigger pull. That was good, but I still wasn’t pleased about the two failures.

Unfortunately, in a later stage of testing, I discovered the light strikes couldn’t be blamed on staging the trigger. While shooting the gun with a continuous double action stroke, I experienced repeated light strikes with the Armscor ammo–another seven, from the remainder of the 50 round box, for a failure rate of 18%. Each of the failed rounds fired with a second strike, but it was clear to me the gun did NOT like this ammo, and I was glad I’d only bought a single box of it.

The gun ran 100% with every other brand of ammunition I tried, including 250+ rounds from Winchester, Speer, Remington, Federal, Freedom Munitions, PMC, and my buddy’s Dillon 550 press (using Federal primers). I didn’t get a single hiccup from anything but the Armscor ammo, even when I staged the gun, so I’m going to write this one off as an incompatibility between the gun and the Armscor ammo for now, and give the Taurus a clean bill of health.

Coincidentally, I happened to be testing a newly-received custom S&W from a popular shop and that gun also experienced a number of light primer strikes and failed ignitions. The custom gun (which costs 3-4 times as much as the Taurus) has a bobbed hammer as well, but the pull weight is much lighter, around 10 pounds. Shooting for accuracy, and staging the DAO trigger, I had multiple light strikes with .38 Special Speer Gold Dot. That gun has been sent back for repair.

We normally shoot bobbed hammer guns with a continuous stroke that ensures better ignition reliability, but they should also fire with absolute reliability from a staged hammer condition. If they don’t, then something has to change–the gun, the ammo, or both. Since the 856 Exec ran flawlessly with everything except the Armscor brand, I’m not going to blame the gun, but the experience does serve as a warning about the importance of throughly testing your equipment.

Under the Hood

I mentioned earlier that I disassembled the Taurus to have a look inside, and I was both intrigued and disappointed by some of the things I found in there.

I should probably start by dispelling the common notion that the Taurus action is a duplicate of the Smith & Wesson action. There are certainly many similarities, and it’s closer to the S&W than to any other design, but the Taurus 856 action has some unique features of its own that deserve attention.

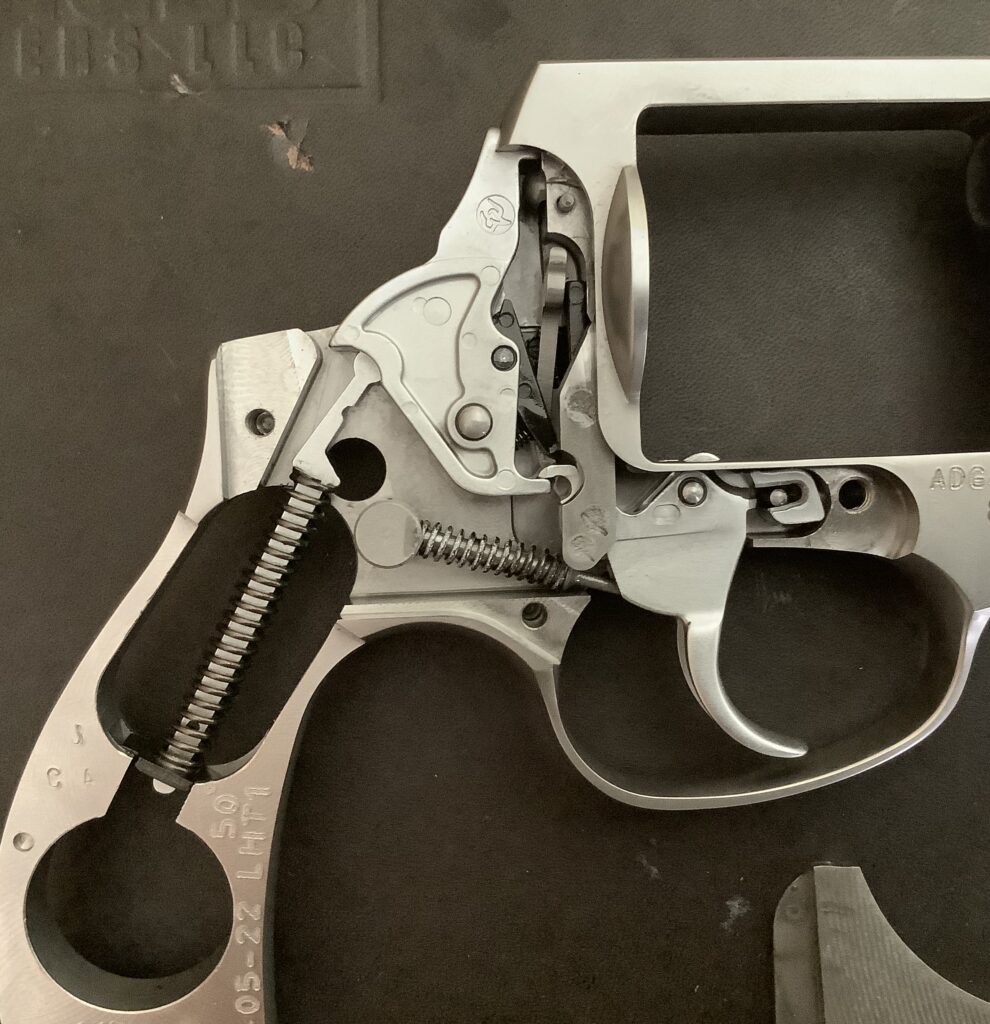

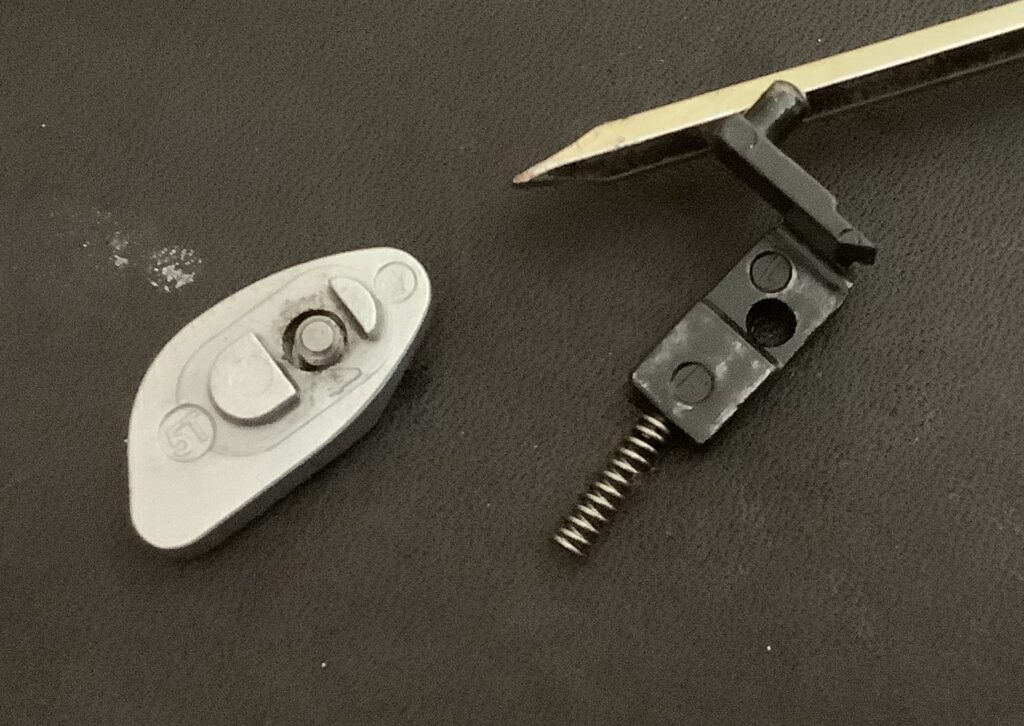

One of these is the way the cylinder stop is powered. In the Taurus 856 design, there’s a spring-loaded plunger that rides inside the yoke axle that gets inserted into the frame, and this plunger powers the cylinder stop, instead of a small torsion or coil spring, as you see on other designs. This sure makes it easier to remove and install the cylinder stop! A caution, however: If you’re used to disassembling Smith & Wessons, and aren’t aware of this plunger, you can easily lose it when you remove the yoke from the frame—if you don’t believe me, go ask Kevin about that! ; ^ ) Fortunately, I was pre-armed with this information, courtesy of his experience.

The traditional S&W-style rebound slide is absent on the 856 as well. Instead, a coil spring powers a center strut which passes through a rounded swivel at the back. The swivel incorporates a post on its backside, which gets inserted into a matching hole in the frame to secure the assembly at the rear. Up front, the center strut bears on the backside of the trigger, to power its reset. It’s much easier to remove and install these parts on the 856 than it is to remove the rebound slide on a S&W, and I suspect this system also reduces the friction that can degrade a trigger pull. A clever bit of engineering, I think.

The remainder of the 856 action is similar to the basic S&W design, and won’t confuse anyone familiar with those guns.

It was interesting to catalog how many 856 action parts were produced using MIM. By my count, the hammer, sear, trigger, cylinder stop, thumb piece, and bolt were definitely MIM parts, and it’s possible that some of the other small parts were as well. I think the firing pin, hand and rebound swivel were probably machined, and the mainspring strut and transfer bar may have been as well, after they were stamped and formed. All of this seems to be in line with the current industry practice of using MIM where you can, to promote consistent tolerances, reduce unnecessary machining, and reduce costs. Nothing to be concerned about, here.

One thing that did concern me though were two loose metal splinters that I found underneath the top corner of the sideplate, in the area where the firing pin retaining pin is inserted. These nasty bits of garbage, roughly the size of staples, had probably been trapped in place by the sideplate, but I hate to think about the kind of chaos they would have caused, had they floated down into the action. They could have brought things to an abrupt halt if they had migrated anywhere else. Maybe they would have jammed the transfer bar, or interfered with the sear, or jammed the thumb piece, or any number of ugly things that you wouldn’t like on a gun used for protection.

They were obviously missed during assembly, and while we can accept the fact that factories are dirty, humans are human, and mistakes happen, I was disappointed to see them inside Taurus’ premium offering. I have no doubt you could find the same thing inside selected samples from any manufacturer, but you just don’t want to find it in yours.

The remainder of the interior looked like it was well attended to. There were some machining marks in areas that didn’t matter, but the areas that needed to be smooth were suitably smooth. Not having been inside a “regular” 856, I have to assume this is standard for the design.

Surprisingly, I really didn’t see any evidence of polishing on the action surfaces. The Taurus literature is intentionally vague, touting “a custom trigger system” that could easily be interpreted by the consumer to mean the action parts received some extra attention during fitting (in fact, I’ve seen some reviewers report they thought the gun’s action has been tuned), but I didn’t see anything that left me with that impression. Frankly, I attribute the smoothness of the gun’s action to the consistency of the MIM’d hammer, sear and trigger, and the lack of a drag-inducing rebound slide, more than anything else. I think the overwhelming majority of the special attention given to the 856 Executive Grade is focused on the exterior of the gun, not the interior—on the cosmetics, more than the guts.

Sights

The rear sight on the 856 Executive Grade is a simple trough that has been milled into the topstrap. It’s a bit narrow, at 0.130”, with the front sight being 0.120” wide. I would prefer a wider opening in the rear, to let a little more light through on either side of the front. A rear notch about 0.150” or even 0.160” wide would be preferred on a gun that will be used for close and fast engagements.

I would also prefer a deeper rear notch. The milled notch on the rear sight is rather shallow, and there’s just not a lot of front sight to see when you obtain good sight alignment. This sight picture reminds me a lot of the standard S&W J-frame sight picture, which doesn’t win any awards for ease of use. Although the 856 is a small frame gun, I think Taurus has a little more real estate to work with on this three-inch, six-shot gun, and I wish they would have used it to give us a deeper and wider rear notch for sight alignment. A dovetailed, Novak-style blade (like we’ve seen on some distributor exclusives from Ruger) would have been really neat on this premium offering.

The fixed rear sight is finished in satin stainless, like the rest of the frame, so Taurus did do us a favor by making the ramped front sight black. This eliminates the “silver-on-silver” sight picture that can be hard to define, especially in bright sunlight, on many stainless guns with fixed sights. The ramped front is also serrated to reduce glare.

The front sight is pinned into place with a roll pin, which conceivably opens up the gun to replacement sight options. I see that Taurus sells an Ameriglo night sight for their small frame revolvers in their online store, which has a bright orange square with a tritium dot in the center. That looks like it would be a real nice sight for a gun like this, assuming it’s well-regulated. If I was going to carry the 856 Exec, I’d definitely look into this option.

I took a look at the XS Sights website and found they also offered a replacement front sight for the 856 revolvers, which incorporates their standard dot with a green or orange colored ring. This too, would be a fine option for the 856 Executive Grade, for those who wanted a front sight with color contrast and a tritium dot, assuming it’s properly regulated.

I honestly struggled a bit with the sights on the 856 Exec. I found it was easy to lose the black front sight on the black bullseye targets I was using to test this gun–particularly because it was so short, and there wasn’t enough to see of it, when I had it properly aligned with the rear. If this gun were mine, and I didn’t want to pop for a replacement front sight, I’d probably black out the rear window with a black Sharpie marker and apply a layer of white model paint to the front sight, followed by a layer of orange model paint, to add a little contrast to the sight picture. Perhaps that would help me pick up the nub of the front sight a little better in that tight rear notch.

“Accuracy” Testing

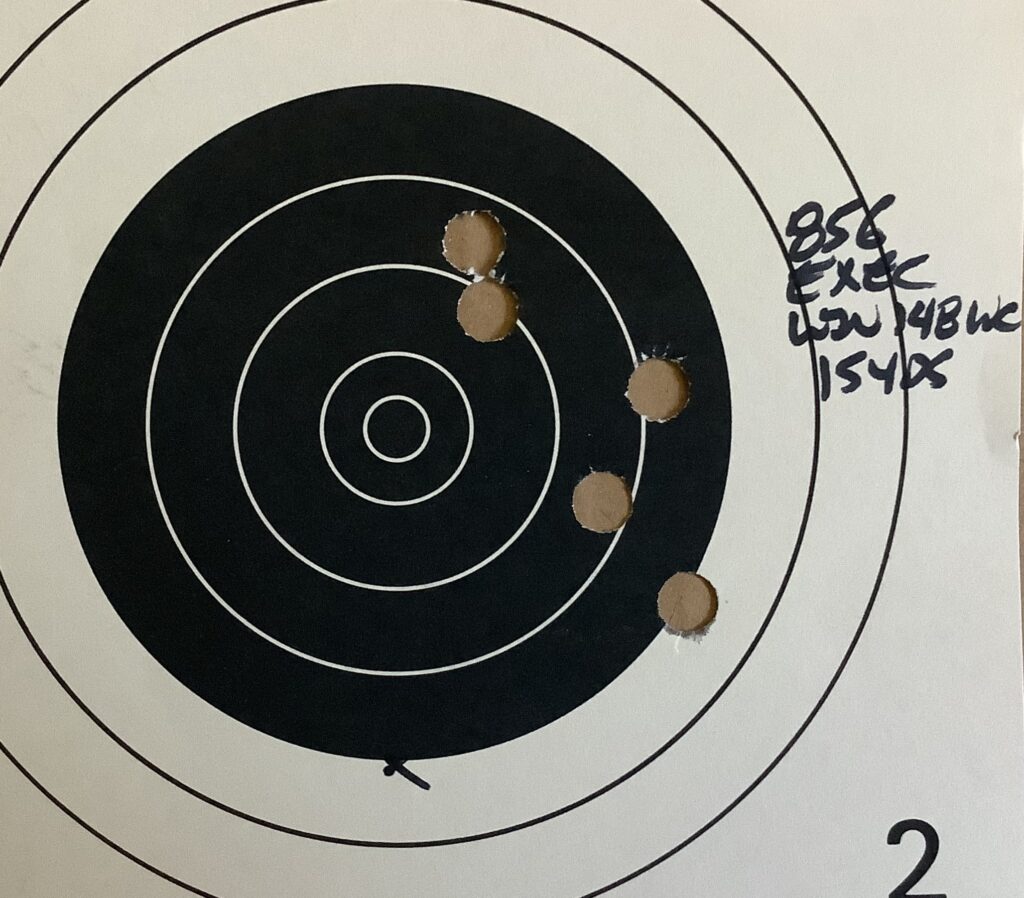

My first shots through the 856 Executive were fired at 15 yards on black bullseyes, using Winchester Super X 148 grain wadcutters. The first few attempts weren’t all that impressive, producing 5-shot groups about 2” high and 1.5” wide (measured from outside edge to outside edge, or outer diameter—OD), centered about 2” above the point of aim, and 1” right of center. I was already a bit tired from other shooting that day, and the heavier trigger was giving me a hard time.

A subsequent effort with a Freedom Munitions load, topped with 125 grain Hornady XTP bullet, produced a much nicer group, standing 1.75” tall and 1.75” wide (OD), centered perfectly for elevation and azimuth. The gun seemed to like that load, or maybe I was just doing a better job on the trigger.

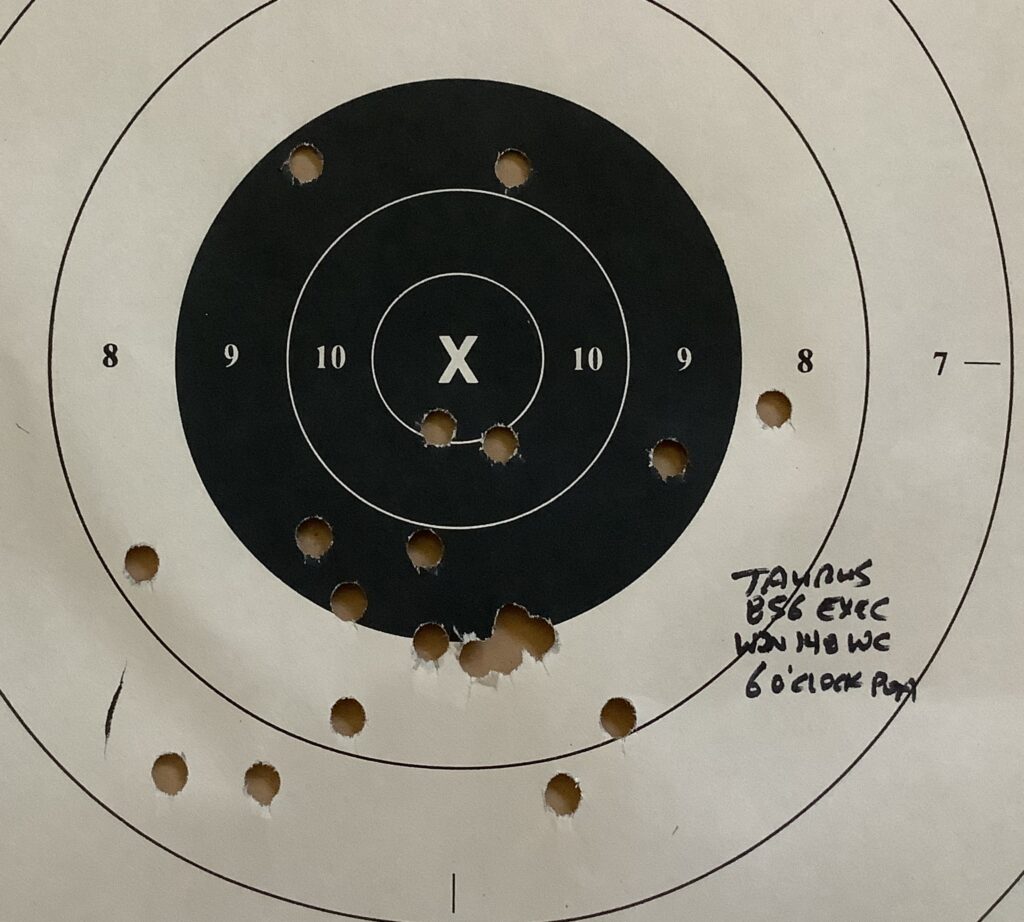

Feeling sporty, I posted a target at 25 yards, and sent 20 rounds of the Winchester wadcutter downrange, using a 6 O’Clock hold on the black 9-Ring. At that distance, the 148 grain bullets gave me a 6” by 6” (OD) group that was well centered for elevation and azimuth, with the core of the group measuring 3” by 3” (OD). I wasn’t going to threaten anyone’s spot on the PPC team with that kind of performance, but the most interesting thing to me was that the target was virtually identical to one I’d just fired with the custom 3” S&W revolver I mentioned earlier. That gun has a DA trigger pull that weighed about three to four pounds less, and excellent, fixed sights from Dave Lauck. Had I not been careful to mark the targets before I brought them home, I wouldn’t have been able to tell the difference between them.

Frustrating myself

On another trip to the range, I reattempted the 25-yard work, hoping to improve my performance and gain a better idea of what the gun is capable of. I brought along the Winchester 148 grain wadcutters and the Freedom Munitions 125 grain XTPs again, and added some PMC Bronze 132 grain full metal jacket and Armscor 158 grain full metal jacket rounds to the mix.

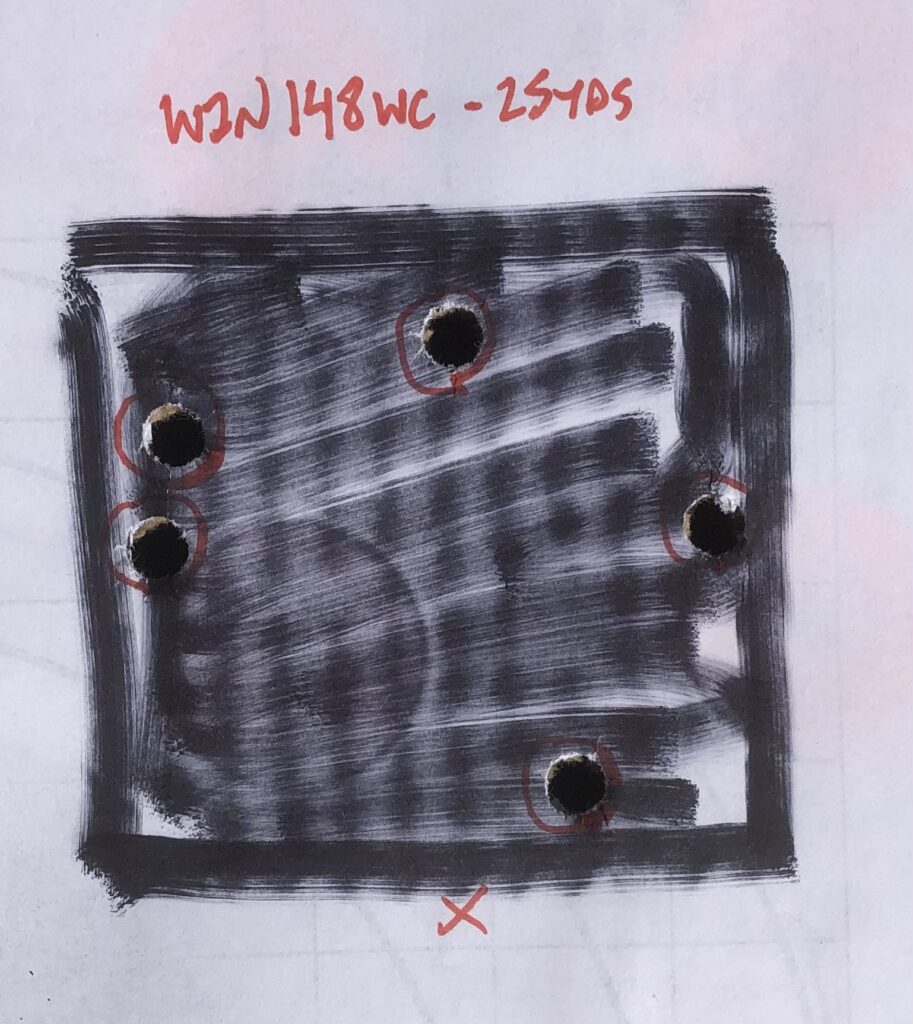

Shooting from a braced position on top of my backpack, I proceeded to fire a 10-round group with each load on a bullseye, using a center hold. When that was finished, I went back and shot a 5-round group with each load on a 4” square target that I drew with a marker, using a 6 O’Clock hold. After shooting a few targets, I realized that using a center hold on the black bullseye target was a bad idea, because I was having a hard time seeing the black front sight against the target, but I stubbornly continued with this hold for consistency across all four brands of ammo, because I didn’t have enough of each load to start over. The 6 O’Clock hold generally gave me better groups, as you’ll see in the targets, below.

Once again, I found that my trigger finger was quickly fatiguing as I shot these slow fire groups, and by the time I was finished, I was having to assist my tired trigger finger with the off-side index finger, just to pull through the action. This obviously isn’t the best technique for putting accurate rounds downrange, but I was time-crunched and had to do it to finish the work. You’ll also see a trend in the targets where I grouped my shots to the left, which was the result of me pushing the gun, as my tired finger curled around the trigger to obtain better leverage for the heavy pull.

A 10-shot group with the Winchester 148 grain wadcutters gave me a 5” tall by 3” wide (OD) group, and a second 5-shot effort gave me a group of 4” by 4” (OD). Once again, the point of aim was the center of the bullseye for the round target, and 6 O’Clock for the square one:

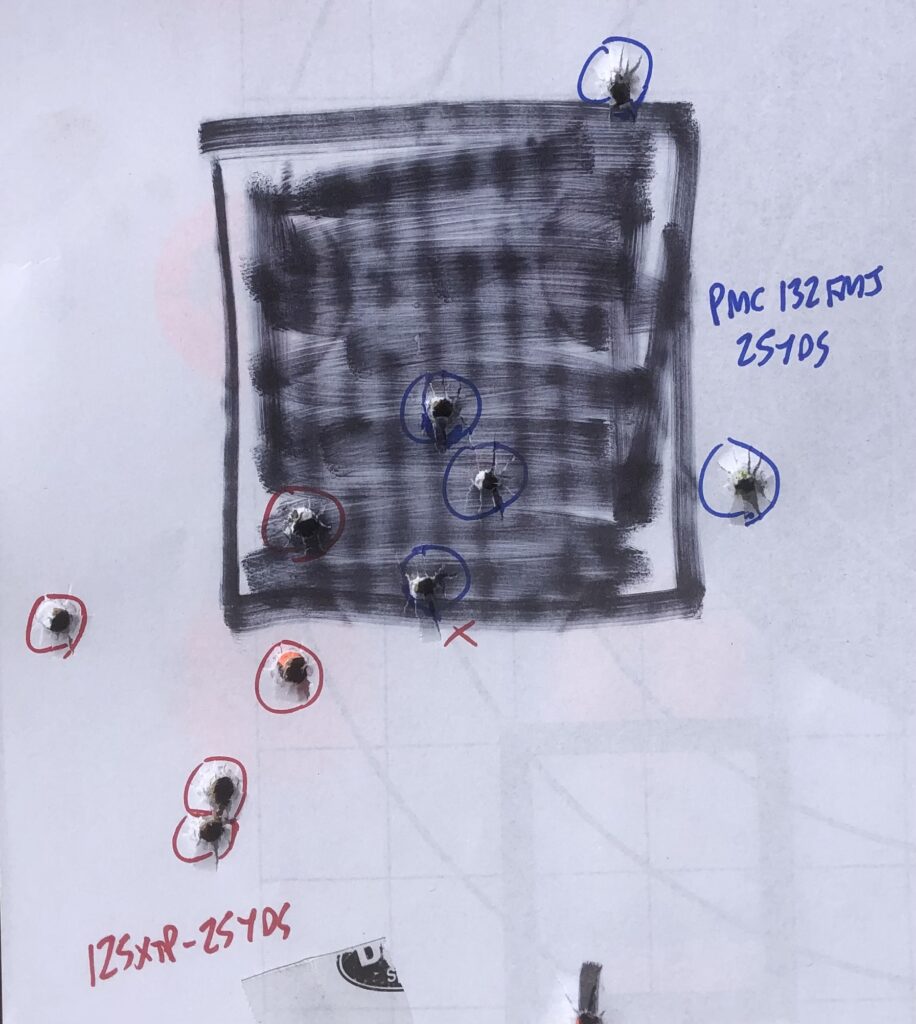

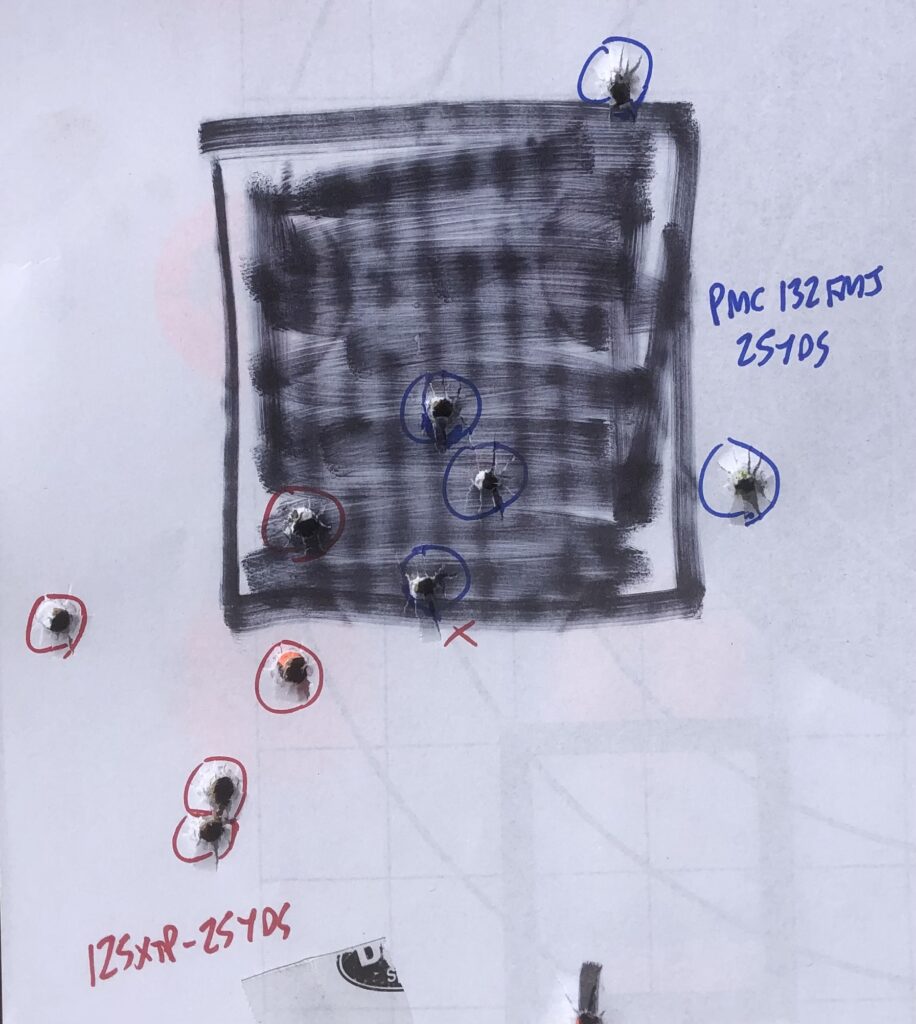

My first, 10-shot group with the PMC 132 grain FMJ was vertically stringed over 8” and I had one that got away from me prematurely while I was fighting the darned trigger, and it went off into the weeds somewhere. I also yanked one outside the bull, around 7 O’Clock. A pretty poor effort. However, I did manage to put three rounds into the center of the bull:

A second attempt with the PMC netted a much better group that was 4” tall and 2” wide (OD), with a high flyer. The best three in that group were vertically stacked in 1.75” by 0.5” (OD) though:

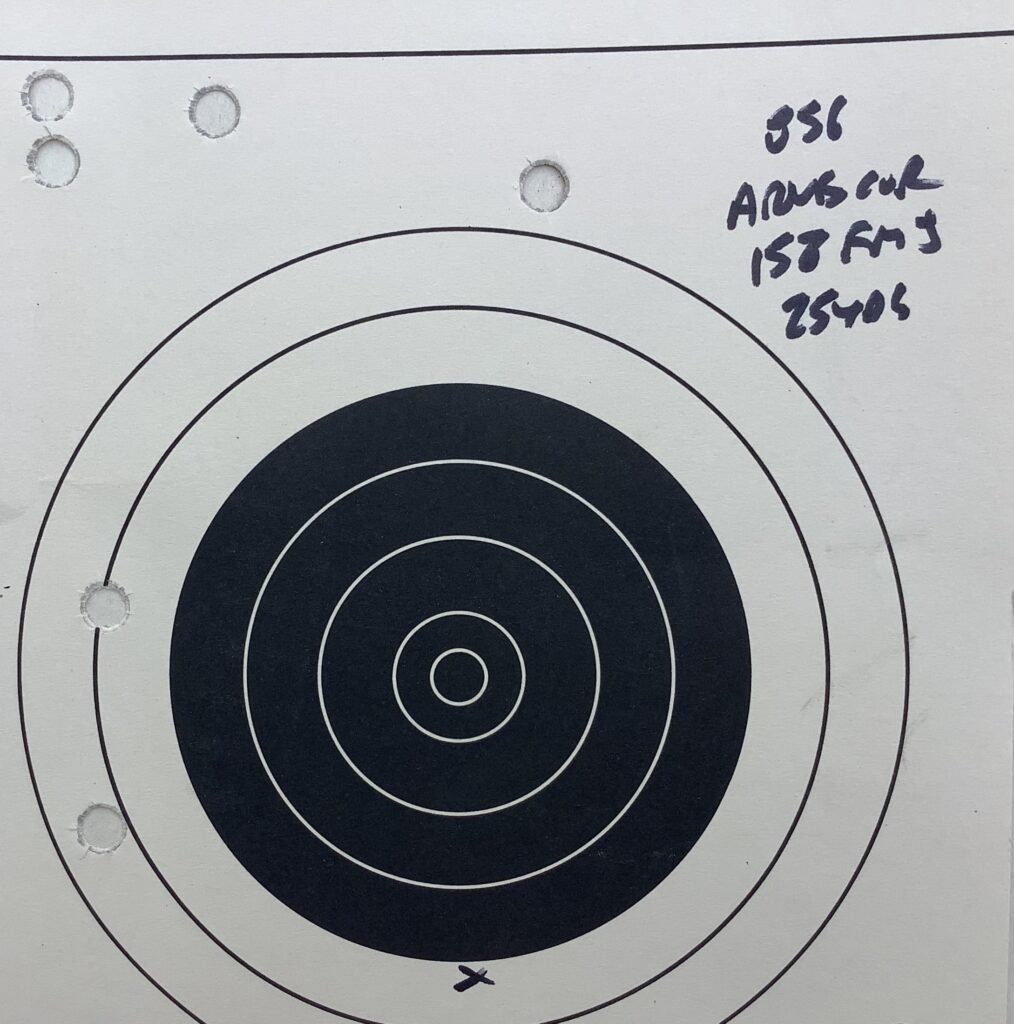

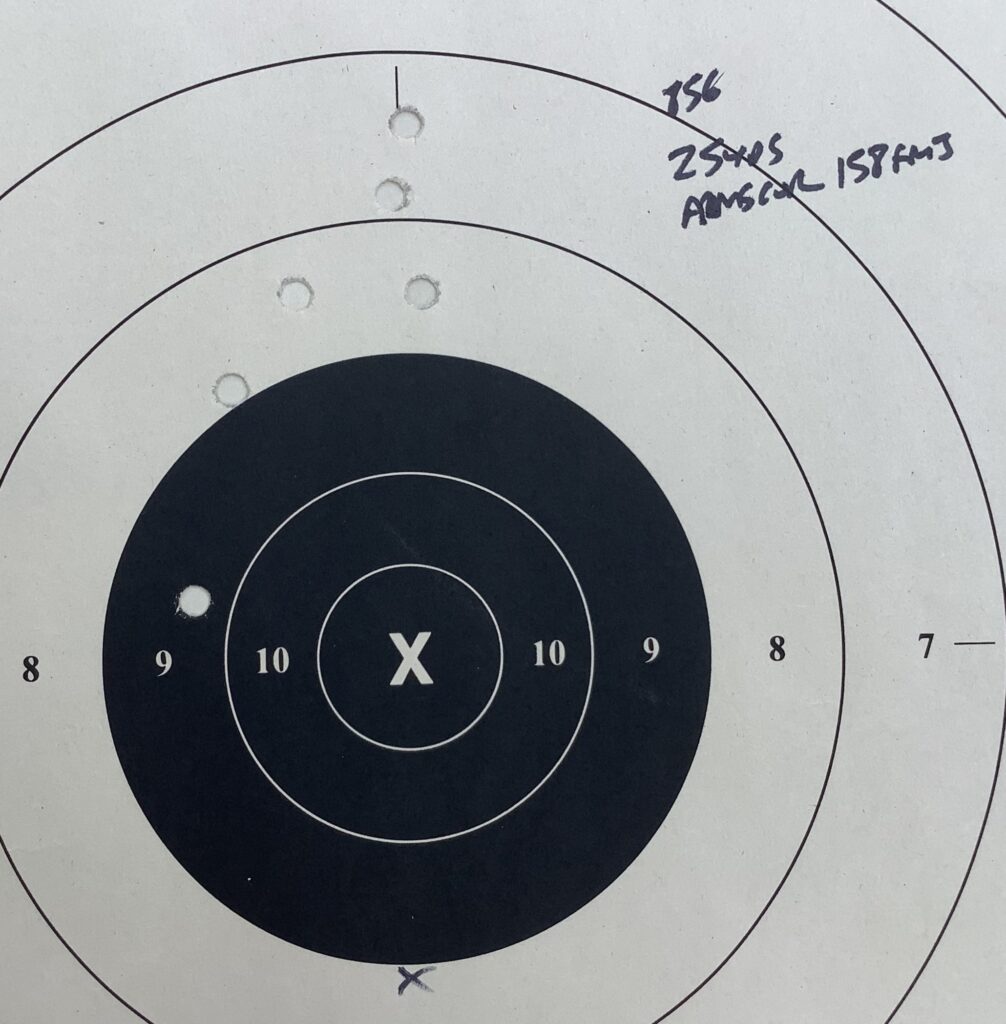

My first 10-shot group with the Armscor 158 grain FMJ was 3.5” tall by 5” wide (OD), with two rounds going just off the paper at 9 O’Clock:

My 5-shot group with the Armscor 158 gr. FMJ was 5” tall by 3” wide (OD), with a called low flyer that was the result of a spastic trigger pull with a tired finger. The best 4 rounds in that group measured 1.5” high by 3” wide (OD):

The 10-shot group with the Freedom Arms 125 grain XTP load measured 5” x 4.25” (OD) and my 5-shot group with the load measured 2.5” tall by 2” wide (OD):

I have to say I was pretty deflated by the time I was done shooting these groups. I felt like I was doing a crummy job behind the trigger and the gun was capable of better performance, but I was struggling with both the trigger and sights. My best efforts were giving me circa-4”-to-5″ groups but I thought they should be much smaller. Kevin’s performance with the optic-equipped version of the 856 showed me the gun was capable of much more, but I couldn’t figure out how to get there.

I struggled to see the small, dark sights clearly, but the good news is that the sights were pretty well regulated. I fired 125, 132, 148 and 158 grain bullet weights, and they all did pretty well. At 25 yards on the bullseye targets, the 125 grain load shot about an inch below point of aim, the 132 and 148 grain loads roughly shot to the point of aim, and the 158 grain load shot about three inches above point of aim. There’s a lot of small-frame .38s out there that can’t match this kind of consistency, so even though I complained about the sights being hard to see, they were the proper height for the job. Kudos to Taurus for that.

Reassessment

The 856 Exec sat on my desk for a week or two, mocking me.

“You say my sights are too small, but you manage to shoot those dinky sights on your 640 pretty well,” it said.

I tried to ignore it, but it continued:

“And you complain about my 13-pound trigger, but you’ve shot heavier ones before and you didn’t whine about them, like you are now. What kind of RevolverGuy can’t handle a 13-pound trigger, anyhow?”

Ugh. The gun was getting on my nerves, but I had to admit, it had a point.

I didn’t go back to the range with it right away, though. Instead, I let it stew for a while, on the back burner in my head, while I worked with another gun I was testing. I dove heavily into that project, but in the background, the wheels were still spinning about the Taurus.

And then I figured it out. I’d been shooting the gun all wrong.

The first job I tackled with the 856 Exec was to shoot groups for record. I shot a few targets at 15 yards, but went straight to 25 yards for the bulk of the work, because I’m stubborn like that.1

Since I was concerned about getting the best accuracy out of the bobbed hammer, DAO gun, I tried to cheat the effort by staging the trigger for my shots on the 25 yard targets. The thought was that I’d be able to finesse the trigger this way, and get the best results, but what I really did was tire the heck out of my finger. When you stage a trigger, you’re holding the pull weight for a (relatively) long time, then having to add a little more to finish the deal. Pull the trigger, pull the trigger, and hold it, hold it, now squeeze s-l-o-w-l-yyyyyy . . . Bang!

That works OK for a bit, but it doesn’t take long before your finger is tired from holding the weight, and that final squeeze becomes less and less coordinated, at the very time you want it to be the smoothest. At your worst, you wind up convulsively jerking the trigger, because your tired and cramped finger has to jerk, to break the stalemate and get the “frozen trigger” moving again.

I concluded that I needed to change my approach with the Taurus. Instead of staging the trigger, I needed to embrace the Zen of the Double Action, and keep that trigger moving once it started, without any staging, without any pauses. If accuracy is 90% about trigger control, then I needed to do a better job of controlling that trigger, and keep it moving smoothly and consistently, instead of starting, stopping, and starting it again. The problem was more with the trigger actuator than the gun, itself.

RevolverGuy 101. Sometimes we forget, and need to be reminded.

Thanks, Taurus.

Rematch

Armed with a new plan of attack, I went back to the range with the gun.

Instead of going straight to the record groups, I thought I’d work on some singles from the holster, to get warmed up. I didn’t have a dedicated Taurus 856 holster, but a DeSantis Flex-Tuk holster for the 3” Kimber K6s fit the 856 Exec nicely.

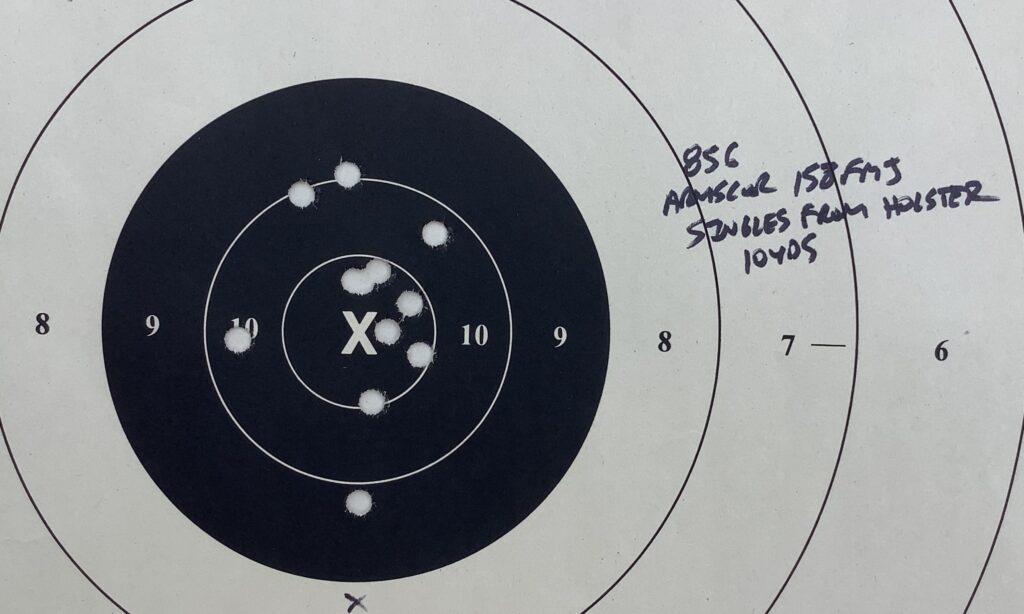

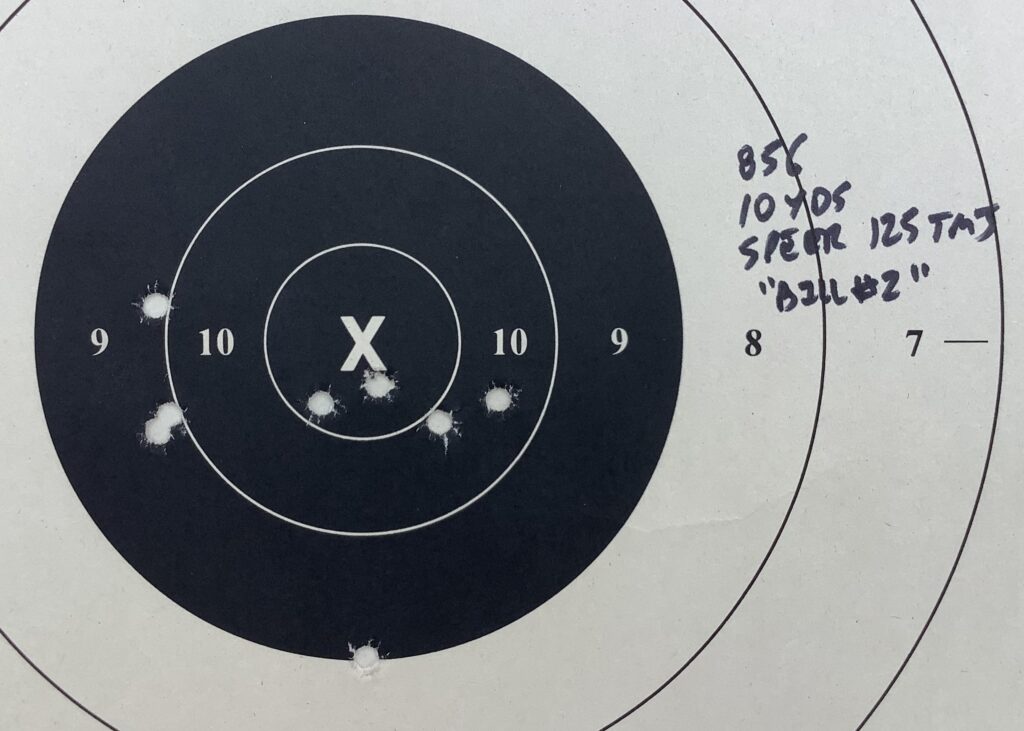

At a distance of 10 yards, with my Competition Electronics timer providing the start signal, I stepped off the X, drew, and fired a single round of the troublesome Armscor 158 grain FMJ on the target. When finished, I reset and did it again. Because the Armscor was giving me occasional failures to fire, I got a few extra “dry reps” in, but twelve rounds later, I had a pretty good looking target:

This was a good start, so I went back to the 25 yard bullseyes with a couple types of ammo, focusing on working the trigger as I had from the holster, with a smooth, continuous press.

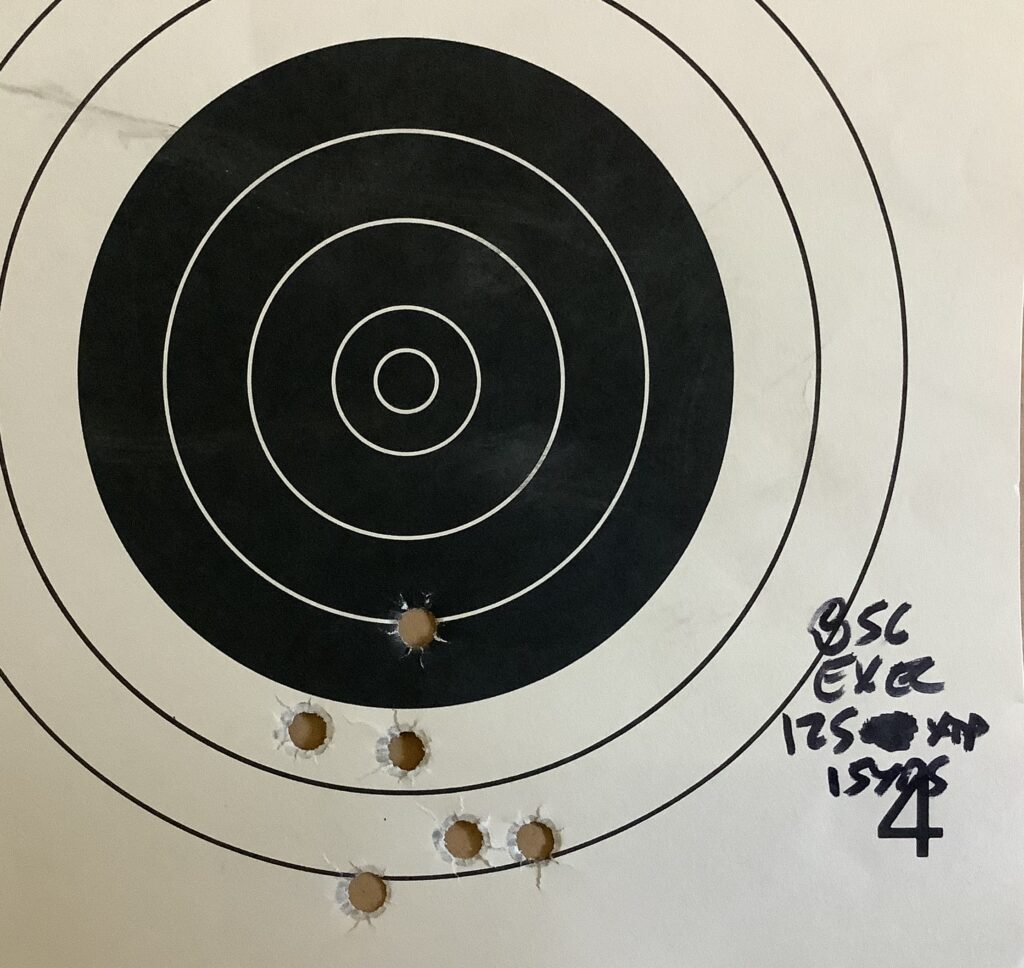

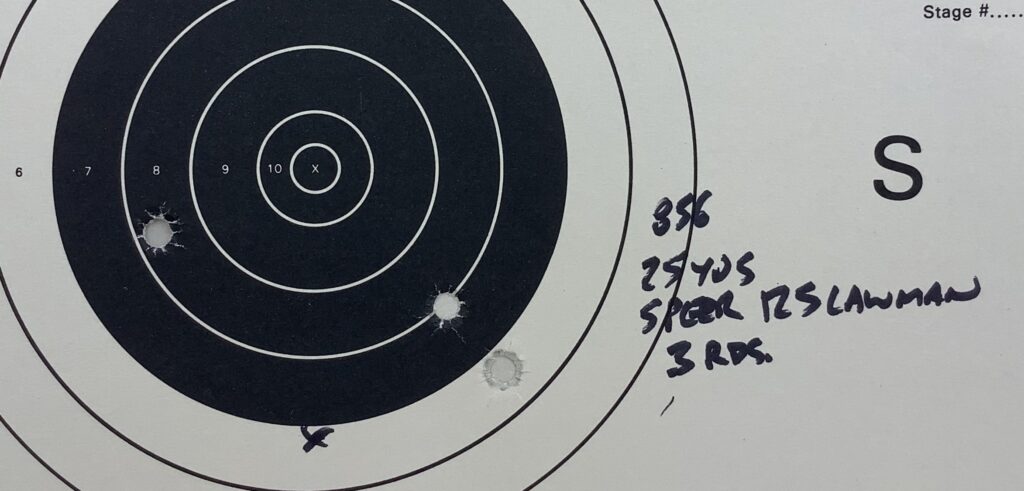

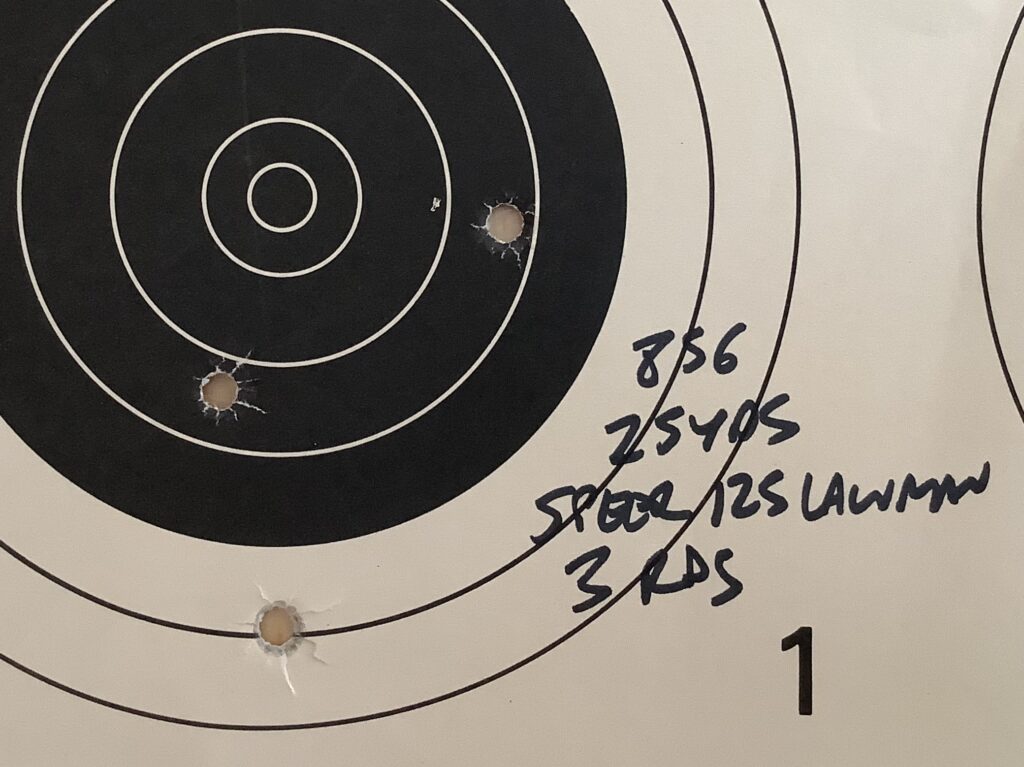

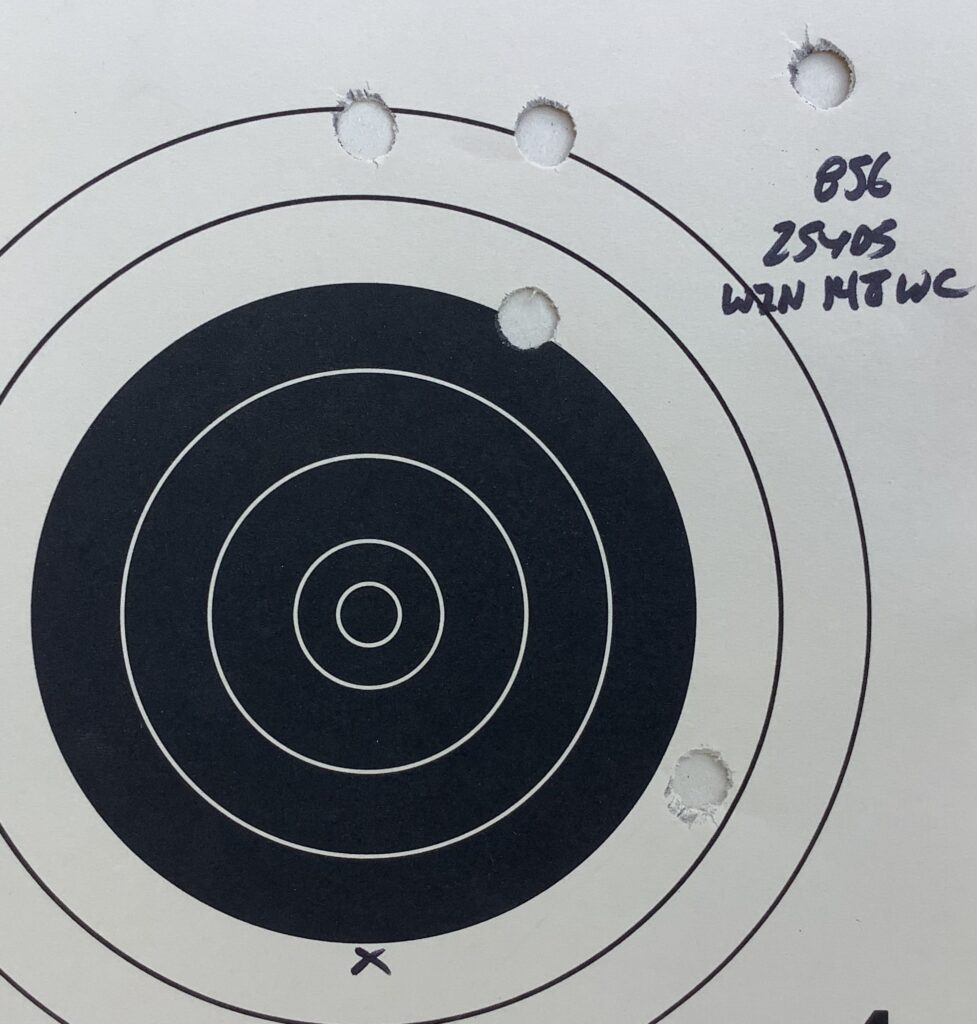

The Speer Lawman 125 grain TMJ ammunition started us off. I fired two different sets of three rounds, to conserve my supply for some drills, and was rewarded with a 1.25″ x 2.5″ (OD) group and a 2.5″ x 1.75″ (OD) group:

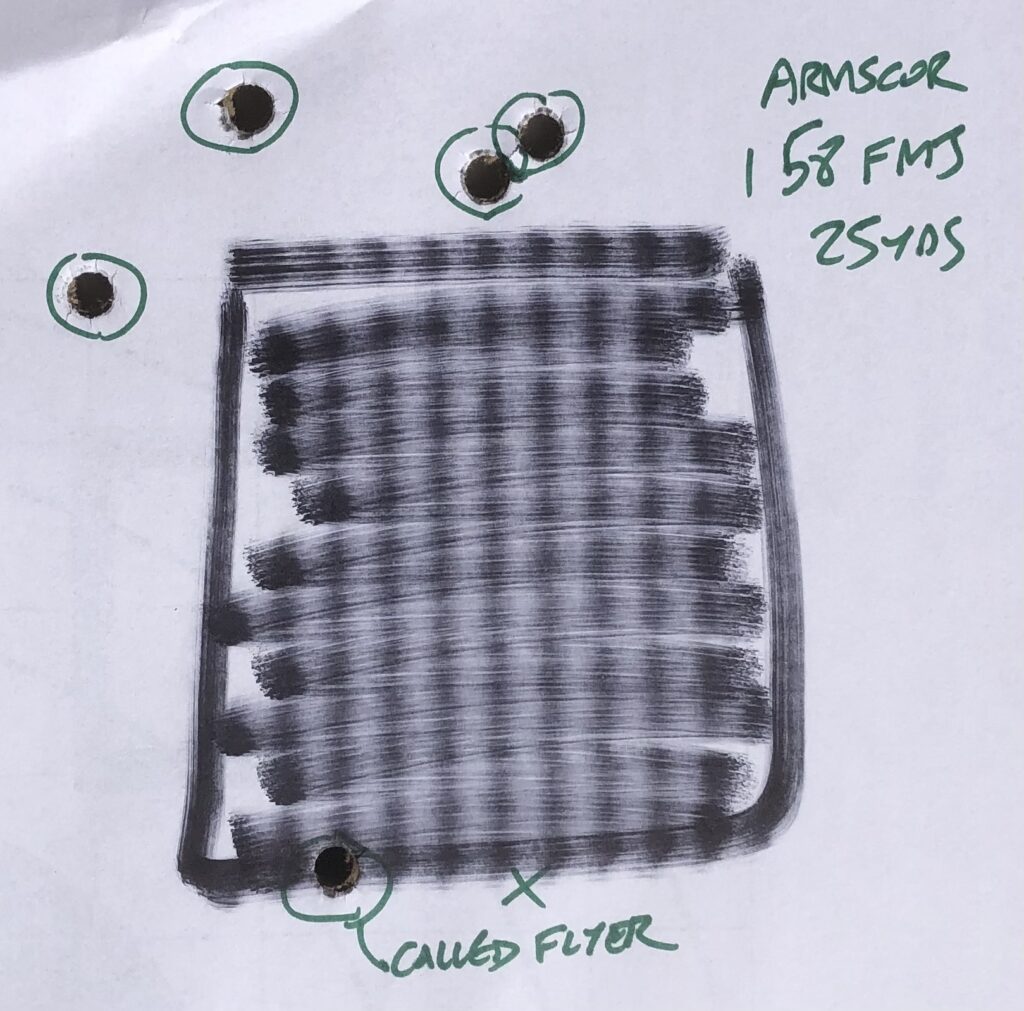

The Armscor 158 FMJ was next, giving me some six-shot groups that I would have been pleased with, had they not been spoiled by one or two flyers that I probably caused by milking the gun. Here’s one with a horizontal cluster of 4 rounds in 0.75″ x 3.25″ (OD):

And a better one with a 5-shot group in 2.5″ x 2.0″ (OD), spoiled by a low flyer:

The Winchester 148 grain Match wadcutter put four rounds into 1.5″ x 3″ (OD), with the fifth round pulled 2.5″ low, because there’s always one that spoils the group:

Overall, this was a much better effort at 25 yards, using the proper trigger technique. I was pleased with the improvement, and felt like I was finally giving the gun a fair shake. Instead of nominal 5″ groups, I was shooting nominal 3″ groups, and that seemed more like it. I have no doubt that a better shooter, or a shooter using a better rest, could still improve on that, but with the tiny, dark sights and 13+ pound, double action only trigger on this gun, three-inch groups is a reasonable measure of the practical accuracy we can expect with an average shooter at the controls, and economy-grade ammo, at 25 yards.2

lights, camera . . .

It was time to give the gun some action in a context that was more appropriate for its given role. This is not a PPC gun after all, so shooting 25 yard bullseyes is really not its raison d’etre.

First up was a repeat of a simple course of fire that I’d shot with a Kimber K6s a few weeks before, at a club training day. This 10-round course was shot from the holster and consisted of the following stages:

-

-

-

- 10 Yards, draw, one round, no time limit (one rep)

- 10 Yards, draw, two rounds in four seconds (two reps)

- 10 Yards, draw, one round, reload, one more round, in six seconds (one rep)

- 15 Yards, draw, one round in three seconds (one rep)

- 15 Yards, draw, two rounds in four seconds (one rep)

-

-

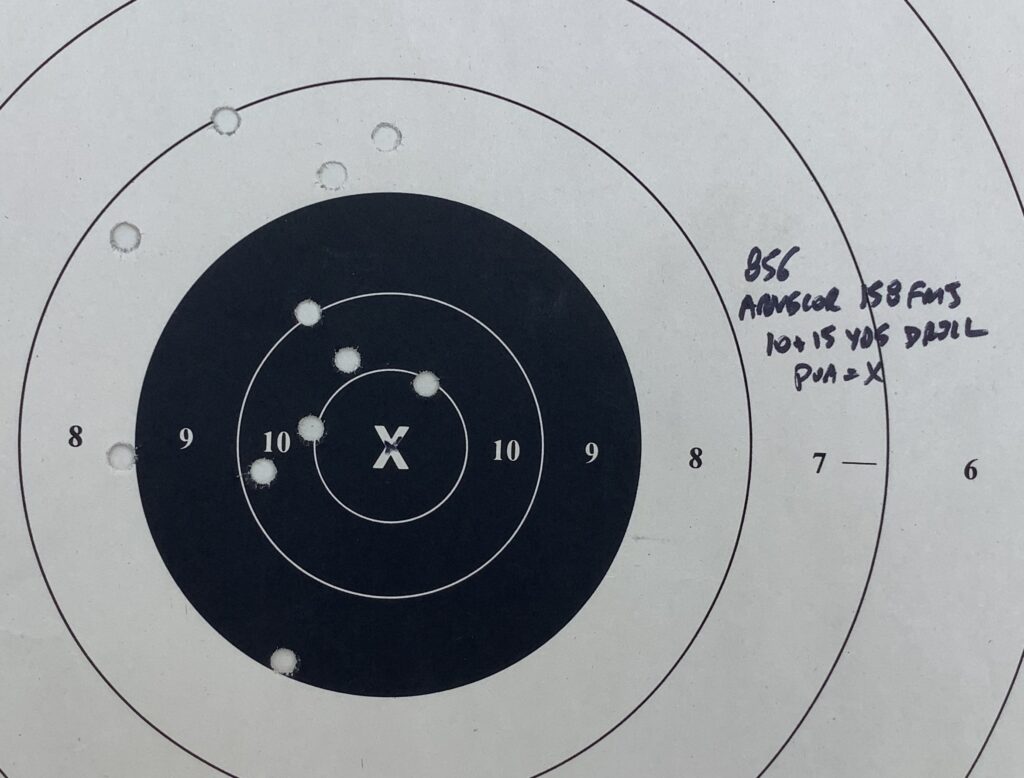

I busted the time for the reload stage (9.08), courtesy of my struggle with the fat grips blocking access for the Zeta6 K-CLIP, and for the pair at 15 Yards (4.51) because I just took too long to verify my sight picture, but made the rest of the times and shot the following target:

Unfortunately, I absentmindedly reverted back to using the “X” as my point of aim, and should have used a 6 O’Clock hold with the 158 grain ammo, since my previous bullseye shooting had shown that it had a tendency to print about two to three inches high at this distance. Oh well.

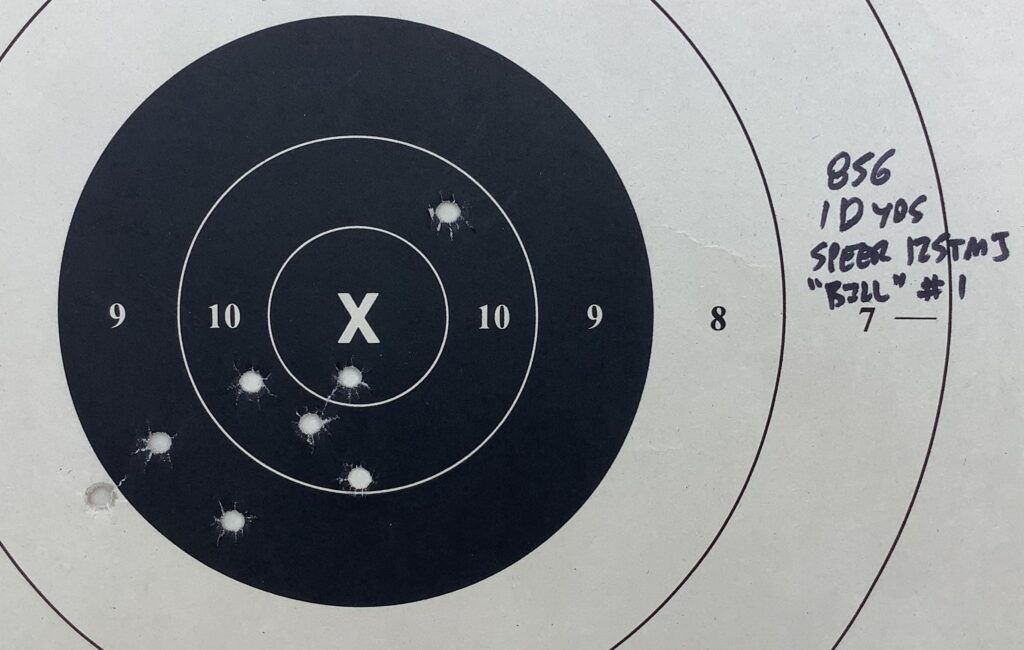

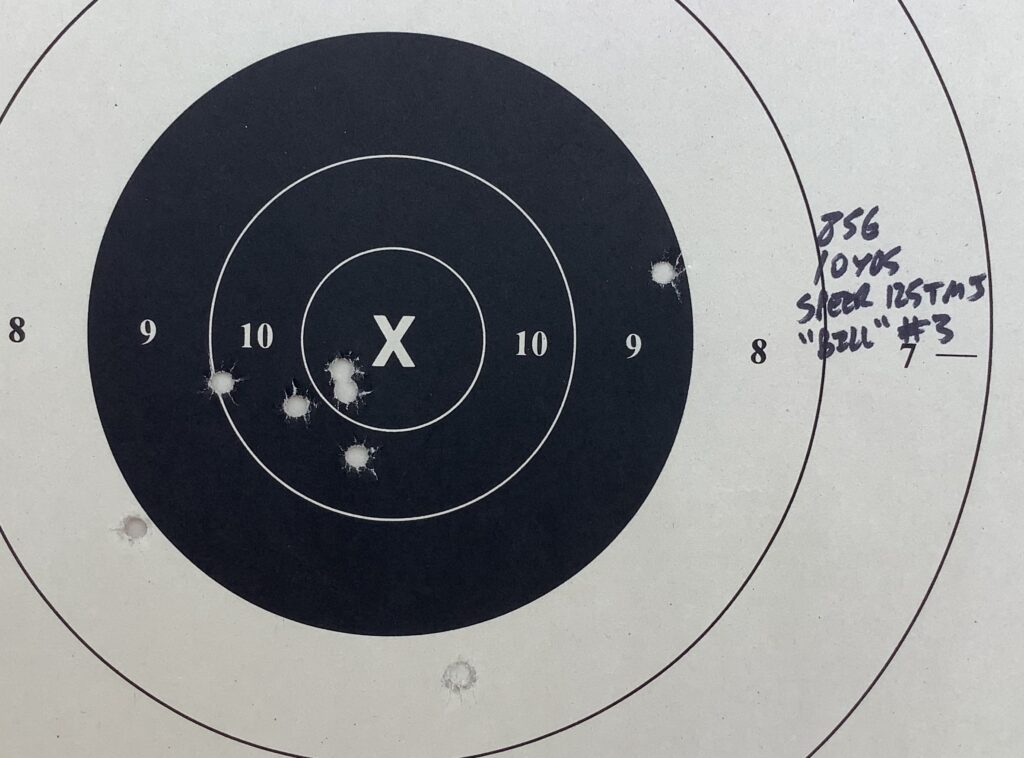

Moving on, I set three targets abreast at 10 yards, spaced with their centers three yards apart, for a pseudo-“Bill Drill” of sorts. At the start of the timer, I fired one round on each target moving left-to-right, reloaded with the K-CLIP, then fired one round on each target moving right-to-left.

I ran this drill four times, using Speer Lawman 125 grain TMJ ammo. My reloading times were slower than in the previous drill, averaging about 10 seconds to unload the gun, dig in my jeans pocket for the clip, refill the gun, and resume firing.

Ten seconds is pretty awful for a reload, and it deserves a little explanation, since there were several issues that kept me from getting the job done faster:

-

-

- The fat grips consistently blocked cases from clearing the inboard chambers, as their rims would bind on the grip panel after extraction. This required me to rotate the cylinder and sweep them clean with my fingers, before proceeding;

- The K-CLIP would bind on the fat grip panel, and I’d have to force it past the interference to get it seated;

- On one occasion, I fumbled the K-CLIP when its pull tab caught the lip of my pocket on the way out, and sent it tumbling to the ground;

- The K-CLIP had a tendency to hang onto one round, and pull it out of the chamber when I removed the loader from the cylinder. This required me to peel the round off the clip and seat it in the chamber, before I could close the cylinder.

-

So, it was slow going on the reloads, which ate up the majority of my circa-17-to-18 second runs (all you ICORE guys are doing the math and probably chuckling at my slow splits, but I’ve never claimed to be fast!), but I was happy with my accuracy, dropping only three rounds out of the black . . . and even those were darned close:

The most interesting thing about all of this dynamic shooting on the clock, was that I never noticed the “heavy” trigger that had plagued me so much when I was shooting slow-fire groups for record. In fact, the only thing I noticed about the trigger was its smooth pull, and its positive reset. The sights were still a challenge, and the grips were very problematic for reloading, but the trigger was good for running the gun “at speed,” and I didn’t feel handicapped by it at all. In fact, I actually enjoyed shooting it.3

So, after the frustration of trying to get the 856 Exec to perform on bullseyes at 25 yards (a job it was not built or meant to do), with an inappropriate trigger technique, I walked away with a new appreciation for the gun after running it in these dynamic drills.

On a subsequent trip, I shot another target at 15 yards that confirmed I was on the right track by focusing on better trigger management, and better illustrated what the gun was capable of:

Comparisons

The 856 Executive occupies an interesting spot in the marketplace, and it’s worth a moment to consider how it compares to other revolvers in the same size and weight class (small frames with 3” barrels).

At an MSRP of $689.99, the 856 Executive is about $240 more than the 3”, matte stainless, Defender version of the 856, so there’s a significant premium to pay for the gun, within the Taurus family. However, even with the higher price tag, the Taurus 856 Executive is less expensive than similar models from the competition.

Based on MSRPs, a three-inch S&W Model 60 will run you about $150 more than the Exec, and a standard Ruger SP101 with a three-inch barrel will run you about $230 more. A Colt King Cobra will cost you about $210 more than the Exec, and the three-inch Kimber K6s will exact the highest premium, of $320.

My experience with these other guns indicates that the additional money will likely buy you a slightly improved trigger pull (especially in the Colt and Kimber guns), and in some cases you’ll get better sights (actually, dramatically better in the case of the Kimber, but they won’t be as well-regulated as the Exec’s). The 856 Exec’s finish and grips will be more attractive though, and you’ll get an additional round in the cylinder, compared to the S&W and Ruger designs. The 856’s trigger face may also be more comfortable on your finger than the narrow and square trigger on the Colt (even if you have to put another three or four pounds of pressure on it, to move it).

In the end, only you can do the calculus to measure the costs and benefits of each of these guns, but I’d say the Taurus 856 Executive definitely deserves to be in the mix, for your consideration.

taking stock

Putting it all together, I’d have to say my experience with the Taurus 856 Executive Grade was mixed, but generally favorable.

Despite the busy markings, I think the gun is handsome, overall, and I also appreciated some of the gun’s design features, like the six-round cylinder, the replaceable front sight, the comfortable extractor rod tip, the well-shaped thumb piece, the chamfered chamber mouths, and the comfortable trigger face.

Discovering the metal splinters inside the gun was disappointing, but I’m hesitant to single out Taurus for it, because that’s just the state of the industry, now. None of the majors are doing a great job with QC these days, and I could easily find the same, or worse, in other brands. I just had to return a Ruger for a manufacturing flaw, and my FFL has been sharing some pretty awful stories about the quality issues he’s seeing on new revolvers from S&W (how about three new guns with such a tight B/C gap that they had to be forced open, straight from the box?), so I have no reason to believe Taurus is doing worse than anybody else in that department. Frankly, we’d like to see all of them improve their game.

I was disappointed that the 856 Executive Grade’s grips blocked me from using a round body speedloader to reload the gun, and really frustrated that they blocked clean extraction of spent cases. On the flip side, I liked the feel of the symmetric thumb shelves on the grips and also appreciated how the proud left panel kept my thumb knuckle from getting banged up on the thumb piece. The grips did a good job of allowing me to control the gun during recoil, but they were such a problem during loading and unloading that I rate them a “fail,” on this gun. They will definitely have to be altered or replaced to make this gun a practical choice. Fortunately, that’s not hard, but it shouldn’t be necessary on the company’s premiere offering.

The sights gave a pretty poor sight picture, to be honest, but since the front sight is installed with a roll pin, it wouldn’t be too difficult to replace it with a better unit. Failing that, I could just paint it, like I have to do on most other guns. I’d still like to have a wider and deeper rear sight, but I’ve lived with that situation on J-Frames for decades, and I suppose I could work around it, even though I shouldn’t have to. An “Executive Grade” gun deserves better sights, in my opinion, and I wish Taurus had shipped the gun in a cardboard box in lieu of the expensive Pelican case, and spent the difference on upgrading the sights, instead. To Taurus’ credit, these sights are properly regulated for the ammunition that is most likely to be fired in them–a detail that’s been ignored in the more expensive models from some of their competitors.

The trigger pull was on the heavier side, and gave me some problems at 25 yards until I corrected my technique. Even then, it was still a bit heavier than I would have liked it to be, but in fairness to the gun, I didn’t notice it a bit during the dynamic, close range shooting that this gun is really designed for. Thankfully, the trigger pull was quite smooth, and the trigger face was both comfortable and ideally-shaped for double action work.

The timing of the action was good, and the gun was 100% reliable with all but one brand of ammunition, despite its lower mass, bobbed hammer. I’m going to give the gun a pass on that, and attribute the problems to some hard primers in that brand of ammunition.

So?

Adding it all up, I think I’d rate the Taurus 856 Executive Grade as a decent value for the price–an economy gun with some attractive design features and cosmetic upgrades, which delivers good performance. It’s not a product category leader, but it doesn’t carry a category leading price tag, either.

The 856 Executive Grade is a nicer revolver than the mainstream Taurus offering, but I think it fell short of its true potential, and I’d really like to see Taurus take a second bite at the “Executive Grade” apple. If I could build a wish list for the “New Taurus,” I’d change the grips on this model to a round butt design with an appropriate speedloader relief, open up that fixed rear sight (better yet, replace it with a good, fixed sight mounted in a dovetail), put a high-visibility sight up front, and see if I could knock a pound or two off the trigger pull, without sacrificing any reliability. If they could do that, Taurus’ competitors would be playing catch up.

*****

endnotes

1. I read an issue of a popular gun magazine recently, where several writers reported seven yard groups for the service-size guns they were testing, and I was rather disgusted by it all. Seven yards for a duty gun? Really?

I’ve always thought 25 yards was a reasonable distance for testing handgun accuracy. Many writers will argue that compact guns like this Taurus should be tested at closer distances, and they may have a point to a degree, but it seems to me you can hide a lot of sins at seven yards. Once you start pushing out to 25 yards, you start to learn a lot more about the practical accuracy that can be expected from the gun and ammo combination. Besides, it’s reasonable to think you might need to shoot your defensive handgun at 25 yards, so it seems like a good idea to test out there. Ever measured an aisle in your grocery store? How about the distances in a typical parking lot?

But honestly . . . evaluating a service gun’s accuracy at seven yards? Please . . .

2. American Handgunner’s Jeremy Clough reported a 3.7” group at 25 yards with his sample, so I think I’m in the right neighborhood by saying this is a circa-three-inch gun at that distance;

3. The experience was reminiscent of my introduction to the Heckler & Koch LEM trigger, actually. Trying to shoot slow fire, precision groups with that trigger was frustrating, but when the shooting got fast and furious (the job it was actually designed for), it really shined. It took me a while to “learn” the LEM, but once it clicked, I really enjoyed shooting it. In fact, I think it’s one of the best autopistol duty triggers on the market.

Vewwy Intewestink writeup with a lot of time invested. A nicely done exterior will never make up for questionable functioning. While the Armscorp ammo may very well be a culprit, the symptoms you had suggest something else within the revolver is in play. As it stood at the end of your tests, I would not trust my life to that revolver.

The first thing that needs to go is the lumber. Having that much grip material that impedes your speed loading ability is a non-starter. Why one would put grips of that design on that particular revolver makes my remaining hairs curl out of confusion. Also, why the under lug on the barrel ? That’s exactly what I (do not) want in a carry gun is more unnecessary weight ! (sarcasm added)

Part of R&D for a gun company developing a defensive-concealed carry revolver should be to make sure it can fully function in its intended capacity. Taurus went to a lot of effort to produce something that has premium performance only to drag it down with, well, I made my point.

I’ll stay with my Smith & Wessons and for life insurance, I don’t put a price tag on it.

Interesting point about the full underlug. When I think about it, it seems to be the standard profile for the breed—the Kimber, Colt, and Ruger and S&W guns I mentioned all have one. The benefit is they look good, and help to dampen muzzle rise, but you’re right that they increase the curb weight, which isn’t ideal for carry.

It appears the new S&Ws are struggling a bit, based on the feedback. That hyperlink in the article is a little shocking, isn’t it? Treasure those older, proven guns that you own!

Mike, excellent job as always with your reviews. Wish you had been writing those when I first got interested in revolvers.

Agree with you strongly on the grips, speed loader blockage but more disturbing is why you would put target style grips on a round but 3 inch revolver. Defeats the purpose. Where are the magna style grips for it ?

Don’t like graffiti filled firearms either that’s what the paper in the box is for.

Tony, I think the design people spend so much time on the big parts, that things like stocks and such are simply ignored, passed off as insignificant details. The new 2020 Python is the same—crummy grips and sights spoil that otherwise excellent effort. In fact, I suspect the Python and Taurus grips come from the same vendor.

Thorough and honest firearms reviews like the Colonel’s make me doubly satisfied with my vintage American-made revolvers that have it all: nice fit and finish, smooth actions and good accuracy. My only regret is I didn’t buy more of them long ago when their prices were reasonable.

Amen, brother.

I got one of these for my mom for her birthday. It was more affordable than a S&W equivalent (which there sort of isn’t), and I thought the grip and 3″ barrel would help her. She hasn’t had the chance to shoot it, for reasons I’d rather not get into, but I shot it a few months ago.

Compared the trigger on the stock 856 I own (also with a bobbed hammer), I didn’t think the trigger pull was that special. Not to say it’s bad, but it didn’t feel noticeably better than a regular 856 trigger. Accuracy wasn’t exceptional when I shot it, but I think I was having a bad day the day I took it out. As it stands now, the 3″ barrel wasn’t any more accurate than the 2″ barrel on my regular 856.

My biggest complaint is with the grips. They rattle, they don’t help (me) with shooting, and they interfere with speed loaders. The only speed loaders I’ve tried that work with the grips are the Pachmayr speed loaders, and I cannot recommend those to anyone due to inconsistent QC. The ones I have work, but every attempt at getting more has given me duds.

I think the 856 Executive Grade would benefit a lot from better grips. As it is now, I would not buy one for myself.

That said, I admit I am rather biased now, as I’ve quit Taurus revolvers in general due to some issues I’ve had this year. I’ve kept my 856, along with an old .22LR model, but I’ve gone back to my 642 and S&W revolvers in general.

Thanks for the great data point, Axel. I really don’t think the guts are any different between the models. I didn’t see any evidence of polishing or fitting inside the Executive. The changes from the base model are mostly cosmetic, I think, outside of the chamfered chambers and bevel on the cylinder edge.

Thank you for the review. I like my old Taurus 85, now residing in a chicken coop’s lock box for Copperhead control on that part of the farm. My wife recently used it on Johnny No-Legs during an inspection at sundown.

In our limited experience Taurus 85 revolvers can run well and last a long time. For SD and CCW, I did not test 3” guns but probably still would have paid the premium for a Kimber. The trigger makes a big difference at the range, though I am not sure about how much I’d notice it in a gunfight.

Never had a light strike on the Kimber. Over the years and several thousand rounds the old 85 developed an occasional light strike on reloads, necessitating a new firing-pin spring.

The 85s were a real solid value. I kinda miss having them on the market.

With my 79 year old arthritic hands, 13 lb DA triggers are no longer tolerable, and I have had my gunsmith install reduced-power springs in three different Taurus 856 revolvers that now have measured 7.5-8.5 lb DA triggers. The guns have fired several hundred rounds of Federal, PMC, Winchester, and Georgia Arms ammunition without any light strikes so far. If I were 20 years old again, however, I would have left the triggers unmodified because all were smooth. right out of the box.

I really like the standard front night sight on the 3-in 856 Defender and and am thinking about replacing the ramp sight on my 2-in 856 with one. The night sight and the ramp sight look to be exactly the same height.

The 3-in 856 Defender revolver comes with both boot grips and a Hogue Monogrip. Surprisingly, my large hands have found the smaller boot grips more comfortable to shoot because, unlike the Hogue Monogrip, they cover the back strap giving a bit longer reach to the trigger.

Steve, that’s great info, and much appreciated.

I’ve been playing with a Wolff spring kit, and while the mainspring was a good fit, the trigger return spring was too long (Wolff advises on the website and in the product literature that it might need to be modified for some newer models—apparently the 856 is one of them) and would need to have several coils clipped. I did not do that, and stayed with the OEM spring for the meantime. The new mainspring, by itself, doesn’t seem to change much, and I suspect I’ll have to modify that Wolff trigger return spring to make a significant change in the pull weight.

I’m glad to hear of your success with the front night sight, and will keep that in mind as a substitute. Like you, I find the open back Hogues reduce the trigger reach too much, and prefer an enclosed backstrap, so your point towards the boot grips is very useful. Thanks!

I am pretty sure my gunsmith using the Gallaway spring kit

I used the depth gauge on my electronic caliper to measure the heights of the top of the factory night sight and factory ramp sight above the top of the barrel on two of my 856 revolvers: the first with a 3-in barrel (night sight) and the second with a 2-in barrel (ramp sight). I measured 0.174-in for the night sight and 0.173-in for the ramp sight, a difference of only 0.001 in.

VERY helpful! Thank you Sir!

Thanks for this review.

Armscor is the culprit. Recent acquisition and testing of the 158 grain FMJ load in a 2″ 856 UL CH resulted in failure to fire in at least one third of rounds fired. Can’t call them “light strikes” because the primer has a solid impression, but the face of the primer itself is concave, as though it deformed during impact. Except for one saved example, I fired the rest with a second hit.

To be fair, this occurred only after I replaced the trigger return and mainsprings with a Galloway kit, but I had no problems with any other ammo after that modification, and the action is substantially lighter and smoother. The solution: 125 gr +P Remington green box, which shoots to POA at 10y with a 6:00 hold.

The factory sight is similar to that on the Executive and fades out on a typical overcast day. Its orange/tritium Ameriglo replacement gives far better results, but could stand to be a skosh taller.

The replacement VZ 320 grips tend to roll up in the hand on recoil–the palm swells are too fat and the backstrap needs to be flattened. Overall they’re too rounded in cross section for consistent grip at speed.

Factory “magnas” exist. They look great as long as you don’t look too closely and are best used with standard pressure loads. I use the VZ retention pin, which fits more tightly, preventing or reducing rotation of the magnas.

The above additions will undoubtedly fit the Executive.

Still looking for an ideal load for my UL. It’s not yet as accurate as a mid-60s Cobra, but it’s not yet broken in.

Sorry for the length of the post. Stream of consciousness before adequate caffeination.

Old Wolf, thanks for the excellent feedback. I’m very happy to have the Armscor primers confirmed as the culprit. I don’t know where they’re sourcing their primers, but they’re too hard.

I’d hoped that the Ameriglo replacement would solve the problem, but if you’re saying it’s a little too short, then I’m hesitant to go that route. I can file down a sight that’s too tall, but one that’s too short is more difficult to work around. Maybe the XS Sights unit will be a better path.

The VZ 320 grips kinda look like a potato on the gun, so I can envision what you’re describing with respect to their feel and function. Being G10, they can be sanded and shaped, but that’s a delicate operation. Easy to screw that up. I see the “Magnas” for $30, but I’d need a grip adapter to make those work. I wonder if the plain factory rubber grips, at $10, wouldn’t be a better option? They appear to have a closed backstrap and flatter sides.

Have you tried wadcutters in the UL yet?

Not yet. I’m thinking Underwood.

The rubber grips are actually pretty good, but are kinda sticky and also bring the bore axis up a little more than I like.

Thank you for a detailed and frank analysis of the Exec, Mr. Wood. Far too many gunrag reviews read like recycled press releases, but not the articles published at Revolverguy. The new Taurus (and Rossi) revolvers are mighty interesting compared to the often mediocre and routinely overpriced offerings from the legacy brands. For all the Exec’s merits I’m wondering if the Defender with an aftermarket spring kit might not be a better value for purpose. In the meantime you’ll find me shopping for vintage Smith & Wessons and Rugers…

Thank you Sir. I had a good introduction to the new Rossis at SHOT and would be eager to see a production sample—I hope they’ll be as good as I expected. I’m glad to see the brand come back to the market.

Of all the legacy gunmakers, S&W has been the one that disappoints the most—so much potential there, but they’re coasting on their old reputation, not listening to the customer’s demands (better sights, no lock, return discontinued models, be innovative) and letting the QC falter. It’s telling that Taurus beat them to the party, with the first red dot guns.

I honestly think Taurus could give them a run for the money, with some small tweaks to this 856 Exec. It wouldn’t take much, as I outlined; better sights, better grips, and a spring kit. Easy stuff, really.

Smith and Wesson seems to be on the same downward trajectory as Colt back in the late 70s and throughout the 80s: increasingly poor quality control, stodgy firearms, unreasonably high prices, and a let-them-eat-cake attitude toward their customers. It took Colt decades of disastrous management decisions, financial losses and bankruptcy to return to being a respectable, innovative manufacturer. Maybe Smith is about to relearn the same ugly lessons as Colt.

Indeed, Sir. An excellent observation. Probably worthy of an article!

Well said, and it’s a damn shame. It seems like S&W’s revolver management has either been asleep at the wheel for the past two decades or is woefully uninformed.

I think you hit a double there, Zach.

Enjoyed the review, as always. I picked up one these a little while back. For the price they are hard to beat.

The trigger pull is quite smooth, even though it is north of 12#. Running it in IDPA matches, I can’t say that it bothers me too much.

The nice wooden grip or stock had to go. Couldn’t run any decent speed loader in it . My loader of preference is the 5Star. I bought the Hogue mono grip off the Taurus website and it functions well like Hogues generally do. Also picked a UM tactical holster from the site. It is actually a pretty decent holster; and you use it IWB or OWB.

Got tired of the paint on the front sight and broke down and got an XS front sight for it. So far so good, much easier for my old eyes to pick up.

Basically, it’s not perfect, but for the price range it’s more than suitable.

Thanks Donald! I’m curious—is the XS Sight properly regulated? What bullet weight and velocity are you shooting, and where does the gun shoot at, say, 15 and 25 yards? High? Low? To the point of aim?

I can see where the Hogues would be a great improvement. I’d like to find a grip with a covered backstrap. The search continues.

Mike, your expertise and thoroughness never cease to impress. The 856 Executive piqued my interest to the extent that I purchased one. Fit and finish were surprisingly good, I personally like the sideplate logo rollmark, and unlike my new (otherwise excellent) GP100, this Taurus didn’t need to be returned to the factory immediately due to QC issues.

I agree with you on the grip situation. It’s completely befuddling that Taurus would opt for comparatively large, square-butt grips on a concealed carry piece. Especially ones that clearly block a speedloader. I swapped mine out for a (curiously discontinued for small-frame Taurus revolvers) Pachmayr Compac set and I couldn’t be happier.

I also concur with a previous commenter. A full underlug isn’t so bad on a 3″ barrel, but I’d really like to see more partial underlug options for 4″+ revolvers. The only new production one that comes to mind is the GP100 Match Champion. (I still won’t consider a new S&W thanks to that internal lock and frame reshape that came with it.)

The 856 Executive trigger definitely seemed to be on the heavier side, but I’m hoping it lightens up a little bit with use. One thing I can definitely confirm, however, is that I was having numerous failures to fire with bulk Armscor ammo. The rounds that failed to fire in the 856 also failed to fire in my 1970s-era S&W Model 10 I had out on the same range day. The primers must be especially robust on Armscor ammo. Otherwise, the 856 ran everything else I threw at it with no issues. Those chamfered cylinder holes certainly made loading a breeze, and I was quite impressed with how much they made a difference.

I also agree with your sentiments on wishing for a slightly deeper rear sight channel. I applied some brightly-colored enamel model paint to the front sight to help it stand out a bit, but I do prefer the look of the front ramp from an aesthetic standpoint.

I look forward to hearing your thoughts on other new entrants into the market, and especially how Taurus/Braztech’s new Rossi line of revolvers compare to the 856 Exec. I can only hope that folks in the industry read this blog and take advice from the actual revolver expert that’s been around the block and is kind enough to share his informed opinion with the rest of us!

Zach, thanks for the kind words, and for the excellent information. It’s good to know that you encountered the same thing with the Armscor ammo, as that definitely gets the Taurus guns off the hook. It sounds like painting the front sight was a good stopgap for improving the sight picture, and a set of Compacs would be just the ticket for this gun—too bad they discontinued them.

Most RevolverGuys probably won’t recall the short-lived, L-Frame, S&W 619 and 620 revolvers, but I wish they had stayed in the catalog. The fixed sight 619 had no lug, just the forward locking point, and the adjustable sight 620 had a half lug. I liked those configurations and, like you, wish we had more options like those to choose from (minus the stooopid lock, of course).

I was favorably impressed with the new Rossis I shot back in January, and we’ve talked about obtaining one to test, but my state laws are still blocking that effort. I’ve got Kevin busy testing some other guns for us, and when he’s done with those assignments, maybe we’ll have him tackle the Rossis next.

Thanks again for the great feedback and the kind words! Much appreciated!

If Smith had updated their M12 for +P, improved QC and kept it in the catalog, I’d buy three.

The same could be said, maybe, of the new Colt Cobras if they were available with LW frames.

And if I could get my head around that mickey mouse trigger return spring.

Hey Mike,

Thanks for your insight on the Executive. Your thoughts on shooting it like a combat gun vs. a target gun are appreciated. You rightly emphasize how important properly relieved and shaped grips are for the mission of a fighting revolver. I’ve been spending lots of time with some 856’s of late, and my opinion of them is mostly favorable. Two of the ones I’ve shot had pretty decent actions, but the third seemed to have been built on a Friday or a Monday! The trigger pull was pretty rough, and the thumb piece operated really stiffly. The good news is both have gotten better with use. I’m pleased with the commitment Taurus has displayed towards revolver development and improvement, unlike some of its competitors. They are building common sense guns with good features at an affordable price. I hope to share some observations on the 856 Ultra Lites soon, as well as some holsters and support gear. Rock on!

Thanks Kevin! I’m looking forward to hearing more about your experience with the 856 lineup. These guns seem to be quite popular and I’m glad to give them some attention here in these pages. Sorry to hear about your Monday gun! I’ve had those!

Really like mine but did install the small factory grips, works fine with speedloaders and more concealable…also added the Taurus orange/night front sight.

Jim, what ammo are you shooting, and how does it print with that orange night sight installed? To point of aim? High/Low? At what distance?

Pardon my jumping in here, but I hope this helps.

With the Ameriglo and 320s:

At 10y, with 125 gr Rem +P JHP, 12 rounds into a 3″ bull, group center about 2″ above 6:00 POA.

Group approximately 2 1/2″ “tall”, 1 5/8″ wide. 50 foot slow fire NRA B-2 target.

With the Ameriglo and “magnas”:

Same distance, same hold, Winclean 125 gr JSP, 18 rounds into a group centered approximately

2″ above 6:00 POA, but 6 rounds from different cylinder loads out in the 5 and 6 ring of the B2, resulting in a group approximately 5″ tall, 3″ wide.

Even with the lighter load, the Magnas tend to shift in the hand.

EXCELLENT info, thank you Sir! Very helpful.

This revolver needs a trifecta of improvements. A better trigger, better sights (adjustable windage and evaluation rear + fiber/ tritium front sights) and a grip that can use a speed loader. In the end, we all love value, but few of us will sacrifice performance. Sometimes spending just a little more gives you a lot more. Will the engineering team rise to the challenge or be thwarted by the accountants at Taurus? I think we all know the answer! Taurus needs to understand that good is the enemy of excellent. They can’t co-exist!

I hear where you’re coming from, Carlos, but I would mention that perfect is also the enemy of good. It’s reasonable to expect a better trigger on this model than a standard 856-Taurus advertises it with a tuned action and should certainly deliver. This gun is enough of a value (I just saw them on GunBroker for 515.00-570.00) that investing in a pair of grips for speedloader compatibility and changing the front sight for a tritium one can be done and still keep the gun affordable. These two DIY changes are easy to accomplish and address the other issues you bring up. They also make the Executive a serious carry revolver! An adjustable rear sight on a gun like this is a subjective preference. I personally like the ruggedness, lack of sharp edges, and low profile a fixed rear offers on a concealed carry revolver. The 856 rear sight could be improved, but its serviceable and bullet proof as-is. Maybe in the future Taurus will open a “custom shop” and let consumers choose from options to build revolvers to their preferred specifications. How cool would that be???

Just skimmed this article. While the Exec Grade looks like a pretty keen revolver I wouldn’t give you two “Joe Biden” bucks for it. First it’s a Taurus, second they use proprietary parts whic means if you need a part you have to SEND THE GUN BACK TO TAURUS. Some years ago (because I couldn’t afford a S&W) I purchased a 2 1/2″ .357 with the internal hammer, meticulously tuned the action, installed a XS front sight, completely disassembled and reblued it, HOWEVER, I lost he front pin that holds the extractor spring and plunger. Long story short, when the gun came back from Taurus the action was totally redone with new factory parts and a worse than original action it was terrible. I didn’t replace any parts with the action job just stoned, filed and polished the originals.. I called Taurus on this and really din’t seem to care one way or the other . There may be folks out there who like Taurus but I don’t. I guess you do get what you pay for.

I can appreciate your frustration Carl, but I don’t think it’s fair to single out Taurus with those complaints.

All of the manufacturers use proprietary parts, and none of them are good about selling parts to customers. I’ve even had gunsmiths complain to me that they couldn’t obtain parts from the manufacturer. That’s just an industry issue, not a Taurus issue.

Same for the replacement of your non-factory spec parts. Every manufacturer will replace those if you send the gun in for warranty service. Most will make you sign a waiver acknowledging it, as part of the warranty return. It’s a liability thing for them. They can’t return the gun with parts that have been altered and/or don’t meet factory specs.

Again, I understand the frustration, but Taurus is not the problem!