The Kimber K6s revolver was introduced at the 2016 SHOT Show, and while I got to handle it in the Kimber booth, I didn’t get to shoot it until the following year’s Media Day at the Range. That first cylinder full convinced me that I was holding a very special gun, and would need to spend more time with it in the future.

So, I was very eager to return to the SHOT Show Media Day in January of 2018, and revisit the gun. When the gates opened that morning to let the crowd into the range, I hot-footed it to the Kimber booth to send more rounds downrange through the super snubby. Upon reaching the booth, I was excited to see that Kimber had several new variants to offer, including a 3” stainless version and a “Deep Cover” (DC) version with upgraded features. I shot the entire lineup and the experience reinforced my impression from the years before—these were special guns that needed further attention.

Research project

I first learned of the K6s in the weeks leading up to SHOT Show 2016. Kimber marketing teased all of us with an ad that hinted at what was coming, and a few sources leaked some info about the gun. Excited about what I heard, I mentioned the gun to Grant Cunningham when I was on the phone with him prior to the show, and was surprised to learn that he had been part of the team that created it. That info wasn’t public yet, and Grant was bound by nondisclosure agreements that prevented him from sharing details at this early stage, so he couldn’t answer the long list of questions that I had. However, he encouraged me to report back with my observations after I saw the gun and opened the door to future discussions.

As I mentioned, I didn’t get a chance to shoot the gun that year, but my brush with it kindled a strong interest in it. Several conversations with Grant and Kimber employees ensued, and eventually led to an interesting story about the design and development of this gun. If you haven’t read that story yet in these pages, I encourage you to take a look at it, because it’s a deep dive into the innards of the K6s.

Trigger time with the K6s DC

Talking to engineers and consultants is enlightening, but to truly understand a firearm, you need to burn some powder. To that end, your RevolverGuy team has been working with several samples of the K6s for a while now, and after spending some time with the K6s, we now have enough experience to make informed comments on it.

If you haven’t seen Justin’s excellent review of the 3” stainless version yet, I highly encourage you to go and read it. He has some detailed observations about the gun that are worth reading, and I think it’s worth noting that our experiences with these guns have been very similar in some areas.

The following is my field report on the K6s, based on carrying and shooting the DC model, which differs from the standard 2” K6s Stainless model in its black “diamond-like carbon” (DLC) finish, G10 grips, and tritium night sights. I’ll make note of a few features along the way when I have a specific comment about them, but for general information about the design, I’ll refer you to my earlier article.

Reliability

There’s no more important characteristic of a self-defense firearm than reliability, so let’s start there. Right up front I need to say that my sample of the K6s DC has been extremely reliable. I have experienced no failures to fire, no breakages, or any other gun-related malfunctions during the test period. Some of you out there are saying to yourselves, “of course, it’s a brand new gun,” but I’m here to tell you that workmanship and reliability is no longer a given these days. I won’t digress into the changes in the industry that have brought us to this point, but will simply say that it’s not uncommon for new guns from the major brands to be defective from the start, or break early in their service lives, so it was exciting to see my K6s perform so well.

I wanted to push the K6s DC hard in my evaluation, so I decided to shoot the gun without performing any routine maintenance, to see how long it would go. I took the gun as it was shipped, and started shooting without performing any cleaning or lubrication along the way. This isn’t how I normally do business, but I thought it would be instructive to see how the K6s DC handled the neglect.

I ran the gun hard. The majority of rounds sent downrange were fired in defensive training classes and drills. The gun was shot fast, reloaded fast, and shot fast again. It didn’t get babied, and there were times that it got so hot that I burned my hand on the cylinder during reloads. Even the accuracy testing sessions were expedited, due to range time. The Kimber kept up a brisk pace, overall.

The gun ran for a total of 464 rounds before it finally became too dirty to continue shooting. These 464 rounds included:

275 rounds of Federal American Eagle, .38 Special, 130 grain, FMJ

54 rounds of Winchester Ranger, .38 Special +P, 130 grain, JHP

42 rounds of Winchester .38 Special, 158 grain, RNL

36 rounds of Remington .38 Special +P, 158 grain, LSWCHP

33 rounds of Winchester .38 Special +P+, 110 grain, JHP

24 rounds of Remington .357 Magnum, 125 grain, JHP

This is a significant accomplishment, I think. I keep my Smith & Wesson 640 meticulously clean, but the action starts to get sluggish after 150 rounds or so, and pretty soon thereafter, the cylinder will no longer close due to the buildup of crud under the ejector star. By comparison, the Kimber’s action didn’t slow down until around 400 rounds, and went to 464 before its cylinder wouldn’t go into the frame.

There’s two things to note about this. First, my K6s DC was delivered with a sloppy excess of white grease on the ejector rod and under the ejector itself. I knew this would attract fouling and gunk things up quickly, but wanted to see how long it would take, so I left it. I suspect that I would have easily made it past 500 rounds if I had just wiped the excess off before shooting commenced.

More importantly, the K6s cylinder design incorporates a clever and noteworthy feature that helps to ensure reliability. The area underneath the ejector star is relieved to create a “debris channel” that gives unburned powder grains and other trash a place to go. This excellent feature stops gunk from building up under the extractor and preventing it from seating flush, and I think it had a lot to do with how long this neglected K6s was able to run without attention.

A dry fire warning

Sadly, I can’t leave the issue of reliability without commenting on something that happened to a test gun in our pool. One of our fellow RevolverGuys is an industry professional that I talked into buying a stainless K6s, and from the very start he’s been feeding me valuable and detailed information about his sample. I consider this gun to be part of our T&E effort, so I’m obligated to report what happened to it.

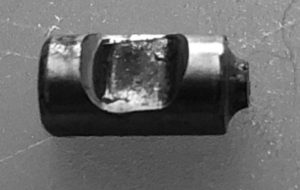

The firing pin on his gun broke early in its service life. The gun had only fired about 250 rounds to date (all of it factory .38 Special, except for a few dozen factory .357s), but it had also been dry fired extensively. Our man estimates that he had several hundred dry fires on this gun–without using snap caps–before it broke.

After discussing it with him, we came to the conclusion that the dry firing is probably what precipitated the failure. Without a live primer or a snap cap to cushion the blow, the firing pin was probably getting battered into the frame. A stress riser was created in the pin (perhaps at the location of a manufacturing defect?), and the tip sheared off.

Thankfully, the broken firing pin was discovered during routine inspection and maintenance. The gun was sent to Kimber, who quickly replaced the firing pin and firing pin spring under warranty. The customer service was excellent–Kimber paid for the two-way shipping, and the work was done quickly, only taking 7 days round-trip.

I spoke to Kimber about the issue and mentioned a similar report I’d seen on the internet about a K6s firing pin failure. I wanted to know if these isolated incidents pointed to a bigger trend. Was there something about the design, the materials, or the production process that needed attention?

I was assured that while Kimber has seen a few guns with this problem, the numbers have been very small—“on the order of tens of guns, out of tens of thousands made.” Despite the infrequent nature of this failure, my Kimber contacts tell me they’re busy examining their design, materials, and processes to identify and fix the cause, so it won’t reoccur. I’m not happy that this problem occurred, but I’m encouraged that Kimber is taking it seriously. I’ve seen other occasions where manufacturers were not as responsive to potential problems, but I get the feeling that Kimber isn’t ignoring this one.

Kimber concurred that we were on the right track with our diagnosis, that the extensive dry firing had either accelerated or caused the issue. Kimber has not issued any recommendations about dry fire yet, and the K6s owner’s manual is silent on it, but RevolverGuy is going to recommend that you use snap caps in your revolver when dry firing it to mitigate this risk.

I should note that my own gun has been dry fired about a hundred times without snap caps and has fired 540 rounds of factory ammunition to date without failure. I’ve also shot 150 rounds through another T&E K6s, a 3″ stainless gun like Justin’s, without any issues so far. It’s likely that the failed gun was an unfortunate exception, but I will be using snap caps from this point forward as a dry fire precaution. We’ll be sure to keep you posted on any new developments in this area.

March 2021 Update: The repaired gun broke again, after more dry firing, and we received news of other confirmed firing pin breaks on hammerless K6s samples after very limited dry firing.

The problem moved Kimber to redesign the firing pin and change the material to steel, in lieu of the original Titanium. The new firing pin has a more robust nose profile, which requires a new bushing design to match.

The new firing pin first appeared in the DA/SA variant sometime in 2019, and has now (as of late 2020/early 2021) been incorporated into the hammerless K6s variants. There have been no problems reported with the new firing pin design. See this article for more information about the new K6s firing pin.

If an owner of an older K6s experiences a problem with their old firing pin, they can return the gun to Kimber and have it upgraded to the new part. Kimber advises they have only seen a very, very small number of these failures, and don’t believe it’s necessary to retrofit all guns with the old firing pin design on a precautionary basis. However, if you experience a problem with yours, Kimber will make it right.

RevolverGuys are strongly advised to refrain from dry firing any firearm without snap caps, and are also advised to inspect/check their firing pin as described in the function check article in these pages.

Ejection

Early in the test period, I noticed that I occasionally had cases hang up in the cylinder after hitting the ejector rod. This typically happened on the chambers that were closest to the frame, and I had to pluck them out manually.

This was not the gun’s fault. Instead, I think the habits I developed around other guns with shorter ejector rods are to blame. As I became more experienced with the K6s, I realized that the cases always cleared the cylinder cleanly when I paid attention to what I was doing and gave the rod a full stroke. The cases only hung up when I didn’t fully and/or forcefully push the ejector rod. The problem here was operator error, so, hit the ejector rod firmly, push it all the way, and you won’t have any issues.

Of interest, the K6s ejector rod throw is about 0.93” compared to about 0.65” on my .38 Special, 1.875” S&W Model 640, and 0.98” on a .357 Magnum, 3” S&W Model 65. Given that the .38 Special case body (excluding rim thickness) is only about 1.096” long (1.230” for .357 Magnum), it’s plain to see that the K6s has more than ample throw to chuck the cases out of the way. It’s almost a small frame gun with a medium frame extractor rod. Somebody was thinking, here.

Frame dimensions

The K6s is a little taller than my .38 Special, 1.875” S&W Model 640 if you measure to the top of the K6s’ sights, but if you measure from the bottom of the grip frame to the upper surface of the top strap, the guns are both about 4.125” tall. However, the recoil shoulder on the K6s is lower on the backstrap, with the point about 3.375” up from the bottom of the frame, compared to 3.625” up from the bottom on the S&W 640.

I could feel this difference when shooting the K6s. It’s my preference to shoot these little guns with the web of my hand very high on the backstrap, to reduce the bore axis and gain additional control in recoil. With the 640, I can “choke up” very high on the backstrap with my larger hand (I wear a Size 11 or 12 glove) and comfortably place the web up and over the hump, but the shape of the K6s backstrap forced me to grip it much lower.

I couldn’t ride my hand up as high on the backstrap of the K6s, and it felt strange at first. However, I have to admit that I became accustomed to it, and it didn’t seem to significantly affect my shooting or my control of the revolver. It’s odd, but in photos the K6s appears to have a much longer grip frame than my 640, but both of them extend about 1.2” below the bottom of the trigger guard, and the overall heights (minus sights) are the same, so it’s probably just an illusion created by the different profiles of the grips they wear.

Cylinder release

The K6s cylinder release is a vast improvement over what I’m used to, and it’s one of my favorite features on the gun.

I have a long history of S&W J-Frames cutting the knuckle on my shooting hand thumb with the bottom edge of the cylinder release. All my personal J-frames have had their latches polished to remove sharp edges, but the checkering on the thumb piece still makes me bleed anyhow. I’ve played around with alternative grasps, but have never found a satisfactory solution for this problem, and have learned to accept it as one of the tradeoffs that go with big hands shooting small revolvers wearing boot grips.

The K6s is different though. Perhaps it’s because the backstrap forces me to grip the gun lower on the frame, or perhaps it’s because the cylinder latch on the Kimber is nicely rounded (straight from the factory, no less!) and the checkering is less aggressive, but whatever the reason, the Kimber doesn’t draw blood.

Well, that’s mostly true. When I went to full house, 125 grain, .357 Magnum loads, the gun finally did bite my thumb knuckle a little, but I never had a single problem shooting the .38 Special +P loads that usually scrape me up in the S&W. That’s a heck of an improvement for me, and I was thrilled to discover it.

Grips

The G10 stocks on the K6s are simply beautiful. The grey and black laminate is a perfect accent to the black DLC finish on this model, and the gun looks fantastic with them on there. The G10 is durable stuff, and I think it will shrug off dings and scrapes much better than wood.

The DC’s grips are completely smooth, which will appeal to some and drive others crazy. I love the smooth surface because they don’t grab clothing like some checkered or rubber grips do, which makes the gun draw more easily from a pocket, and also helps to prevent printing. Additionally, they’re more comfortable against bare skin when carrying concealed.

I also appreciated the smooth surface because it allowed my hand to shift around on the grip and establish a good grasp on the weapon while it was in the holster. Sometimes a heavily-checkered or rubber grip traps your hand where it lands during the draw, and won’t let it slide around to make necessary corrections before the gun comes out, so your grasp suffers for it.

I know Justin didn’t care for the smooth stocks of the 3” Stainless version, but those long handles lack any kind of finger grooves. I found the finger grooves on these G10 grips did a good job of anchoring the gun during recoil, and didn’t feel like I needed checkering to control the gun. Incidentally, I like the longer, smooth wood grips on the 3″ stainless very much. They were comfortable and gave me good control of the gun, which goes to show that there’s a lot of personal preference involved in grips. What works for my hand may not work for yours, and vice versa.

I will complain about speedloader clearance, though. Even though the G10 grips are relieved on the left side for a speedloader, there simply isn’t enough room for the speedloader body to get in there without running afoul of the grip panel. The grip on the DC prevented me from using all the speedloaders in my inventory (including S.L. Variant, Safariland, Dade, and Jetloader devices sized for the K-Frame), except for the HKS style. I could make the “DS” version of the HKS (designed for the Colt D-Frames, like the Dick Special) work with .38 Special ammunition, but I still encountered some binding issues with this combination. When the DS HKS was loaded with longer .357 Magnum cases, the grip interference was significant. It was the same story for the wood grips on the 3″ stainless, except the binding with the HKS loader and .38 Special ammunition was even worse than it was with the G10 grips on the DC, making the speedloader almost useless.

For those who are curious, the S&W K-Frame-sized model “10” HKS loader was worse. The cartridge spacing on the K-Frame is wider, so the bigger loader could get the noses of the cartridges into the chambers, but they bound up as you pushed them deeper into the cylinder. This prevented me from getting the body of the loader past the point where it was binding on the grip panel, making a clean release impossible.

It’s a shame that Safariland doesn’t make the Detective Special-sized Comp speedloader anymore. I’d like to see if one of those units would fit, but I just can’t find one to try. As Justin mentioned, the industry needs to get behind this gun and provide some good speedloader options for it. The same loaders would work on Colt’s Cobra-series of guns, so there’s definitely a market for them.

I hate to say it, but I’m going to have to take a file and some sandpaper to those beautiful G10 and wood grips if I want to use a speedloader without interference (Note: I later did. See the April 13, 2019 entry on DIY Grip Modifications). Unfortunately, the third man on our test team reports that the rubber grips on the standard K6s suffer from the same malady.

This could have been one area where Kimber really separated themselves from the rest of the pack, but they didn’t. I’m not sure why the industry hasn’t managed to get this right in over a half a century, but there it is.

Sights

The K6s DC sights are one of those good news / bad news propositions. On the good side, I’ve never seen a small frame revolver with sights as good as these. The Ruger LCR sights were an improvement on the standard J-Frame, but the K6s sights are in a class all by themselves. These sights offer a big and blocky sight picture, just like you get with a good set of autoloader sights. There’s a good amount of light on either side of the blade, and if you like 3-dot patterns (I don’t) you’ll be thrilled to find them there.

The first time I raised a K6s on target at SHOT 2017, I immediately lowered the gun back to low ready, before firing a shot. I turned my head and told fellow RevolverGuy Steve Tracy with a huge grin that, “these sights are EXCELLENT!” Honestly, these are REAL sights and legions of snubby fans who have suffered with skinny blades and shallow troughs machined into top straps will rejoice at the K6s sight picture.

Alas, they’re not regulated for anything you’re likely to shoot. Sigh. My experience with the K6s is that it shot low with all loads tested. I don’t claim to be any kind of expert marksman, but achieved the following results from an unsupported, standing position:

| Load | 7 yds | 10 yds | 15 yds | 25 yds |

| Win, 110 gr +P+ JHP, .38 Spl | 2.25” below POA | Not Tested | 5” below POA | 8” below POA |

| Win, 130 gr FMJ, .38 Spl | 3” below POA | 3” below POA | 2” below POA | 2.5” below POA |

| Win, 130 gr +P JHP, .38 Spl | Not Tested | 2” below POA | 2” below POA | Not Tested |

| Win, 158 gr RNL, .38 Spl | 1.5” below POA | Not Tested | 3.5” below POA | 8” below POA |

| Rem, 158 gr +P LSWCHP, .38 Spl | 1.5” below POA | Not Tested | 4.5” below POA | 13” below POA |

| Rem, 125 gr JHP, .357 Mag | 2.5” below POA | 3” below POA | Not Tested | Not Tested |

The Kimber engineers tell me that the sights are regulated for .357 Magnum, 158 grain ammunition at a distance of 15 yards. I didn’t relish the idea of shooting a bunch of 158 grain Magnum ammo to test the theory, but was saved by the third member of our test team. From a bench rest at 25 yards, he obtained the following results:

| Load | Point of Impact (5 round group) |

| Speer Gold Dot, .357 Mag, 135 gr GDHP | 3” below POA |

| Black Hills Ammo, .357 Mag, 158 gr JHP | At POA |

| Remington, .357 Mag, 158 gr Semi-JHP | 4” below POA |

| Independence, .357 Mag, 158 gr JSP | 1” above POA |

| CCI Blazer, .357 Mag, 158 gr JHP | 1.5” above POA |

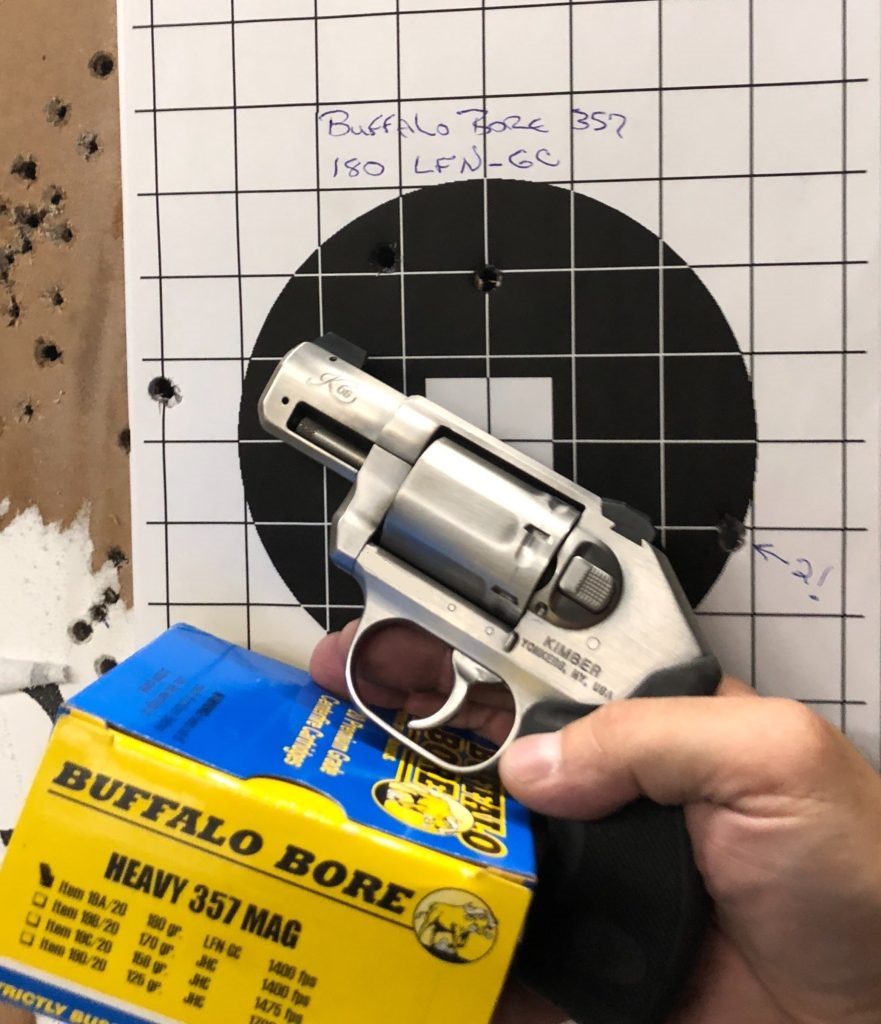

| Buffalo Bore, .357 Mag, 180 gr LFN-GC | 4” above POA |

Additionally, he obtained the following results with .38 Special ammunition, shooting from the bench at 25 yards:

| Load | Point of Impact (5 round group) |

| Federal, .38 Special +P, 129 gr Hydra-Shok JHP | 4” below POA |

| Federal, .38 Special, Gold Medal Match, 148 gr WC | 4” below POA |

| Speer Gold Dot, .38 Special, 125 gr GDHP | 3.5” below POA |

| Federal, .38 Special, 125 gr JSP | 3” below POA |

| Super Vel, .38 Special +P, Super Snub, 90 gr JHP | 8” below POA |

| Speer Gold Dot, .38 Special +P, 135 gr GDHP SB | 2.5” below POA |

I think the trend here is clear—the gun shoots low with almost anything that you will put in it. We’re used to that on snubbies (I have to hold over with my 640 as well), but I had hoped this time it would be different.

The 158-grain .357 Magnum loads look like they would be pretty close to point of aim at 15 yards, based on the 25 yard results, but I have to wonder why Kimber would settle on this as a standard. I seriously doubt that many K6s shooters are going to routinely feed this gun with 158 grain, .357 Magnum ammunition. Why not regulate the sights to the most commonly used personal defense and training loads in this class of gun?

I’ll note that the DC model has a tritium dot in the front sight blade, and sometimes this makes for a taller sight. The front blade on the DC is about 0.22” tall, and there’s honestly not a lot of extra material above the tritium tube. You could file a little bit of the height off as Justin did with his S&W 640 Pro, but you won’t be able to do much.

This is an area where Kimber could have shown the industry how it’s done. They wowed me with the high quality sight picture, but missed the mark on regulation. Considering the premium price for this gun, I was really hoping that Kimber would have nailed this. Fortunately, the front sights are pinned in, so it’s possible that someone will eventually offer properly-regulated replacement blades someday . . . maybe even Kimber.

Odds and ends

Kimber did some clever engineering on the yoke of this gun. There’s a removable collar or ring that rides on the yoke, which Kimber calls the “gas check.” The gas check is designed to take the brunt of the high pressure gas that escapes out the front of the cylinder when the gun is fired. This protects the yoke from flame cutting, and if the component becomes worn, it’s easily and cheaply replaced.

The Diamond-Like Carbon (DLC) coating on the Deep Cover model of the K6s is worth remarking on. I’m not a chemical or materials engineer, but I gather that there are as many as seven different “recipes” for DLC, each varying in its mix of SP3 (diamond), SP2 (carbon), and fillers. Each DLC recipe has its own capabilities, but in general, DLC is bonded to an underlying material to increase hardness, improve wear resistance, resist corrosion, and improve lubricity.

The DLC certainly does give the gun a slick finish, and I suspect its self-lubricating qualities make at least a little difference in the smoothness of the action. It will certainly protect this carry gun from corrosion caused by sweat or acids in your fingerprints (yep, “stainless” will rust—ask me how I know), and it did make the gun a little easier to clean up when it finally got a well-deserved bath.

Another significant advantage in this application is that it allows Kimber to provide a revolver with a matte black finish that won’t wear off. The DLC is hard stuff—depending on the recipe, it can be even harder than a diamond—and I don’t expect that this gun will develop any shiny wear spots over time. I’ll let others argue about whether or not there’s a tactical advantage to having a gun with a matte finish, but it certainly reduces glare on a sunny day at the range.

The DLC finish adds somewhere around a hundred and fifty dollars to the MSRP, and you’ll have to decide if it’s worth the premium. I personally like the black finish very much, and think it’s handsome. I don’t know if I’m too concerned about abrasion, but I like the idea that the finish reduces friction and protects the stainless from corrosion. I could certainly live with the plain stainless model (been carrying guns like that for decades), but I’m kinda glad that I got the fancy one to work with.

Putting it all together

I’ve been nibbling at the edges in this field report without commenting directly about the overall shooting experience, so let me say it: this is the best shooting compact revolver I’ve ever handled.

Shooting the full-house, 125 grain, .357 Magnum in this gun was too much horsepower for my tastes, but I actually shot tighter groups with this load than with any other (maybe I focused better with the powerful loads?). The recovery between shots was slower than I liked however, so the K6s DC—like all my other snubs—will remain a .38 Special +P gun for me. Stoked with .38 Special +P loads, the K6s is not only a great shooting snub, but a great shooting gun, period.

Shortly after master gunsmith Paul Liebenberg stood up the Smith & Wesson Performance Center to do quality custom work on Smith & Wessons, I sent my Model 640 to Springfield to have them round and polish the trigger face, polish the sharp edges on the cylinder release, and perform a “duty action” job on the trigger. The J-Frame action is tough to work on, since the geometry doesn’t leave a gunsmith much to work with to improve the pull without sacrificing reliability, but the talented folks at the Performance Center worked some magic on the gun. They gave it an action that’s the envy of every other J-Frame I’ve ever come across–lighter, extremely smooth, and 100% reliable.

This K6s nearly equaled it, straight from the box. The K6s DC trigger pull is slightly heavier than my custom 640, but more importantly, it’s just as smooth. When you combine the excellent trigger pull with the strong handling qualities of the K6s frame and the outstanding sight picture afforded by those beautiful sights, you’ve got a winning package.

The K6s DC has been an excellent performer in my testing. I was disappointed to learn about the firing pin break on the one gun, but all the samples I’ve worked with have been solid so far. The sight regulation issue stinks, but to be fair, all my other snubs have sight regulation issues too. I’m still shooting better with the K6s than with any other snubby I’ve fired.

Over the years, snubs have developed reputations as “phone booth guns” with limited practical range, but the sights and trigger on the K6s DC make it a legitimate 25 yard gun . . . if you know where to hold. I daresay that the K6s shoots better than some of the most popular subcompact pistols on the market.

The K6s extends the effective range of the snubby revolver, and that sixth shot somehow seems to push it into a new class. I’ve always used my J-Frames as pocket guns, and never carried one on the belt. I’ve always felt that if I’m going to carry on the belt, then I’ll carry a more substantial gun than a 5-shot J-Frame, but the handling qualities and the extra round in the K6s DC cylinder seem to change the calculus, somehow. This could be a legitimate belt gun.

Back to the future?

It’s interesting that the work I paid the Performance Center to do on my 640 is totally unnecessary on the K6s DC. The trigger face is rounded and smooth from the factory, and so is the cylinder release. The trigger is excellent from the start.

I’m reminded of the era when the new Kimber first appeared on the scene with their 1911 pistols, and turned the industry upside down. For the first time, shooters didn’t need to send their brand new 1911s to a gunsmith for custom work, as the most desirable custom features were factory standard on the new Kimbers.

Decades later, it seems they’re trying to do the same thing with revolvers. I’m impressed with their progress so far, and with a few small tweaks to the otherwise excellent grips and sights, they’ll be there.

Try the 5 Star speed loader. I use them on all my smubbies.

The K6 looks like the best features of the Colt DS (6-shot), the Ruger GP/SP (cylinder button), and the S&W J/K frames. Downside is that it isn’t as likely to ride comfy in pants pockets like a S&W 642 does.

Should Colt ever decide to bring out their newest ‘Defective Special’ in .357 Magnum, then a side by side run between the DS and K6 would be interesting.

I am pleasantly surprised at how well it pocket carries. You need the right pants, belt, and pocket holster. A pair of Lands End Chinos swallows it and it seems no heavier than my Taurus 85 stainless.

I believe I commented in Justin’s post that it seems Kimber fell into the “because that is how it has always been done” trap when it came to regulating the sights. It’s too bad because they seem to have avoided that issue in most other regards.

Since you said you could see yourself carrying this on a belt, tell me more about the holster. You only show part of it, but the stitching and color make me think it is a DeSantis L-Gat Slide holster. Are holsters for this gun a better fit than speedloaders?

Greyson,

We have a couple full reviews of K6S holsters coming soon, including the L-Gat.

Justin

I own one of the first 6000 made. Got it barely fired 3 weeks ago, with all the goodies in the original box for $250 less than retail. I pocket carry it with a Simply Rugged holster and Daltech belt, loaded with .38 +p. It handles .357 target loads almost as well as my big GP 100.

The original owner must not have liked how low it shoots below POA, even at 5 yards, and sold it. Front sight is TALL. Since it is a black ramp sight, a file and some more range time will work it out. The trigger is spooky good.

I practice reloads with a speed strip, but Kimber does make speedloaders. You might try one. I am going to order one soon.

BTW, what is up with the odd prescription references in this post? Someone hack the site?

Does Kimber actually make that loader? It looks like a bespoke 5-Star Firearms loader.

RE: prescription references, I’ve just looked at the post from several different devices from half a dozen different IPs and I don’t see anything. I’ve also looked at the raw HTML and don’t see anything. Can you please elaborate? Thanks!

The prescription refs were only in the links, but now they are gone. Saw them on my iPad when I first posted. Looked like highjacked links to me.

As for the speed loader, I have yet to get my hands on one, but since Kimber sells them I presume they work with a K6S. I do like the ease of carry for the speed strip, however.

Kimber had some in use at their booth during Media Day at SHOT Show. I think they are 5-Star products with the Kimber logo. They worked OK–I remember some mild interference–but I don’t like the counter-clockwise release.

I had the chance to use the Kimber-branded loaders again this week, and they fit without interference from the factory grips. I’m not a fan of the CCW release, but there isn’t another speedloader that fits this well with the factory grips.

I modified my Kimber grips to work with other loaders and will do a story on that soon. Standby . . .

Mike,

Get with it. The Smiths, Rugers and now the KImber cylinders

go counter clockwise so why not the speed loaders?

Only Colts and Mother Earth spin clockwise and both are

abnormal. Try to prove otherwise.

Haha! I think this old dog would get a case of vertigo if he tried to learn that new trick. Some things you just can’t undo, like a lifetime of twisting HKS knobs clockwise. ; ^ )

Same trouble with my thumb vs Chief’s Special… modified my grasp… awkward but it works. Definitely not a comfortable weapon to shoot. That said, I just got the 3″ stainless K6s! Tried it out last week with only .38 Spl, no magnum ammo, at about 7 yards. Seems to shoot about a half inch low at that distance with 158 grain standard pressure. It is certainly more comfortable than the 3″ HB model 36, even with VZ grips. The 3″ Ruger LCRX was more comfortable, however, at least with the larger grips!

Oh, almost forgot! The blue Pachmayr K frame speedloaders seem to work best (least poorly?) of what I have, but also release the wrong way (anticlockwise).

“Somebody was thinking, here.”

Thank you.

; ^ )

Well done, Grant! I take it that you weren’t in charge of sight regulation though . . .

Another thorough and informative review. Thanks!

I hope the folks at Kimber are reading (and heeding) it….

Are you familiar with the ‘Altai’ K6S grips from Altamont?

I was not familiar with those grips, but I really like them. I wish more after-market grips for the SP101 had that kind of profile. I may have to get a K6s just ’cause I like the accessories better (though the speedloader issues would bother me).

I’ll check them out Bill! Thanks!

QUOTE: “I was assured that while Kimber has seen a few guns with this problem, the numbers have been very small—“on the order of tens of guns, out of tens of thousands made.”

Is this number accurate? “Tens of thousands” sounds awful high to me for a relatively new wheelgun design, by a manufacturer previously know only for 1911’s. I’m not saying it isn’t a good gun, nor that “tens of thousands” won’t eventually be sold…I just question how many have been made and sold up to this point. I would imagine that many consumers are like me, cautiously waiting to see if the design “takes root” and is reliable, durable and successful…before considering buying one ourselves. Anything new and different takes time to get established…so I just question the tens of thousands figure.

Brian, it’s a good question, and I can only answer that it was the info I was provided, so that’s why I used a direct quote. The serial numbers on my T&E guns are in the 31XXX and 32XXX range, which indicates the “tens of thousands” is an accurate figure.

These guns have been in production for several years now. Given the impressive numbers we’ve seen over the last few years for NICS checks, I think “tens of thousands” is a reasonable figure, even for a new revolver design from a “1911 company.”

Just went shooting again. The smooth grips are ok, but tend to shift around a little so I might have to get some VZ grips or something. The big issue, however, is the surprising and copious amounts of lead I cleaned out of the barrel. I used CCI brass on my first go around, didn’t have issues. This time used .38 Magtech fmj. I don’t know if that made a difference.

Some ammo just leads more than others. The powders burn hotter, or the lead is softer. Sometimes, if you don’t get a good gas seal (bullet undersized for the bore), the blow by gas will cause it. Your Magtech FMJ certainly has an exposed lead base that can be eroded by gases, and deposited in the barrel.

Hope you can find a clean burning alternative. Sounds like a return to CCI Brass might be in order?

Thanks for doing a honest assessment of the K6. It’s good to know about the firing pin issue.

I have a 2017 production K6S that had to go back to Kimber for a cylinder timing issue. When I stagged the trigger, the cylinder would not always lock into the cylinder stop. Kimber was great about addressing the problem. They promptly sent a paid return authorization and repaired it in a week. Now it achieves lock-up much sooner in the trigger pull cycle.

I agree with your assessment of its handling. It’s a great firearm with a lot of potential. I do wish that there was more after market support for it. (A reduced power spring kit anyone?)

Tim, that’s excellent feedback, and I’m glad they got you squared away. These guns aren’t perfect, but I’ve never owned one that was. Once I get the grip situation fixed, I’ll be pretty happy. The sight regulation is a bummer, but I don’t think there’s much I can do to fix it with the night sights, so I’ll just have to learn the holdoffs . . . like I do for every other snub I have.

The industry really does need to get behind this gun. Holsters are catching up a little bit (DeSantis and Galco have quite a few options, but others need to get on the stick), but the speedloader situation needs attention, and I’d love to see some aftermarket sight options.

You are very welcome.

The new external hammer K6’s with longer barrels look interesting. I am hoping to see your assement of them.

I shot them this past week at the show and we’ll be getting one for T&E before long. If you’re a fan of exposed hammers, you’ll probably like this one. The DA and SA pulls were nice.

I have to tell a story on myself: I was excited to shoot the external hammer gun, but when I raised it on target the first time, I fired all 6 chambers in DA. I reloaded and did the same for another cylinder before it dawned on me that I needed to try the SA trigger, since THAT is what made this model special! I had to chuckle at myself over that. A lifetime of only thumbing the hammer back on SA guns will do that to you!

You guys will be pleased to hear that Kimber made good on their promise to investigate the firing pin issue. In response to our report, they did some testing and honestly had a hard time replicating the break with any kind of reliability. They confirmed our suspicion that the FP break on our sample was the result of dry firing without snap caps.

Out of caution, Kimber wound up redesigning the FP for the new external hammer models. The new design will eventually be applied to the hammerless guns, as well.

It’s nice to see they are so committed to delivering a good product.

Thanks for the update Mike. Coincidentally, I just had to send my K6S back to Kimber yesterday due to a broken firing pin. Mine was purchased in fairly early production (# 6XXX) and while I have less than 200 rounds of live fire I have often dry fired it. Luckily I found out at the range and I don’t carry the K6S as a primary. As was your experience, the Kimber customer service rep was excellent and sent me a prepaid shipping label. I look forward to getting it back in the next few weeks repaired and ready to rock. I will start using snap caps for dry firing just in case. It’s unfortunate that Kimber’s first design couldn’t stand up to dry firing, or maybe it is just a bad pin or spring in my gun that would have eventually broke with use (live or dry). I have been dry firing my Smith & Wesson and Ruger revolvers for decades with no snap caps and no problems. Well, no product is perfect. Thanks again for the great review and information!

Tony, I’m disappointed to hear you had this problem, but glad you got it fixed without too much drama. I REALLY appreciate you reporting it to us, here. It helps to reinforce that our experience is supported by other data points.

Kimber explained the new FP setup for the external hammer models incorporates a newly designed FP, made from a different material (steel replaces Ti). The FP spring rate is changed to support the heavier FP, and the bushing that the FP passes through has been redesigned for the new shape of the FP nose, which has a longer radius.

I asked if there were plans to go back and incorporate this system into the hammerless guns, and they indicated that would probably happen down the road. Right now, the efforts are focused on getting the external hammer production up and running, but I won’t be surprised to see an engineering change for the hammerless guns once the external hammer pipeline settles into a rhythm.

In the meantime, we reiterate that it’s important to use snap caps if you’re going to dryfire your K6s!

I would say if you’re doing an appreciable amount of dry practice in any firearm you should probably be using snap caps.

Agreed!

Thanks to reviews like these that help us make buying decisions. I was down to the K6S and the SP-101 for a hiking magnum. What sold me to the Ruger is the ejector throw and the slightly superior ballistics from the extra .25″ of bbl.

Glad it was helpful, Frank. For the record though, the extra quarter inch of barrel really has no practical effect on ballistics. The naturally occurring variation between barrels creates much more of a difference than that little bit of extra length.

The SP101 is a fine gun and should serve you well. Enjoy!

My firing pin broke after about 200 rounds it was dry fired but with snap caps sent it back they fixed and returned it within a week. But still cost me time and shipping.

Jerry, that’s an important data point to add to the mix. Thank you for sharing it with us. I sure hope Kimber will modify the hammerless FP design soon.

I just had a firing pin break on my K6S DAO. October 20, 2019. I bought it, new, from my LGS in August, 2019. About 130 factory .38 Spls through it and a couple hundred dry fires all with snap caps. It’s born on date, confirmed with Kimber, was December of 2017. They are sending me a return label and covering the repair.

Does anyone know if they have actually changed the firing pin to steel or fixed the problem some other way?

Scott, sorry to hear you had that experience. From what I know, the design and materials have remained unchanged on the hammerless guns. The external hammer guns have a redesigned FP, made from a new material (steel, not Ti). I’ll get an update on the hammerless guns in January when I see the Kimber folks at SHOT Show. We’ve had a distressing number of people report FP breaks here–you’re probably #6 or so. That’s not right.

I purchased a K6. It took some time to get through the background check here in my state (different discussion). When I got the firearm home I noticed that the cylinder spins freely without locking in position??? I can’t figure out why it doesn’t lock in position? Any thoughts/ideas? I have not pulled the trigger

Scott, if the cylinder spins freely when it is closed, then you have a problem with the gun. I’d contact Kimber Customer Service and have them send you a repair shipping label.